69-2042—01 6 69-2042—01 7 69-2042—01 8 69-2042—01 9

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Limited-Honeywell Limitée

35 Dynamic Drive

Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2010 Honeywell International Inc.

69-2042—01 M.S. Rev. 09-10

Printed in U.S.A.

a Flash Code Descriptions:

- Flash Fast: rapid blinking.

- Heartbeat: Constant ½-second bright, ½-second dim cycles.

- 4-second solid on pulse followed by “x” 1-second flashes indicates

flame current to the nearest mA. This is only available in run mode.

- A single flash code number signifies that the LED flashes X times at 2

Hz, remains off for two seconds, and then repeats the sequence.

Table 3. Green LED Status Codes.

Green LED

Flash CodeaIndicates Next System Action Recommended Service Action

OFF No “Call for Heat” Not applicable None

Flash Fast Power up - internal check Not applicable None

Heartbeat Normal startup - ignition

sequence started(including

prepurge)

Not applicable None

4 Seconds ON

then “x” flashes Device in run mode. "x" =

flame current to the nearest

μA.

Not applicable None

2 5 minute Retry Delay

– Pilot flame not detected

during trial for ignition

Initiate new trial for ignition after retry delay

completed. If system fails to light on next trial for ignition check gas supply,

pilot burner, spark and flame sense wiring, flame rod

contaminated or out of position, burner ground connection.

3Recycle

– Flame failed during run Initiate new trial for ignition. Flash code will

remain through the ignition trial until flame is

proved.

Ifsystem failstolightonnexttrialforignition,checkgassupply,

pilot burner, flame sense wiring, contamination of flame rod,

burner ground connection.

4 Flame sensed out of

sequence If situation self corrects within 10 seconds,

control module returns to normal sequence. If

flame out of sequence remains longer than 10

seconds, control will resume normal operation 1

hour after error is corrected.

Checkforpilot flame.Replacegasvalveifpilotflamepresent.If

no pilot flame, cycle “Call for Heat.” If error repeats, replace

control.

5 Damper Error:

– Damper required but not

present

– Damper failed to open

within 60 seconds

– Damper failed to close

within 60 seconds

If damper error corrects, ignition control

resumes normal operation. Checkdamper connection,damperwiring,and24Vconnection

on control.

Replace damper if necessary.

6 Control Internal Error Controlmodule remainsin waitmode. Whenthe

fault corrects,control module resumes normal

operation.

Cycle “Call for Heat.” If error repeats, replace control.

7 Flame rod shorted to ground Control moduleremains inwait mode.When the

fault corrects,control module resumes normal

operation.

Check flame sense lead wire for damage or shorting. Check

thatflamerodisinproperposition.Checkflamerodceramicfor

cracks, damage or tracking.

8 Low secondary voltage

supply Controlmodule remainsin waitmode. Whenthe

fault corrects,control module resumes normal

operation.

Check transformer and AC line for proper input voltage to the

control. Check with full system load on the transformer.

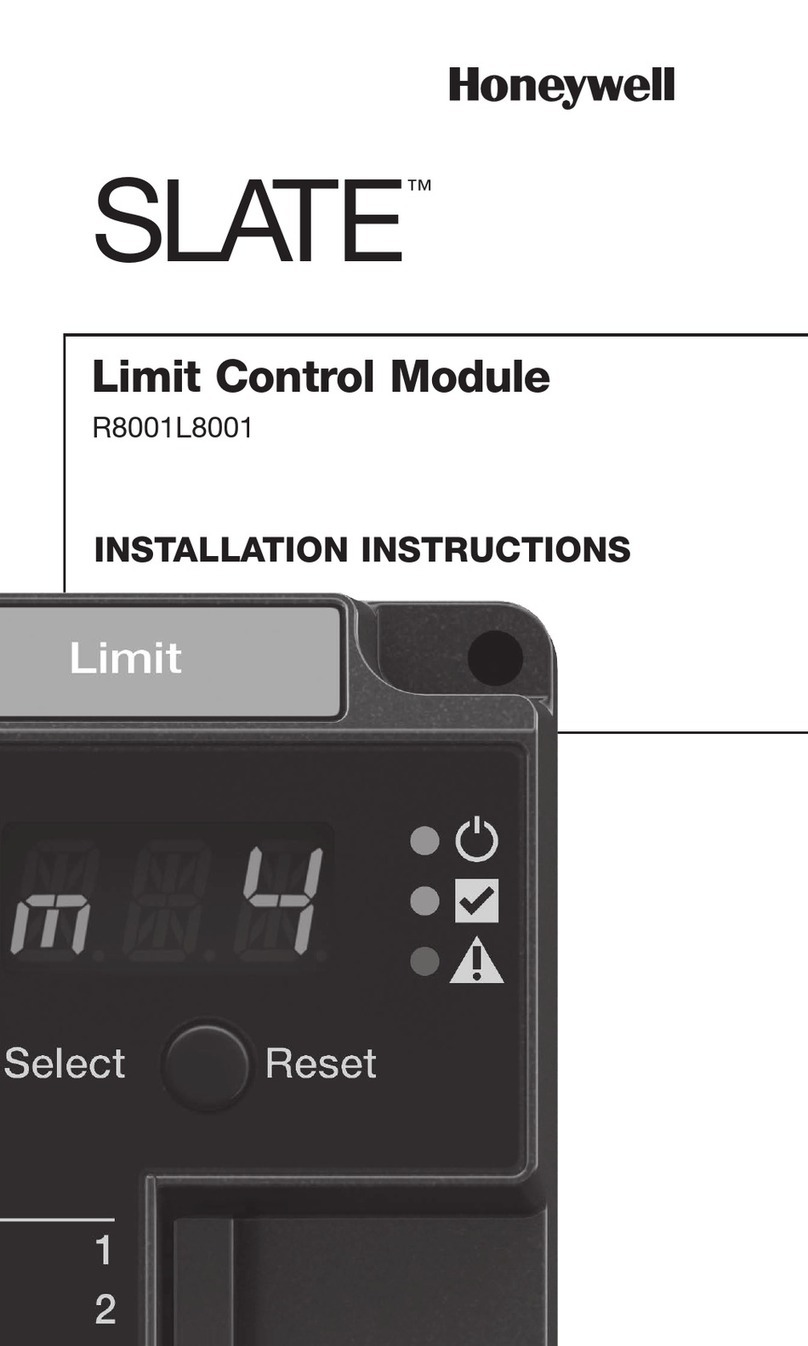

Fig. 5. Measuring flame current with micro-ammeter.

+

–

FLAME

PURGE

PRE

90 SEC

15 SEC

TRIAL

IGNITION

FOR

J1

P1

CURRENT 0 SEC

STATUS

30 SEC

+

–

FLAME

PURGE

PRE

90 SEC

15 SEC

TRIAL

IGNITION

FOR

J1

P1

CURRENT 0 SEC

STATUS

30 SEC

M31283

002.3

DC

µA

FLAME CURRENT MEASUREMENT

Flame current of the device can be meaured using a standard

micro-ammeter by simply inserting the meter probes into the

holes labeled FLAME CURRENT, as shown in Fig. 5.

• Flame current must be measured with pilot valve lit but no

main gas flowing.

• Disconnect MV leadwire from the control before measuring

flame current.

• Set meter to DC μAmp scale.

• Ensure meter leads are positioned correctly [+/-].

NOTE: Trying to measure the pilot flame current in series with

the wiring will not be accurate.

Recommended Minimum Pilot Only Flame Current:

• Must read steady 1 μAmp DC minimum.

• Flame current should be 2 μAmp or greater for reliable

appliance operation.