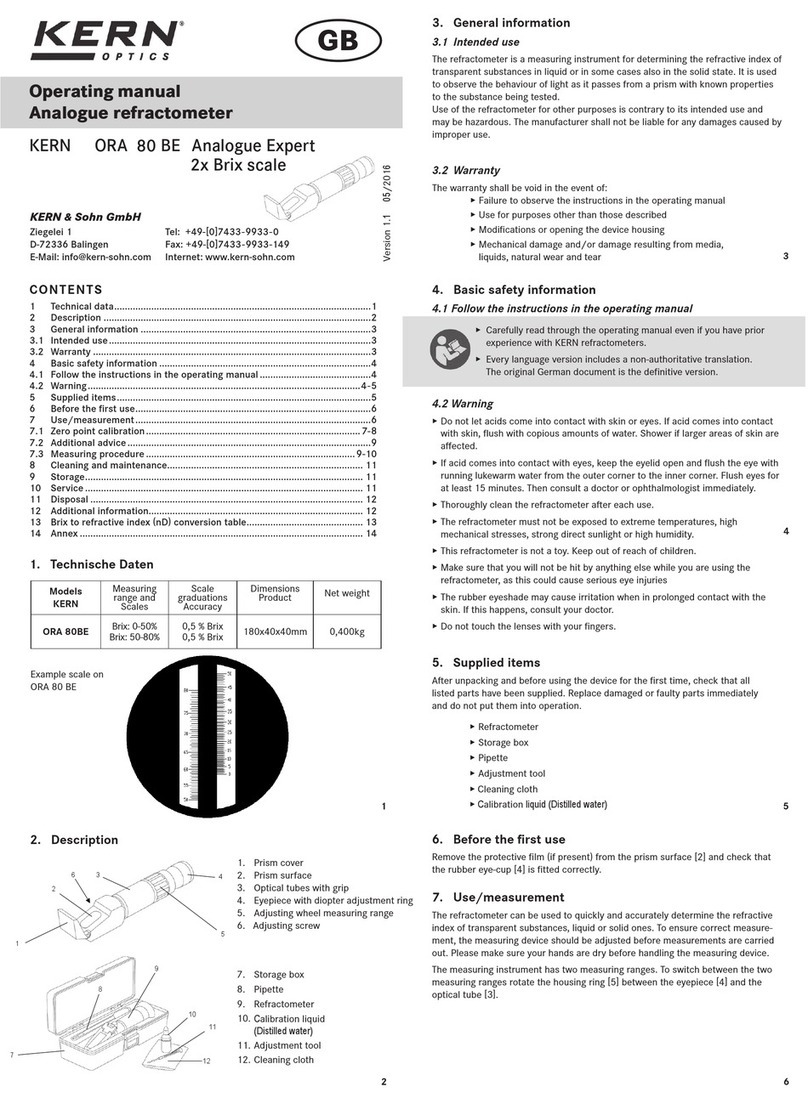

Seahorse XF24 Installation guide

XF24 Training Manual

1

support@seahorsebio.com • +1-978-671-1600 • www.seahorsebio.com Boston • Copenhagen • Shanghai

XF24 Analyzer Consumables

XF Stress Test Kits & Reagents

Part # Description # of

Microplates

103015-100 XF Cell Mito Stress Test Kit 6

103020-100 XF Glycolysis Stress Test Kit 6

102504-100 XF Plasma Membrane Permeabilizer 6

102720-100 XF Palmitate-BSA FAO Substrate 3

XF FluxPaks

Part # Description # of Cartridges

100850-001 XF24 FluxPak 18

100867-100 XF24 FluxPak mini 6

101174-100 XF24 Islet Capture FluxPak 6

XF Microplates

Part # Description # of

Microplates

100777-004 XF24 V7 PS Cell Culture Microplates 10

101122-100 XF24 Islet Capture Microplates 6

XF Media & More

Part # Description Quantity

100840-000 XF Calibrant 500ml bottle

102353-100 XF Base Medium 2 x 1L bottle

101135-100 Capture Screen Insert Tool 1 reusable device

XF24 Port Layout

XF24 Analyzer

Quick Info

D

C

B

A

Instrument Serial #

CONTACT SEAHORSE BIOSCIENCE

Need to order consumables?

Go to: www.seahorsebio.com/order

Need technical support?

Go to: www.seahorsebio.com/techsupport

support@seahorsebio.com • +1-978-671-1600 • www.seahorsebio.com Boston • Copenhagen • Shanghai

XF MICR OP L ATE

Recommended assay volume: 500-1,000 µL per well.

