4.1. MANDATORY SAFETY INSTRUCTIONS. (The following instructions must be observed together with chapter 1 safety).

DANGER! Use of a damaged stone is dangerous and may cause damage and/or personal injury.

WARNING! Ensure grinder is unplugged from mains power supply before attempting to change grinding stones (or wheel). Only persons

qualified under the “Abrasive Wheels Regulations” and holding a current grinding wheel certificate are authorised to change & dress grinding

stones (wheels).

Grinding stones (wheels) used with machine must be of an adequate speed rating and suitable for the material to be ground.

Ensure the maximum speed specification of the cutting stone is the same as, or higher than, that indicated on the machine data plate.

Check grinding stones are secure and are not worn or damaged, that there are no fissures or cracks. If damaged replace immediately.

Ensure replacement stone is not damaged in any way such as cracks, deformations or splinters etc. Also check the mounting flanges to

ensure they are not deformed, burred or chipped. Damaged items must NOT be used as they may cause irregular pressure on the stone

which may cause stone to break. DO NOT over tighten a stone. Never tamper with a stone in order to adapt it to different size holder.

Install a new stone as in 4.2. Once mounted on the grinder test the stone before use by facing the grinder in a safe direction (point

away from yourself, others and vulnerable items) and run for a short time. Dress the stone if necessary.

