SEA USA USER 1 24V DG R1 User manual

USER 1 - 24V DG R1

24V ELECTRONIC CONTROL UNIT FOR SLIDING GATES AND BARRIERS

67411535 REV 07 - 06/2014

International registered trademark n. 2.777.971

SEA USA Inc.

10850 N.W. 21st unit 160 DORAL MIAMI

Florida (FL) 33172 USA

Tel. -

Toll free:

:++1-305.594.1151 ++1-305.594.7325

800.689.4716

web site: www.sea-usa.com

e-mail: [email protected]

Details

General

An appliance shall be provided with an instruction manual. The instruction manual shall give instructions for the installation,

operation, and user maintenance of the appliance.

The installation instructions shall specify the need for a grounding-type receptacle for connection to the supply and shall stress the

importance of proper grounding.

The installation instructions shall inform the installer that permanent wiring is to be employed as required by local codes, and

instructions for conversion to permanent wiring shall be supplied.

Information shall be supplied with a gate operator for:

a) The required installation and adjustment of all devices and systems to effect the primary and secondary protection against

entrapment (where included with the operator).

b) The intended connections for all devices and systems to effect the primary and secondary protection against entrapment. The

information shall be supplied in the instruction manual, wiring diagrams, separate instructions, or the equivalent.

Vehicular gate operators (or systems)

A vehicular gate operator shall be provided with the information in the instruction manual that defines the different vehicular gate

operator Class categories and give examples of each usage. The manual shall also indicate the use for which the particular unit is

intended as defined in Glossary, Section 3. The installation instructions for vehicular gate operators shall include information on

the Types of gate for which the gate operator is intended.

A gate operator shall be provided with the specific instructions describing all user adjustments required for proper operation of the

gate. Detailed instructions shall be provided regarding user adjustment of any clutch or pressure relief adjustments provided. The

instructions shall also indicate the need for periodic checking and adjustment by a qualified technician of the control mechanism

for force, speed, and sensitivity.

Instructions for the installation, adjustment, and wiring of external controls and devices serving as required protection against

entrapment shall be provided with the operator when such controls are shipped with the operator.

Instructions regarding intended installation of the gate operator shall be supplied as part of the installation instructions or as a

separate document. The following instructions or the equivalent shall be supplied where applicable:

a) Install the gate operator only when:

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet (1.22

m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings anywhere in

the gate, and in that portion of the adjacent fence that the gate covers in the open position,

3)All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will

not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not over-

tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

e) (not applicable)

f) Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and where the

user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible

controls shall have a security feature to prevent unauthorized use.

USER 1 - 24V DG R1

International registered trademark n. 2.777.971

267411535 REV 07 - 06/2014

g) The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not cause the

operator to start.

h)Aminimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible.

i) For gate operators utilizing a non-contact sensor:

1) See instructions on the placement of non-contact sensors for each Type of application,

2) Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the gate is

still moving, and

3) One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier.

j) For a gate operator utilizing a contact sensor:

1) One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the leading

edge, trailing edge, and postmounted both inside and outside of a vehicular horizontal slide gate.

2) One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

3) One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

4) Ahardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor and

the gate operator is not subjected to mechanical damage.

5) A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for entrapment

protection functions shall be located where the transmission of the signals are not obstructed or impeded by building

structures, natural landscaping or similar obstruction. A wireless contact sensor shall function under the intended end-

use conditions.

6) One or more contact sensors shall be located on the inside and outside leading edge of a swing gate.Additionally, if the

bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel, one or

more contact sensors shall be located on the bottom edge.

7) One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

Revised 56.8.4 effective February 21, 2008

Instruction regarding intended operation of the gate operator shall be provided as part of the user instructions or as a separate

document. The following instructions or the equivalent shall be provided:

IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce the risk of injury or death:

ATTENTION: pour réduire le risque de dommages ou mort:

1. READAND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3.Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4. Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object activates the non-

contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to adjust and retest the gate

operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make repairs to gate

hardware.