When performing the medium exchange, ensure that the nal volume of XF Assay Medium allows

for injection volumes. The nal volume in the wells during the assay must not exceed 1,000 µL.

XF INJECTION PORTS

Recommended loading volume: 75 µL

(Do not exceed 95 µL due to the risk of contaminating the instrument)

Ensure that all injection ports used in the assay protocol are loaded with an equal volume to prevent

failures. (i.e., if injecting compound through ports “A” and “B”, all “A” and “B” ports must be loaded

with either compound or assay medium).

EXAMPLE VOLUMES FOR AN XF ASSAY

Number of compound injec-

tions in assay 1234

XF Assay Medium in wells after

medium exchange 525-900 µL 525-825 µL 525-750 µL 525-675 µL

Injection Port A 75 µL 75 µL 75 µL 75 µL

Injection Port B 075 µL 75 µL 75 µL

Injection Port C 0 0 75 µL 75 µL

Injection Port D 00075 µL

Total volume per well 600-1,000 µL

XF24 Recommended Assay Volumes

Corporate Headquarters

Seahorse Bioscience Inc.

16 Esquire Road

North Billerica, MA 01862 US

Phone: +1-978-671-1600 •800-671-0633

www.seahorsebio.com

European Headquarters

Seahorse Bioscience Europe

Symbion Science Park

Fruebjergvej 3

2100 Copenhagen

Denmark

Asia-Pacic Headquarters

Seahorse Bioscience Asia

199 Guo Shou Jing Road

Suite 207

Pudong, Shanghai 201203 CN

Cutaway graphic of a single

probe and well

4

Pre-

t

r

aining

How does a Seahorse XF Analyzer work?

Take 15 minutes to watch these six videos and you’ll have a good

foundation

for

understanding

XF Assays.

Introductory videos available at

http://www.seahorsebio.com/learning/videos.php

a. Energy Pathways (2:06 minutes)

b. Transient Microchamber (2:12 minutes)

c. Drug Injection Ports (1:51 minutes)

d. Validation 1 (2:23 minutes)

e. Validation 2 (1:19 minutes)

f. Measure Glycolysis (2:58 minutes)

Download software to your laptop or desktop:

http://www.seahorsebio.com/resources/sitesearch/search.php?q=software

5

Basic Procedure

XF Assay Roadmap

After Your

Assay

Data

interpretation

After Your

Assay

Next

experiments

Planning Your Assay

•

Obtain materials

•

Reconstitute

kits

•

Review media

requirements

Day Prior to Assay

•

Hydrate

cartridge

•

Seed cells

Day of Assay

Prepare

and

run

assay

•

Prepare assay

medium

•

Wash cells

•

Prepare assay

compounds

•

Load cartridge

with compounds

•

Design/load

instrument

protocol

•

Run assay

Basic Procedure

6

Contact Seahorse Technical Support: www.seahorsebio.com/techsupport

Sample XF Assay Workflow Diagram

Seed cells and

incubate overnight

in growth medium Hydrate sensor

cartridge overnight

Day Before XF

Assay

Day of XF

Assay

Change medium

t

o

bi

car

bona

te

-f

ree

low-buff

ered

assay

me

diu

m

Add compounds

to reagent ports

XF

Ass

a

y

Calibrate

sensors

Basic Procedure

7

XF24 Analyzer Materials List

Materials required or recommended for a successful XF24 assay.

Required

The following are the materials required to run an XF24 assay.

•

XF24 Analyzer with Controller

•

Non-CO2 Incubator (37°C) or XF Prep Station

•

XF24 FluxPak (Part # 100850-001 ) or XF24 FluxPak mini (Part # 100867-100)

•

pH Meter

•

Inverted Phase Contrast Microscope

•

Pipette

•

P20 and P1000 Pipette tips

•

Low-buffered non-bicarbonated Medium for Assay

(e.g. DMEM, KHB, RPMI without bicarbonate)

Recommended

The following are materials recommended to help you achieve optimal results. These include ensuring

optimal instrument functioning, compound reconstitution, and assay experience.

