3.1 Air Supply

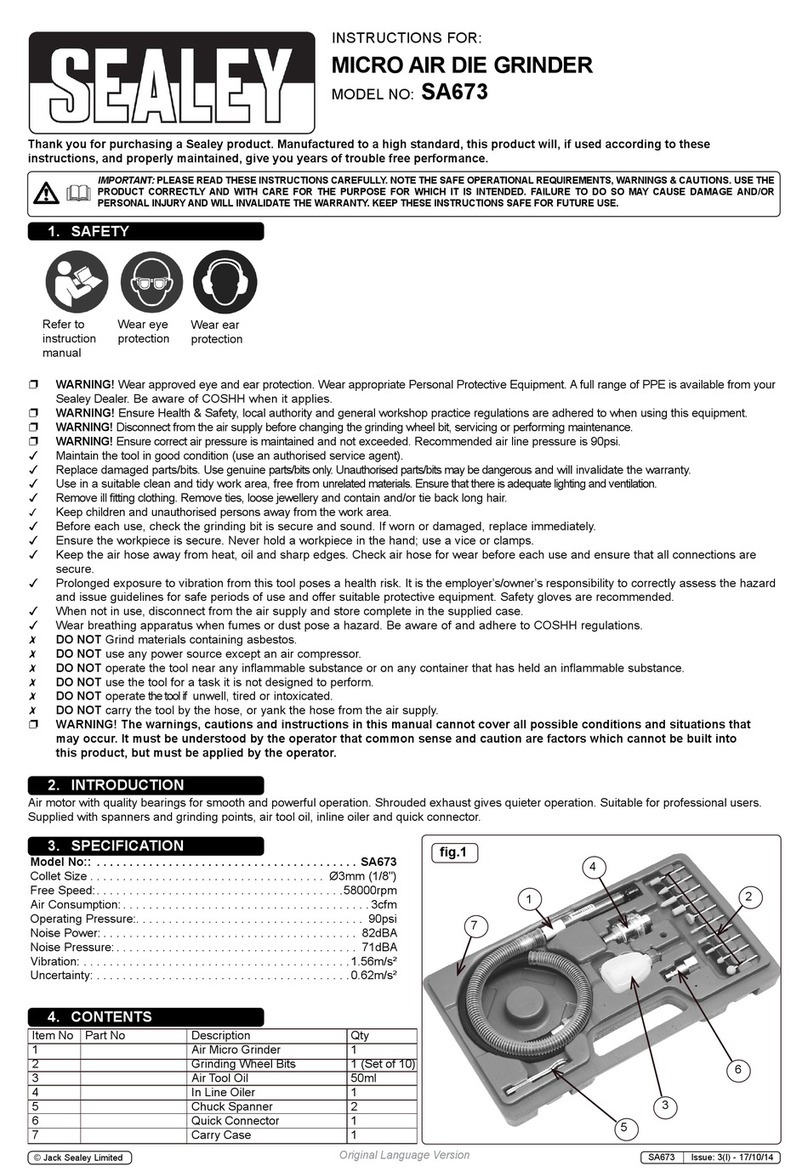

Recommended hook-up procedure is shown in fig 1.

"WARNING! Ensure the air supply is clean and does not exceed 90psi while operating the

die grinder. Too high an air pressure and unclean air will shorten the product life due to

excessive wear, and may be dangerous causing damage and/or personal injury.

3.1.1 Ensure die grinder air valve (or trigger) is in "off" position before connecting to the air

supply.

3.1.2 You will require an air pressure of 90psi, and an air flow according to specification.

3.1.3 Drain the compressor’s air tank daily. Water in the air line will damage the die grinder.

3.1.4 Clean the compressor’s air inlet filter weekly.

3.1.5 Line pressure should be increased to compensate for unusually long air hoses (over 8

metres). The minimum hose diameter should be 1/4” I.D. and fittings must have the same

inside dimensions.

3.1.6 Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain

that all connections are secure.

3.2 Couplings.

Vibration may cause failure if a quick change coupling is connected directly to the die

grinder. To overcome this, connect a leader hose to the grinder. A quick change coupling

may then be used to connect the leader hose to the air line recoil hose. See fig 1 & 2.

"WARNING! Disconnect die grinder from air supply before changing accessories, servicing

or performing maintenance. Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

5.1 If the air supply does not have an oiler lubricate the air die grinder daily with a few drops of

Sealey air die grinder oil dripped into the air inlet to prolong its life.

