WARNING! Ensure you read, understand and apply the safety instructions in Section 1

before use.

WARNING! This system has been designed to prevent the operator from handling the log

during the splitting process. For safety reasons the operator must not ask a second person

to place or handle the log. The system is designed to be operated by one person only.

WARNING! Always split a log along its grain. Never attempt to split a log laid across the

machine as this could be dangerous for the operator and could seriously damage the splitter.

WARNING! Never attempt to split a log if it is sitting at an angle.

▲DANGER! Never attempt to split a log sitting on another log, split only single pieces at a time.

5.3. Pump the foot pedal of the hydraulic pump to raise the splitter log support to a suitable

working height.

5.4. Place a log securely on the log support.

5.5. When logs of approximately the same length are to be split, the wedge can be set to avoid

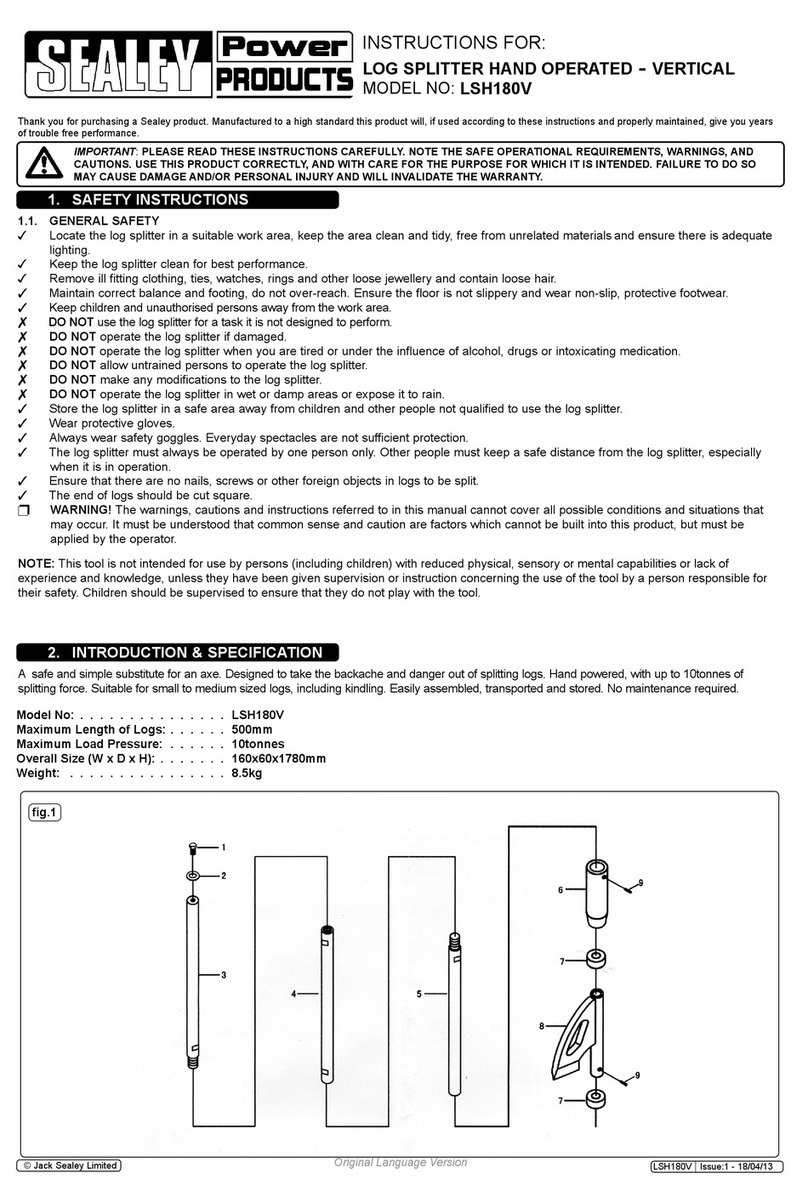

having to pump the ram to operate through it’s full stroke every time. Pull both of the

wedge release pins out of the locating holes in the post (fig.7), and adjust the wedge as

near to the log as possible and replace the wedge release pins ensuring that they have

both located into a hole - Make sure the wedge release pins are firmly seated in the post

holes before continuing - the wedge may have to be raised slightly to do this.

5.6. Ensure the log is stable and keeping hands out of the way of the wedge, pump the foot

pedal (fig.7) to raise the log up tight against the wedge, continue with even strokes of the

foot pedal until the log is split.

5.7. Remove or stack the logs as you work and regularly clear the area of any accumulated

wood chips and other debris to keep the work area safe.

5.8. To lower the splitter log support, release the pressure from the hydraulic pump by pushing on the release lever (fig.7), the springs will

force the log support to lower.

5.9. Wipe down the log splitter to remove tree sap or dirt after each use and tidy the work area ready for the next work session.

5.10. When the splitter is not in use, thoroughly clean it and store it in a dry location with the hydraulic pump at it’s lowest position to minimise

corrosion.

6. MAINTENANCE

6.1. HYDRAULIC PUMP

6.1.1. To add oil to the hydraulic pump:

6.1.1.1.Remove the two springs from the log support and undo the two allen bolts, remove the hydraulic unit from the base unit.

6.1.1.2.Position the hydraulic unit vertically and remove the round rubber oil plug on the back of the unit’s housing. Using a piece of wire or

similar, dip into the oil to check it’s level. It should be immediately below the plug hole (¾ full). Add hydraulic jack oil if required (see

6.1.1.4. for specification).

6.1.1.3.Replace the rubber oil plug and re-assemble the log splitter.

6.1.1.4.After one year the hydraulic oil should be replaced in order to extend the life of the unit. Use hydraulic jack oil only.

IMPORTANT: Only fully qualified personnel should attempt hydraulic maintenance or repair.

NOTE: Use Sealey quality hydraulic jack oil, Model No.s HJO500MLS / HJO5LS to top up or replace the hydraulic fluid.

6.1.1.5.When draining the oil make sure that no dirt is allowed to enter the hydraulic unit.

6.1.2. Periodically check the hydraulic unit’s piston and ram for signs of corrosion. Clean exposed areas with a clean oiled cloth.

6.2. HYDRAULIC PUMP WILL NOT LIFT

6.2.1. The oil level may be low. Check oil level as described in section 6.1.1.2. and top up if necessary.

6.2.2. The pump may have air trapped in the system. To eliminate trapped air, open the release valve by pushing on the release lever and

pumpthefootpedalofthepumpatthesametime,throughitsfullstroke,veorsixtimes.Closethereleasevalve.

6.2.3. Hydraulic pump’s piston ‘O’ ring seal may have become worn. If this is suspected take the jack to an approved agent for servicing.

LS575VH.V2 | Issue 3 (H,F,1,4,5,6) 4/2/2019

Original Language Version

© Jack Sealey Limited

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

g.7