•

Uninterrupted power source

•

Internet access

•

Balance

•

Stir plate

•

Cell counter/Hemacytometer

•

Water bath set at 37°C

•

Micro centrifuge

•

Touch vortex

•

Centrifuge with adaptors for cell culture plates

•

Pipetting Reservoirs

•

15 and 50 mL conical tubes

•

Sterile filter bottles (0.22 uM filter) and cap

Basic Procedure

8

Available Kits and Reagents

The following are materials offered by Seahorse Bioscience to assist you in designing assays to examine

cellular metabolism. Each kit and reagent is designed to address your specific experimental question. If

you have any questions about which kits and reagents may be appropriate for your experiments, please

visit our website http://www.seahorsebio.com/ or contact Technical

Support http://www.seahorsebio.com/support/tech-support.php.

•

XF Prep Station (Part # 100900-100)

•

XF Medium (requires storage at 4°C)

o XF Base Medium (Part # 102353-100)

o XF Assay medium (Part # 102365-100)

•

XF Stress Test Kits

o XF Cell Mito Stress Test Kit (Part # 103015-100)

o XF Glycolysis Stress Test Kit (Part # 103020-100)

•

XF Reagents and Substrates

o XF Plasma Membrane Permeabilizer (Part # 102504-100)

o XF Palmitate-BSA FAO Substrate (Part # 102720-100)

Basic Procedure

11

Seeding cells in an XFe24 or XF24 Cell Culture

Microplate

XF assays are performed in Seahorse 24-well XF Cell Culture

Microplates in conjunction with an XF24 sensor cartridge. Each

microplate is formatted in a typical 24-well design, as shown. The

seeding surface of each well is similar to that of a typical 96-well

(0.275 cm2). This procedure describes recommendations for

seeding adherent cell types for use with the XF24 Analyzer.

A two-step seeding process is recommended when seeding XF24 cell culture microplates.

The two-step process produces a consistent and even monolayer of cells.

1. Harvest and re-suspend the cells to desired final concentration to seed in 100 μL of growth

medium. Optimal cell seeding numbers vary widely, though are typically between 10,000 –

80,000 cells per well and must be determined empirically (see Optimization Protocols).

2. Seed 100 μL of cell suspension per well (as shown in figure below); do not seed cells in

background correction wells (A1, B4, C3, D6). Be sure to put medium only (no cells) in the

background correction wells. Allow plate to rest at room temperature in the tissue culture

hood for one hour. This will promote even cell distribution and reduce edge effects.

3. Place plate in a standard cell culture incubator to allow cells to adhere. This generally takes

approximately 1 hour for strongly adherent cells, but may take 5-6 hours for less adherent cell

types. Monitor adherence using a microscope.

4. After cells have adhered, add 150 μl of growth medium to each well (see figure below),

bringing the total volume of medium in the well to 250 μl. When adding medium to the wells,

add it slowly to the sides as not to disturb the newly attached cells.

5. Allow the cells to grow overnight in a cell culture incubator. Monitor growth and health of

cells using a microscope.

Hint: Hold the pipette tip at an

angle and rest the tip just

below the circular rim at the

top of the well for best

technique and most

homogeneous

cell layer.

Basic Procedure

12

Preparation of Assay Media for Use in XF Assays

This basic procedure details the preparation of assay media for use with

(1) XF Cell Mito Stress Test Kit, and (2) XF Glycolysis Stress Test Kit

Seahorse recommends the use non-buffered assay medium for XF assays to ensure accurate, functional

measurements of metabolic phenotypes in an ambient environment. The optimal assay media for the

XF Cell Mito Stress Test and the XF Glycolysis Stress Test are different. Both can be prepared starting

with the XF Base Medium and adding different substrates as determined by your cell model. Substrate

requirements are cell type specific and may need to be determined empirically. For the XF Cell Mito

Stress Test, assay medium with user-added glucose, sodium pyruvate and glutamine is recommended

(see 1). For the XF Glycolysis Stress Test, assay medium with user-added glutamine is recommended

(see 2).

1. XF Cell Mito Stress Test Assay Medium

For one tissue culture plate: if rinsing manually, 100 mL of assay medium is sufficient; if rinsing using

the XF Prep Station 200 mL of assay medium is sufficient.

Materials

Source

Cat #

XF Base Medium

Seahorse Bioscience

102353-100

Glucose

Sigma

G7528

Sodium Pyruvate (powder)

Sigma

P5280

Sodium Pyruvate (liquid, 100 mM)

Sigma

S8636

L-Glutamine

(200 mM)

Life Technologies

25030-081

0.2 µM Sterile Filter

pH Meter

1 N NaOH

Method

1. Warm 100 mL XF Base Medium to 37°C.

2. Add glucose for the desired final concentration using the following table.

Basic Procedure

13

Final glucose concentration

Grams of glucose per 100 mL

2.5

mM

0.045

g

5.5

mM

0.10

g

10

mM

0.18

g

25

mM

0.45

g

3. Add the desired amount of sodium pyruvate using powder or liquid using one of the following

tables.