7. The entrance is for vehicles only. Pedestrians must use separate entrance.

8. SAVE THESE INSTRUCTIONS.

International registered trademark n. 2.777.971

3

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014

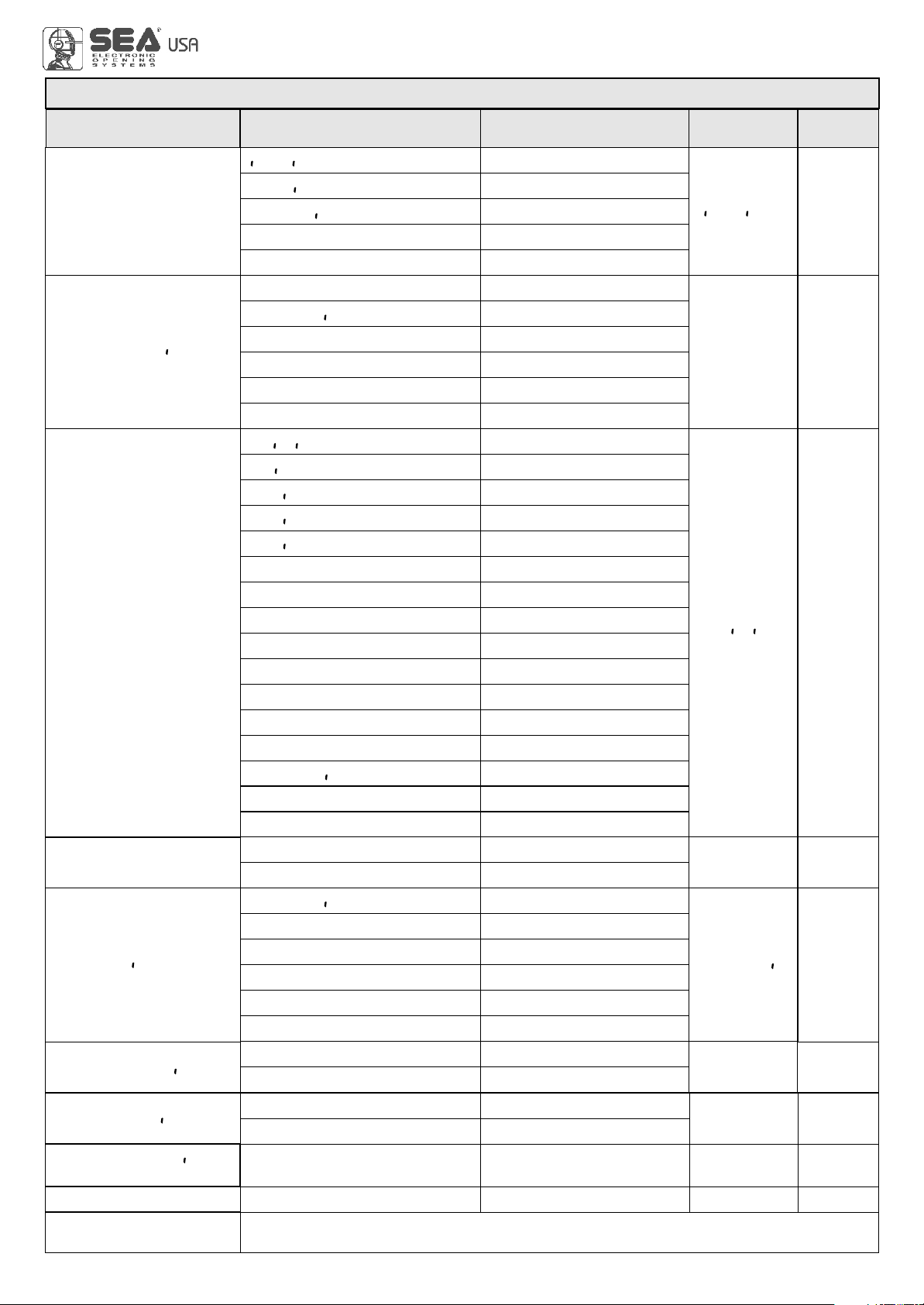

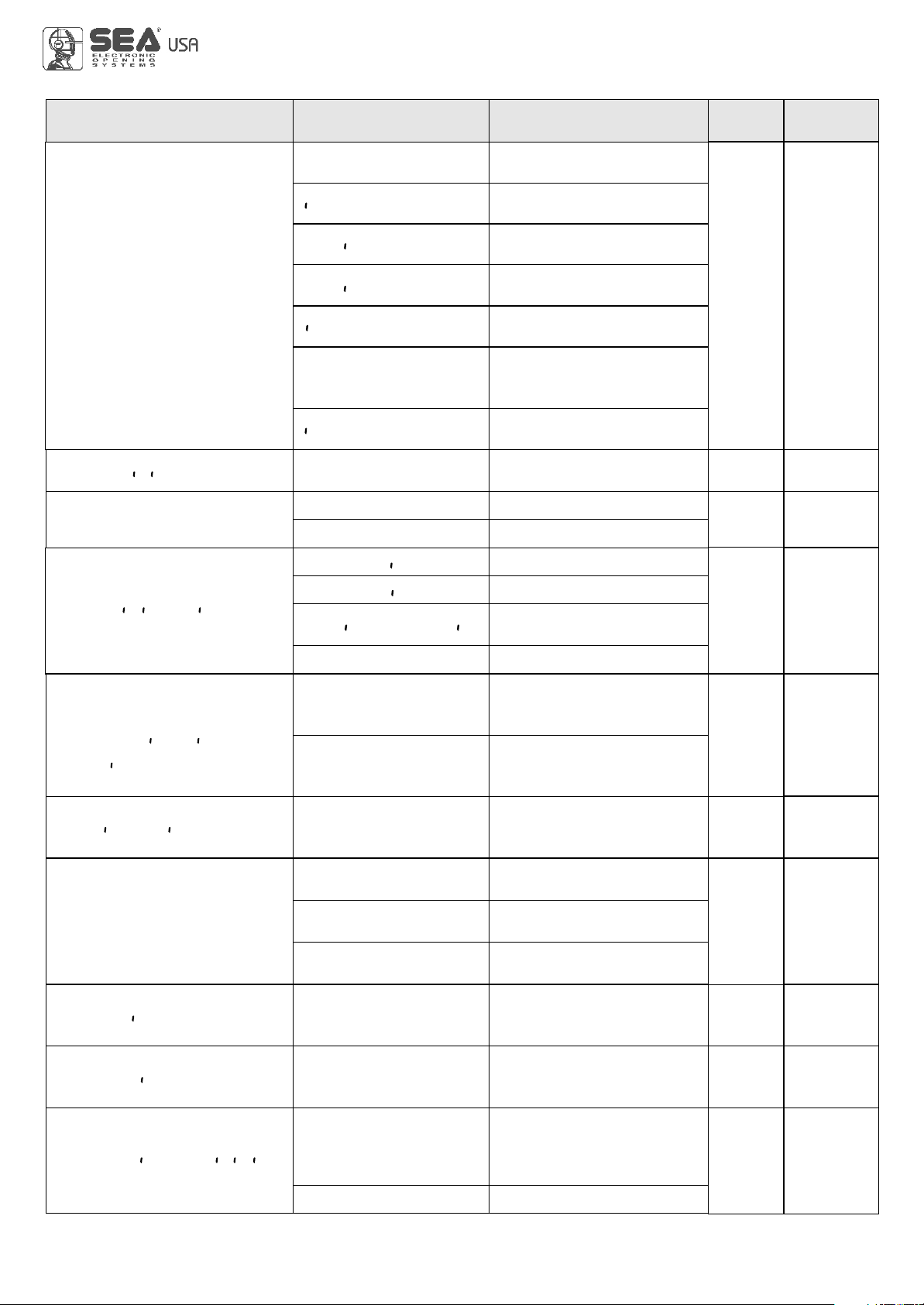

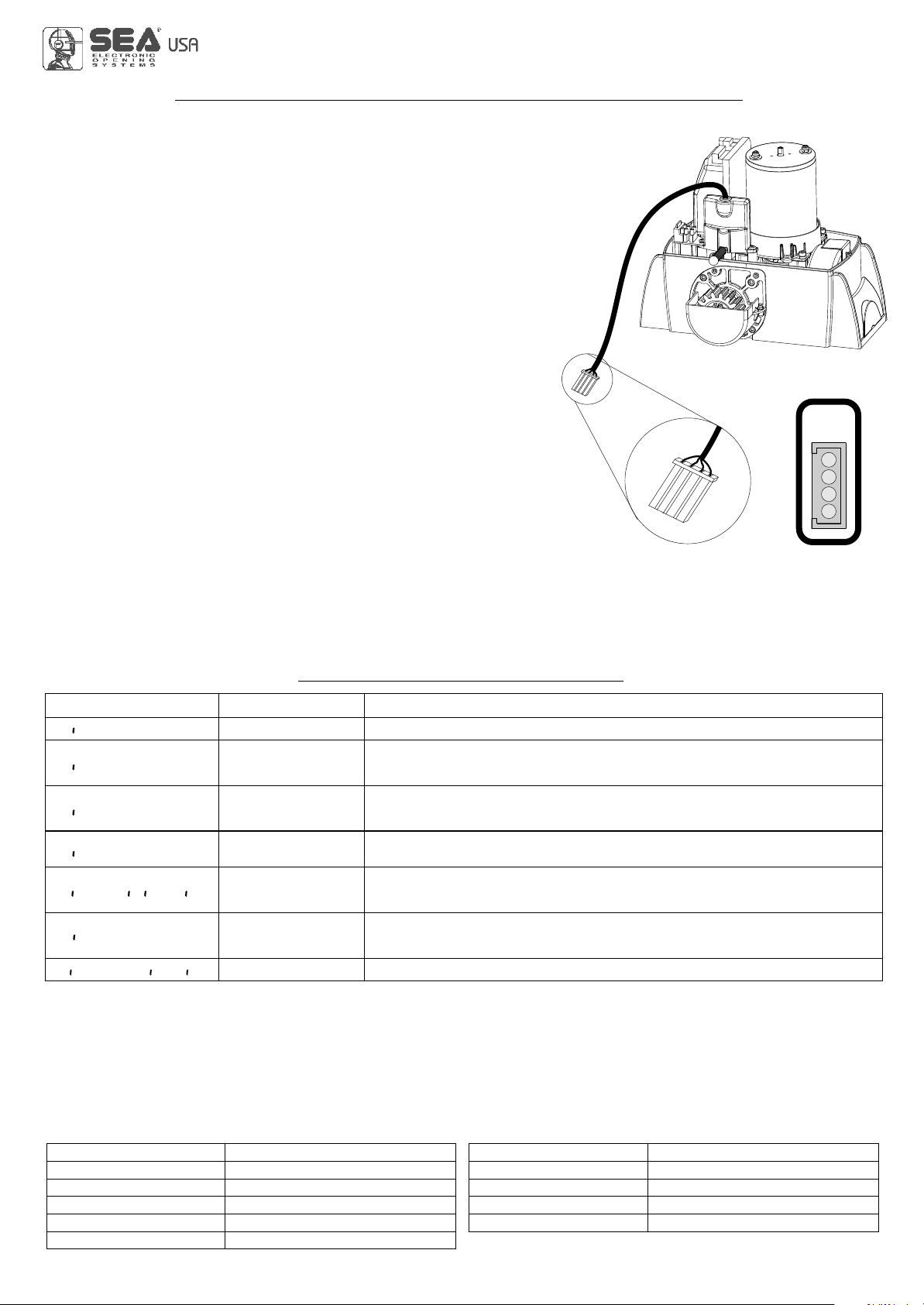

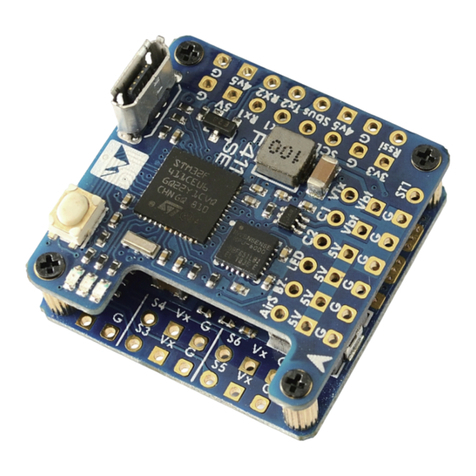

DESCRIPTION OF THE COMPONENTS

CN1 = Input/Output connector

CN2 = Limit switch connector

CN3 = Jolly-Jolly 2 connector

CN4 = Master/slave connector

CN5 = Courtesy light output plug

CN6 = Motors connector

CN7 = Batteries connector

CN8 = Power connector

CNA = RX Receiver connector

CNP = Programming connector

EXP = External module connector

OK = Programming button

DOWN = Programming button

UP = Programming button

RD1 =Motors piloting Mosfet

RD3 = Motors piloting Mosfet

R1 = Motors command relay

R2 = Motors command relay

PR1 = Rectifier jumper

F1 = Fuse 10 AT

CN8 F1

CN1

CNA

CN3

CN5

CNP

CN6

RL2

RL1

CN2

CN4

CN7

UP DOWN OK

RD3

RD1

PR1

DISPLAY

1 2 3 4 5 6 7 8 9 10 11 12 13

1

EXP

POWER FUSE BATTERY

- S +

MOTOR LIGHT

MASTER/SLAVE

PROG

RADIO MODULE

JOLLY

LIMIT SWITCH

156 mm (6 inches)

100 mm (4 inches)

RECEIVER RX

JOLLY-JOLLY2

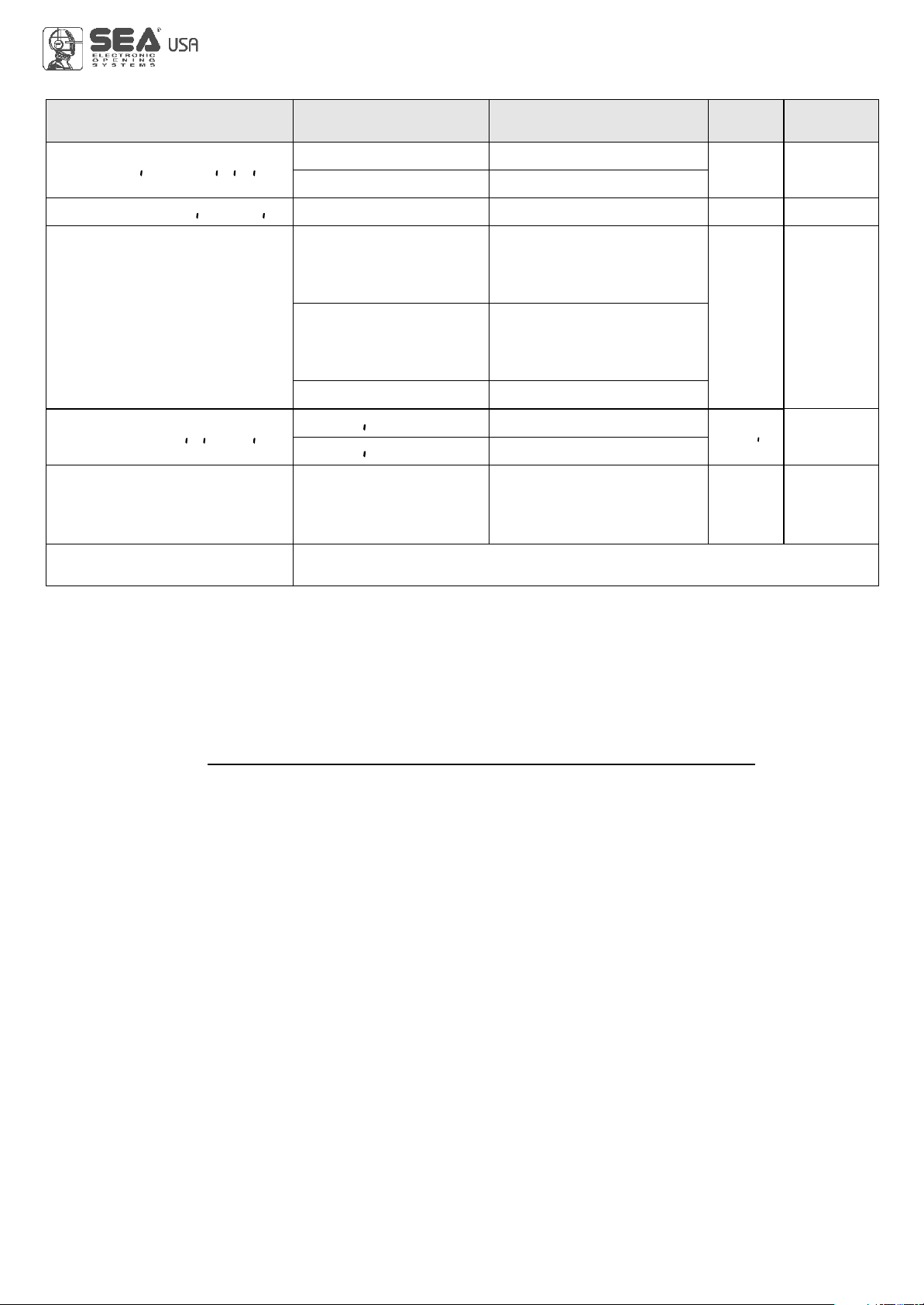

TECHNICAL SPECIFICATIONS

Control unit power supply

Absorption in stand by

Environment temperature

Specifications of external enclosure

:

