© Jack sealey limited Original Language Version

model no ...........................................................BG200/99.V3 supplied with

.........................................................2 x stones motor Power

..................................................................600W supply

..................................................................230V, 50Hz Axle diameter

.............................................................. 16mm no load speed

........................................................2850rpm Weight ............................................................................

20kg

unpack the product and check contents should there be any damaged or missing parts

contact your supplier immediately.

Warning!Before assembly check to ensure grinder is unplugged

from mains.

4.1. eyeshield.

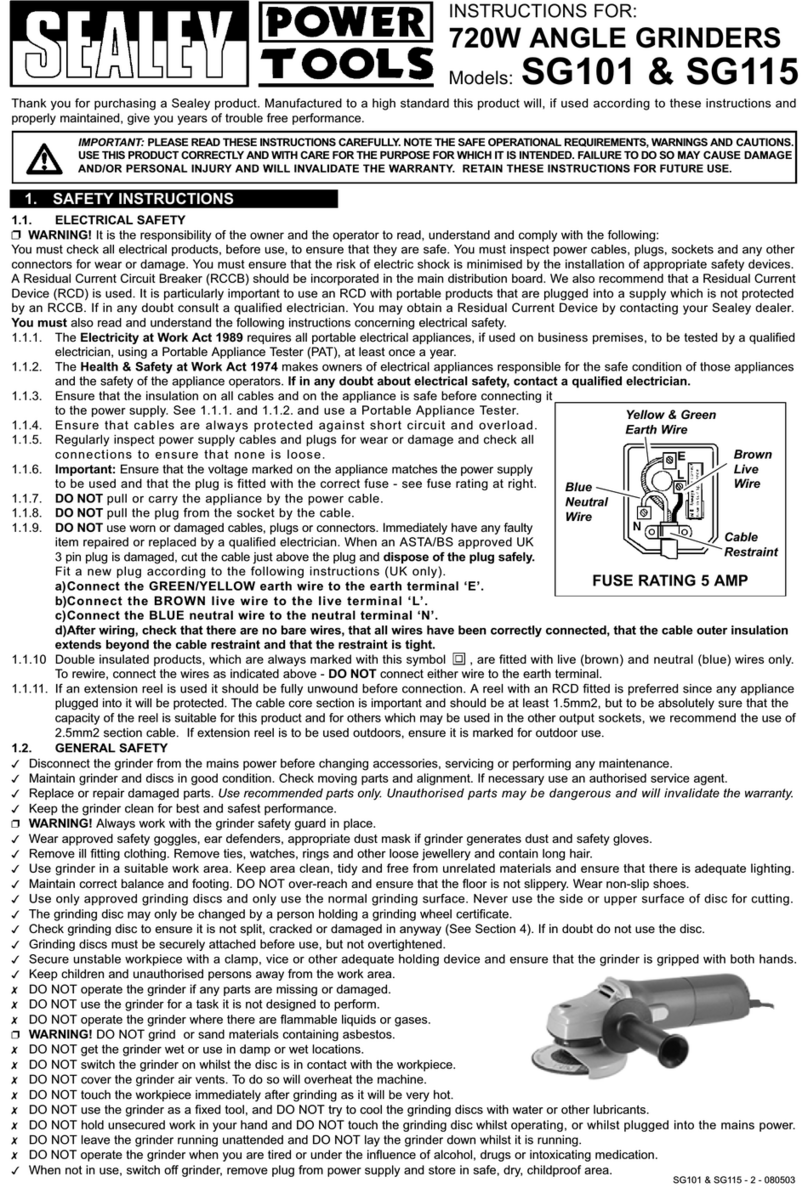

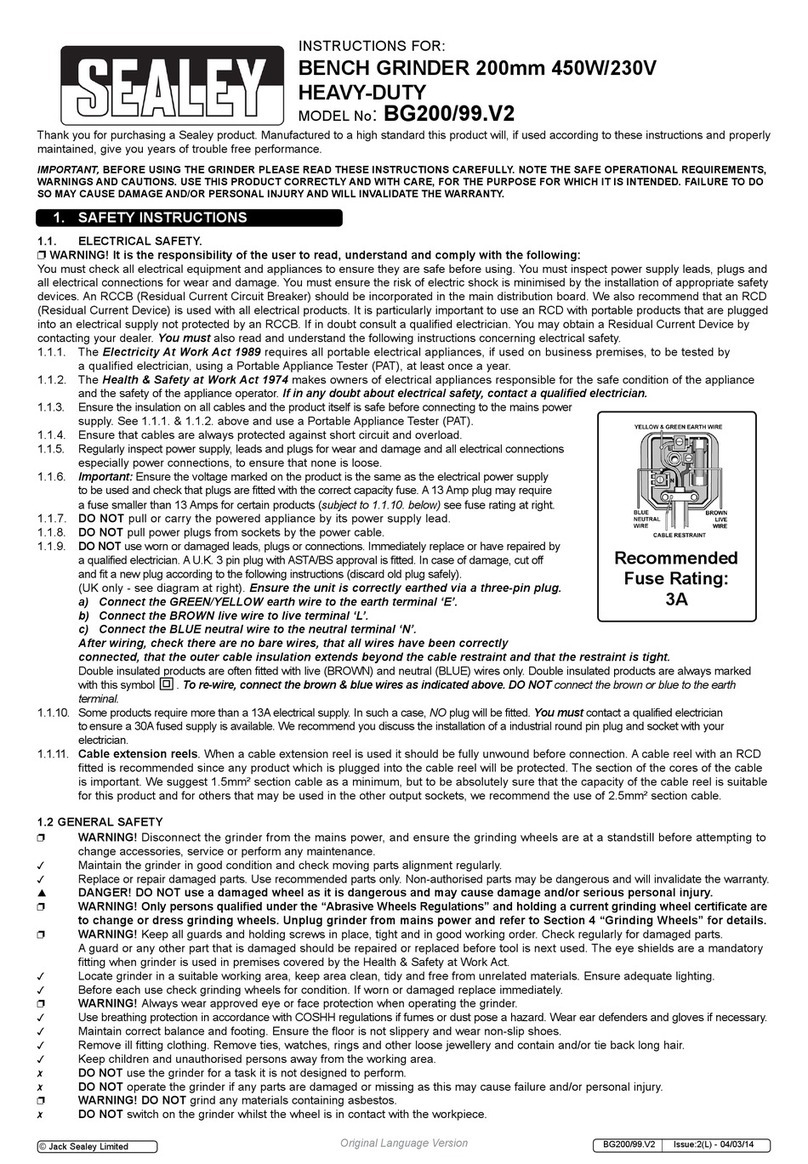

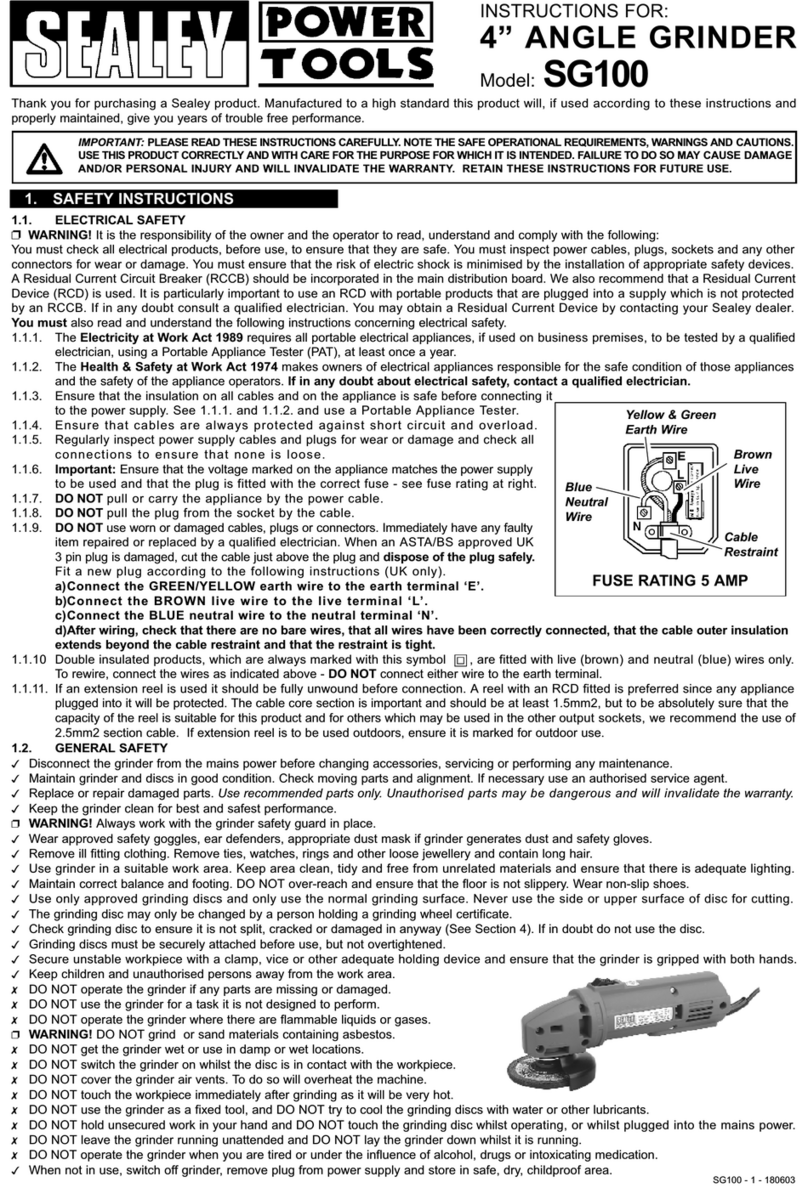

4.1.1. remove retaining screws (fig 1. A) from the eyeshield bracket.

4.1.2. Position the eyeshield bracket on the underside of the stone cover and align holes (fig

2) 4.1.3. fix eyeshield to cover with screws (fig 2.1). if the shield is loose and drops

down, tighten shield screws (fig 3.2)

4.1.4. Loosen screw (fig 3.1.) and adjust the arrestor so it

is 2mm from the stone face (fig 4).

