Contents

1 About this document........................................................................ 5

1.1 Scope......................................................................................................... 5

1.2 Target groups of these operating instructions........................................ 5

1.3 Additional information.............................................................................. 5

1.4 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Improper use............................................................................................. 7

2.4 Requirements for the qualification of personnel.................................... 8

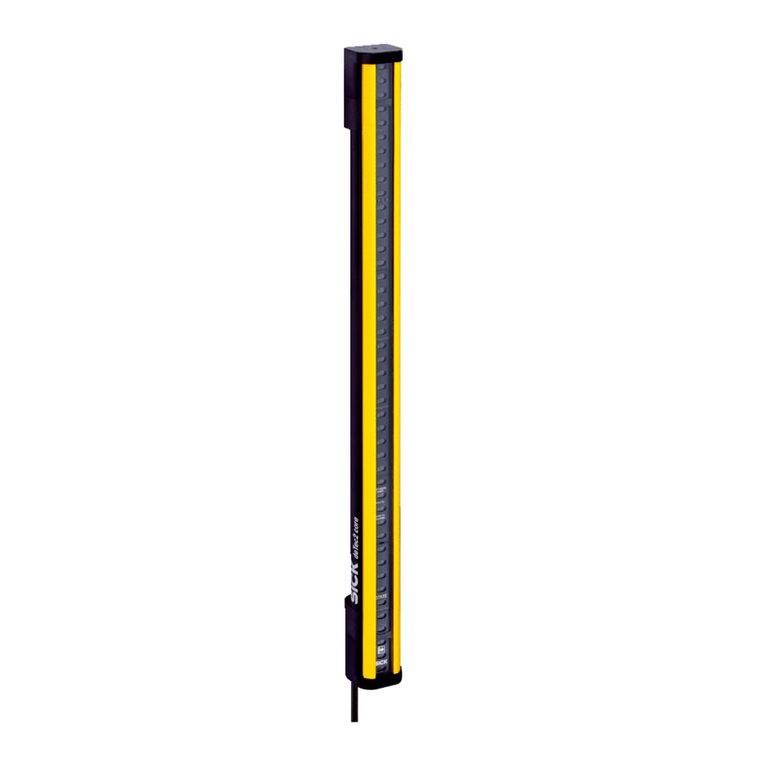

3 Product description........................................................................... 9

3.1 Design and function................................................................................. 9

3.2 Product characteristics............................................................................ 9

3.3 Manual unlocking..................................................................................... 11

4 Project planning................................................................................ 13

4.1 Manufacturer of the machine.................................................................. 13

4.2 Operating entity of the machine.............................................................. 13

4.3 Design........................................................................................................ 13

4.4 Integration in the electrical control system............................................. 16

4.5 Testing plan............................................................................................... 19

5 Mounting............................................................................................. 21

5.1 Orientation of the safety switch............................................................... 21

5.2 Mounting several safety switches............................................................ 21

5.3 Mounting the safety switch...................................................................... 21

5.4 Mounting the actuator.............................................................................. 23

5.5 Mounting the escape release.................................................................. 24

6 Electrical installation........................................................................ 25

6.1 Notes on cULus......................................................................................... 25

6.2 Device connection.................................................................................... 25

6.3 Connection of a safe series connection.................................................. 25

7 Commissioning.................................................................................. 28

7.1 Teach-in..................................................................................................... 28

7.2 Thorough check during commissioning and modifications................... 30

8 Operation............................................................................................ 31

8.1 Actuating the auxiliary release................................................................. 31

8.2 Actuating the escape release.................................................................. 31

8.3 Preventing unintentional closing of the movable physical guard.......... 31

CONTENTS

8020562/2022-07-07 | SICK O P E R A T I N G I N S T R U C T I O N S | flexLock 3

Subject to change without notice