:

: -20 +55 (

:

24 V~

30 mA

-4°F +122°F)

305 x 225 x 125 mm (12 x 9 x 5 inches) - Ip55

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014

4

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

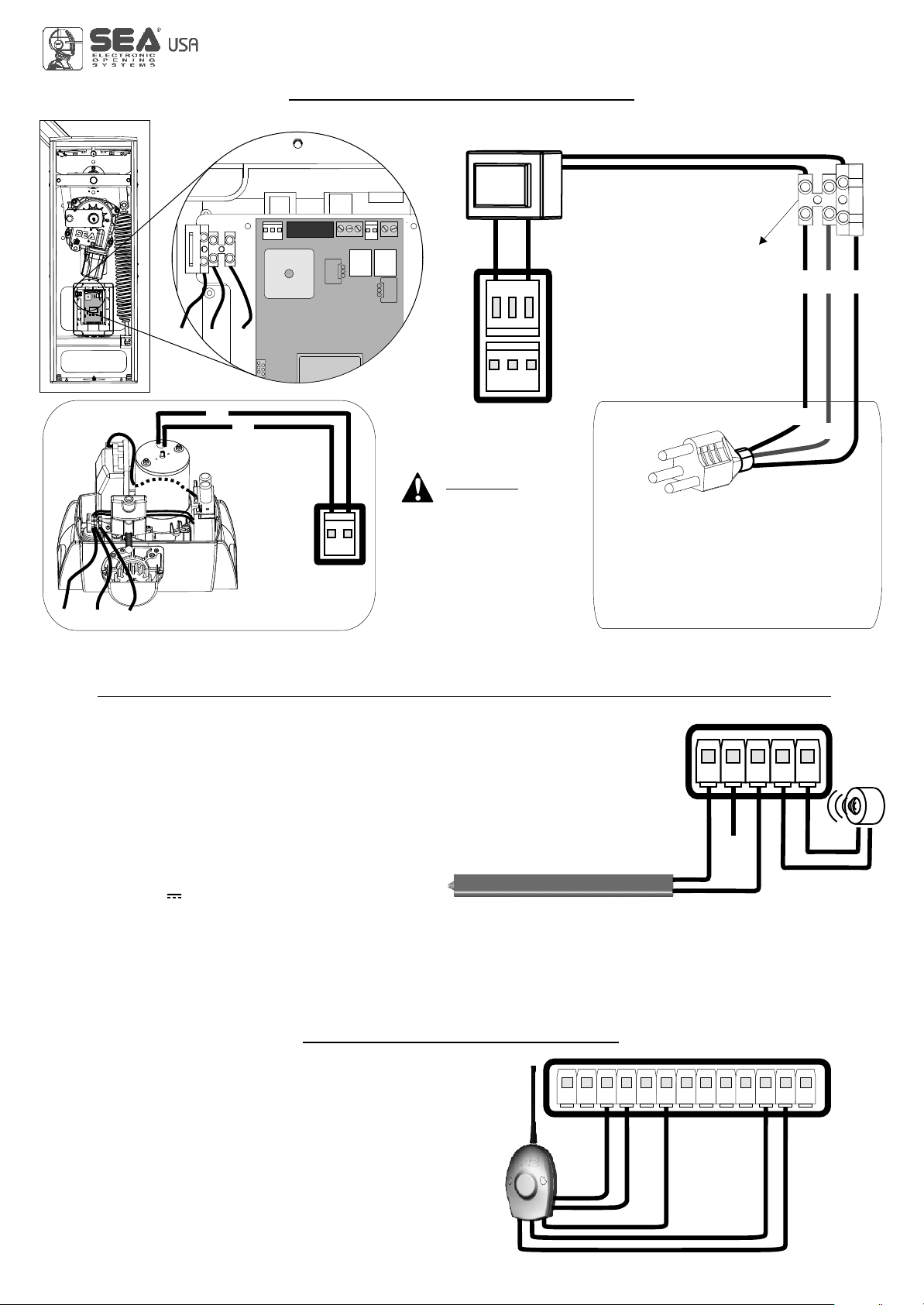

CONNECTIONS

LIGHT (CN5)

Max 100mA

POWER (CN8)

24V~

MOTOR (CN6)

M

Max 200W

JUMPERS

123 4 5 6 7 8 910 11 12 13

CN1

Start

Stop

Common

Antenna

START Ped.

Common

Photocell 1

Common

ANT COM START

PEDST

STOP COM PH1 PH2

EDGE

AUX

COM 24V (FL)-

AUX

(24V 200 mA max)

24V 750 mA max

(Accessori)

Safety edge

The herein reported functions

are available starting from

revision 34.

Flash (-)

Photocell 2

+ +

- -

123 4 5 6 7 8 910 11 12 13

CN1

ANT COM START

PEDST

STOP COM PH1 PH2

EDGE

AUX

COM 24V (FL)-

Start

Stop

Common

Antenna

START Ped.

Common

Photocell 1

Common

AUX

(24V 200 mA max)

24V 750 mA max

(Accessori)

Safety edge

Flash (-)

Photocell 2

+ +

- -

Optional

WARNING: The control unit is designed with the automatic detection of not used N.C. inputs (photocells, Stop and Limit switch) except the

SAFETY EDGE input. The exclude inputs in self-programming can be restored in the “Check inputs” menu without need to repeat the

programming (pag.13).

Obligatory jumper without accessory connection.

67411535 REV 07 - 06/2014 5

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

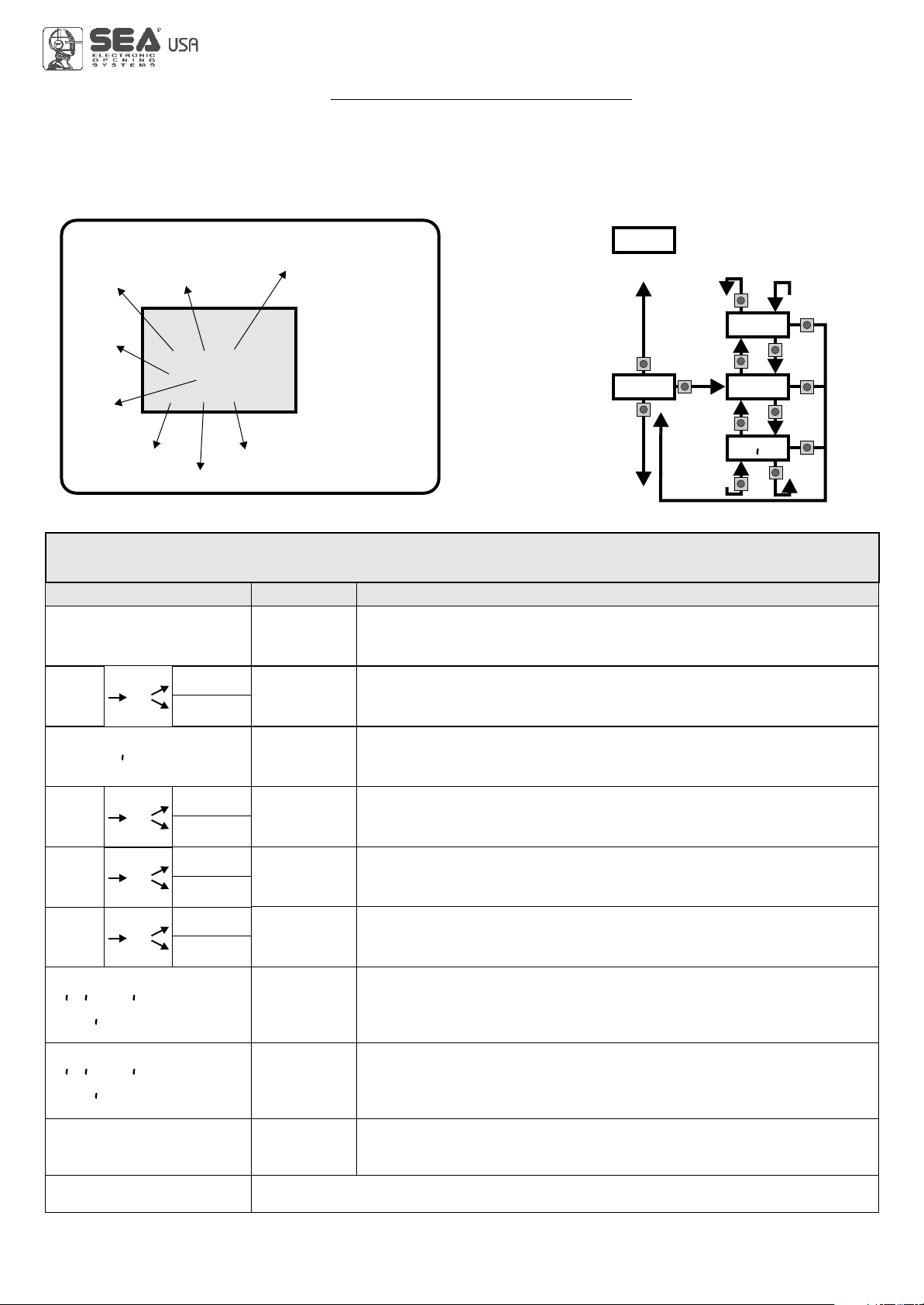

UPDOWN

QUICK START

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

2

3

4

5

6

7

8

OK

OK OK

OK OK

OK OK

OK OK

OK OK

OK OK

UP

UP

UP

UP

UP

UP

UP

PRESS

BUTTON STORED

TRANSMITTERS

START

MOTOR

REVERSE

MOTOR

LOGIC

PAUSE TIME

START IN

PAUSE

PROGRAM-

MING

TEST START

PROGRAMMING

BUTTONS

OK

DOWNUP

9

Skip this step if you do not want to program a transmitter

Press the

button of the

TX to be

stored

OK to exit

Menu or press

the button of

the next TX to

be stored

OKOK Choose the type of

motor with

UP or DOWN

To confirm and return

to main menu

Choose "ON" with UP or

DOWN button only if in

programming the motor starts

in opening

Return to menu 7,

place the gate halfway

and repeat

the times programming

With UP or DOWN

choose

the desired logic

To confirm and return

to main menu

With UP or DOWN

choose a delay for

automatic closing

To confirm and return

to main menu

Skip this step

if you wna tto work

in half-automatic

logic

With UP or DOWN

Choose ON

To confirm and return

to main menu

With UP or DOWN choose ON

to start times learning

At the end of the selflearning

the control unit returns automatically

to the main menu

With

UP or DOWN Choose

ON to start test

To confirm and return to

main menu

Skip this step if a TX has already been stored

1

MENU

SEA

SET

MENU

SEA

SET

OK

UP

LANGUAGE ITALIANO

UP

ALL OTHER PARAMETERS HAVE DEFAULT SETTINGS WHICH ARE USEFUL FOR THE 90% OF THE APPLICATIONS

BUT CAN BE HOWEVER SET THROUGH THE SPECIAL MENU. FOR ENTERING INTO THE SPECIAL MENU MOVE

ON ONE OF THE MENU AND PRESS THE UP AND DOWN BUTTONS AT THE SAME TIME FOR 5 S.

