© Danfoss | 2021.09 | 3AQ315252253183en-010301

AMI 120 NL-1

Safety Notes

To avoid personal injury and damage to

the device or other property, it is

necessary to read and follow these

instructions carefully.

Assembly, start-up, and maintenance work

must be performed by qualified and authorized

personnel.

Comply with the instructions of the system

manufacturer or system operator.

Do not remove the cover before the

power supply is switched off.

Mounting Position ❶

The actuator should be mounted with the valve

stem in either a horizontal position or pointing

upwards.

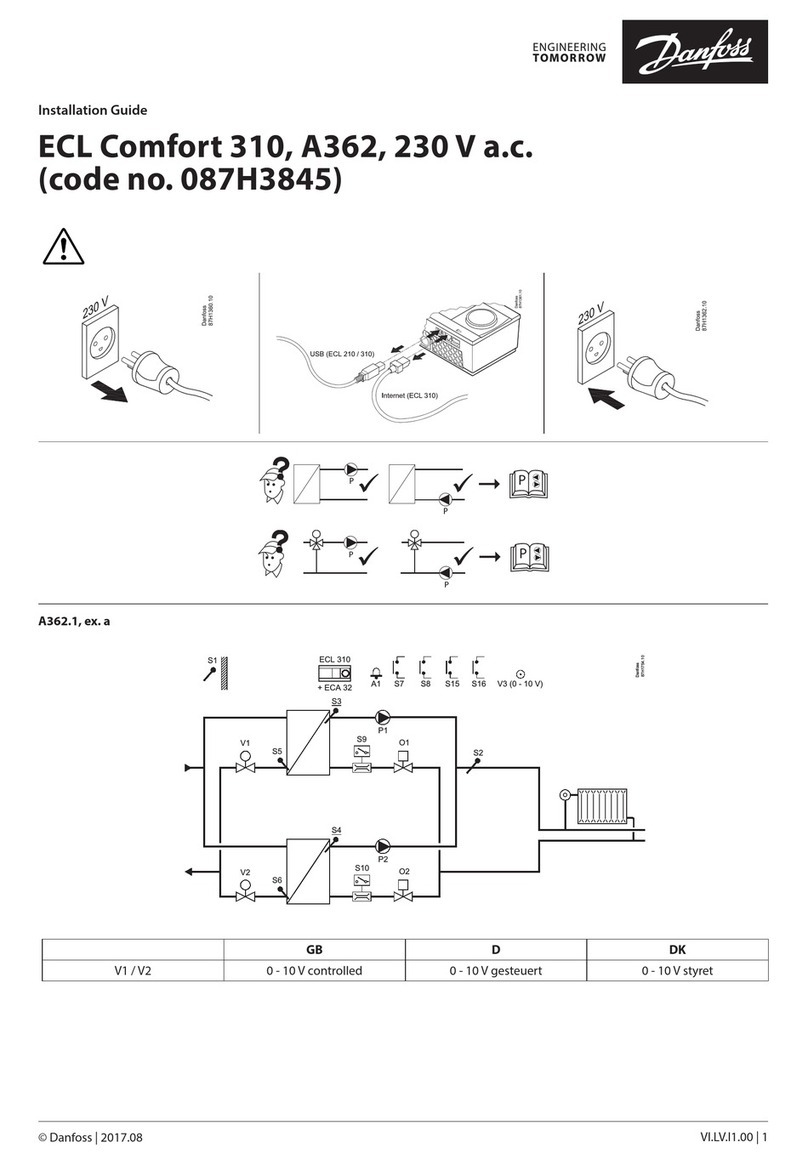

Wiring ❷

AC 24 V

Connect via Class 2 (North America)

or Safety Extra-Low Voltage (SELV)

(Europe). Failure to comply can lead to

equipment damage or personal injury.

Switch off power before wiring the

actuator!

1. Make all wiring connections in accordance

with local, national, or regional regulations.

2. For applications requiring conduit, a field

supplied 1/2” trade size electrician’s fitting

and lock nut can be mounted in the actuator

enclosure. Use flexible metallic tubing or its

equivalent with the field supplied fitting.

3. Insert wiring material through the removable

plug or conduit fitting, and connect to the

terminal block using the applicable wiring

diagram ❷.

4. Optionally, end position feedback is

available on terminal 4 and terminal 5, which

indicates actuator’s end position travel. Both

contacts are normally open.

Jumper position setting

Do not remove the cover before the

power supply is fully switched off.

