Air motor with quality bearings for smooth and powerful operation. Shrouded exhaust gives

quieter operation. Suitable for professional users. Supplied with spanners and grinding points, air

tool oil, in-line oiler and quick connector.

3.1 AIR SUPPLY

Recommended hook-up procedure is shown in fig 1.

WARNING! Ensure the air supply is clean and does not exceed 90psi while operating the

die grinder. Too high an air pressure and unclean air will shorten the product life due to

excessive wear, and may be dangerous causing damage and/or personal injury.

3.1.1 Ensure die grinder switch is in the "off" position before connecting to the air

supply.

3.1.2 You will require an air pressure of 90psi.

3.1.3 Drain the compressors air tank daily. Water in the air line will damage the die grinder.

3.1.4 Clean the compressors air inlet filter weekly.

3.1.5 Line pressure should be increased to compensate for unusually long air hoses (over 8

metres). The minimum hose diameter should be 1/4” I.D. and fittings must have the same

inside dimensions.

3.1.6 Keep hose away from heat, oil and sharp edges. Check hose for wear, and make certain

that all connections are secure.

3.2 COUPLINGS

Vibration may cause failure if a quick change coupling is connected directly to the die

grinder. To overcome this, connect a leader hose to the grinder. A quick change coupling

may then be used to connect the leader hose to the air line recoil hose. See figs 1 & 2.

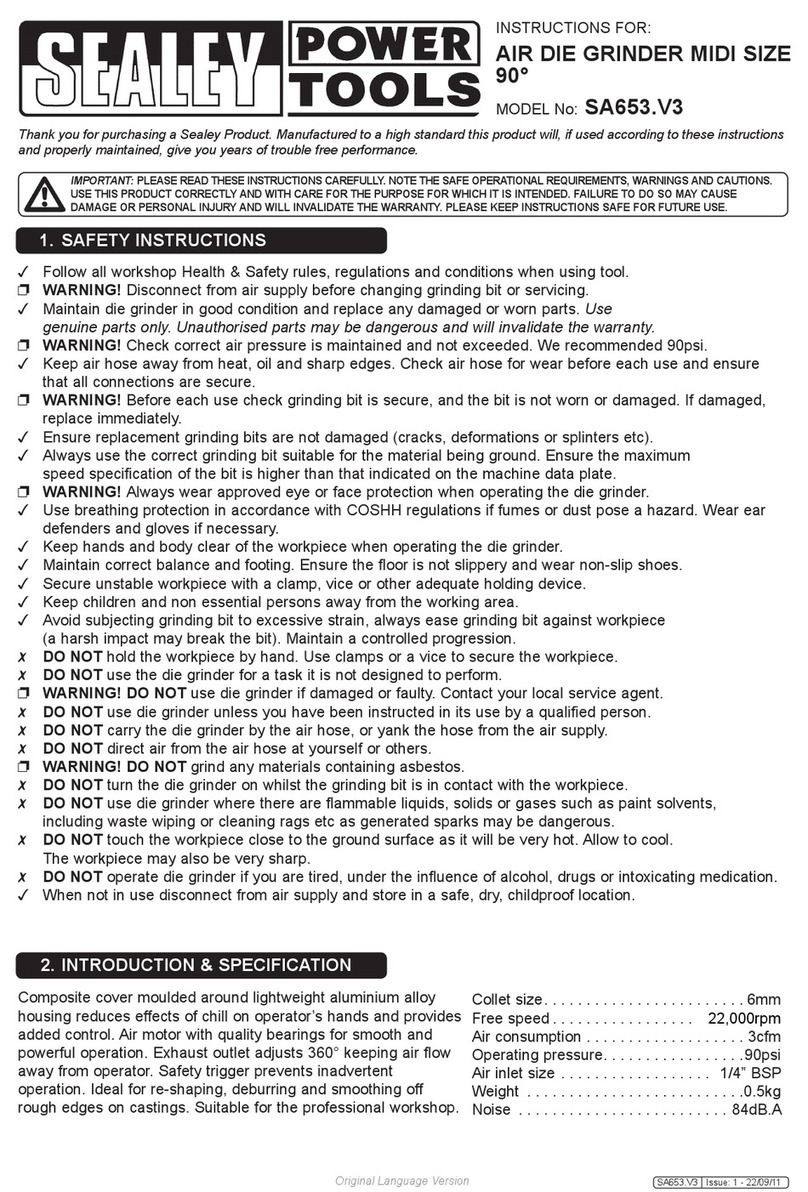

2. INTRODUCTION & SPECIFICATION

3. PREPARING TOOL FOR USE

Contents: ..................Air Micro Grinder

. . . . . . . . . . . . . . . . 10 Grinding Points

. . . . . . . . . . . . . . . . . . . . . . Air Tool Oil

. . . . . . . . . . . . . . . . . . . . . .In-line Oiler

. . . . . . . . . . . . . . . . . Quick Connector

. . . . . . . . . . . . . . . . . . Chuck Spanner

Free Speed: ......................58000rpm

Collet:.........................Ø3mm (1/8”)

Operating Pressure:....................90psi

DANGER OF FIRE/EXPLOSION HAZARD

WARNING! The grinding process can produce streams of sparks which are a potential source of ignition, especially when grinding

metal.

DO NOT use the grinder where there are flammable liquids, solids or gases.

DO NOT allow grinder sparks to make contact with the operator’s clothing or any other fabric such as cleaning rags. Fabrics

contaminated with inflammable materials such as petrol, oil, grease, paint and solvents are a particular fire hazard.

To reduce the risk of clothing catching fire the operator should wear wool or cotton outer garments treated with a fire retardant in

preference to man-made fibres.

Risk of Hand Arm Vibration Injury

Micro Air Die Grinder Model SA673 when operated in accordance with these instructions and tested in

accordance with EN 28662-2: 1994 results in the following vibration emission declared in accordance with

BS EN12096: 1996.

Measured vibration emission value: ...........0.2m/s²

Uncertainty: ..............................0.1m/s²

These values are suitable for comparison with emission levels of other tools that have been subject to

the same test.

This tool may cause hand-arm vibration syndrome if its use is inadequately managed.

Recommended Measures to reduce risk of hand-arm vibration syndrome:

This item represents a low Hand Arm Vibration risk to users. The calculated maximum usage period exceeds 8

hours. We recommend appropriate safety equipment is utilised and regular breaks for the operator are

employed to reduce any residual risk of fatigue or repetitive strain injury.

Original Language Version SA673 Issue: 2 - 12/11/09