SE Controls SHEVTEC 30A Manual

SHEVTEC PSU PANEL

Technical information and operating instructions

10 611

v4 09.19

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding.

Introduction:

The SE Controls range of

control systems are built

and tested control panels

specically for Smoke and/

or Environmental Ventilation

Systems and for use with SE

Controls supplied equipment.

They must not be used for any other

application or in conjunction with

other manufacturers’ products without

prior consultation with SE Controls.

Application:

The SHEVTEC PSU Panel is a

powerful 24 Volt DC control

system designed for 2-wire

24V DC actuators in a smoke

control and/or environmental

ventilation system.

Operating from a 230VAC supply,

the SHEVTEC PSU Panel can deliver

up to 30/60/90 Amps to drive

24 Volt motorised actuators.

The SHEVTEC PSU Panel can be

mounted in a centralised plant

room location. Each SHEVTEC PSU

Panel can operate independently

or be linked to others to produce

a networked control system. The

networked control system in turn

can operate standalone or be linked

to a building management system.

Installation of this equipment must

only be carried out by competent

and qualied persons.

The Installer and user are requested

to read, understand and retain

this information pack with the

panel for future reference.

This information pack must be

retained for future reference by

the client and be made available

for reference by persons installing,

servicing or modifying the panel.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 2

Contents

Content

3. Connections 10

3.1. Power and

control connections

10

3.2. Actuator

connections

11

3.3. Manual

Control Points

12

3.4. Fire Alarm Inputs

(FRA, ARA, SMK)

14

3.5. Smoke

Detectors (SMK)

15

3.6. Day to Day

Switch (DYO, DYC)

16

3.7. Thermostat (TST) 17

3.8. BMS Analogue

Input (AI1)

18

3.9. Rain Sensor (RNS) 19

3.10. Network

Connection (NTA,

NTB, SCR)

20

4. System Design 21

4.1. System Design 21

4.2. Design checklist

for each PSU Panel:

21

4.3. Design checklist

for each MCP:

21

4.4. Design checklist

for each actuator/vent

21

Content

5. Installation,

Commissioning

and Fault nding

22

5.1 Fixing 22

5.2 Low voltage

connections

22

5.3. Mains Connection 23

5.4. Battery installation 24

5.5. First power-

up tests.

24

5.6. Basic Fault Finding 25

5.7. B at te r y

Replacement

26

6. Wiring Schematics 27

6.1. 30A PSU Panel 27

6.2. 60A PSU Panel 28

6.3. 90 PSU Panel 29

Content

1. General

Information

4

1.1. General Safety

Information

4

1.2. Health and Safety 4

1.3. Environment 4

1.4. User

Responsibilities

4

1.5. Maintenance 5

1.6. Installation

and Connection

5

1.7. Fault Finding 5

1.8. Contact

Information

5

1.9. Certication 5

1.10. EN12101-10:2005

Certication

5

2. Specication 6

2.1 Device Overview 6

2.2 PSU LED Status 6

2.3. PSU Jumper links 7

2.4. PSU Volt free

relay contacts

7

2.5. PNC Fuse Chart 8

2.6. PNC Internal

Control Board

Indicators

8

2.7. Recommended

Cables Types

9

2.8. Hierarchy

of Functions

9

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 3

Important Notices

• Failure to install the

device in accordance

with the manufacturer’s

instructions will invalidate

any warranties.

• Failure to follow current

electrical regulations

governing the installation

of xed equipment can

lead to prosecution

and may invalidate

any warranties.

• Unless otherwise

indicated, you must not

adjust or remove existing

manufacturers cabling or

use terminal outputs or

inputs for purposes other

than their design without

written authorization

from SE Controls.

• Consumable items e.g.

fuse & batteries where

replacement is needed

must be replaced with

parts of equivalent

manufacturing standard/

compliance and rating.

SE Controls accepts no

liability for failure to

comply with the above

statements or the

installation and operation

guidance in the following

sections of this guide

and reserves the right to

invalidate the warranty

of the controller

SE Controls reserves

the right to introduce

any modications

and improvements to

the contents of this

publication without

the obligation of

giving prior notice.

