WARNING! Wear approved eye safety protection, ear defenders and, if dust is generated, respiratory protection.

9 Maintain correct balance and footing. Ensure the oor is not slippery and wear non-slip shoes.

9 Remove ill tting clothing. Remove ties, watches, rings, and other loose jewellery, and contain and/ or tie back long hair.

9Keep children and unauthorised persons away from the working area.

9Secure non-stable work piece with a clamp, vice or other adequate holding device.

9 Remove adjusting keys and wrenches from the machine and its vicinity before turning it on.

8DO NOT use equipment for any purpose other than that for which it is designed.

8DO NOT operate the polisher/sander if any parts are damaged or missing as this may cause failure or possible personal injury.

WARNING! DO NOT sand any materials containing asbestos.

8DO NOT switch the polisher/sander on whilst the head is in contact with the work piece and avoid unintentional starting.

8DO NOT get the polisher/sander wet or use in damp or wet locations or areas where there is condensation.

8DO NOT allow untrained persons to operate the polisher/sander.

8DO NOT operate the polisher/sander when you are tired, under the inuence of alcohol, drugs or intoxicating medication.

8DO NOT use the polisher/sander where there are ammable liquids, solids or gases such as paint solvents, etc.

8DO NOT leave the polisher/sander operating unattended.

8DO NOT carry the polisher/sander with your nger on the power switch.

8DO NOT pull the cord to remove the plug from the power supply.

9 Use a qualied person to lubricate and maintain the polisher/sander.

9 When not in use unplug from the mains power supply and store in a safe, dry, childproof area.

LEAD PAINT WARNING! Paint once contained lead as a traditional ingredient. Contact with the dust from the removal of such paint is

toxic and must therefore be avoided. The following action must be taken before using machine as a sander:

1. User must determine potential hazard relating to age of paint to be removed. (Modern paints do not have lead content).

2. DANGER! Keep all persons and pets away from the working area. The following are particularly vulnerable to the effects of lead

paint dust: Expectant women, babies and children.

3. We recommend personal protection by using the following safety items:

A) Paint Spray Respirator (Sealey ref. SSP1699) B) PE Coated Hooded Coverall (Sealey ref. SSP266). C) Latex Gloves

(Sealey ref. SSP24).

4. Take adequate measures to contain paint dust, akes and scrapings. Wear safety equipment, as in (3) above and thoroughly

clean all areas when task is complete.

5. Ensure the paint waste is disposed of in sealed bags or containers according to local regulations.

2. INTRODUCTION

Variable speed control for sanding and polishing. Speed varies from 1000 to 3000rpm. Alloy bevel gear head with composite motor housing.

Supplied with Ø170mm backing pad and side handle.

3. SPECIFICATIONS

Model no: ............................................................... MS900PS

Pad size: ................................................................. Ø170mm

Thread size: ........................................................ M14 x 2mm

No load speed:..............................................1000 - 3000rpm

Power:.........................................................................1300W

Supply:...........................................................................230V

Weight:.......................................................................... 3.8kg

Noise power: ..............................................................102Lwa

Noise pressure:............................................................ 91Lpa

Vibration:................................................................ 7.678m/s²

Uncertainty:..................................................................... 1.5k

