9Avoid unintentional starting and ensure the lock-on button is disengaged before use.

9Use suitable detectors to determine if utility lines are hidden in the work area or contact local utility companies for assistance.

Contactwithelectriclinescanleadtoreandelectricshock.Damagingagaslinecanleadtoexplosion.Penetratingawaterline

causes property damage and may cause electric shock.

9Hold the tool only by the insulated gripping surfaces when performing an operation where the cutting tool may contact hidden wiring

or its own cord. Contact with a “live” wire will also make the exposed metal parts of the power tool “live” and shock the operator.

9 Whenworkingwithmachine,alwaysholditrmlywithbothhandsandprovideforasecurestance.Thepowertoolisguidedmore

securely with both hands.

9 Alwayswaituntilthemachinehascometoacompletestopbeforeplacingitdown.Thetoolinsertcanjamandleadtolossof

control of the power tool.

9Take protective measures when dust can develop during working that is harmful to one’s health, combustible or explosive.

9 Alwaysusetheauxiliaryhandlesuppliedwiththemachine.Lossofcontrolcancausepersonalinjury.

8DO NOT work materials containing asbestos. Asbestos is considered carcinogenic.

8DO NOT force the drill to achieve a task it was not designed to perform.

8DO NOToperatedrillwherethereareammableliquidsorgasses.

8DO NOT get the drill wet or use in damp or wet locations.

8DO NOToperatethedrillifanypartsaremissingorthedrillisdamagedasthismaycausefailureand/orpossiblepersonalinjury.

8DO NOToperatethedrillwhenyouaretired,undertheinuenceofalcohol,drugsorintoxicatingmedication.

8DO NOTcarrythedrillwithyourngeronthepowerswitch,orcarrybythepowercord,orleavethedrillrunningwhilstunattended.

8DO NOTover-reachandensuretheoorisnotslipperyandwearnonskidshoes.

8DO NOT hold unsecured work in your hand.

8DO NOT use the machine with a damaged cable. DO NOTtouchthedamagedcable,butturnothepowersupplyatsocket.

8DO NOTusethedrillwithouttheauxiliaryhandletted

9 Whennotinuse,switchdrillo,removeplugfrompowersupply,cleanthedrillandstoreinsafe,dry,childproofarea

1.3. DIAMOND CORE DRILL BIT SAFETY

WARNING! Once a core cutter is within the hole and cutting, it can snag or grab at any moment without warning. This can easily

harm your wrist or arm.

9 Whendrillingthroughoorsmakesuretheareabeneaththeooryouareworkingoniscordonedoandthatco-workersareaware

ofwhatyouaredoing.Thecoreislikelytofallfromtheceilingwhenyouhavenisheddrilling.

9Check both the inside and outside of the core drill for damage, wear or debris before using it.

9Silica dust will be created when drilling concrete wear a mask.

9Diamond core drilling is the slowest method of cutting a hole. Have realistic expectations as to the time required for cutting.

2. INTRODUCTION

Manufactured using high quality components for performance and reliability. Lightweight and compact unit. Fitted with soft start, variable

speed and overload protection. Designed for use in construction and other applications when working with masonry and concrete. Supplied

with adaptor, water cooling kit and side handles. Can be used independently or with optional Model No. DCDST Diamond Core Drill Stand.