• This equipment has no

mains on/o switch and is

intended for permanent

connection only.

• Do NOT allow abuse or

mishandling of the device.

• Do NOT adjust or

alter the device or its

enclosure including

labelling/marking.

• Do NOT use this controller

for any other purpose

other than that intended

by the manufacturer.

• Do NOT allow installation

of this equipment

by persons not

electrically qualied.

• Damage to the equipment

due to failure to test

the electrical integrity

of external wiring will

invalidate any warranties.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 4

1. General Information

1.3. Environment

This equipment is tted with a pair of lead

acid batteries which contain a corrosive gel.

These batteries must be regularly inspected

for damage and condition. Lead acid batteries

are classied as hazardous waste and must

be disposed by an authorised and licensed

recycler. They must not be disposed of in

household waste or ‘general waste’ skips.

Redundant electronic products are classied as

hazardous waste under the WEEE regulations

(Waste Electrical and Electronic Equipment).

Electronic parts must be disposed by an authorised

and licensed recycler. They must not be disposed

of in household waste or ‘general waste’ skips.

If recycling facilities are not locally available,

contact SE Controls who can arrange for recycling

and disposal of old electronic products.

1.4. User Responsibilities

United Kingdom Only: BS 7346-8:2013 is

a British Standard code of practice for the

planning, design, installation, commissioning and

maintenance of smoke control systems. Section

9 of the standard (Maintenance and Servicing)

states that frequent inspection of the system

should be undertaken by a named suitably-trained

member of the premises management team.

Routine inspection of the system should be carried

out in accordance with BS 9999:2008, Annex V.

For countries outside the United Kingdom:

Please check with the local the re authority in

your area regarding smoke control legislation,

dierent user responsibilities may apply.

Smoke control equipment should only be

maintained by a competent person with specialist

knowledge of smoke control systems and

sucient information regarding the system.

1.1. General Safety Information

Read and observe the information

contained in these instructions.

Please keep these safety instructions for

future reference and maintenance. Reliable

operation and the prevention of damage

and risks are only granted if the equipment

is assembled carefully and the settings are

carried out according to these instructions and

to the operating instructions of the drives.

Please observe the exact terminal assignment,

the minimum and maximum power ratings (see

technical data) and the installation instructions.

1.2. Health and Safety

Electrical Safety: Warning 230 V AC mains supply

can cause death, serious injury or considerable

material damage. Disconnect the equipment

from the power supply at all poles before

opening, assembling or carrying out any work.

Electrical safety of batteries: Short circuiting

of the lead acid batteries can cause high

currents to ow which can cause rapid heating

and a re risk. Take care to avoid this when

transporting and handling batteries. Keep

batteries disconnected during installation

and modication of the installation.

Competence: This equipment is designed for

professional installation only by qualied, trained

and safety conscious electricians or skilled and

trained sta with considerable knowledge of

electrical equipment installation. These instructions

must be followed and retained for future reference.

Application: this equipment is designed

exclusively for the purposes of controlling

automatically opening smoke and

environmental ventilation equipment.

Personal Protective Equipment: It is

recommended that suitable PPE is worn at all

times during the installation and connection

of actuator products in accordance with a

recommended safe system of work.

Handling and storage: This equipment is

heavy. Care must be taken in transportation to

the installation location and during tting. The

equipment must not be dropped, impacted,

allowed to get wet or abused in any other way.

Mishandling can result in serious damage to

the housing and the components therein.

Risk of crushing: this equipment can

automatically close windows and other appliances

without warning. Beware risk of serious

injury from crushing of hands or ngers.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 5

1.5. Maintenance

A smoke control system should be checked

and serviced periodically in accordance

to local smoke control legislation.

Smoke control systems have to be serviced and

checked for defects at least once per year by an

authorised, trained and competent person.

Within the UK a suitable service contract

with SE Controls is recommended for this

purpose (see page 7 for contact information).