Addition of sodium pyruvate from powder:

Final pyruvate concentration

Grams of pyruvate per 100 mL

0.5

mM

0.0055

g

1.0

mM

0.011

g

2.0

mM

0.022

g

5.0

mM

0.055

g

10.0

mM

0.110

g

Addition of sodium pyruvate from 100 mM liquid:

Final pyruvate concentration

mL of pyruvate solution per 100 mL

0.5

mM

0.5

mL

1.0

mM

1

mL

2.0

mM

2

mL

4. Add the desired amount of L-glutamine using the following table.

Addition of L-glutamine from 200 mM liquid:

Final glutamine concentration

mL of glutamine solution per 100 mL

1

mM

0.5

mL

2

mM

1

mL

4

mM

2

mL

5. Adjust pH to 7.4 using 1 N NaOH. Note: medium will respond quickly to NaOH, use small volumes

and add slowly to adjust pH.

6. Filter Sterilize with a 0.2 µM filter.

7. Keep the XF Cell Mito Stress Test Assay Medium at 37°C until ready to use.

Basic Procedure

14

2. XF Glycolysis Stress Test Assay Medium

For one tissue culture plate: if rinsing manually, 100 mL of assay medium is sufficient; if rinsing using

the XF Prep Station 200 mL of assay medium is sufficient.

Materials

Source

Cat #

XF Base Medium

Seahorse Bioscience

102353-100

L-Glutamine

(200 mM)

Life Technologies

25030-081

0.2 µM Sterile Filter

pH Meter

1N NaOH

Method

1. Warm 100 mL of XF Base Medium to 37°C.

2. Add the desired amount of L-glutamine according to table below.

Final glutamine concentration

mL of L-glutamine solution per 100 mL

1

mM

0.5

mL

2

mM

1

mL

4

mM

2

mL

6. Adjust the pH to 7.35 ± 0.05 using 1 N NaOH. Note: medium will respond quickly to NaOH, use

small volumes and add slowly to adjust pH.

8. Filter sterilize with a 0.2 µM filter.

9. Keep the XF Glycolysis Stress Test Assay Medium at 37°C until ready to use.

Basic Procedure

15

Washing Cells in XF24 Cell Culture

Microplates

This basic procedure describes replacing the growth medium with assay medium for adherent cells

grown in XF24 cell culture microplates prior to being assayed using an XF24 Analyzer.

1. Warm the pre-made Assay Medium to 37oC.

(See basic procedure - Assay Media Preparation).

2. Retrieve your cell plate from the CO2 incubator.

3. Look at cells under the microscope to:

a. Confirm cell health, morphology, seeding uniformity and purity (no contamination).

b. Ensure cells are adhered, and no gaps are present.

c. Make sure no cells were plated in the background correction wells.

4. Wash cells with Assay Medium

a. Remove all but 50 µL of the culture medium from each well.

b. Rinse cells two times with 1 mL of assay medium.

c. Add the desire final volume, for example, 450 µL of assay medium to each well for a final

volume of 500 μL/well

5. Look at cells under the microscope to ensure that cells were not washed away.

6. Place the plate in a 37°C incubator without CO2 for one hour prior to the assay.

Basic Procedure

20

Loading the XF24 Sensor Cartridge with Compounds

The XF24 Sensor Cartridge Loading Guide will help ensure consistent and accurate cartridge loading for assays on

the XF24

Extracellular

Flux Analyzer. This procedure is intended for use following cartridge hydration.

Recommended

injection volume is 75 µL. See

Recommended

Volumes for XF24 and XFe24 Assays.

Requirements for Proper Compound Loading:

1. Each series of ports must contain the same volume (For example, all A ports must be filled with the same

volume; all B ports must be filled with the same volume, etc.).

2. All wells, including Background Correction or blank wells, need to have vehicle or compound loaded in the

port being used to ensure proper injection in all wells.

3. All

compounds

should be diluted with the

appropriate

aqueous vehicle (such as XF Base Medium) before

being loaded into the sensor cartridge. Refer to Compound Preparation guide.