4.1.5. Securely tighten arrestor screw (fig 3.1).

4.2. tool rest.

note: some models may already have the tool rest assembled, but stone clearance must still

be checked.

4.2.1. take tool rest (fig 5) and align it with bolt slot on the inside of the grinding stone cover

(X).

4.2.2. Pass bolt (A) through both slots and place

washers (B) onto bolt.

4.2.3. Position the rest at a maximum of 2mm from the stone surface and secure the

assembly by tightening knob (c).

4.2.4. turn the grinding stones by hand to ensure clearance of above items.

4.3. installation.

4.3.1. securely bolt the grinder to a fireproof workbench using the base holes as a template. check

that all assembly nuts and bolts are secure then read section 5 (grinding stones) before use.

5.1. mandatOry Safety inStructiOnS. (the following instructions must be observed together with

chapter 1 safety).

▲danger! use of a damaged stone is dangerous and may cause damage or personal injury.

Warning! ensure grinder is unplugged from the mains power supply before attempting to

change grinding stones (or wheel).

5.1.1. Only persons qualified under the “Abrasive Wheels Regulations”

and holding a current grinding wheel certificate

are authorised to change and dress grinding stones (wheels).

5.1.2. Grinding stones (wheels) used with machine must be of an adequate speed rating

and suitable for the material to be ground.

5.1.3. ensure the cutting stone’s maximum speed specification is higher than that indicated

on the machine data plate.

5.1.4. check grinding stones are secure, and the stone is not worn or damaged, that there

are no fissures or cracks. if damaged replace immediately.

5.1.5. ensure replacement stone is not damaged in any way such as cracks, deformations

or splinters etc.

5.1.6. Also check the mounting flanges to ensure they are not deformed, burred or chipped. damaged

items must nOt be used as they may cause irregular pressure on the stone which may cause

stone to break. dO nOt over tighten a stone. never tamper with a stone in order to adapt it to a

different size holder. 5.1.7. install a new stone as in 5.2. once mounted on the grinder test the

stone before use by facing the grinder in a safe direction (point away from yourself,

others and vulnerable items) and run for a short time. dress the stone if necessary.

5.2. Stone changing procedure.

Warning! unplug grinder from the mains power supply before changing stone.

5.2.1. raise the eye shield up, and away from the stone.

5.2.2. loosen and pull the tool rest out as far as possible, but, dO nOt remove it (fig 6).

5.2.3. Remove the screws from the side of the wheel cover and remove the

cover (fig 6).

BG200/99.V3 | Issue 1 19/12/16