All batteries need to be checked to see if

they are within specication and in good

condition at least once a year and replaced

at least every FOUR YEARS (please observe

the battery commissioning label).

Ensure that supply voltage and batteries are

disconnected before any maintenance work or

mechanical/ electrical alterations are made.

The system must be protected

against unintentional start-up!

After maintenance, modication or repair

the system must be functionally retested.

Compatibility; this equipment should only

be used to operate with motors and other

products approved by SE Controls. No liability

will be accepted and neither guarantee nor

service is provided if unapproved products are

used in conjunction with this equipment.

1.6. Installation and Connection

Installation should be carried out by an

authorised, trained and competent electrician.

Ensure correct cable type is used throughout the

installation. All low voltage cables are to be routed

separately from mains voltage cables and other

electrically noisy cables. Flexible cables must not

be plastered over and freely suspended cables

must be provided with strain relief. Cables must

be installed in such a way that they cannot be

sheared, twisted, pierced or otherwise damaged

during installation or use. Junction boxes should

be accessible for inspection and maintenance.

Do not attempt to install or alter

the installation of the panel whilst

connected to the power supply.

1.7. Fault Finding

In the unlikely event that a problem occurs

with the control panel, users are urged to

contact SE Controls for assistance.

If the system operates from mains power

but when mains power is removed will not

operate from batteries, it is possible that

the batteries will require replacement.

There are no user repairable parts. Fault

rectication must only be carried out by

authorised and competent persons.

1.8. Contact Information

For sales, technical support and

maintenance please contact:

SE Controls

Lancaster House

Wellington Crescent

Fradley Park

Licheld

Staordshire

WS13 8RZ

Tel: 01543 443060

Fax: 01543 443070

Website: www.secontrols.com

1.9. Certication

SE Controls hereby certify that the parts and

services detailed hereon have been manufactured,

inspected, tested and supplied in accordance with

the conditions and requirements of the procedures

as documented in the Company Quality Assurance

System to ensure conformance with SE Controls’

specications, and with the contract or order

conditions of our BS EN ISO9001:2008 registration.

1.10. EN12101-10:2005 Certication

Our equipment is built and tested in accordance

with EN12101-10:2005 requirements.

Certication can be provided upon request.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 6

2.1. Device Overview

Part numbers 30A SHEVTEC Panel FCS12001030

60A SHEVTEC Panel FCS12001060

90A SHEVTEC Panel FCS12001090

Dimensions 30A (600 X 400 X 250) (W x D x H)

60A (600 X 600 X 250) (W x D x H)

90A (800 X 800 X 300) (W x D x H)

Mass Approx. 30A 20 KG

60A 25 KG

90A 35 KG

Supply Range 1 – 230Vac +/- 10% 12.5A max per PSU at 50hz

Range 2 – 110Vac +/- 20% 7.0A max per PSU at 60hz**

Output Nominal 24VDC 4-channels combined output 8 Amps each

Battery Backup (30A) 2 x 12VDC 22.0Ah sealed lead-acid

(60A) 4 x 12VDC 22.0Ah sealed lead-acid

(90A) 6 x 12VDC 22.0Ah sealed lead-acid

Expected Battery Life 3+ Years @ 25 C

Real Time Clock Battery Life 10 Years

Cable Entries Cable entries are via up to 32 20mm cable glands

IP Rating IP32

Humidity Range 10 to 90% Non-Condensing

Storage – 20°C to 50°C

Operating Temp – 5°C to 40°C

Battery Standby Time 72Hours with maximum 100mA standby drain current *

*Standby drain current comprises enabled re inputs, communication cards, and other loads.

**Use at 110Vac has not been approved to EN12101-10.

2.2. PSU LED Status

LED Colour Detail

LD1 Batt Connected Green Battery connected; this LED will be ON if the battery is connected.

LD2 Charged Red Battery charged, this LED will be ON if the battery is charged.

LD3 Charging Yellow This LED will be ON whilst the battery is charging.

LD4 Mains OK Green This LED will be ON if there is mains present.