· The Jumper is factory set in position “A”

With the jumper in position “A”, an “ON”

command at position 1 of the terminal block

will cause the actuator spindle to extend (valve

closes). An “OFF” command will cause the

spindle to retract (valve opens)

· Moving the jumper to position “B” will

reverse the actuator’s action

With the jumper in position “B”, an “ON”

command at position 1 of the terminal block

will cause the actuator spindle to retract (valve

opens). An “OFF” command will cause the

spindle to extend (valve closes).

Installation ❸

1. Check the valve neck. The actuator should

be in the full up position ①(factory setting).

If it is not, refer to the manual override

instructions and reposition the actuator to

its full up position ❸①.

2. The actuator is fixed to the valve body by

means of a ribbed nut which requires no

tools for mounting. The ribbed nut should

be hand tightened only.

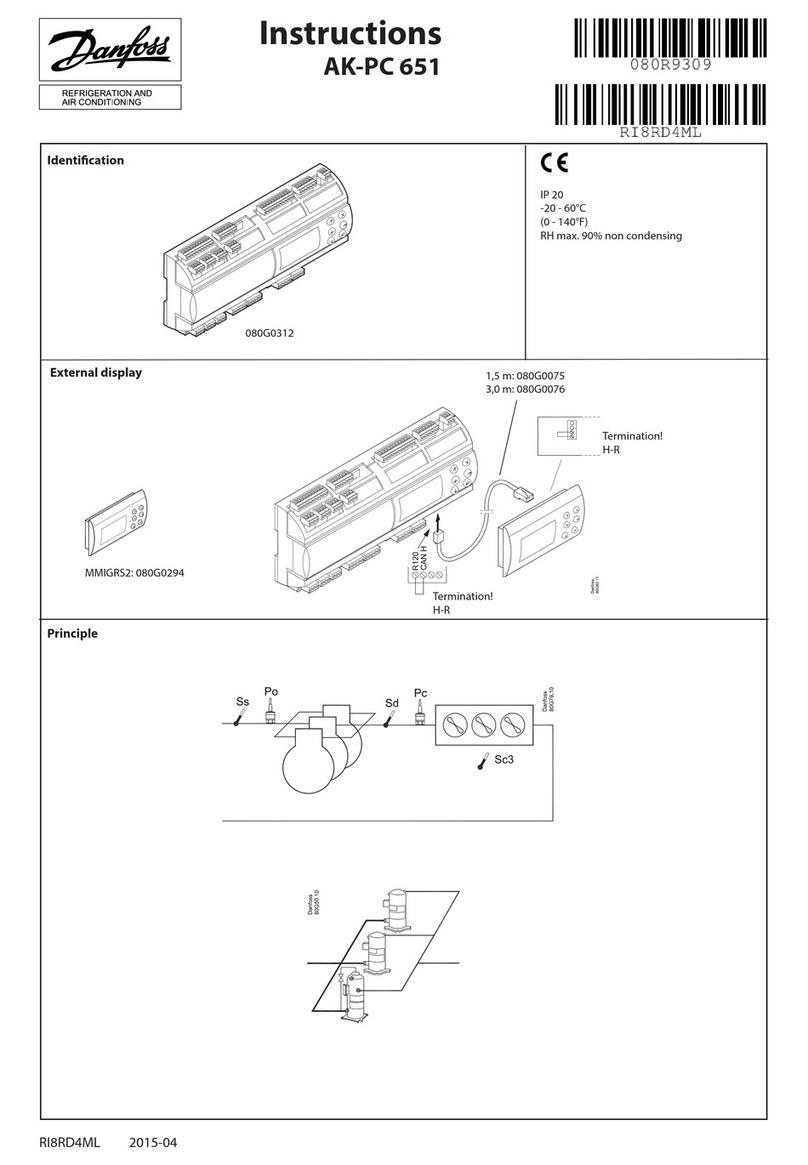

Manual override ❹

(for service purposes only)

Do not use the manual override if

power is connected!

- Remove cover ①

- Press and hold the button (on the bottom

side of the actuator) ②during manual

override ③

- Replace cover ④

- Install actuator on valve ⑤

Remark:

A ‘click’ sound after energizing the actuator

indicates that the gear wheel has jumped into

normal position.

Don’t dismount the actuator from

the valve when it is in a stem down

position!

If dismounted in a stem down position, there is a

high risk that the actuator gets stuck.

ENGLISH