PROGRAMMING

MENU

SEA

SET

(See

page 7)

(See

page 7)

If the motor has

magnetic limit switches,

select "Magnetic"

in the special menu:

34-Limit switch type

RECEIVER

MISSING

If on the display

appears the item:

Check if a receiver has

been connceted

(see page 4)

The gate will execute a CLOSING-OPENING-CLOSING CYCLE

67411535 REV 07 - 06/2014

6

7

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

MENU Default

1 - langvage

SET

espanol

engl sk

fran(a s

tal ano

stop

start

Erg ax

U

Erg

uerg

off

on

off

1,2,3

Italian

English

French

Spanish

Start

Stop

External module

Joint

Sprint 3 meters

Sprint 4 meters

Sprint 5 meters

Storm 5 meters

Storm 6 meters

Storm 7 and 7.5 meters

Saturn

Mercury 800

VergL.5 meters

VergL.4 meters

VergL.3 meters

Erg Maxi

Verg

Erg

start

Ped Start.

off

Avto at (

U

off

tal ano

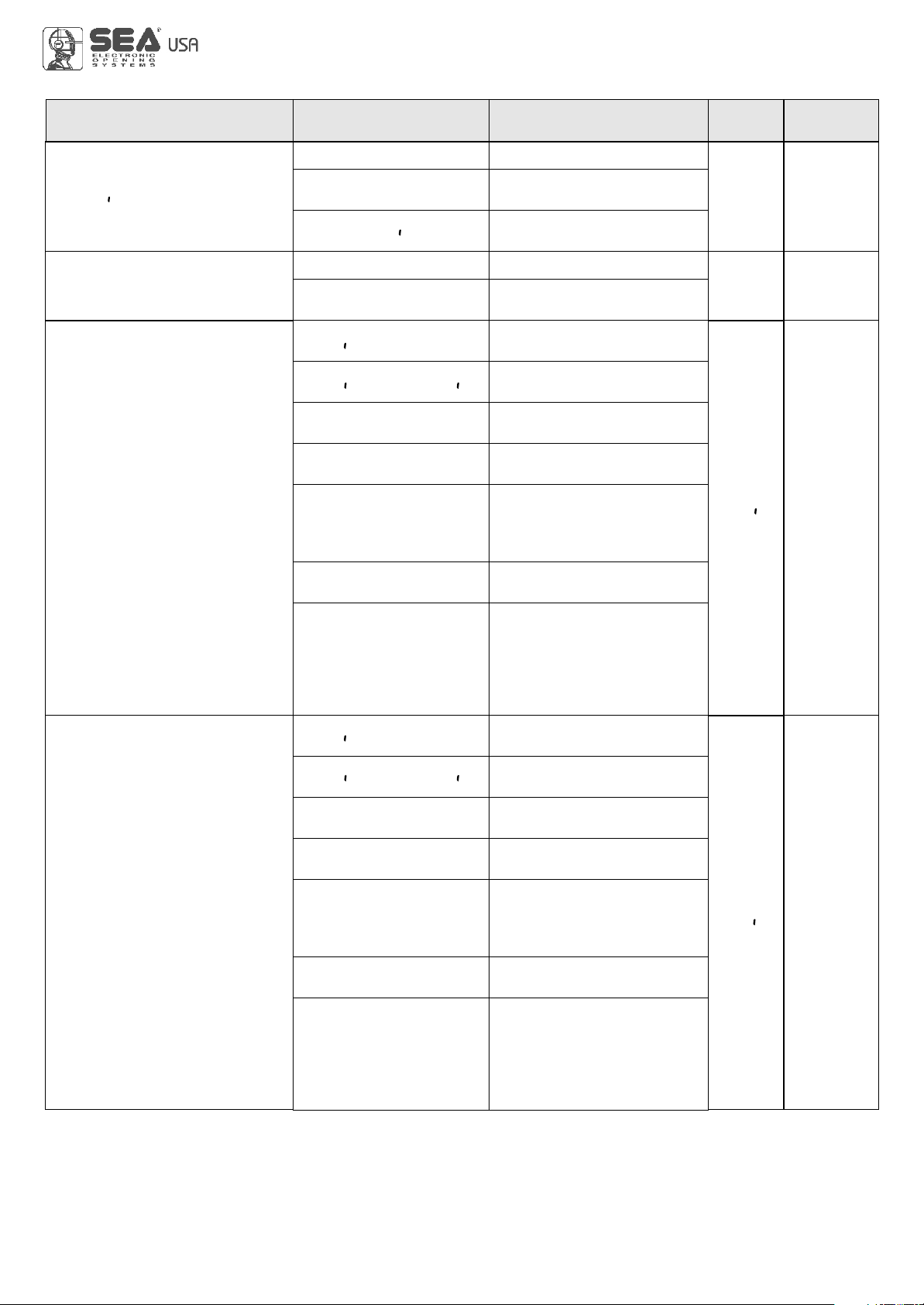

MENU FUNCTIONS TABLE USER1 24V DG R1

Description Set value

U

2 - trans tters

(Lear e ory

UU

External odvle

U

Pedestr an Start

Delete a trans itter

U

3 - otor

U

Jo nt

Spr nt 3 eters

U

Spr nt 4 eters

U

Spr nt 5 eters

U

Stor 5 eters

U

U

Stor 6 eters

U

U

Stor 7.5 eters

U

U

satvrn

Er(vry 800

U

Uergl.5 eters

U

Uergl.4 eters

U

Uergl.3 eters

U

Sl d ng

Sl d ng

U

4 - reuerse otor

5 - log (

Avto at (

U

open-stop-(lose-stop-open

2 bvttons

safety

Dead an

U

open-stop-(lose-open

6 - paVse t e

U

Pedestrian Start

Delete single transmitter

Sliding

Synchronized right motor

Synchronized left motor

Automatic

Step by step type 1

Step by step type 2

Two buttons

Safety

Dead man

Disabled

Setting from 1s to 4min.

Delete transmitter memory

dut(k Dutch

7 - starT n pavse

8 - progra ng

UU

off

on

Off on

off

off

In pause start is not acceped

In pause start is accepted

Times learning start

9 - test start

end

Off on off

Start command

Select END and press OK to exit the menu.The menu

deactivates automatically after 2 minutes

(See page 8)

(See page 9)

67411535 REV 07 - 06/2014

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

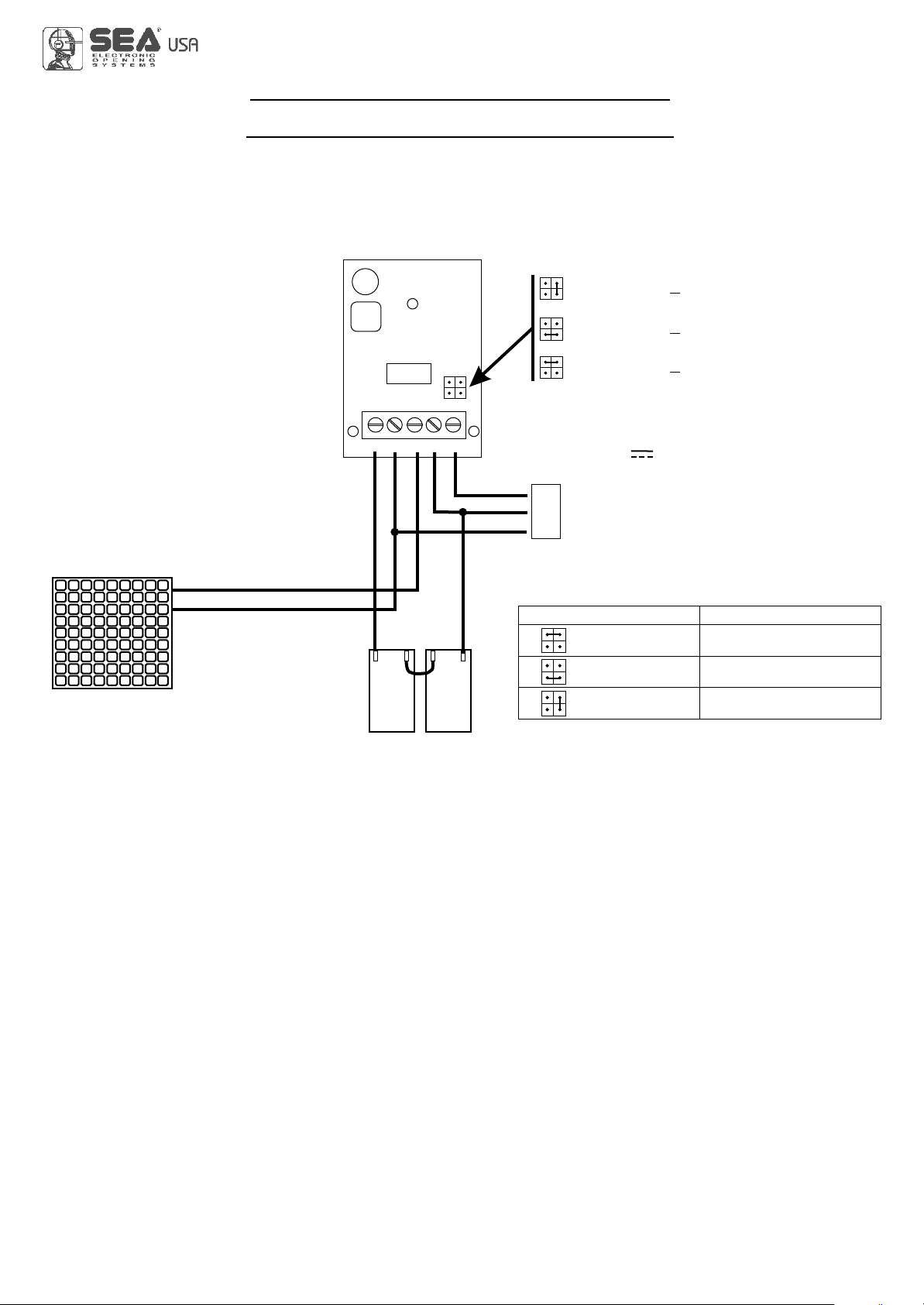

WORKING TIMES SELF LEARNING

Fig. 1 Fig. 2 Fig. 3

Fig.4

The control unit is pre-set with the default settings, to start the control unit with the DEFAULT settings just keep

pressed the UP and DOWN buttons at the same time power supplying the control unit the display shows the

message init.