4. The hydrated XF sensor cartridge must remain in the utility plate and be placed flat on the work surface

throughout the loading procedure. Do not lift or angle the

plate/cartridge

away from the work surface

while loading.

5. Handle the XF24 cartridge very carefully. Hold the base of the utility plate when

transporting

a

cartridge. Do not hold the cartridge and utility plate between your thumb and fingers. Avoid

traveling

with the cartridge. To mitigate the accidental discharge of compounds prior to starting the

assay, the best practice is to hydrate the cartridge and load the injection ports adjacent to the XF24

Analyzer.

Loading the Sensor Cartridge with Compounds:

Step 1 –Pre-warm injection compounds to 37oC.

NOTE: It is strongly recommended that injected

compounds

be at pH 7.35-7.4 at 37°C

prior to loading into the injection ports.

Step 2 –Orient the XF Assay Cartridge:

When preparing for compound injections, you must

identify the injection ports. The XF24 Sensor Cartridge

has four injection ports, labeled D, C, B, and A as shown

in the image to the left. Orient the XF24 Sensor Cartridge

with the bar code on the right. The triangular notch will

be on the bottom left corner.

Triangular notch Bar Code

Basic Procedure

21

Step 3 –Load the XF24 Cartridge

Using a p200 or a multichannel pipette, load 75 µL of injection compound into the

desired injection ports according to your plate

map/groupings

using the following

technique:

1. Hold the tips at a 45° angle

2. Place the tips halfway into the injection ports with the bevel of the tip against the

opposite wall of the injection port

a. Do NOT insert the tips completely to the bottom of the injection ports as

this

may cause compound leakage through the port.

3. Gently and completely load the

compounds

into the ports via a single stream

a. NOTE: It is important to avoid air bubbles

b. NOTE: Do NOT tap any portion of the cartridge in an attempt to alleviate

air

bubbles. This may cause compound leakage through the injection

port.

Step 4 –Inspect Injection Port

Inspect complete loading of each injection port by bringing the cartridge to eye-level

while maintaining the base of the cartridge on a flat surface. The liquid should be all

the way down at the bottom of the injection ports. Record the position of any ports

which appear uneven for later data analysis.

Recommended

Pipettes and Tips:

1. Biohit Proline Plus (10-100 µL) OR BioPette Plus (20-200 µL) with:

a. Biohit Optifit Tip (catalog # 790351) or

b. VWR Ultrafine Flextop Tips (Catalog # 37001-532 (USA); 7320504 (EU)) or

c. Rainin 250 µL Tips (Catalog # RT-205)

2. Viaflo 300 µL (Dispense volume set to 75 µL, Dispense rate set to 8) with:

a. Integra 300 µL Tips (catalog # 4433)

Operation of the Prep Station for Medium Exchange

The Prep Station can be used to change the cultured medium to an assay medium before an XF

experiment. After the medium exchange, the dispensed and aspiration probes are automatically

washed using the DI water and cleaning fluid bottles from the back of the prep station. The tubing from

the medium bottle must be manually cleaned by the user.

Materials:

Prep Station

70% ethanol (500 mL)

DI water (500 mL)

XF96 or XF24 tissue cultured plate containing adhered cells

150 mL Assay Medium (Make sure medium is warmed to 37oC in water bath)

3 –50 mL conical tubes

Using the Prep Station to do Medium Exchange

1. Check to make sure the water bottle and clean bottle are filled with DI water and 70% ethanol

respectively. If the yellow light in front of the prep station is turned on, it indicates that the

volume is too low. Fill the bottle with the correct solution.

Indicator

Water Bottle

Clean Bottle

2. Check to make sure the waste bottle is not full. If it is full, empty the waste bottle according to

your lab protocol.

3. Remove the empty media bottle and place the bottle containing warmed assay medium into the

media slot. Remove the cap containing the tube from the empty Media bottle and place the cap

containing the tube into the Assay Medium bottle.

*The medium bottle is not sterile. Make sure to remove an aliquot of the assay medium for

drug dilutions.

4. Remove the lid from the tissue culture plate containing the cells.

5. Place the cells vertically (A1 facing the Seahorse logo head).

6. Launch the Seahorse Prep Station software by clicking on the “Seahorse XF Prep Station”icon

7. Select “Seahorse Guest.”

8. Click on the “Media Change” tab

9. Select “Do Prime”and type in the desired final volume in µL, for example 180 µL if using the

XF96 or XFe96 Analzyer or 500 µL if using the XF24 or XFe24 Analyzer.

