INSTRUCTIONS FOR:

CAR POLISHER 150mm 12V

MODEL No: ER1512P

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1.1. GENERAL SAFETY

WARNING! Ensure that Health & Safety, local authority and

general workshop practice regulations are adhered to when

using this polisher.

Familiarise yourself with the application, limitations and

potential hazards of the polisher.

WARNING! Disconnect from the cigarette socket and ensure

that the pad is at a complete standstill before changing

accessories, servicing or performing any maintenance.

Maintain the polisher in good condition (use an authorised

service agent).

Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the

warranty.

Use the polisher in a suitable work area and keep the area

clean and tidy and free from unrelated materials. Ensure that

there is adequate lighting.

Keep the polisher clean for best and safest performance.

Before each use check all attachments for condition. If worn or

damaged replace immediately.

Ensure that there are no flammable materials near the work

area.

WARNING! Wear approved safety eye protection.

Maintain correct balance and footing. Ensure that the floor is

not slippery and wear non-slip shoes.

Remove ill fitting clothing. Remove ties, watches, rings and

other loose jewellery and contain and/or tie back long hair.

Keep children and unauthorised persons away from the work

area.

Avoid unintentional starting.

DO NOT use the polisher for any purpose other than that for

which it is designed.

DO NOT operate the polisher if any parts are damaged or

missing as this may cause failure and/or personal injury.

DO NOT switch the polisher on until the head is in contact with

the panel and switch the unit off before removing the head

from the panel.

DO NOT use the polisher with abrasive cleaners or rubbing

compounds as excessive paint removal may result.

DO NOT get the polisher wet or use in damp or wet locations

or areas where there is condensation.

DO NOT allow untrained persons to operate the polisher.

DO NOT operate the polisher when you are tired or under the

influence of alcohol, drugs or intoxicating medication.

DO NOT use the polisher where there are flammable liquids,

solids or gases such as paint solvents, etc.

DO NOT leave the polisher operating unattended.

DO NOT carry the polisher with your finger on the power switch.

DO NOT pull the cord from the cigarette socket.

Use a qualified person to maintain the polisher.

When not in use, unplug from the power supply and store in a

safe, dry, childproof area.

WARNING!Connect only to 12V DC in car cigarette socket.

3. SPECIFICATION

2. INTRODUCTION

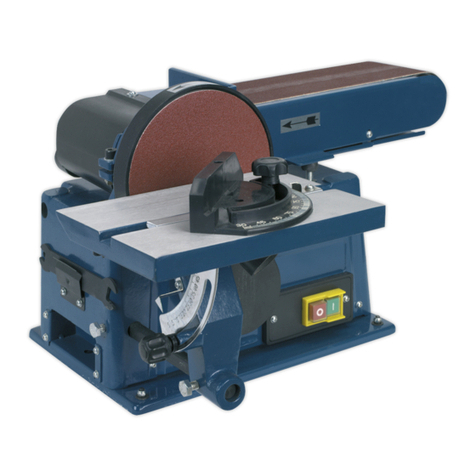

Random orbital polisher with Ø150mm 3-ply foam pad and two

polishing bonnets. Smooth operation provides even buffing/polishing

with no hot spots. Impact resistant ABS housing. Supplied with 5mtr

cable with 12V cigarette plug.

Model No: .......................................ER1512P

Supply:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12V

Speed: .......................................... 3300rpm

Pad Size: ........................................Ø150mm

Replacement Backing Pad:........................ER150P.BP

Replacement Bonnet Terry Cloth: ...................ER150P.TB

Replacement Bonnet Synthetic Wool:................ER150P.WB

NoisePower ..................................... 61.9dB.A

NoisePressure...................................72.9dB.A

4. OPERATION

WARNING! Ensure that you read, understand and apply

the safety instructions in Section 1.

WARNING! Excess pressure can cause damage to

paintwork and will put the polisher motor under strain.

Polishers returned with burnt out motors will be

rejected as a warranty claim. Normally the weight of the

polisher is sufficient.

WARNING! Do not use the polisher with abrasive or

rubbing compounds.

4.1. Before each use, check that the bonnet is clean and free of

abrasive particles and is undamaged and that the pad rotates

freely.

4.2. Apply a small amount of polish/wax evenly over the surface of

the bonnet. Do not apply polish directly to the vehicle surface.

4.3. Hold the polisher firmly by the handle and place the polishing

face onto the panel to be polished.

4.4. Start the polisher using the red On/Off switch on the handle

ensuring that the pad is still in contact with the vehicle panel.

4.5. Move the polisher with broad sweeping strokes over the

surface in a criss cross pattern. Do not apply pressure to the

polisher when in use. Work in logical areas and re-apply the

polish/wax at intervals during the polish application process.

Do not allow the foam pad to become saturated with polish/

wax as this will make polishing more difficult and will reduce

pad life.

4.6. Polish/wax should be applied to difficult-to-reach areas by hand.

4.7. Switch Off the polisher before lifting it from the panel when

polish application is completed.

4.8. Remove the application bonnet and replace it with the wool

bonnet.

4.9. Buff the polish/wax in the same order it was applied. Do not

put pressure on the polisher but allow its weight and action to

do the job.

4.10. Badly oxidised paint may require several applications. Do not

use abrasive compounds.

4.11. If the polish/wax is difficult to buff too much has been applied.

This may also cause the bonnet to come off the pad.

WARNING! Do not immerse the polisher in water.

5. MAINTENANCE

5.1. Always store the polisher on its side so that the foam pad does

not become compressed and/or distorted.

5.2. Remove the bonnet when not in use to allow the foam pad to

dry out.

5.3. Clean the bonnet regularly by hand washing with soap and water.

DO NOT immerse the foam pad in water. Washing the bonnet is

sufficient.

5.4. If the foam pad requires replacement return the unit to your

local Sealey dealer as this is not a user servicable part.

Original Language Version ER1512P Issue: 2 - 02/11/10