The DEFAULT settings are shown in the Menues table.

NOTE: When using a B200 motor or magnetic limit switches in general; make sure that the control unit is set on magnetic limit switch

before learning.

MENU 34 - TYPE OF Li i T SUiT(X - AGNETI(

1) Disconnect the power supply, release the motor (Fig. 1) and put the leaves manually next to the stop in closing (Fig. 3-4).

2) Reset the mechanical lock (Fig. 2)

3) Select PROGRA ING on the display, press OK and than one of the UP or DOWN buttons. Now the gate will automatically execute a closing,

opening and reclosing cylce.

Note: If the motor starts in opening, remove and re-put power supply, select on the display REUERSE OTOR. And through the UP and DOWN

button put it on ON, or if you have the Jolly programmer, activate the motor and limit switch exchange function. If the motor starts in closing and

stops, remove the power supply and reverse the motor cables, then repeat the programming procedure.

4)The self-learning is done.

ATTENTION: This procedure is potentially dangerous and should only be performed by qualified personnel in safety conditions.

U U

U

FUNCTION LOGIC

AUTOMATIC LOGIC

Astart impulse opens the gate.A second impluse during the opening will not be accepted.

Astart impulse during closing reverses the movement.

SECURITY LOGIC

Astart impulse opens the gate.A second impulse during opening reverses the movement.

Astart impulse during closing reverses the movement.

STEP BY STEP TYPE 1 LOGIC

The start impulse follows the OPEN-STOP-CLOSE-STOP-OPEN logic.

STEP BY STEP TYPE 2 LOGIC

The start impulse follows the OPEN-STOP-CLOSE -OPEN logic.

DEAD MAN LOGIC

The gate opens as long as the START button of opening is pressed; releasing it the gate stops. The gate closes as long as the button connected

to the PEDESTRIAN START is pressed; releasing it the gate stops. To execute complete opening and/or closing cycles the related

pushbuttons must be constantly pressed.

2 PUSHBUTTONS LOGIC

One start opens, one pedestrian start closes. In opening the closing will not be accepted. In closing a start command reopens, a pedestrian start

command (closes) will be ignored.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item Start in paVse and

choosing ON or OFF. By default, the parameter is OFF.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item Start in paVse and

choosing ON or OFF. By default, the parameter is OFF.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item Start in paVse and

choosing ON or OFF. By default, the parameter is OFF.

NOTE 1: To have the automatic closing it is necessary to set a pause time, otherwise all the logic will be semi-automatic.

NOTE2: It is possible to choose, whether to accept or not, the start in pause, selecting in the MENU the item Start in paVse and

choosing ON or OFF. By default, the parameter is OFF.

UU

67411535 REV 07 - 06/2014

8

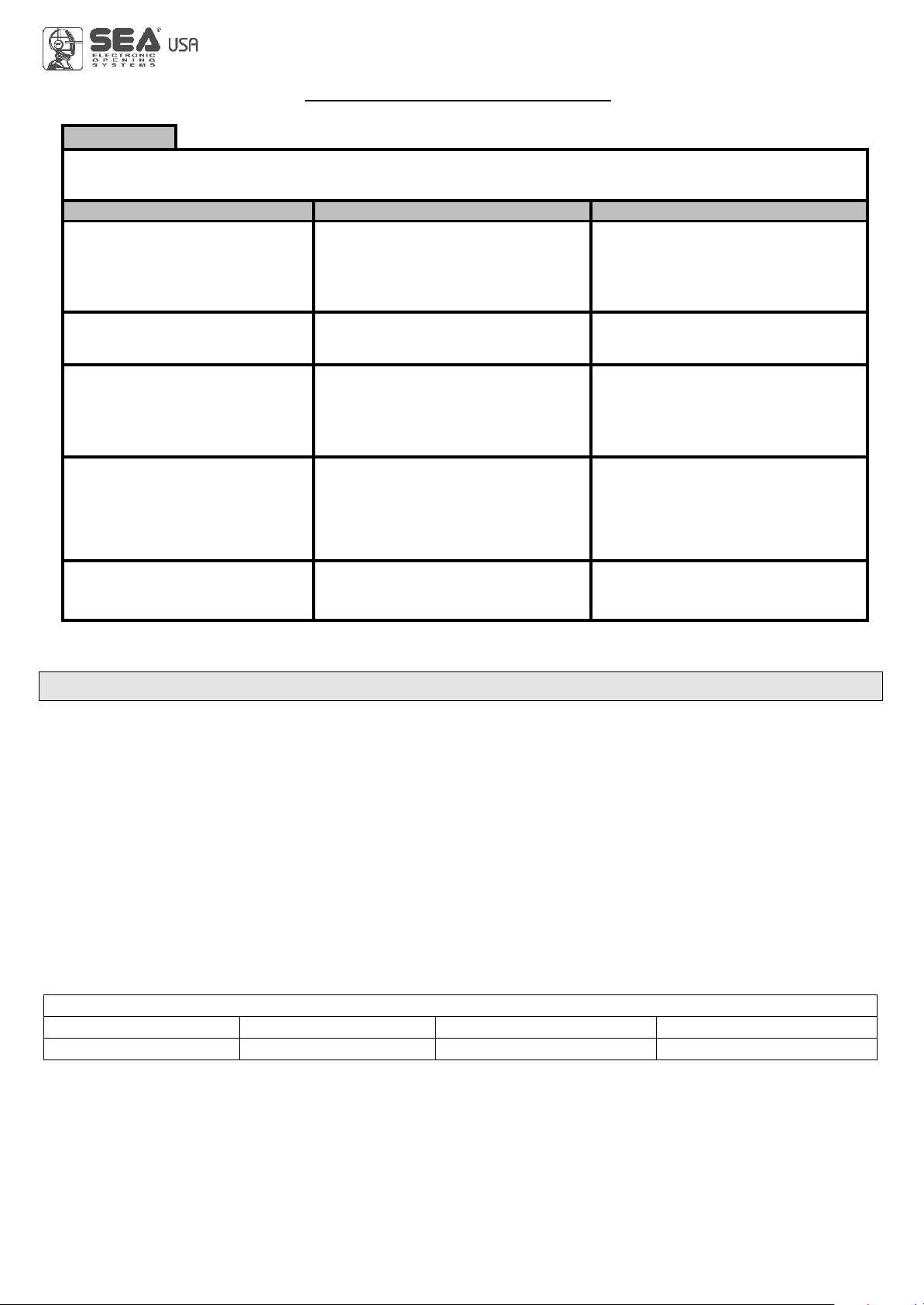

PRESS AT THE SAME TIME FOR 5 SECONDS TO ENTER OR TO EXIT THE SPECIAL MENU

MENU SP Default

SET

30 100

30 100

30 100

10 100

10 100

Off

5 100

Off

5 100

0.0 5.0

Setting from 30 to 100 * 80

* 40

* 80

* 70

* 70

Off

* 30

* 30

1 240

bvzzer

Off

Off on

Normal

Buzzer

Off

1 240

100 10e4

20 100

= start

Off

0 100

0 10e4

30

* 70

10e4

0

= start

1 - speed

2 - sloudoun speed

3 - learn ng speed

4 - open ng torq

5 - (los ng torq

7 - (los ng sloudoun

8 - preflasx ng

10 - (ourtesy l gxt

6 - open ng sloudoun

9 - flasx ng l gxt

Only (los ng

Nor al

U

L gxt

aluays

N (y(le

11 - traff ( l gxt reseruat on

12 - pedestr an open ng

13 - pedestr an PAUSE

14- a((elerat on

15 - a ntenan(e (y(les

U

16 - perfor ed (y(les

U

N (y(le

Nor al

U

SPECIAL MENU FUNCTIONS TABLE USER 1 24V DG R1

UP and DOWN

press END or

UP and DOWN

For entering into the special menu move on one of the menu and press the

buttons at the same time for 5 s. For exiting the special menu move on one of the

menu and press the buttons at the same time for 5 s.

Description Set Value

Setting from 30 to 100

Setting from 30 to 100

Setting from 10 to 100

Setting from 10 to 100

Disabled

Disabled

Setting from 5 to 100

Setting from 5 to 100

Pre-flashing active only

before closing

Control lamp

Always ON

Disabled

Courtesy light setting

from 1s to 4min.

Setting from 20 to 100

Pause in pedestrian

opening same as in

total opening

Disabled

Acceleration ramp

Setting from 1s to 4 min.

Setting from 100 to

100000

Pre-flashing time

Courtesy light in cycle

When setting this function

the pedestrian input will be

activated to work on the

auxiliary board SEM

(traffic light management).

Reports the executed

cycles. Keep pressed OK

to reset the cycles

SPECIAL MENU

UPDOWN

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014 9

MENU SP Default

SET

stop

Nor al

U

17 - t er

U

off

8x2

off

Description Set Value

ON PXOTO2

ON PEDESTR AN ENTRY

Nor al

U

18 - edge

19 - PXOTO1

(LOS NG

Stop AND (LOSE

(LOSE

PAUSE RELOAD

OPEN NG AND (LOS NG

20 - PXOTO2

stop

(LOS NG

Stop AND (LOSE

(LOSE

PAUSE RELOAD

OPEN NG AND (LOS NG

(LOS NG

OPEN NG

Disabled

Timer function active

on photocell 2

Timer function active on

pedestrian input

Edge is active and

protected by a 8k2 resistor

Photocell active in closing

Photocell active in opening

and closing

The photocell gives a

command to close during

opening, pause and

closing

The photocell charging the

pausing time

Photocell active before

opening

The photocell stops in closing

and closes when released

Photocell active in closing

Photocell active in opening

and closing

The photocell gives a

command to close during

opening, pause and

closing

The photocell charging the

pausing time

Photocell active before

opening

The photocell stops in closing

and closes when released

Normal N.C. contact

If the photocell is occupied

during opening, pause or

closing, the gate reopens

completely and closes

without observing the

pause time.

If the photocell is occupied

during opening, pause or

closing, the gate reopens

completely and closes

without observing the

pause time.