10. Select “Do Rinse.”

11. Click on “Start”

*Note: The Prep Station will prime the manifold with XF Assay Media and performs two

aspirations and dispenses cycles. There will be a pause in the operation, then the prep

station will perform a third aspiration and dispense cycle. Do not remove the cell plate until

all 3 cycles are complete!

12. After the medium exchange, remove the plate from the medium exchange station and put the

lid back on top of the tissue cultured plate.

13. Place the tissue cultured plate in a non-CO2 37oC incubator or prep station until ready to use.

Non-CO2 37oC incubator

Cleaning the Prep Station

1. Fill up two 50 mL conical tubes with DI water. Fill up one 50 mL conical tube with 70% ethanol.

2. Remove the cap containing the tube from the assay medium bottle and place the tube into one

of the 50 mL conical tube containing DI water from #1.

3. Click “Prime Manifold”from the tab of the prep station software.

4. Select “Media”

5. Click “Start”

6. After the cycle is finished, transfer the tube to the 50 mL conical tube containing 70% ethanol.

7. Click “Start”

8. After the cycle is finished, transfer the tube to the second 50 mL conical tube containing DI

water.

9. Click Start.

10. After the cycle is finished, put the cap containing the tube back into the empty media bottle.

Basic Procedure

Cell Density with the XF Glycolysis Stress Test

The XF Glycolysis Stress Test is run with four different cell densities to determine the optimal cell density

to use in your XF assays. In a typical cell density optimization assay, only three basal measurements

need to be taken to determine the optimal cell seeding density. However, for the purposes of providing

richer data for discussion, we will run the XF Glycolysis Stress Test and inject (A) Glucose, (B) Oligomycin

and (C) 2-Deoxy-D-glucose (2-DG). In this experiment, we will use 1.0 µM oligomycin, although the

optimal concentration may be different (as is investigated in the next experiment).

Plate Layout:

Injections:

Port A: Glucose - 10 mM final concentration in the well

(80 mM stock)

Port B: Oligomycin - 1.0 µM final concentration in the well

(9 µM stock)

Port C: 2-DG –100 mM final concentration in the well

(1 M stock)

Cell #

10 K

20 K

40 K

80 K

22

Contact Seahorse Technical Support: www.seahorsebio.com/techsupport

Protocol:

1. Prepare XF Glycolysis Stress Test Assay Medium (warmed to 37°C).

2. Thaw 1 set of vials from XF Glycolysis Stress Test Kit

(glucose, oligomycin and 2-DG).

3. Retrieve your cell plate from the CO2 incubator. Note the time.

4. Look at cells under the microscope to:

a. Confirm cell health, morphology, seeding uniformity and purity (no contamination).

b. Ensure cells are adhered, and no gaps are present.

c. Make sure no cells were plated in the background correction wells.

5. Wash cells with XF Glycolysis Stress Test Assay Medium

a. Remove all but 50 µL of the culture medium from each well.

b. Rinse cells two times with 1 mL of assay medium.

c. Add assay medium to each well for a final volume of 500 μL/well.

6. Look at cells under the microscope to ensure that cells were not washed away.

7. Place the plate in a 37°C incubator without CO2 for one hour prior to the assay.

8. Prepare the stock compounds from the XF Glycolysis Stress Test (For more details, refer to the

XF Glycolysis Stress Test User Guide)

a. Important: Use

compounds

the same day they are

reconstituted.

Do not refreeze. Discard any

remaining compound.

b. The XF Glycolysis Stress Test Kit includes 6 foil pouches each containing oligomycin, 6 vials

containing glucose and 6 vials containing 2-DG. The kit reagents are sufficient for 6 complete XF

Glycolysis Stress Test assays in a 96 or 24-well XF Cell Culture Microplate.

c. Remove one foil pouch containing oligomycin and 1 vial containing glucose and 1 vial containing

2-DG from the kit box.

d. Allow

compounds

to warm to room temp in the sealed pouch/vials for

approximately

15

minutes.

e. Re-suspend each component with prepared assay medium in volumes described in Table 3 with a

p1000 pipette. Gently pipette up and down (~10 times) to solubilize the

compounds.

Vortex the

2-DG for at least 1 minute to ensure that it goes into solution.

Volume of Assay Medium

Final Concentration

Glucose

3000

µL

100

mM

Oligomycin

720

µL

100

µM

2-DG

3000

µL

500

mM

Other Seahorse Measuring Instrument manuals