4. CONTENTS

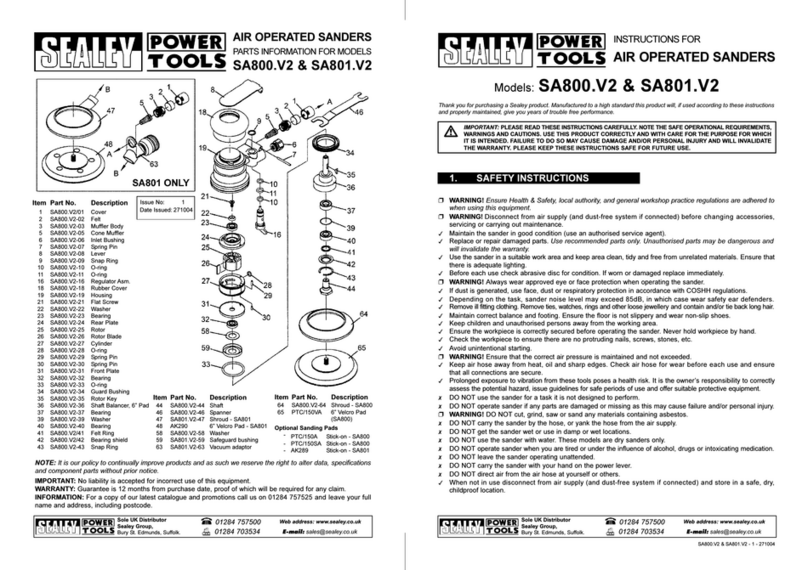

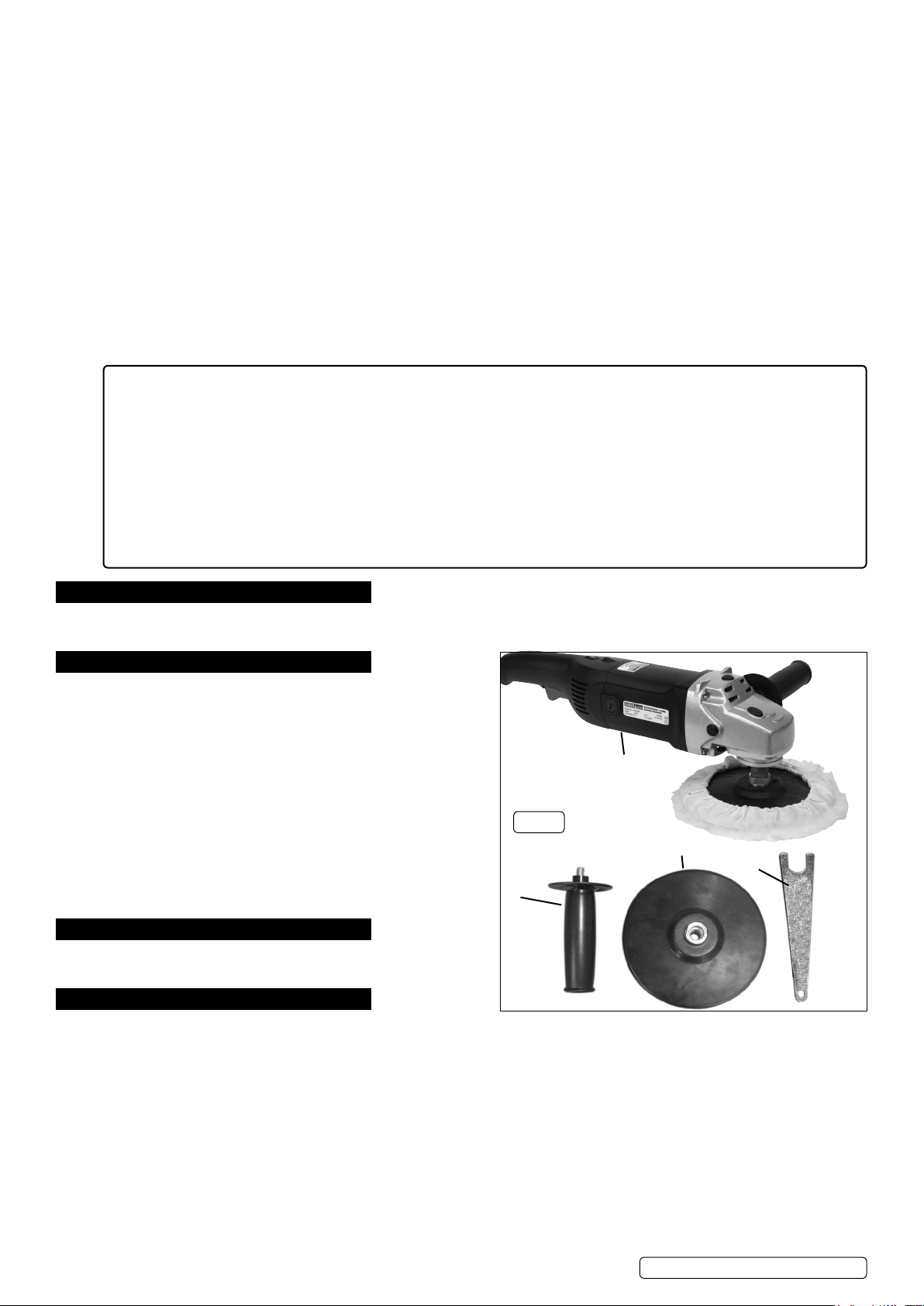

