10

STOP

The pump must be stopped by powering off the motor.

Centrifugal pumps may be stopped with the adjustment valve either open or

closed; a non-return valve must be installed on the delivery piping, in order to

protect it from water hammer.

After stopping the pump also close any auxiliary shutter devices or other types of

external flushing.

Any cooling must only be interrupted after the pump has reached ambient tem-

perature.

In the event of prolonged stops, completely empty the pump to prevent freezing

issues during the cold season or corrosion due to possible chemical alteration of

the liquid standing in the pump.

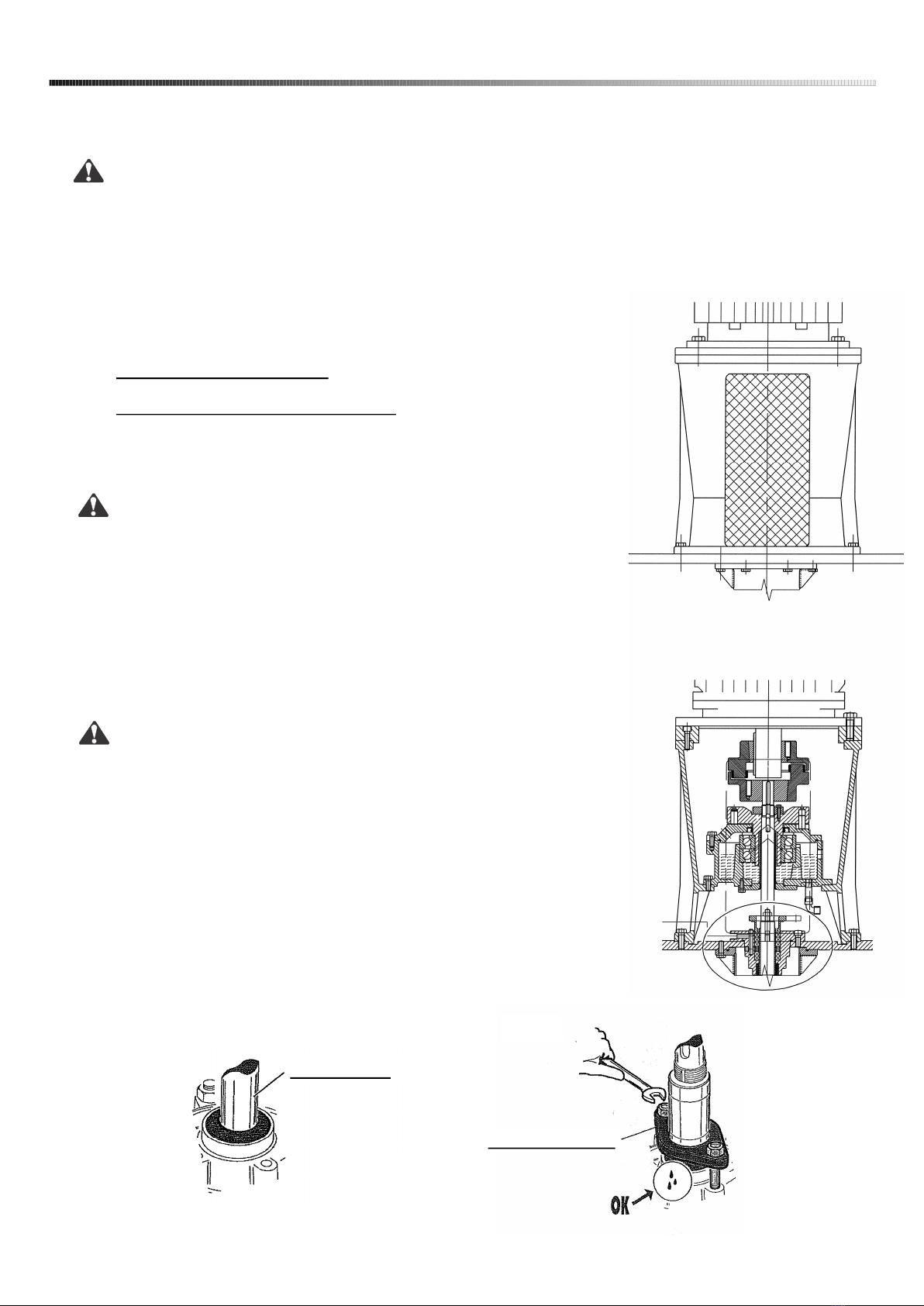

4.2 • REGULATION AND OPERATION CONTROL

Below is a description of the main checks to be carried out after starting up the

pump.

HEAD

The delivered flow rate of the pump is a function of the head developed according

to the pump's operation curve.

After starting up ensure the head developed by the pump matches the rated one.

For the calculation read the values displayed by the pressure gauge on delivery

and vacuum gauge on intake and apply the following formula:

H = differential head (m)

Y = specific weight at pumping temperature (Kg/dm 3)

Pm= delivery pressure

Pa = intake pressure

In the event the pump head is lower than rated, slowly close the delivery regula-

tion valve until reaching the

correct value.

Pressure leaks greater than the design, result in a greater head developed by the

pump than the rated one. In this case, to obtain the correct head value, the plant

must be modified to reduce

the leaks.

VIBRATIONS / NOISE

Operation at rated pump speed must take place without abnormal vibration or

noise. Should there be any, immediately stop the pump, seek the cause and elim-

inate it.

10,2 (Pm - Pa)

H = ————————-

Y

4. OPERATION AND USE

STOP

The pump must be stopped by powering off the motor.

Centrifugal pumps may be stopped with the adjustment valve either open or closed; a non

stalled on the delivery piping, in order to protect it from water hammer.

After stopping the pump also close any auxiliary shutter devices or other types of external flushing.

Any cooling must only be interrupted after the pump has reached ambient temperature.

In the event of prolonged stops, completely empty the pump to prevent freezing issues during the cold season or corro-

sion due to possible chemical alteration of the liquid standing in the pump.

STOP

The pump must be stopped by powering off the motor.

Centrifugal pumps may be stopped with the adjustment valve either open or closed; a non

stalled on the delivery piping, in order to protect it from water hammer.

After stopping the pump also close any auxiliary shutter devices or other types of external flushing.

Any cooling must only be interrupted after the pump has reached ambient temperature.

In the event of prolonged stops, completely empty the pump to prevent freezing issues during the cold season or corro-

sion due to possible chemical alteration of the liquid standing in the pump.