INSTRUCTIONS FOR

WOOD MORTISING ATTACHMENT

MODEL NO: MA10.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

9Familiarise yourself with the applications and limitations of the mortising attachment, as well as the potential hazards.

9WARNING! Disconnect the drill from the mains power and ensure the spindle is at a complete standstill before changing accessories.

Maintain the mortising attachment in good condition.

9Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Keep work area clean, uncluttered and ensure adequate lighting.

9Keep tool bits and chisels clean and sharp for best and safest performance.

WARNING! Always wear approved eye or face protection when using the mortising attachment. Use a face or dust mask if dust is

generated.

9Keep hands and body clear of the work table when operating the mortising attachment.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain and/or tie back long hair.

9Keep children and unauthorised persons away from the work area.

9Ensure the work piece is correctly secured before operating the mortising attachment.

9Remove adjusting keys and wrenches from the machine and its vicinity before turning it on.

8DO NOT use the mortising attachment for any purpose other than that for which it is designed.

8DO NOT operate the mortising attachment if any parts are damaged or missing, as this may cause failure and/or personal injury.

8DO NOT switch the mortising attachment on whilst the bit or chisel is in contact with the work piece.

8DO NOT hold the work piece by hand. Use the clamps provided to secure the work piece.

8DO NOT allow untrained persons to operate the mortising attachment.

8DO NOT operate the mortising attachment when you are tired or under the influence of alcohol, drugs or intoxicating medication.

9When not in use store in a safe, dry, childproof area.

2. INTRODUCTION

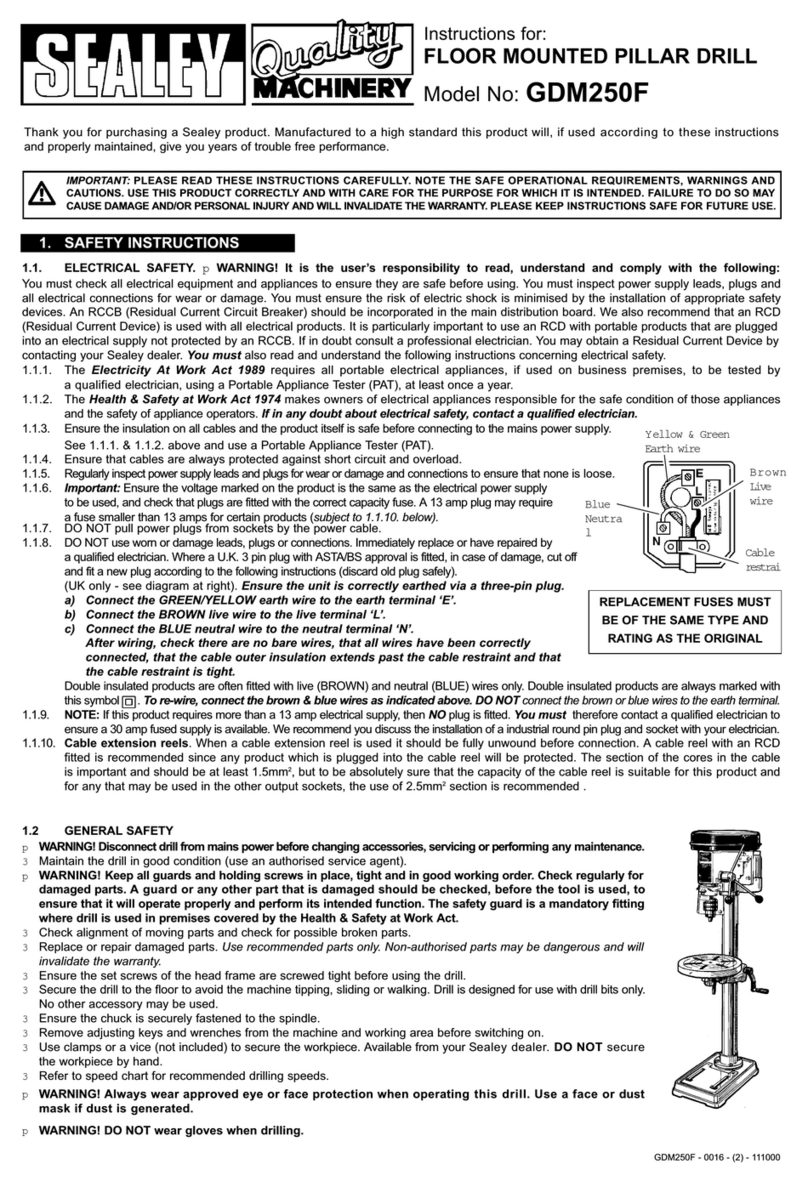

Suitable for use with Sealey and other leading makes of drill. Includes three chisel and bit sets and four mounting rings. Supplied in carry-case.

