INSTRUCTIONS FOR

MINI DISC

AIR SANDER

Model: MA20.V2

Thank you for purchasing a Sealey Product. Manufactured to a high standard this

product will, if used according to these instructions and properly maintained, give

you years of trouble free performance.

IMPORTANT:PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY,

AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500 E-mail: sales@sealey.co.uk

Web: www.sealey.co.uk

01284 703534

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data,

specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this equipment.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy our latest catalogue and promotions, call us on 01284 757525 and leave

your full name, address including your postcode.

MA20.V2 - 2 - 160702

pWARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to

when using this equipment.

pWARNING! Disconnect from air supply before changing accessories, or servicing ,or performing any maintenance.

3Maintain the sander in good condition (use an authorised service agent).

3Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will

invalidate the warranty.

3Use in a suitable work area. Keep area free from unrelated materials and ensure that there is adequate lighting.

3Before use check abrasive pads for condition. If worn or damaged replace immediately.

3Ensure there are no flammable or combustible materials near the work area.

pWARNING! Always wear approved eye (or face) and hand protection when operating the sander.

3Use face, dust, or respiratory protection in accordance with COSHH regulations.

3Remove ill fitting clothing. Remove ties, watches, rings, other loose jewellery and contain and/or tie back long hair.

3Wear appropriate protective clothing and keep hands and body clear of working parts.

3Maintain correct balance and footing. Do not over reach, ensure the floor is not slippery, wear non-slip shoes.

3Keep children and unauthorised persons away from the working area.

3Check moving parts alignment on a regular basis.

3Ensure workpiece is secure before operating the sander. Never hold a workpiece by hand.

3Check the workpiece to ensure there are no protruding screws, bolts, nuts etc.

3Avoid unintentional starting.

pWARNING! Ensure correct air pressure is maintained and not exceeded. Recommended pressure 70-90psi

3Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure

that all connections are secure.

7DO NOT use the sander for a task it is not designed to perform.

7DO NOT operate sander if any parts are damaged or missing as this may cause failure and/or personal injury.

pWARNING! DO NOT sand any materials containing asbestos.

7DO NOT carry the sander by the hose, or yank the hose from the air supply.

7DO NOT force, or apply heavy pressure to the sander; let the tool do the work.

7DO NOT place air line attachments close to your face and do not point at other people or animals.

7DO NOT operate sander when you are tired, under the influence of alcohol, drugs or intoxicating medication.

7DO NOT use sander where there are flammable liquids, solids or gases such as paint solvents and including

waste wiping or cleaning rags etc.

7DO NOT carry the sander with your finger or hand on the power lever.

7DO NOT direct air from the air line at yourself or others.

3When not in use disconnect from air supply and store in a safe, dry, childproof location.