5.2 Clean the die grinder after use.

5.3 Loss of power or erratic action may be due to the following:

a) Excessive drain on the air line. Moisture or restriction in the air pipe. Incorrect size or

type of hose connectors. To remedy check the air supply and follow instructions in

chapter 3.

b) Grit or gum deposits in the die grinder may also reduce performance. If your model has

an air strainer (located in the area of the air inlet), remove the strainer and clean it.

Flush the die grinder out with gum solvent oil or an equal mixture of SAE No 10 oil and

paraffin. Allow to dry before use.

5.4 For a full service contact your local Sealey service agent.

5.5 When not in use, disconnect from air supply, clean die grinder and store in a safe, dry,

childproof location.

4. OPERATING INSTRUCTIONS

5. MAINTENANCE

6. PARTS LISTS

3. PREPARING TOOL FOR USE

2. INTRODUCTION & SPECIFICATIONS

fig 1

fig 2

One-handed straight type die grinder with aluminium body and trigger with safety catch. Chuck

accepts grinding points with Ø6mm shanks. SA67.V3 is supplied with a selection of popular sized

grinding points, two spanners and carry-case. 4.1 OPERATING

"WARNING! Ensure you have read, understood and apply safety instructions.

4.1.1 Connect the die grinder to the air supply.

4.1.2 To start, hold firmly and push the trigger locking lever forward whilst depressing trigger.

4.1.3 The bit must be running at its maximum speed before attempting to grind the workpiece.

4.1.4 Slowly and smoothly bring the grinding stone toward the workpiece (avoid jerky

movements).

Exert adequate pressure on the die grinder to grind according to the type and size of the

material you are working with. Avoid subjecting stone to excessive strain or harsh impacts.

Always hold die grinder firmly and ease grinding stone against workpiece. Maintain a

controlled adequate progression.

4.2 CHANGING GRINDING STONES

"WARNING! Disconnect from the air supply before changing grinding stone.

4.2.1 Check that grinding stones are not damaged in any way such as cracks, deformations

or splinters etc. Damaged stones must not be used.

4.2.2 Use wrenches provided to loosen collet locking collar. Insert grinding bit and re-lock collar.

#DO NOT allow die grinder to free run for an extended period of time as this will shorten its life.

SA67.V3, SA671.V3 - 2 - 100807

MODEL . . . . . . . . . . . . . . . . .SA67.V3

Collect size . . . . . . . . . . . . . . . .Ø6mm

Free speed . . . . . . . . . . . . .22,000rpm

Air consumption . . . . . . . . . . . . . .4cfm

Operating pressure . . . . . . . . . . .90psi

Air inlet size . . . . . . . . . . . . . .1/4”BSP

Weight. . . . . . . . . . . . . . . . . . .0.60kg

Vibration level . . . . . . . . . . . .3.38m/s2

Uncertainty value . . . . . . . . . .1.35m/s2

Airborne noise . . . . . . . . . . .82.8dB(A)

. . . . . . . . . . . . . . . . . . . . . .83.3dB(C)

Ø6mm shanked stones . . . . . . . . . .10

MODEL . . . . . . . . . . . . . . . .SA671.V3

Collect size . . . . . . . . . . . . . . . .Ø6mm

Free speed . . . . . . . . . . . . .22,000rpm

Air consumption . . . . . . . . . . . . . .4cfm

Operating pressure . . . . . . . . . . .90psi

Air inlet size . . . . . . . . . . . . . .1/4”BSP

Weight. . . . . . . . . . . . . . . . . . .0.60kg

Vibration level . . . . . . . . . . . .3.38m/s2

Uncertainty value . . . . . . . . . .1.35m/s2

Airborne noise . . . . . . . . . . .82.8dB(A)

. . . . . . . . . . . . . . . . . . . . . .83.3dB(C)

SA67.V3 GRINDING STONES:

SA67WO1 MOUNTED WHEEL (10mm x 25mm)

SA67WO2 MOUNTED WHEEL (20mm x 20mm)

SA67WO3 MOUNTED WHEEL (25mm x 22mm)

SA67WO4 MOUNTED WHEEL (25mm x 10mm)

SA67WO5 MOUNTED WHEEL (20mm x 26mm)

SA67WO6 MOUNTED WHEEL (20mm x 25mm)

SA67WO7 MOUNTED WHEEL (25mm x 25mm)

SA67WO8 MOUNTED WHEEL (16mm x 26mm)

SA67WO9 MOUNTED WHEEL (25mm x 25mm)

SA67WO10 MOUNTED WHEEL (25mm x 25mm)