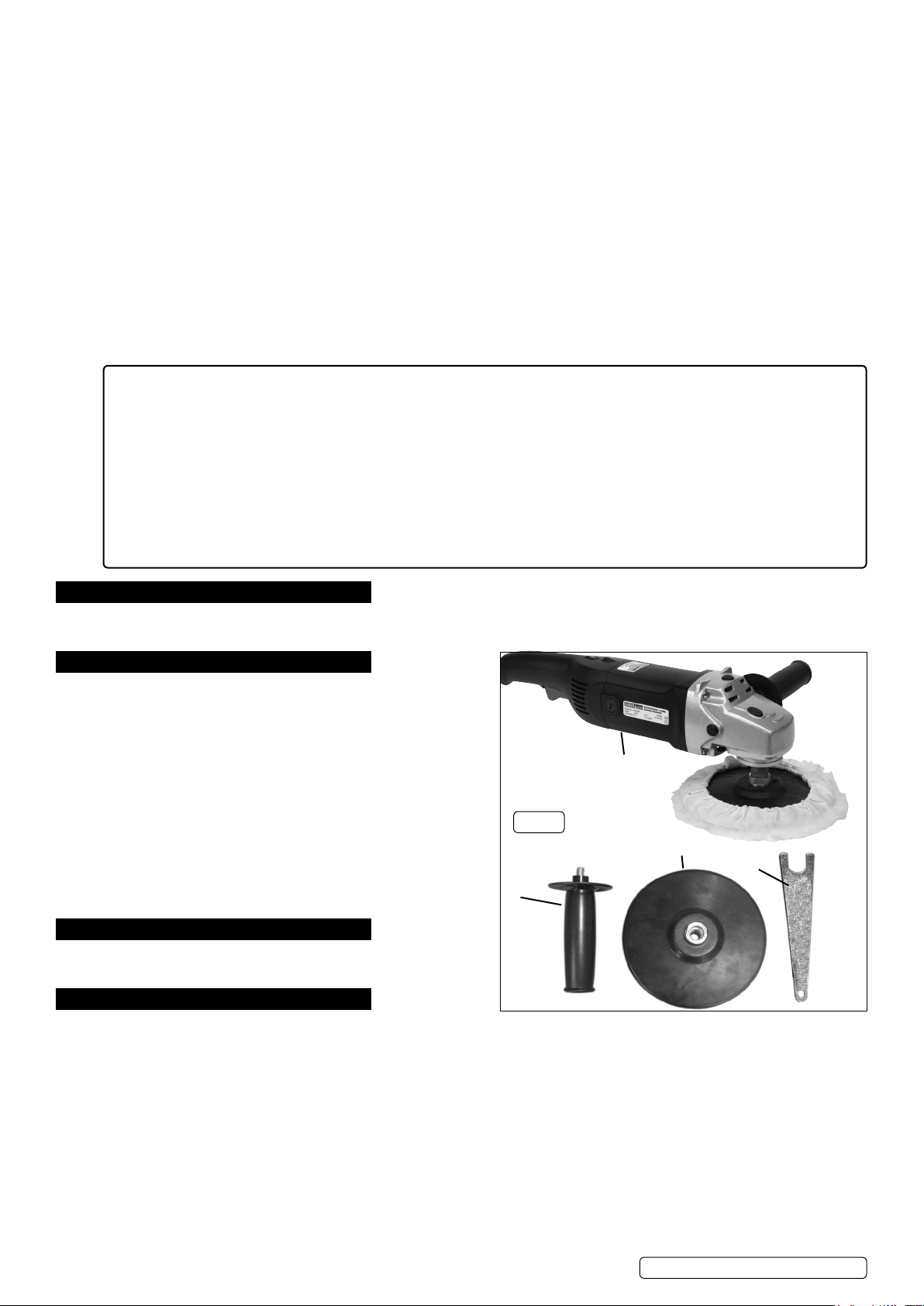

Refer to g.1

1: Polisher Unit, 2: Side Handle, 3: Pad, 4: Spanner.