2. Specication

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 7

2.3. PSU Jumper links

Jumper Jumper Detail

LK1 Fitting a jumper link to the right hand side connects E and G together,

with the link on the left hand side E and G are not connected.

LK2 Fitting a jumper link to the right hand side connects M and 0 together,

with the link on the left hand side M and 0 are not connected

LK3 Fitting a jumper link to the right hand side connects C and E together,

with the link on the left hand side C and E are not connected

LK4 Fitting a jumper link to the right hand side connects K and M together,

with the link on the left hand side K and M are not connected.

LK5 Fitting a jumper link to the right hand side connects A and C together,

with the link on the left hand side A and C are not connected.

LK6 Fitting a jumper link to the right hand side connects I and K together,

with the link on the left hand side I and K are not connected.

2.4. PSU Volt free relay contacts

VFC Contact Open Contact Close

Fault Not in Fault In fault

Mains OK Mains detected Mains failed

Power and control board Indication and fuses

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 8

2.5. PNC Fuse Chart

Fuse Function If open circuit

116 A 24V AC Input Not Used with SHEVTEC PSU.

21 A PER - Battery backed supply Standby LED goes out; PER supply terminals

o; If external alarm connected will set o.

3500 mA AUX - Auxiliary supply Not Used with SHEVTEC PSU.

416 A Battery Power and control board will power down.

510 A Actuator1 When open circuit Actuator relay 1 will not function

610 A Actuator 2 When open circuit Actuator relay 2 will not function

Note: If a fuse clears, check wiring / external devices for damage and

incorrect termination / earth faults before replacement.

2.6. PNC Internal Control Board Indicators

LED Colour Detail

LD1 POW Green Not Used with SHEVTEC PSU.

LD2 WINK Red Reserved communication cards use -

Illuminated when SERV Pressed

LD3 HEALTHY Green Healthy Lamp - Lit when controller has no faults

LD4 ACTIVATED Red Lit when the controller is activated by a re input or via the

Manual Control Point Does not respond to NV demands

LD5 MAINTENANCE Yellow Lit when maintenance input is active

LD6 WDG Yellow Watchdog - Flashes at 1Hz to indicate embedded

rmware is loaded and running.

LD7 PSU Green On when power supply ok

LD8 BAT Red Lit when controller is powered from SHEVTEC PSU.

LD9 Green Lit when actuator (1) is closing

LD10 Red Lit when actuator (1) is opening

LD11 Green Lit when actuator (2) is closing

LD12 Red Lit when actuator (2) is opening

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 9

2.7. Recommended Cables Types

Cabling For Minimum number of cores Recommended Cable Type

Mains Supply Cable 2c + Earth FP Plus

OS2 MCP 4c + Earth FP Plus

24VDC actuator 2c + Earth FP Plus

OS2 Smoke detector 3c + Earth FP Plus

OSlink Network Cable 2c + Earth FP Plus

SHEVTEC Repeater Panel 4c + Earth FP Plus

Day to Day switch 3c + Earth Any Appropriate Cable Type

Rain sensor 3c + Earth Any Appropriate Cable Type

Thermostat 2c + Earth Any Appropriate Cable Type

PIR sensor 3c + Earth Any Appropriate Cable Type

All cabling should be in accordance with relevant standards and regulations

for electrical Installation such as BS8519:2010 and BS7671.

2.8. Hierarchy of Functions

In operation, the control inputs are organised in a strict hierarchical priority order.

1. Maintenance (highest priority)

2. Override alarm

3. Manual Control Point (close demand)

4. Manual Control Point (open demand)

5. Fire alarm

6. Auto Reset Fire Alarm

7. Smoke Detector

8. Slave (Follower) demand

9. Mains Failure

10. Rain Sensor

11. Thermostat / 0-10V / Day to day switch (lowest priority)

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 10

3. Connections

3.1. Power and control connections

All terminals have a cable capacity of

2.5mm2 stranded or 4mm2 solid. Each

terminal is identied with a 3 letter code

which is expanded on the terminal label.

Do not interfere with xing or

location of the thermistor.

The following sections are to be used for

guidance only and are subject to change.