4.2. Stone Changing Procedure. WARNING! unplug grinder from the mains power supply before changing stone.

4.2.1. Raise the eye shield up, and away from the stone.

4.2.2. Loosen and pull the tool rest out as far as possible.

4.2.3. Remove the screws from the side of the wheel cover and remove the cover.

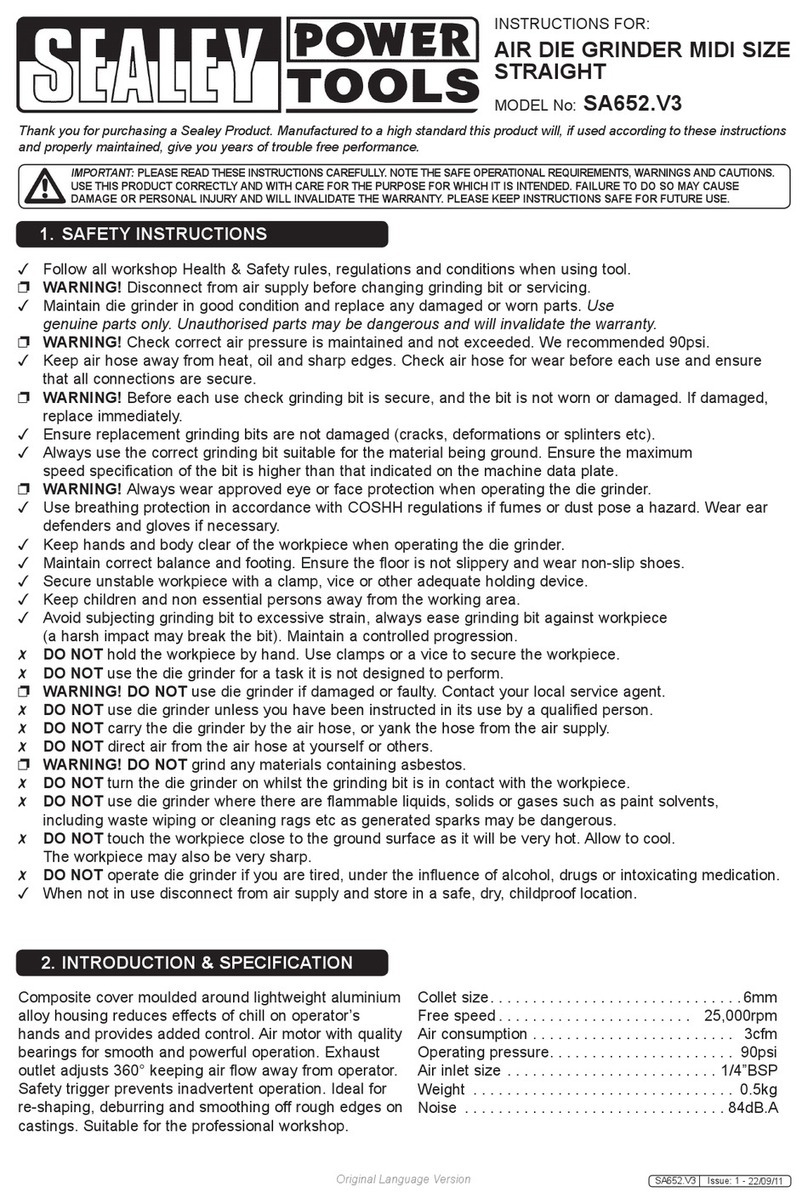

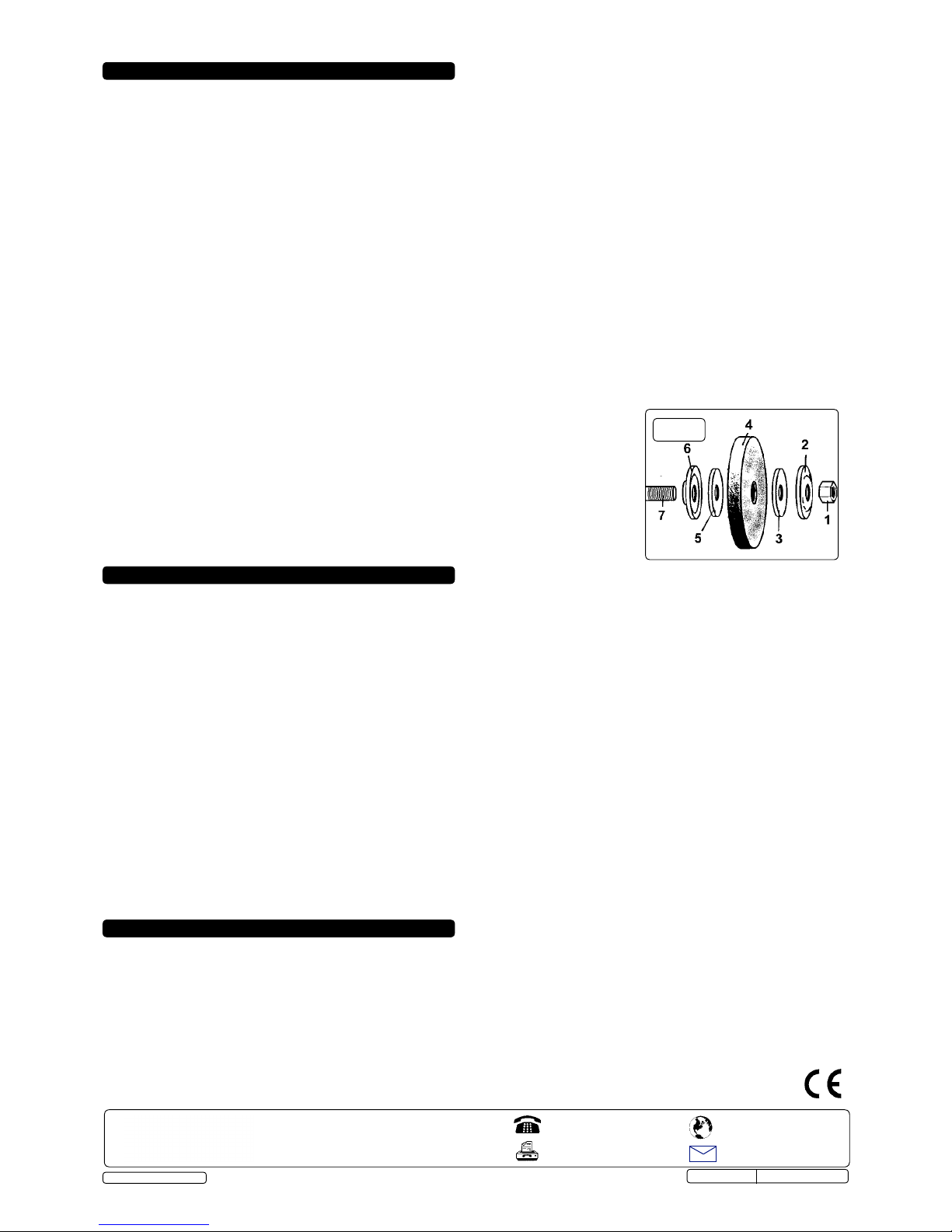

4.2.4. Hold grinding stone firmly. To protect your hands use cloth or wear gloves. Unscrew retaining nut (fig 6.1).

Note: The nut on the right side of the grinder has standard right hand thread (undo anti-clockwise). The left side nut has a left hand

thread and must be loosened by turning clockwise. It may be necessary to strike the wrench sharply in the loosening direction with the

heel of your hand to loosen the nut.