Delay pause ti e

u

Delay pause ti e

u

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014

10

27 - fototest

0

0

* 10

off

off

Off

0 15

Off

1 100

Off

Off

On

1 10

0 100

0 100

Off

10 99

6

MENU SP Default

SET Description Set Value

22 - POS T ON RE(OUERY

23 - OTOR RELEASE

U

24 -ant ntrvs on

ONLY (LOS NG

ONLY OPEN NG

OPEN NG AND (LOS NG

26 -d agnost (S

25 - FLASX NG L GXT AND

t er

U

PXOTO1

PXOTO2

PXOTO1-2

29 - (LOS NG TOLERAN(E

28 -OPEN NG TOLERAN(E

30 - OPEN NG SENS T U TY

Regulates the recovery of

the motor inertia

Disabled

Setting from 1 to 100

Only on limit switch in opening

Only on limit switch in closing

On limit switches in closing

and in opening

Disabled

Shows last event

(See alarms table)

Auto-test active only on

Photo1

Auto-test active only on

Photo2

Auto-test active on

Photo1 and Photo2

Adjusts the amperometric

tolerance in relation to the

detected stop in closing

Adjust the amperometric

tolerance in relation to the

detected stop in opening

Disabled

PXOTO1-2

The flashing light remains

ON with active timer and

open gate

The flashing light remains

OFF with the active timer

and open gate

Adjustable from 10 to 99.

Increasing the value the

reversing on obstacles

will be delayed.

21 - 24u avx

ALUAYS

N (Y(LE

N pavsE

fototest

N (Y(lE AND fototest

OPEN NG

(LOS NG ALUAYS

AUX output always

power supplied

AUX output power

supplied only during opening

AUX output power

supplied only during closing

AUX output power

supplied only during pause

AUX output for

connection of photocell

TX to autotest

AUX output active only

during cycle

AUX output only during cycle

with fototest function active

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014 11

MENU SP Default

SET

---- ----

Mechanical limit switch

Description Set Value

35 - passuord

34 - TYPE OF L T SU T(X

U

U

E(XAN (AL

Agnet (

U

END

U

E(XAN (AL

Magnetic limit switch

Allows the entering of a

password which blocs the

modification of the control unit

parameters.

Select END and press OK to exit the special menu.

The special menu deactivates automatically after 20 minutes.

Note 1: The * indicates that the default value may change depending on the selected motor type.

Note 2: After initialization the parameters "motor type" and "limit switch type" remain son the value chosen in

the setup program.

0 50

33 - aster-slaue

U

aster

U

Slaue

off

off

0

* 10

Off

10 99

31 - (LOS NG SENS T U TY

32 - PXOTO off n (LOS NG

Disabled

Setting from 10 to 99

Setting from 0 to 50

For applications with two

motors in master-slave,

you can set the control

unit as slave

For applications with two

motors in master-slave, it

allows to set the control

unit as master

Disabled

With a new control unit all menus can be displayed and set and the password will be disabled.

Selecting one of the Menus and keeping UP and DOWN pressed at the same time for 5 seconds, you will access the

SP Menu containing the Passuord Submenu.

Pressing OK in the Passuord Menu, you will proceed with the entering of the numeric code of the 4-digit

PASSWORD.

Use UP and DOWN to increase or decrease the number, press OK to confirm it and you will pass automatically to the

entering of the next number. Pressing OK after the last entered number the word SvRE? appears, confirm the

activation of the PASSWORD and the message Ok appears, pressing UP or DOWN instead you can cancel the

operation and NO OPERATION will appear on the display.

Once entered the PASSWORD, it will be definitively activated, once the display switch off timeout has expired, or by

turning off and on again the control unit. Once the PASSWORD has been activated, the menus of the display can be

only displayed but not set. To unlock them you must enter the correct PASSWORD in the Passuord menu, if the

password is wrong the message ERRor will appear.

At this point, if the password has been entered correctly, the menus will be unlocked and it will be possible to change

the parameters of the control unit again.

If the control unit has been unlocked through Passuord Menu, it is possible to enter a new and different password,

using the same entering process as for the first one; at this point, the old password will no longer be valid.

If the password has been forgotten, the only way to unlock the control unit is to contact the SEA technical assistance,

which will assess whether to provide the procedure to unlock the control unit or not.

Note: The password cannot be set through the Jolly or Jolly 2 terminal.

PASSWORD ENTERING MANAGEMENT

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014

12

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

The settings of the control unit are made through the UP, DOWN and OK buttons. The UP and DOWN buttons to scroll through the MENUS and

SUBMENUS. By pressing OK you enter from MENU into SUBMENU and confirm the choice.

Moving in the language menu pressing the UP and DOWN buttons at the same time you access the SP MENU for special settings.

Moving in the language menu pressing the OK button for 5 seconds, you enter the CHECK MENU, where you can check the operating status of

all inputs.

MENU

SEA

SET

---

--

---

DISPLAY INPUT STATUS

When the segment

is ON during self-

learning, the input

status is closed or

OFF.

Start

Start

pedestrian

Stop

Limit

Switch

opening

motor 1

Photocell 1

Photocell 2

Edge 1

Limit

Switch

closing

motor 1

Initial system

Software Version

Programming example

u.001

uerg

UP

OK

UP

UP

UP

DOWN

DOWN

DOWN

OK

OK

OK

DOWN

otor

U

S(orr

Jo nt

UP

start

EDGE

PHOTO1

PHOTO2

0.0u

END

MENU

Exit menu

MENU FUNCTION TABLE CHECK USER1 24V DG R1 INPUTS

To access the Menu for input check keep pressed OK for about 5 seconds.

Description Description

Start test

The contact must be N.O. If activating the related command on the

display the item SET lights up, the input will be working.

If SET is always on, check the wirings.

Stop test

Pedestrian

start test

The contact must be N.C. If activating the related command on the

display the item SET lights up, the input will be working.

If SET is always on, make sure that the contact is a N.C. one

The contact must be N.O. If activating the related command on the

display the item SET lights up, the input will be working.

If SET is always on, check the wirings

Safety

edge test

Photocell 1

test

Photocell 2

test

The contact must be N.C. If activating the related command on the

display the item SET lights up, the input will be working.

If SET is always on, make sure that the contact is a N.C. one

The contact must be N.C. If activating the related command on the

display the item SET lights up, the input will be working.

If SET is always on, make sure that the contact is a N.C. One

The contact must be N.C. If activating the related command on the

display the item SET lights up, the input will be working.

If SET is always on, make sure that the contact is a N.C. one.

Opening limit

switch test

Closing limit

switch test

The contact must be N.C. If activating the related command on the display

the item SET lights up, the input will be working. If SET is always on,

make sure that the contact is a N.C. one or that the related

limit switch is not occupied.

The contact must be N.C. If activating the related command on the display

the item SET will light up, the input will be working. If SET is always on,

make sur that the contact is a N.C. one or that the related

limit swith is not occupied.

Batteries’

voltage level Batteries charge level indicator

PedESTR AN Start

L T SU T(H

OPEN NG

U

L T SU T(H

(LOS NG

U

stop

enabled

OK

blo(ked

OK

OK

Note: If the Stop, Photocell 1 and Photocell 2 contacts are not bridged in self-learning, they will be deactivated

and can be reactivated through this menu, without repeating times self-learning.

enabled

blo(ked

enabled

blo(ked

OK

enabled

blo(ked

INPUT CHECK MENU

67411535 REV 07 - 06/2014 13

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

RADIO TRANSMITTER SELF LEARNING

WITH RECEIVER ON BOARD OF CONTROL UNIT

!!

ROLLING CODE:

press twice

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

OK

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

SEA

SET

MENU

SEA

SET

UP

MENU

OK

SEA

MENU

SEA

SET

MENU

SEA

SET

MENU

SEA

SET

SET

OK

OK

OK

OK

OK

OK

per 10 s.

TRANSMITTERS

START

PEDESTRIAN

START

EXTERNAL

MODULE

STOP

DELETE A

TRANSMITTER

0OK? OK

CLEAR

MEMORY OK

PRESS

BUTTON STORED

1 2 3 4

0

1

2

3

4

5

TABLE EXAMPLE

Transmitter

button

Memory

location Serial number Customer

STORED

STORED

STORED

PRESS

BUTTON

PRESS

BUTTON

PRESS

BUTTON

WARNING: Make the radio transmitters programming before you connect the antenna and insert the receiver into the

special CMR connector (if available) with turned off control unit.

With RF UNI module it will be possible to use both Coccinella Roll Plus transmitters, max. 800 codes (buttons), and radio

transmitters with fixed code, max. 100 codes (buttons). The first memorized radio transmitter will determine the type of the

remaining radio transmitters.

If the receiver is a Rolling Code, press twice the button of the radio transmitter that you want to program to memorize the first TX.

Notes:

- Enter radio transmitters learning only when the working cycle stops and the gate is closed.

- You can store max. 2 of the available 4 functions. If the control unit receives a code which was already associated to another function it will be

updated with the new function.

In the case of transmitters with fixed code it is necessary to press 1 time the button of the transmitter you want to program to store the first

remote control

FIXED CODE:

press once

If you want to program

the pedestrian

start as second

channel.

If you want to

program the

STOP as

second channel.

If you want to

delete a single

transmitter.

If you want to delete

the whole memory

If you want to program

the activation

of the LIGHT

output

as second channel.

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Press the

button of the

transmitter

to be stored

Select with

UP or DOWN

the memory

location

to be deleted

and press OK

Press the

button of the

transmitter

to be stored

If you do not want to execute the cancellation,

press UP or DOWN to return to the

TRANSMITTER menu.

Confirm the cancellation.

67411535 REV 07 - 06/2014

14

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

START - STOP - PEDESTRIAN START - ANTENNA -

PHOTOCELL

START (N.O.) The

An impulse given to this contact opens and closes the automation depending onthe selected logic it can be given by a key switch, a keypad,

etc. To connect the other devices refer to the related instructions leaflets. (ie. loop detectors and proximity switches).

Note1: In DEAD MAN logic it is necessary to keep pressed the Start for the opening of the automation.

Note2:

START is connected between the clamps 2 and 3 of the CN 1 terminal.

In 2 BUTTONS logic this button performs the opening.

STOP (N.C.) The STOP is connected between the clamps 2 and 5 of the CN1 terminal .

The pressure on this button immediately stops the motor in any condition/position. A start command is needed to re-start the movement.

After a stop the motor always re-starts in closing.

Photocell 1 and Photocell 2 Connections

+ = 24V (Accessories) max 750mA COM = 0V PH1 = Photocell contact 1

PH2 = Photocell contact 2

Note: For the autotest connect the TX to theAUX clamp and activate theAutotest function.

The standard setting of the photocell 1 is FOTO CLOSE and the one of the photocell 2 is FOTO

OPEN. The photocell 2 can be set also as TIMER (see TIMER function).

Note3: On the fototest menu you can also activate the self-test even on the single photocell.