5. ASSEMBLY

WARNING! Ensure unit is not plugged into mains before

attempting any assembly.

5.1. Attach the side handle (fig.1.2). Note: there is a mounting hole on either side and the top to suit the application and/or operator.

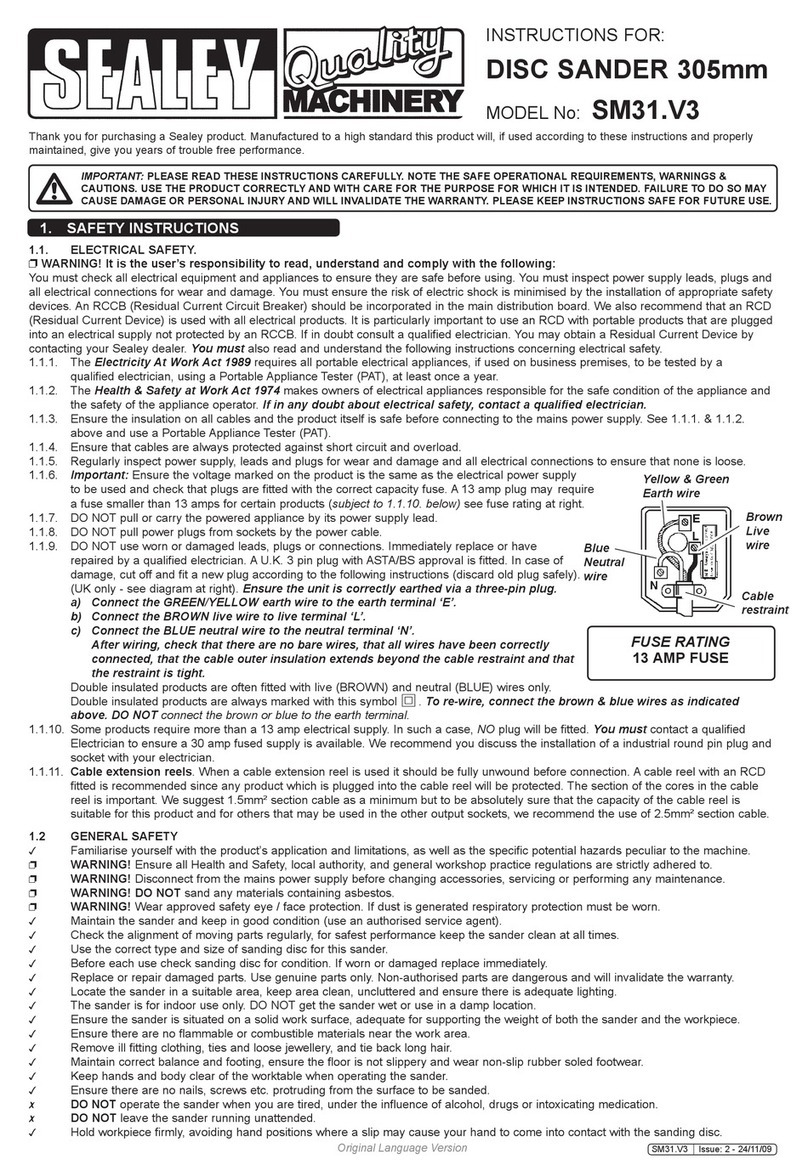

5.2. To attach the rubber pad:

Thread the rubber pad (fig.1.3) on shaft and tighten using spanner (fig.1.4) by holding shaft steady with locking button (fig.2).

5.3. To fit a sanding disc:

Select the grade of self adhesive sanding disc required, peel off the backing and centrally locate the disc onto the rubber pad.

5.4. To fit a polishing bonnet:

Fit the polishing bonnet over the secured rubber pad, using the pull cord, tighten the bonnet and tie a bow to secure, tuck the loose

ends of the bow neatly under the bonnet.

Fig.1

1

2

4

3

Original Language Version

© Jack Sealey Limited MS900PS | Issue 4 (SP) 10/10/17