All external switch contacts are to be volt-free

and capable of carrying 24VDC at low currents.

The maximum cable length for digital

control input signals is 500M.

0-10 Volt signals must remain stable and

‘spike’ free for a period of 2 seconds before

the controller will respond to them. In 10%

step mode, the controller only responds to

0-10V signals in steps of whole volts ±250mV.

In 5% step mode, each step is half a volt.

Environmental ventilation accessories (e.g. rain

sensors) should be powered from the AUX supply.

Essential smoke accessories (e.g. smoke detectors)

should be powered from the PER supply.

Strip the outer sheath of all cables back to the

entry point of the enclosure. Ensure enough

sheath is left to provide mechanical protection

against cable movement over time.

Inner cable cores should be dressed under the

edges of the power and control board. This

provides a neater and more ordered solution.

Only strip inner cores suciently to make a good

electromechanical contact with the terminal blocks.

Where multiple actuator leads are to be

connected to the controller, it is advisable to use

an external junction box to reduce the number

of cable glands required, if using screw-terminal

joints ensure they are of the enclosed type.

The default controller settings have been chosen

to cater for the majority of applications. If alternate

settings are required please contact SE Controls.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 11

3.2. Actuator connections

The 30A PSU has four separately fused 24VDC actuator output channels. Each

output channel has terminals for connecting up to 4 actuators.

The default mode of operation of these outputs is timed o, reversing polarity and is intended

for use with linear and chain actuators. Locking catches, magnetic catches and rotary dampers

can be used but require changes to the default settings of the controller by SE Controls.

Output mode - timed o, reversing polarity

Actuator Full Stroke Period (Environmental Ventilation) - 40 seconds

Alarm Full Stroke Period (Smoke Vent) - 180 seconds

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 12

3.3. Manual Control Points

These switches are used to manually open and close actuators in a smoke control system. There is

a set lock-out period of 5 seconds between successive operations. The actuators open full stroke in

response to a transitory operation of the Manual Control Point. However, to prevent nger trapping

issues, the actuators only close whilst the Reset button on the Manual Control Point is maintained.

Note that the default Manual control point close mode can be changed by SE Controls to close

fully in response to a brief press of the reset button. This mode change is only recommended

where the activated vent is at least 2.5M above ground level to minimise nger trapping issues.

OS2 MCP Part Number FCS00200016

OS2 Tamperproof MCP Part Number FCS00200034

OS2 MCP Adaptor Plate Part Number FCS00200017

All connections to the OS2 MCP are made via the connection PCB mounted

within the adapter plate assembly. (See diagram below.)

The connection PCB has 14 terminals, consisting of 2 pairs of 7 connections. For

OS2 products, it is only necessary to connect to 5 of these signals as follows:

MCP Terminal OS2 Terminal Description

24V PER 24VDC power supply rail

from OS2 controller.

HLT Y FSL Healthy indicator – from OS2 controller.

ACT -- No connection required/

made for OS2 systems.

FLT -- No connection required/

made for OS2 systems.

OPN FSO Open demand – from

Manual control point

CLS FSC Close demand – from

Manual control point

0V 0VP 0V power supply rail from

OS2 controller.

Note that each pair of connections are interconnected within the PCB assembly. The second set

of terminals may be used to daisy-chain multiple MCPs to one zone of the control panel.

24V HLTY ACT FLT OPN CLS 0V 24V HLTY ACT FLT OPN CLS 0V

CN1

CN2

FYS 1402 0018

CN3

HLTY = FSL ACT => BEEP

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 13

The jumper CN3 enables and disables the sounder. The default position is disabled (right)

The PSU must have both battery and mains power removed

before installing the MCP to the adapter plate.

The MCP must be secured using the two xing screws (Torx-T8) on the underside of the MCP module.

Important; for instructions on installation and operation of the MCP refer

to the user guide accompanying the device or contact SE Controls.