Mortising attachment is not suitable for Model No’s SDM30, GDM50B, GDM150B, GDM180B, GDM200F, GDM200F/VS, PDM240F, PDM260F.

3. SPECIFICATION

Model No................................................................. MA10.V2

Collar Diameters ..................................... 40, 52,55,60,65mm

Chisel & Bit Sets ..............................................1/4”, 3/8”, 1/2”

4. ASSEMBLY & OPERATION

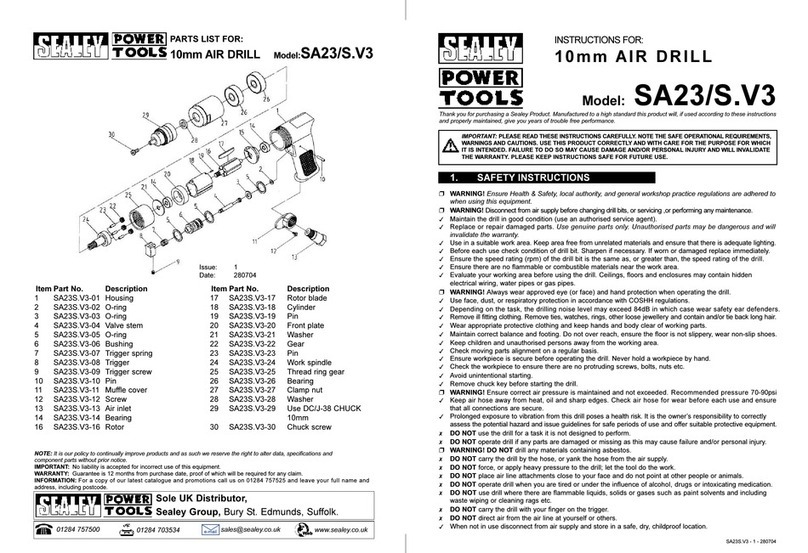

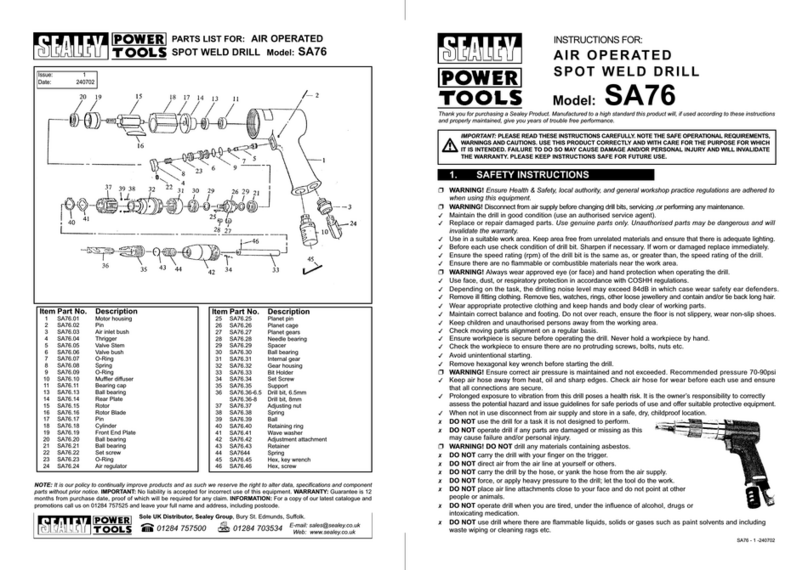

Numbers in brackets refer to the item numbers as shown in the parts diagram.

4.1. Loosely fit bolt (2) and nut (3) to chisel holder (1).

4.2. Mount the chisel holder (1) over the base of the drill quill, using one of the three reducers (14) if necessary, and clamp in place by tightening

nut (3). The threaded hole for thumb screw (4a) at base of chisel holder (1), should be facing directly forward.

4.3. Screw thumb screw (4a) into the threaded hole.

4.4. Insert drill bit shaft and the chisel shaft up through the hole at the base of the chisel holder (1) so that drill bit shaft enters chuck.

4.5. With the shoulder on the chisel approximately 1/32” (0.8mm) from the base of the chisel holder (1) lightly clamp the chisel by tightening

the thumb screw (4a).

4.6. Push the drill bit up as far as it will go and tighten chuck jaws. Release thumb screw (4a) and push chisel up so that shoulder contacts

chisel holder (1), tighten thumb screw (4a). This procedure will give the correct relationship between the cutting edges of the bit and the

points of the chisel.

4.7. Place 15/16” washers (7) on bolts (12) and then pass bolts up through drill table and through fence (11) and rod holder (9). Clamp with

15/16” washers (7) and wing nuts (6).

4.8. Slide steel rod (10) into central boss in rod holder (9) and clamp with thumb screw (4b). Slide arm (5) onto rod (10) and clamp with

thumb screw (4c).

MA10.V2 | Issue 3 15/02/18

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear a mask