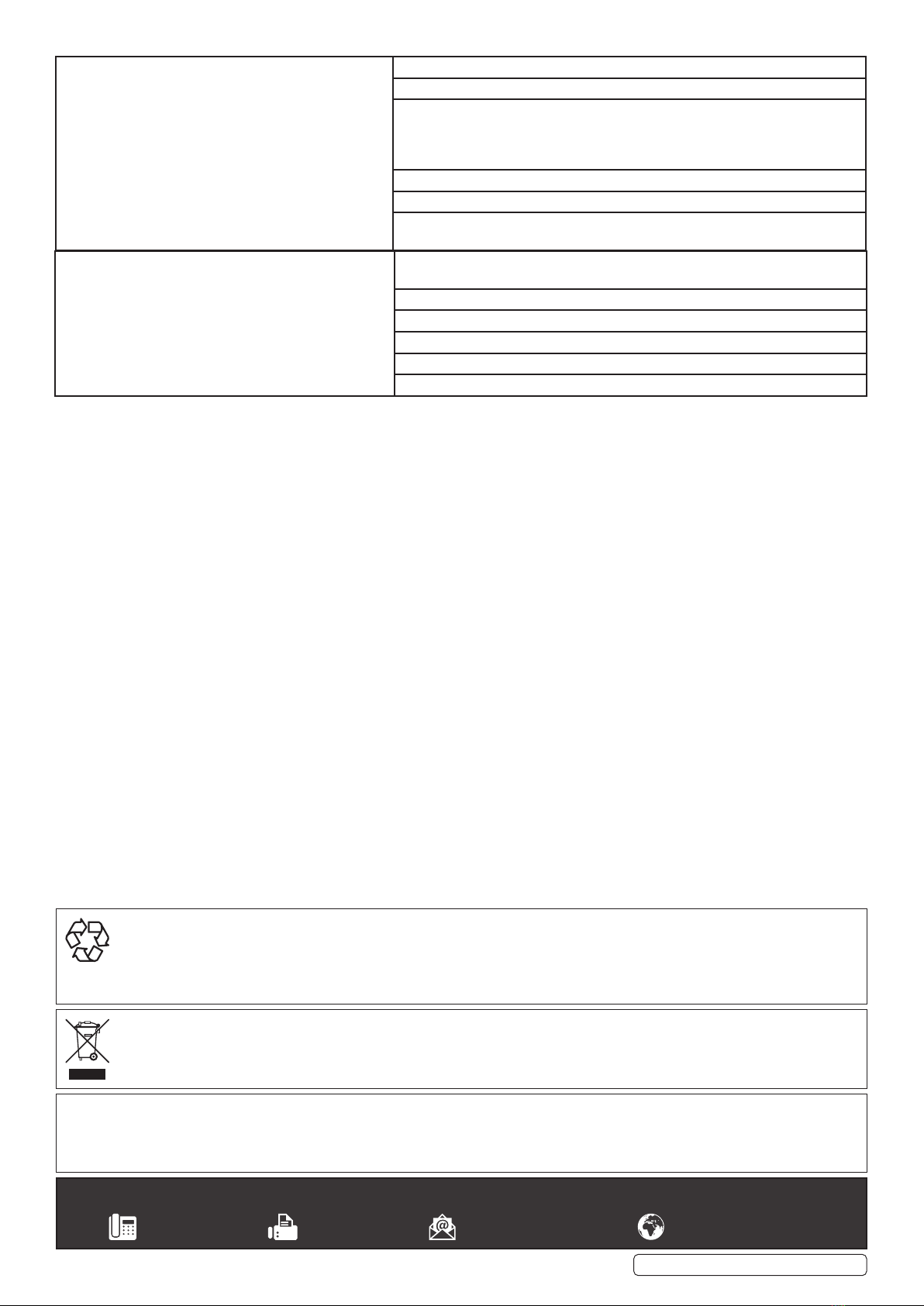

3. SPECIFICATION

Model No:.............................................................. DCD110V

Masonry Drilling Range:..................................... Ø18-160mm

Concrete Drilling Range:.................................... Ø18-130mm

Power Supply:.....................................................110V - 50Hz

Motor Power:...............................................................2300W

No Load Speed: ..................................................0 - 1900rpm

Borehole Depth: ......................................................... 380mm

Maximum Cutter Size:....................................Ø160 x 380mm

Adaptor: ....................................................1-1/4”UNC Thread

Optional Drill Stand: ..................................Model No. DCDST

Cable Length:................................................................. 3.5m

4. OPERATION

WARNING! Make sure there are no cables or pipes hidden in the wall. Never assume that work hasn’t been done by someone else

in the intended drilling area beforehand.

g.1

Original Language Version

© Jack Sealey Limited

Noise power............................................................<85dB(A)

Noise pressure.......................................................... 69dB(A)

Vibration................................................................... <2.5m/s²

Uncertainty................................................................. 1.5m/s²

DCD110V Issue 3 (3) 27/07/2020