The jumper CN1 must be tted in the left hand (“HLTY=FSL”) position.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 14

3.4. Fire Alarm Inputs (FRA, ARA, SMK)

All re alarm input signals require a Normally Closed volt-free-contact which

opens on re signal initiation. The unit comes with all alarms hardware disabled

via jumper links. To enable an alarm input, refer to the gure below.

Each re alarm input has dierent functionality. It is not mandatory to connect a particular type of

device to a particular re alarm input, but to the one(s) that provide the required functionality.

Fire Alarm - Opens on activation; Use of reset from Manual control is allowed.

Auto reset Fire Alarm - Opens on activation; Use of reset from Manual control

is allowed; 30 second lock-out period after activation before reset; 120

second lock-out following reset before subsequent re-activation.

Smoke Detector Input - Opens on activation- Does not allow use of

reset from Manual control until alarm has been reset.

The alarm activation direction, Manual control point’s Switch reaction

mode and lock-out periods can be congured by S E Controls.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 15

3.5. Smoke Detectors (SMK)

Smoke detector heads are required to provide a normally closed volt-free contact. Smoke

detectors should be powered from the PER supply rail. The recommended maximum

number of Smoke detectors is 5 connected to a single SHEVTEC PSU PANEL.

It is important that the quiescent current of the smoke detectors is kept to a

minimum as their current draw will greatly impact on standby times. The peak

current draw on the PER permanent supply should never exceed 1Amp.

Intelligent Optical smoke detector ADA55000318 (Head) ADA45681245 (Base)

This smoke detector is an exclusive S E Controls product and has been specically

designed to operate as part of SE Controls SHEVTEC systems. It has been

marked as such to aid in identication for servicing and replacement.

Other models / types are not suitable products for use in SHEVS and are not compatible.

The new detector is a 2 part assembly comprising a head and a base which clip

together. To prevent interference by unauthorized persons the base incorporates

a locking mechanism which then prevents disassembly without a tool.

The detector head has an LED indicator to provide status information. Distinctive markings

on the head set it apart from other standard types of detector, and each unit is supplied

with a clip-on dust cover which should be removed at commissioning stage.

Single

Multi

Removal of the head DOES NOT cause activation of the system. Once installation is complete,

ensure lock is engaged to prevent unauthorised removal of detector head

The current model is NOT suitable for use with SHEVTEC PSU PANEL Auto Reset alarm

functions. Please seek further advice from SE Controls if this facility is required.

Test using Canned Smoke or other approved smoke generating method. No other method is acceptable.

Important Notes:

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 16

3.6. Day to Day Switch (DYO, DYC)

Connecting terminals DYO and DYC to 0VP will open and close the vent in environmental ventilation

mode. The default mode requires a spring centre 3 position switch having 2 normally open contacts.

The actuator will only move whilst the input demand is in force and the total movement time in the

requested direction is less than 18 seconds (default). Releasing the switch will stop the movement.

The day-to-day inputs only operate whist the controller is in manual operational mode.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 17

3.7. Thermostat (TST)

A simple volt free room thermostat can be used to operate the SHEVTEC PSU PANEL. The

output contact is required to close when a demand to open a vent is required.

When the demand is received, power is applied to the actuator outputs for 40 seconds in the open direction.

When the demand is removed, power is applied to the actuator outputs for 40 seconds in the close direction.

Both of these movements are subject to a 180 second lockout period which prevents frequent unwanted operation.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 18

3.8. BMS Analogue Input (AI1)

A 0-10V BMS analogue demand input channel is provided. It has a 100K input impedance plus a 50ms

anti-aliasing lter. By default, the input is congured to set the actuator position in 10% steps based on a

scaling of 1V==10%,where 100% is the natural ventilation maximum run time (default 40 seconds).

Other input scaling is available. Please refer to SE Controls for details.

A second analogue input, AI2, having the same characteristics as AI1 is

available. This is not used in the default system conguration.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 19

3.9. Rain Sensor (RNS)

An input for the connection of a volt free normally open rain sensor is provided. When the contact

closes, power is applied at the actuator outputs in the close direction for a period of 180 seconds.