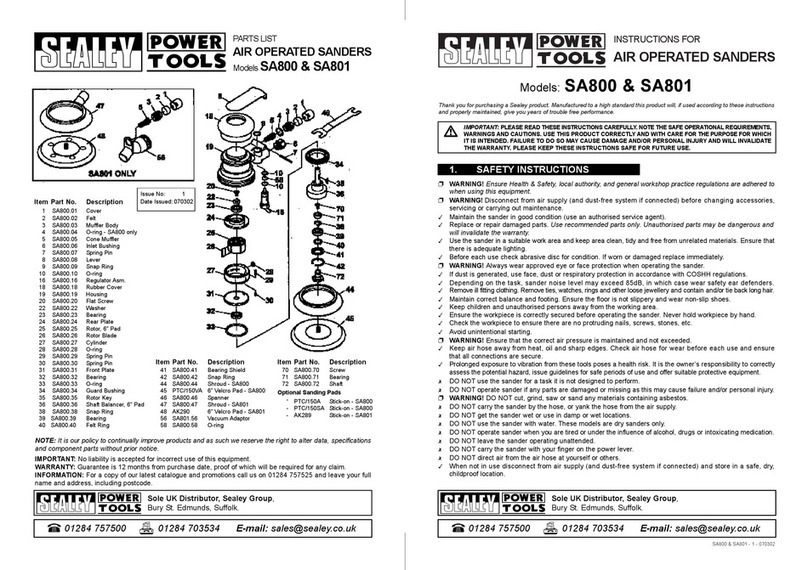

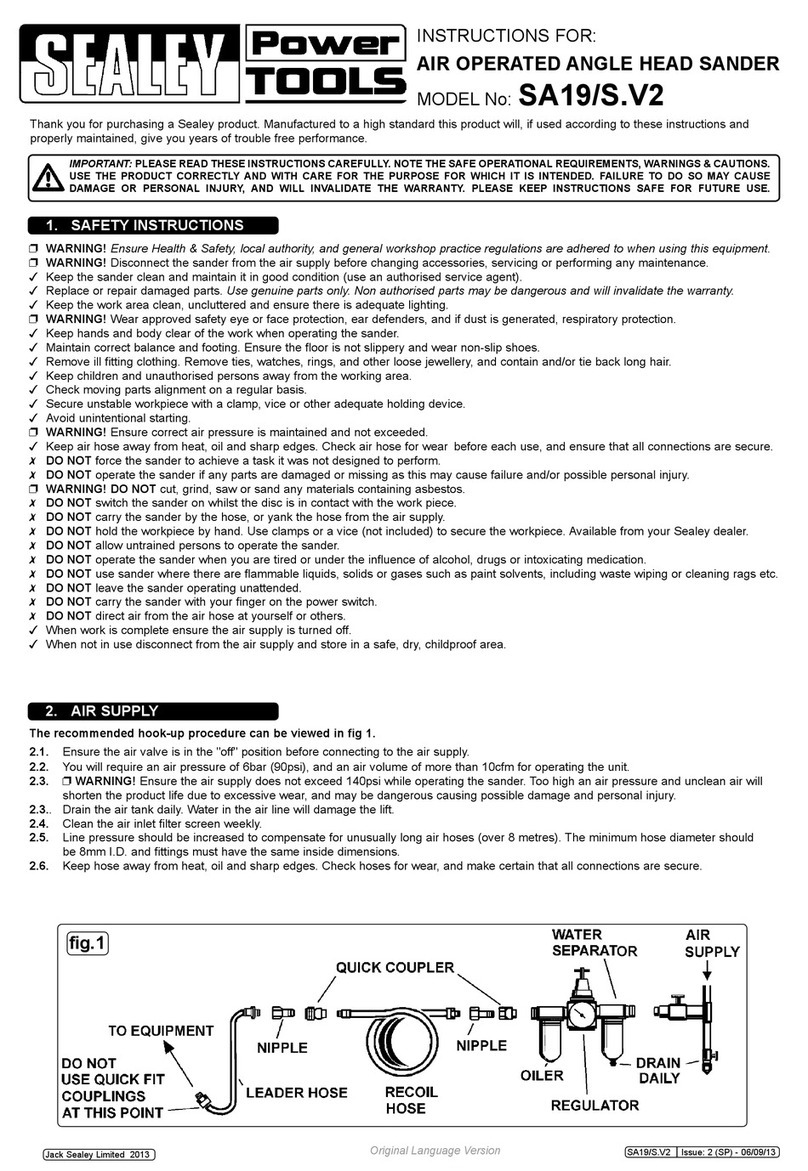

ITEM PART NO DESCRIPTION ITEM PART NO DESCRIPTION

1122-10.04.15N BODY, MOTOR 23 122-11.04.45 SCREW, CONNECTING ROD

2122-10.03.20N HANDLE, RUBBER 24 122-21.50.12 PLUG, VIBRATION SUPPORT

3122-15.01.28 AIR REGULATOR 25 122-29.01.14 NUT

4122-21.50.10 PLUG, VALVE 26 122-13.02.03 WASHER

5122-17.01.25 O-RING 27 122-19.50.56 SUPPORT, RUBBER VIBRATION

6122-25.01.45 SPRING, VALVE 28 122-24.01.26 MOUNT, RUBBER VIBRATION

7122-21.50.15 STEEL BALL 6.7mm 29 122-13.02.04 WASHER, 6x13x1.5

8122-15.01.40N STEM, VALVE 30 122-29.01.13 NUT

9122-31.02.10N BUSH, VALVE 34 122-72.01.31N SILENCER METAL RING

10 122-27.01.48N LEVER 35 122-72.01.30N EXHAUST SILENCER

11 122-23.01.13N PIN, ELASTIC 36 122-32.04.90 BODY, ECCENTRIC

12 122-12.02.20 COVER, MOTOR 37 122-11.05.06 SCREW, SET

13 122-17.01.35 O-RING 38 122-32.03.17 SHAFT, ECCENTRIC BODY

14 B-626ZZ BEARING, 626ZZ 39 B-628-2RS BEARING, 628 2RS

15 122-16.01.25 FLANGE, UPPER MOTOR 40 122-19.01.10 CIRCLIP

16 122-16.01.29 ROTOR 41 122-32.03.18 JOINT, ECCENTRIC BEARING

17 122-16.01.33 BLADE, ROTOR 42 122-11.05.05 SCREW, SET

18 122-19.50.48 SPACER 43 122-88.08.05 SUPPORT FOR DISC 15 X 60

19 122-16.01.31 SLEEVE, MOTOR 44 122-29.01.16 CUBE

20 122-16.01.27 FLANGE, LOWER MOTOR 45 122-88.08.16 DISC 30MM DIAM

21 122-20.02.56 BALL BEARING 46 122-88.08.11VELCRO DISC 38MM DIAM

22 122-37.01.50 ROD, DRIVE SUPPORT CONNECTING

PARTS LIST FOR:

MINI DISC AIR SANDER

Model: MA20.V2

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500

01284 703534

Issue: 2

Date: 160702

E-mail: sales@sealey.co.uk

Web: www.sealey.co.uk