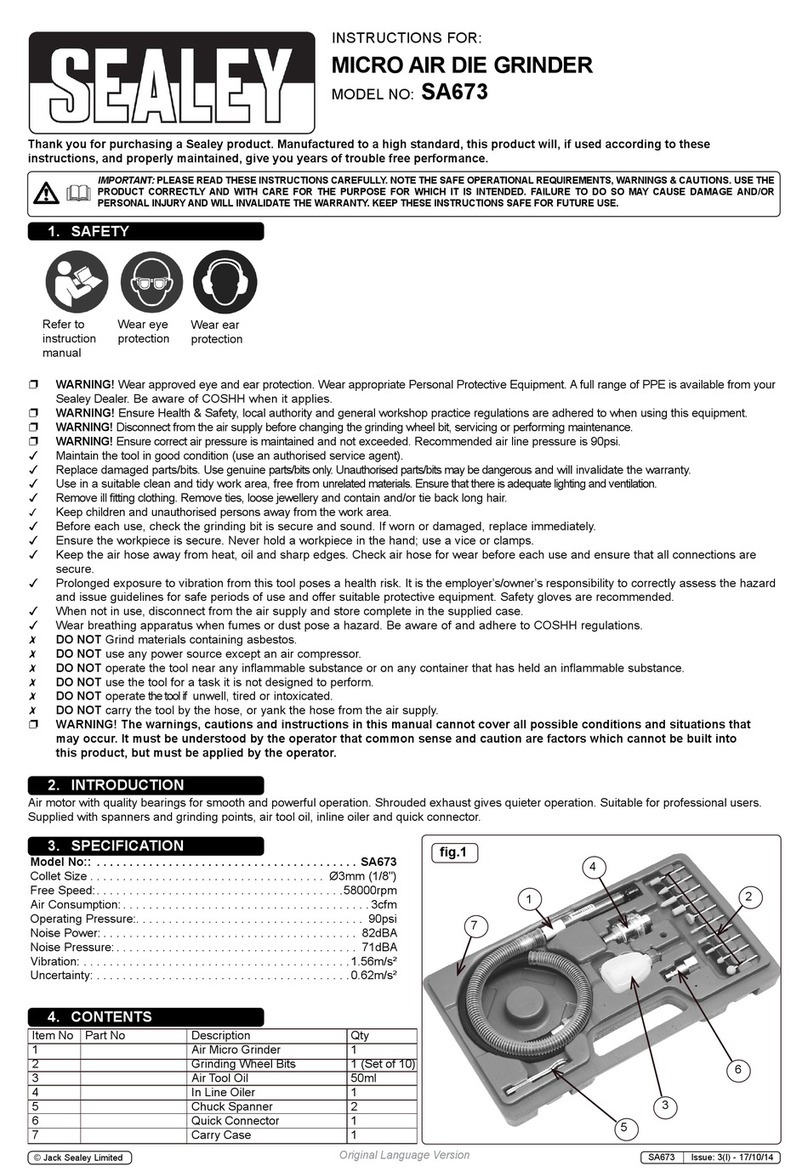

4.2.5. Remove grinding stone washer (fig 6.2), blotter (3),stone (4), 2nd blotter (5), washer (6) from main spindle (7).

4.2.6. Carefully inspect the new stone before installing to ensure there are no fissures, chips, or cracks.

WARNING! DO NOT USE A DAMAGED STONE.

4.2.7. Inspect the blotters, if they are damaged replace them. The grinder must never be used

without stone blotters, should you not have any available when you need to

replace them, cut out a piece of suitable cardboard the same shape for temporary use only.

4.2.8. Install the new stone by reversing steps above. Ensure washers (2 & 6) are installed

with the flange on the outside, (i.e. the concave side against the blotter).

4.2.9. Hold stone steady and secure locking nut. DO NOT over tighten as this may crack the stone.

4.2.10. Replace stone cover, re-adjust tool rest to a maximum of 2mm from stone face and tighten

securely.

Note: You do not require a certificate to change a wire wheel. Assembly is the same as with a stone.

5.1. Pre-use Inspection.

WARNING! INSPECT THE GRINDER BEFORE OPERATING THE MACHINE. ENSURE THE GRINDER IS UNPLUGGED FROM

THE MAINS POWER BEFORE COMMENCING THE INSPECTION.

5.1.1. Check the tool rests are securely fixed at a maximum of 2mm from the grinding stone.

5.1.2. Check that eye shields are in good condition, are secure and that you can see through them clearly.

5.1.3. Turn the grinding stones by hand and check for any damage. Check they do not touch the tool rests and are correctly aligned.

If any of the above checks fail, replace, repair, or adjust as necessary before starting the grinder.

5.2. Stone Use.

Depending on the model, grinders are supplied with one or two aluminous oxide stones. Stones have two grades, fine is preferred

for hard materials and coarse for soft materials.

When grinding, should surface of the stone become “loaded” (coated with particles of the material being ground) it is probably the

wrong grade of stone for the job.

Important reminder: Grinding stones MUST ONLY be assembled by a person holding a grinding wheel certificate. See chapter 4.

5.3. Using the Grinder.

WARNING! Before commencing work, ensure you read, understand and apply the Safety Instructions.

Plug grinder into the mains power supply.

Place the eye shield in its appropriate safety location.

Switch the grinder on and bring the workpiece slowly into contact with the spinning stone, or wire.

When you have completed your task, unplug the grinder from the mains power supply, and clean the machine ready for next use.

6. MAINTENANCE

WARNING! Ensure the grinder is unplugged from the mains power supply before performing any maintenance or service.

6.1. As the grinding stones wear, adjust the positions of the tool rests. The rests must set at a maximum of 2mm from the stone surfaces.

6.2. Regularly remove the grinding stone covers and clean out any dust and dirt.

6.3. The machine motor and bearings are sealed units and require no regular maintenance. Should you require assistance, contact your

local Sealey service agent.

6.4. For information relating to the handling and maintenance of grinding stones refer to chapter 4.

5. OPERATING INSTRUCTIONS

4. GRINDING STONES

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

fig 6

Original Language Version BG200XL Issue: 5(L)- 04/03/14

© Jack Sealey Limited