Can be activated through on-board display or through the Jolly programmer. In both cases it’s a N.O. contact which provoques

the opening of the automation keeping it open until it is activated. When it’s released, the gate attends the set pausing time

and executes the reclosing. The TIMER command can be activated on the inputs FOTO2, START PEDESTRIAN.

Note1: When activated on the pedestrian entry, the pedestrian will be disabled also on the radio transmitter.

Note2: In case of intervention of a security device during the timer (Stop, Ammeter, Edge), to restore the movement it will be

necessary to give a start impulse.

Note3: In case of no power supply with open gate and active Timer the control unit will restore its use, otherwise if during

restore of the power supply the TIMER is not activated it will be necessary to give a start impulse for the reclosing.

TIMER

Antenna

Common

Start

Start ped.

Stop

Common

Photocell 1

CN1

1 2 3 4 5 6 7 8

Photocell 2

RX1

RX2

TX1

TX2

CN1

9 10 11 12 13

Common

24V (Accessories)

PEDESTRIAN START (N.O.) The pedestrian start can be connected

between the clamps 2 and 4 of the CN1 terminal .

This input allows a partial opening the opening space can be set through

the on-board display or through the JOLLY device.

Note1: The contact for partial opening is a N.O. Contact (Normally open).

Note2:In 2 BUTTONS logic it is necessary to keep pressed the Start Ped.

to re-close the automation.

Note3: In dead man logic this button executes the re-closing if you keep it

pressed.

Note4: When closed during pause, the gate will reclose only after this

input has been reopened.

TIMER activation: This input can be transformed into TIMER (See

TIMER).

Options AUX 24V max 200mA can be set with on-board

Display or with Jolly device.

Through the Jolly programmer it is possible to chose when having

tension on the AUX output. The options are: always, only during

opening, only during cycle, only before opening or only during

pause, fototest and in (y(le and fototest.

When using control units with batteries and / or solar panels, we

recommend connecting the accessories which are not used when

operator stands still (e.g. photocells) to a AUX output, setting the

option “in (y(le”. With this setting you can save energy by

lowering power consumption in stand-by, increasing the autonomy

of the system.

OPTIONS ON FOTO1 and FOTO2 adjustable on on- board display or with

JOLLY terminal.

FOTO CLOSE activation ((losing): if occupied, reverses the movement in closing, during

pause it prevent the closing.

Activation repeat pause (pavse RELOAD): If occupied, during pause it recharges the timer

of pause. In closing it reverses the movement.

FOTO OPEN activation (oPEning): If activated the photocell blocks the movement as long

as it’s busy, when released the opening continues.

FOTO PARK activation (stop and (lose) : in opening it is not active; in pause are activated

it commands the closing when released, otherwise it’s not active; in closing it stops the

movement as long as it is busy, when released the closing continues.

FOTO STOP activation (STOP): When activated before the opening the photocell blocks the

automation as long as it is busy, during the opening it will be ignored. In closing the

intervention of the photocell causes the reopening.

Activation PHOTO CLOSE IMMEDIATELY ((lose): The photocell stops the gate as long

as it is occupied in both opening and closing, when released it gives a closing command

(Closing one second after release of the photocell ).

delay pause ti e activation: If the photocell is occupied during opening, pause or

closing, the gate reopens completely and closes without observing the pause time.

u

67411535 REV 07 - 06/2014 15

16

Sensor barriers

This control unit comes with a detection device of motor current absorbtion which allows to

reveal possible obstacles during the opening and the closing of the gate. When this device

intervenes in opening it causes the inversion of the movement for around a second, if it

intervenes in closing it causes the total reopening.

Note1: The ammeter sensitivity is adjustable both in opening and in closing through

the on-board display or through the JOLLY terminal. With high torque the gate

reverses after 5 seconds.

Attention: In case of obstacle, if the automatic reclosing is on, the gate will attempt

to close for 3 times, whereupon a start signal will be necessary to re-establish the

movment.

Limit

Switch

CN2

Flashings Number

9

2

3

6

4

Flashings Number

5

7

6

4 fast

Kind of alarm

Motors fault

Photocell in closing

Photocell in opening

Opening impact

Safety edge

Kind of alarm

Stop

Max. Reached cycles

Closing impact

Limit switch error

Nota1: se nella diagnostica viene visualizzato “Cicli massimi raggiunti”, effettuare la manutenzione e/o azzerare il numero di cicli

eseguiti.

Note2: To exit from the error messages, press OK. If the error persists, make all required checks for the specific error and / or

disconnect the device that generates the error to see if the error disappears.

At each opening and closing of the automation the flashing light will blink. It blinks once per second during opening and twice per

second during closing, while it remains lit during pause.

It is possible to view the alarms also on the flashing light or on the control lamp, simply by observing the number of flashes emitted and

verifying the reference in the table below:

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

LIMIT SWITCH AND SENSOR BARRIERS

ALARMS INDICATIONS

Limit switch

The limit switch can be connected through the special LIMIT SWITCH connector

on the control unit. The control unit can administrate mechanical, inductive and

magnetic limit switches. Only on some special applications il will not be

necessary to connect the limit switches. The control unit will automatically realize

if limit switches are present or not.

1) Through the on-board display or through the JOLLY programmer it is possible

to activate the ani-intrusion function. This function is lied to the presence of at

least one limit switch which, when free, forces the motor to re-close.

Note: if during programming phase the motor and limit switch times should

not be in phase between them, the gate will start in closing, it stops and will

not complete the selflearning of the times, at this point it will be necessary

to switch off the tension and to invert the cables of the motor. The first

movement in selflearning must always be executed in closing.

ATTENTION: When using SEA magnetic limit switches, make sure that the

motor is set on Agneti( li it suitcK present in the special menu.

UU

Signals Kind of alarm Solutions

Motors current failure Sure there are no short circuits on the motor or on the control unit.

24V Power supply

failure

Make sure there are no short circuits on the wiring or on the control unit and

no overloads.

AUX output

voltage failure Make sure there are no short circuits on wiring or control unit and no overload.

Self-test photocells

failure Check the photocells operation and / or connections on the control unit.

Limit switch

activation failure

Check the operation of both limit switches and / or correspondence

between movement direction of the motor and engaged limit switches.

Flashing lamp failure Check connections and / or conditions of the lamp.

Slave failure Check the connection between MASTER and SLAVE or if the SLAVE board is

actually set as such.

FA LVRE OTOR

u

FA LVRE24

FA LVRE24UAVK

FA LVRE SELF TEST

FA LVRE L T SU TCK

U

FA LVRE slaue

FA LVRE FLASK NG L GKT

67411535 REV 07 - 06/2014

9 10 11 12 13

Edge

AUX

Common

FL(-)

CN1

Security edge

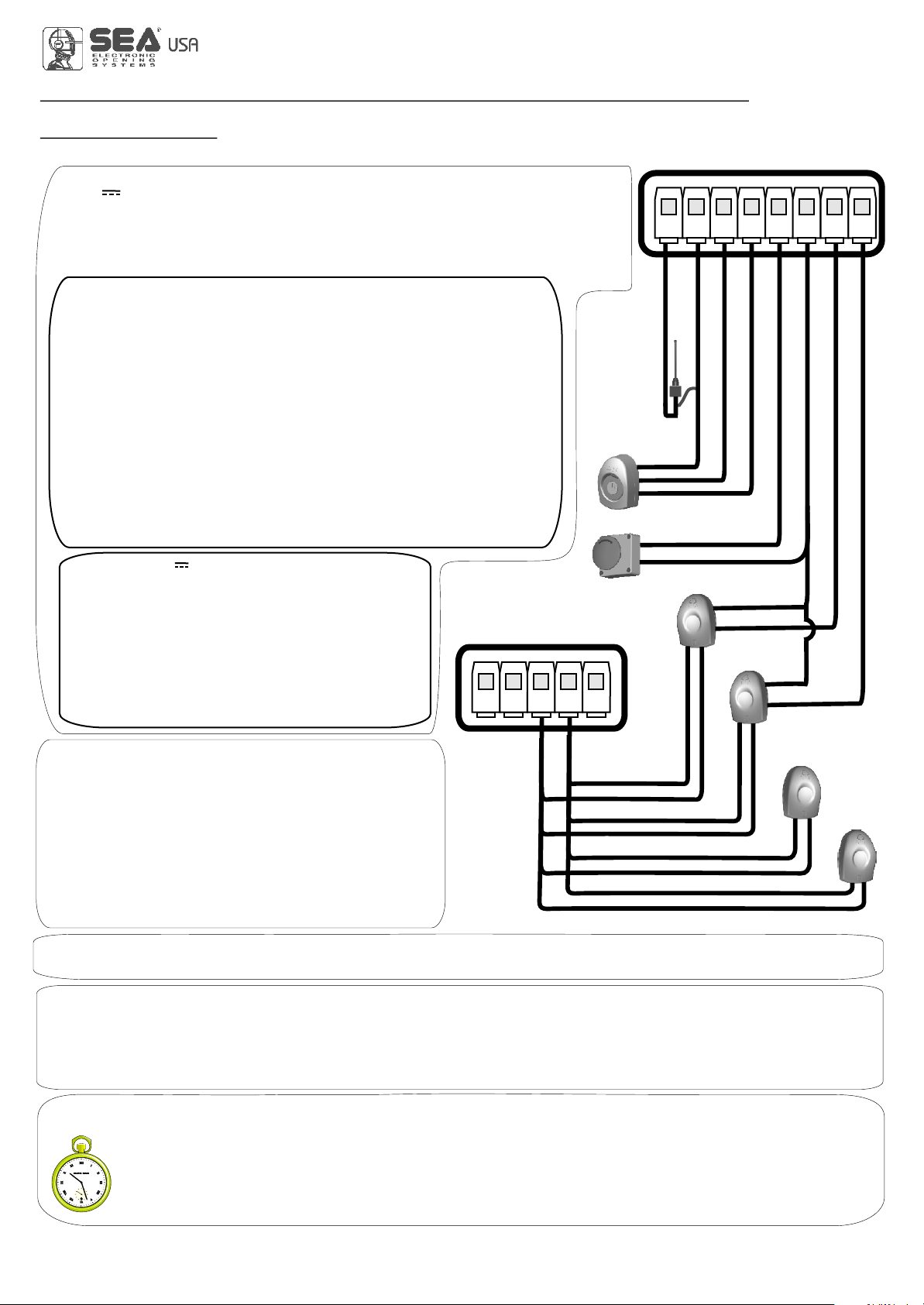

MOTOR POWER SUPPLY

Power input

Input for the connection of the electric

power.

P = SINGLE PHASE 120V~

N = NEUTRAL

G = GROUND NOTICE: for the

connection to the electric

power see the law in force.