At the same time, a 180 second lock-out timer is started. If either the rain sensor remains wet or the lock-

out timer is running, the environmental ventilation controls are ignored. Once the rain sensor dries out and

the lock-out timer times out, the environmental ventilation controls are re-enabled. However, note that the

position of the vent is not automatically reset to the last known position prior to the rain sensor activation.

The rain sensor input can also be used to close the vents from a centralised

control point, by the use of a 7 day timer or a caretaker switch.

+44 (0)1543 443060

sales@secontrols.com

www.secontrols.com

Please keep these operating instructions for future reference and maintenance.

Subject to technical modications. Diagram is not binding. 20

3.10. Network Connection (NTA, NTB, SCR)

Connections NTA and NTB are used for network connection with network interface

plug in boards. The use of these devices is outside the scope of this document. Please

make reference to the individual product user manuals where necessary.

This manual suits for next models

5

Table of contents

Popular Power Supply manuals by other brands

mini-box

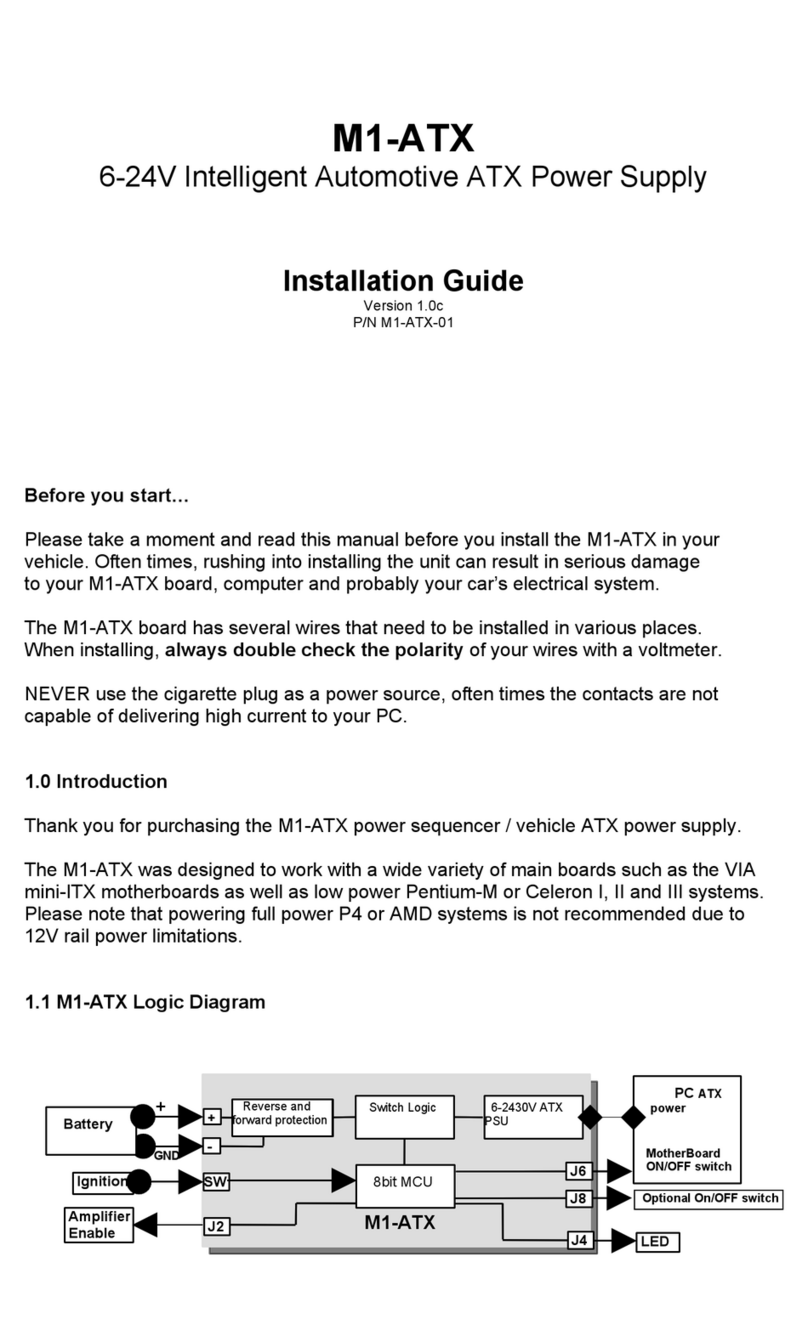

mini-box M1-ATX installation guide

LEGRAND

LEGRAND WIREMOLD 1022306R2 0119 installation instructions

PSS

PSS GP800 Power Series user manual

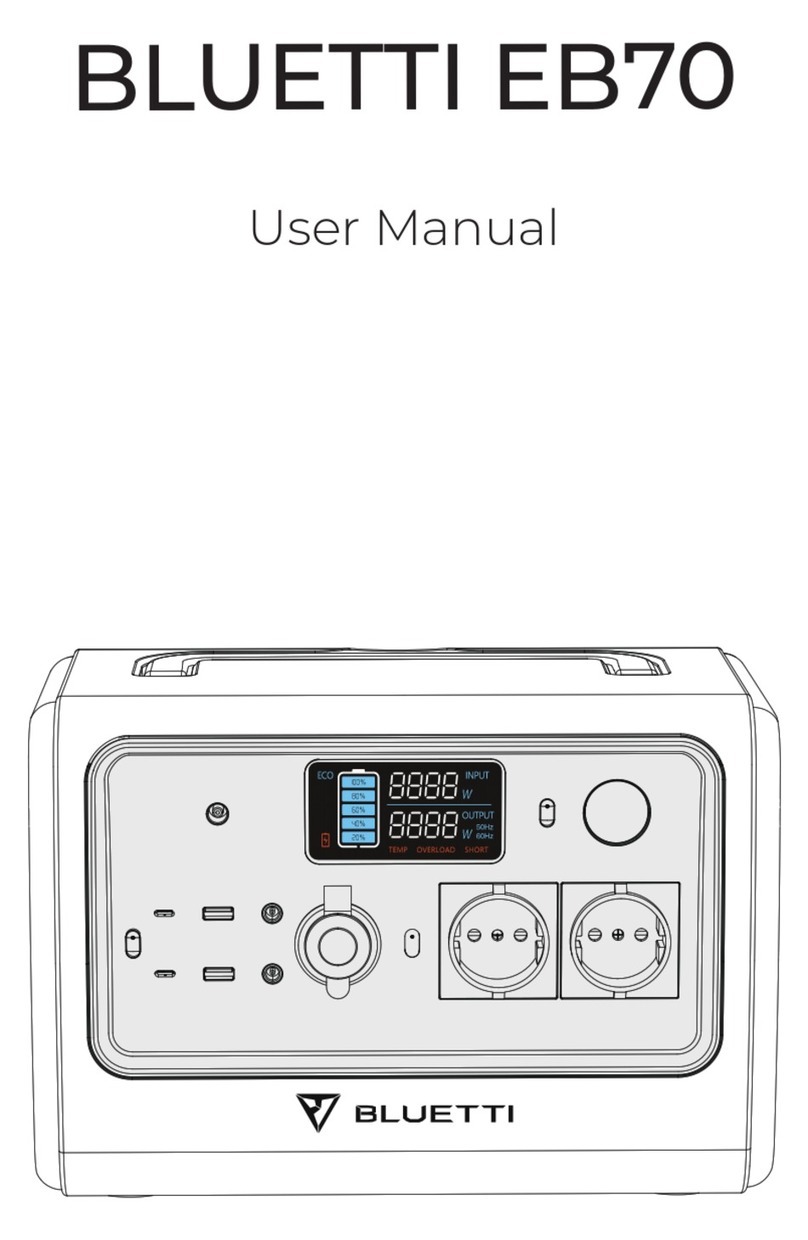

Bluetti

Bluetti EB70 user manual

Allen-Bradley

Allen-Bradley ControlLogix 1756-PA75/B installation instructions

Rockwell Automation

Rockwell Automation 1606-XLE96B-2 instruction manual