TRANSFORMER

3,6 A blow fuse on 230V ~ power supply

6,3A blow fuse on 115V ~ power supply

17

GN

115V~

o

230V~

P

POWER

(CN8)

P G N

MOTOR

(CN6)

M+

M- 12

P G N

+

-

CN1

1 2 3 4 5 6 7 8 9 10 11 12 13

Start

SECURITY EDGE

Between clamps 9 and 11 of CN 1 it is possible to connect an active safety edge on the terminal M8. If this

device is pressed it opens the contact causing a partial inversion of the movement both in opening and in

closing. If not used you must put a jumper between the contacts GND and 9 of CN1.

Note1: contact N.C.

Note2: Through the on-board display or the Jolly programmer it is possible to activate the balanced edge

8K2, in this case the edge contact is controled by a special resistance value revealing the eventual

involuntary short- circuit of the device. In case of imbalance of the device a special alarm will show on the

on-board dispaly or on the JOLLY programmer.

SECURITY EDGE AND WARNING LAMP OR BUZZER

EXTERNAL RECEIVER

Example: Connection of a

radio receiver

For the connection of the

receiver refer to the relative

instructions manual.

Common

Common

Start ped.

-

+

Flashing Lamp 24V 15W (Warning lamp ) or Buzzer

The flashing lamp or buzzer can be connected between the clamps 24V (Accessories) and FL (-) of CN 1.

The warning lamp or buzzer advises that the automatic gate is moving with 1 flash/second in opening and 2 flashes / second in closing. During

pause it remains switched on. Through the warning lamp or buzzer it is also possible to identify alarms lied to the STOP, PHOTOCELL 1,

PHOTOCELL 2 and EDGE devices. Through the display or the JOLLY programmer it is possible to activate the pre-flashing function and/or to

modify the function of the warning lamp/buzzer choosing between fix flashing, control lamp or Buzzer.

WARNING:

Keep the power

cables (motors, power

supply) SEPARATE from the

command cables (push

buttons, photocells and so

on). In order to avoid any

interference it’s preferable to

foresee and use two separate

sheaths.

BUZZER

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

24V (Accessories)

24V (Accessories)

67411535 REV 07 - 06/2014

18

MASTER-SLAVE FUNCTION

CN4

SIGB

COM

SIGA

SIGB

COM

SIGA

M1 M1

To set an installation with two motors in MASTER-SLAVE function it is recommended to do as follows:

1) Set the two motors as if they were two independent installations, make sure that the individual motor works

properly and that the limit switches (when present) are read properly.

2) Once sure of the correct functioning connect the control unit MASTER to the control unit SLAVE through the

special clamp (Code SEA23001220).

3) Now set the control unit, which has to manage the commands and motor 1 (photocell, keyswitch, STOP, safety

edge etc.) as MASTER and the other one which will move motor 2 as SLAVE.

4) Follow up the selflearning of the times of the MASTER control unit.

Note 1: The master and slave settings on the control unit are present in the special menu selecting ASter-slaue.

Note 2:All these operations can also be managed through the JOLLY programmer).

Note 3: On the SLAVE it is possible to set the following functions only: torque, speed, motor type, slowdown speed,

acceleration, deceleration, position recovery, AUX and motor inversion. All other parameters will be set only by the

MASTER control unit.

U

Insert on CN4

of the Master control unit

Insert on CN4

of the Slave control unit

Note: respect the polarity of the cables.

It is recommended to use a two twisted pairs shielded

2

cable with less than 0.5 mm section.

TRAFFIC LIGHT CARD CONNECTION

1 2 3 4 5 6 7 8 9 10 11 12 13

EXP

DS1

DS2

RL4 RL3 RL2 RL1

L4 L3 L2

IC2

-M2+

1 CNP

CN1

L1

M1

24V~ / (ac/dc)

or

230V~

1 2 3 4 5 6 7 8

1

2

3

4

Connect on

EXP terminal

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

67411535 REV 07 - 06/2014

28V Battery charger

Positive battery

Negative battery charger

Battery current (mA) Battery (Ah)

Insert two 12V batteries connected in series.

= charge 200mA

~

~

(BAT)

+

-

GND

PSOL

BAT 28V

+

-

GND

+

CN1

+

-

S

GNDGND

Solar Panel

Batteries

12V 12V

= charge 360mA

= charge 800mA

~

Cod.23101105

800

360

200

12 or 16

7

2

19

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

CONNECTION OF BATTERIES

TO BATTERY CHARGER CARD

Specifications of

optional batteries:

24V Pb 1.2Ah min.

67411535 REV 07 - 06/2014

Page for both instaler and user

WAREHOUSING TEMPERATURES

Tmin TMax Dampnessmin DampnessMax

5% Not condensing 90% Not condensing

MAINTENANCE

Considering the number of working cycles and the kind of gate, if the gate has changed the clutches and doesn’t work

it’s necessary to periodically proceed, with the learning times reprogramming on the electronic control unit.

Periodically clean the optical systems of the photocells.

REPLACEMENTS

Any request for spare parts must be sent to:

Tel. - Toll free:

SAFETYAND ENVIRONMENTAL COMPATIBILITY

Disposal of the packaging materials of products and/or circuits should take place in an approved disposal facility.

STORING

Materials handling must be made with appropriate vehicles..

WARRANTY LIMITS

SEA reserves the right to make any required modification or change to the products and/or to this manual without any

advanced notice obligation.

SEA USA Inc. 10850 N.W. 21st unit 160 DORAL MIAMI Florida (FL) 33172 USA

:++1-305.594.1151 ++1-305.594.7325 800.689.4716

For the guarantee see the sales conditions on the official SEAprice list.

-4 °F + 149 °F

20

International registered trademark n. 2.777.971

USER 1 - 24V DG R1

TROUBLE SHOOTING

Advises

Make sure all Safeties are turned ON

Problem Found Possibile Cause Solutions

Motor doesn’t respond to any

START impulse

Gate doesn’t move while the

motor is running

Gate doesn’t reach the complete

Open / Closed position

The gate opens but doesn’t

close

The gate doesn’t close

automatically

a.) Check the connected N.C. contacts

b.) Burnt fuse

a.) The motor is in the released position

b.) There is an obstacle

a.) Pause time set to high

b.) Control unit in semi-autom. logic

a.) Wrong setting of the limit switches

b.) Error on programming

c.) Gate is stopped by an obstacle

d.) Torque or speed too low

a.)

.) Ammeter alarm

The contacts of the photocells are

connected and open

b.) The stop contact is connected and open

c.) The edge contact is open

d

a.) Check the connections or the jumpers

on the connections of the safety edge or

of the stop and of the photocell if connected

b.) Replace the burned fuse on the

control unit

a.) Re-lock the motor

b.) Remove obstacle

a.) Adjust pause time

a.) Set limit switches

b.) Repeat programming

c.) Remove obstacle

d.) Increase torque parameter

a.) b.) c.) Check the jumpers or the

connected devices and the signals

indicated on the warning lamp

d.) Check if the ammeter alarm has

intervened and eventually increase the

torque parameter.

b.) Set the pause parameter on a

different value from the off

67411535 REV 07 - 06/2014

Table of contents

Popular Controllers manuals by other brands

Mateksys

Mateksys F411-WSE quick start guide

Damega

Damega Intel Siren Installation instructions manual

Honeywell

Honeywell SUPER TRADELINE S8610U Quick reference guide

PS Automation

PS Automation PSL Series Short operating instructions

ABB

ABB CBXi-8R8 Installation and Wiring

ComAp

ComAp IL-NT MRS15 reference guide

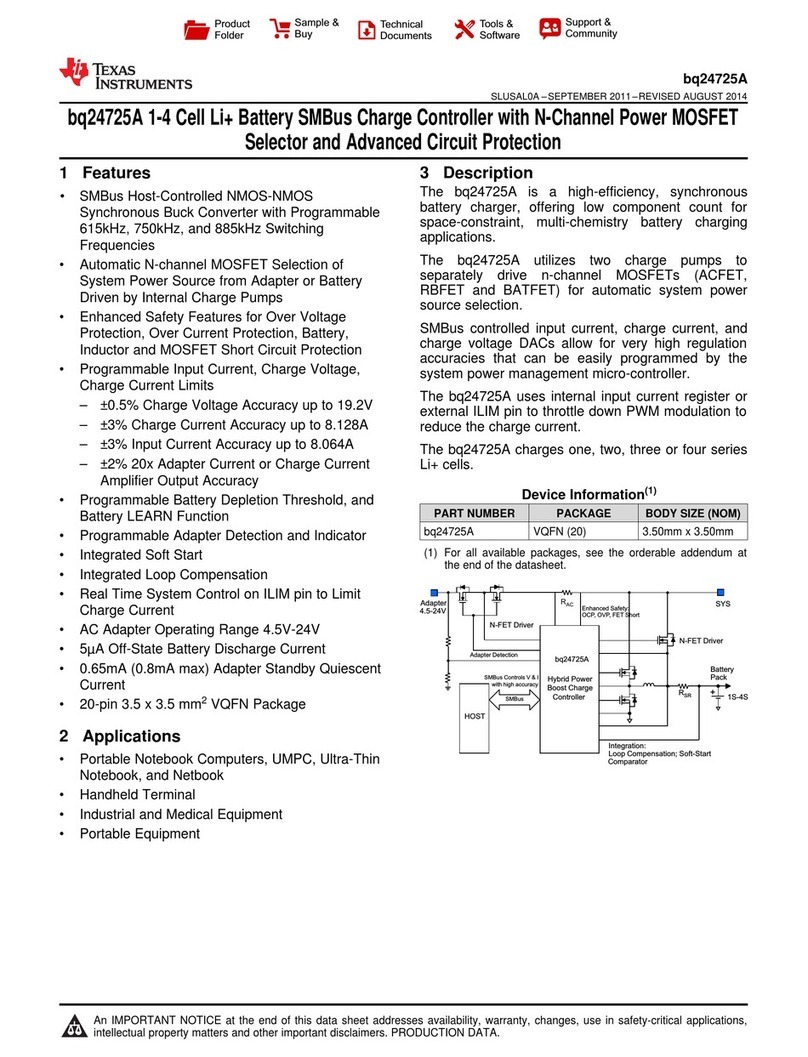

Texas Instruments

Texas Instruments bq24725A manual

GE

GE Masoneilan 4700E instruction manual

Meunier Technologies

Meunier Technologies DICE ES Installation, operation and maintenance manual

enphase

enphase EP200G101 Quick install guide

HighPoint

HighPoint SSD7505 Quick installation guide

Regin

Regin REGIO EEDO manual