©Jack Sealey Limited Original Language Version SM750 Issue No.1 27/11/12

spigots into the 'L' shaped slots either side of the sanding disc

until the table stops, then lift the table up until the spigots stop

at point (S) on either side. Retaining the table in this position,

insert a clamping knob (K) through the curved slot in one of the

sanding table adjustment scales and screw it into the threaded

hole provided in the flange around the disc. Tighten the knob to

hold the table in position and then screw the second knob 'K'

into position on the other side of the table.

4.2.2 Place the adjustable, horizontal angle guide into the slot in the

table when required and adjust the angle to your needs.

4.3 Attaching the sanding belt backing plate.

4.3.1 Referring to fig.5, position the backing plate (A) behind the belt

and insert the two socket cap screws provided through the

slots in the plate and screw them down, finger tight. See

fig.5(F) The plate should just touch the back of the belt without

applying any pressure to it. Finally tighten the two screws with

a 3mm hex key.

4.7 Dust extraction.

4.7.1 Both the belt and the disc are provided with dust extraction

ports for connection to a workshop extractor system or a

vacuum cleaner and it is recommended that these facilities be

used if they are available.

4.7.2 If no extraction facilities are available you must wear suitable

respiratory protection. Contact you local Sealey dealer for a full

range of protective equipment.

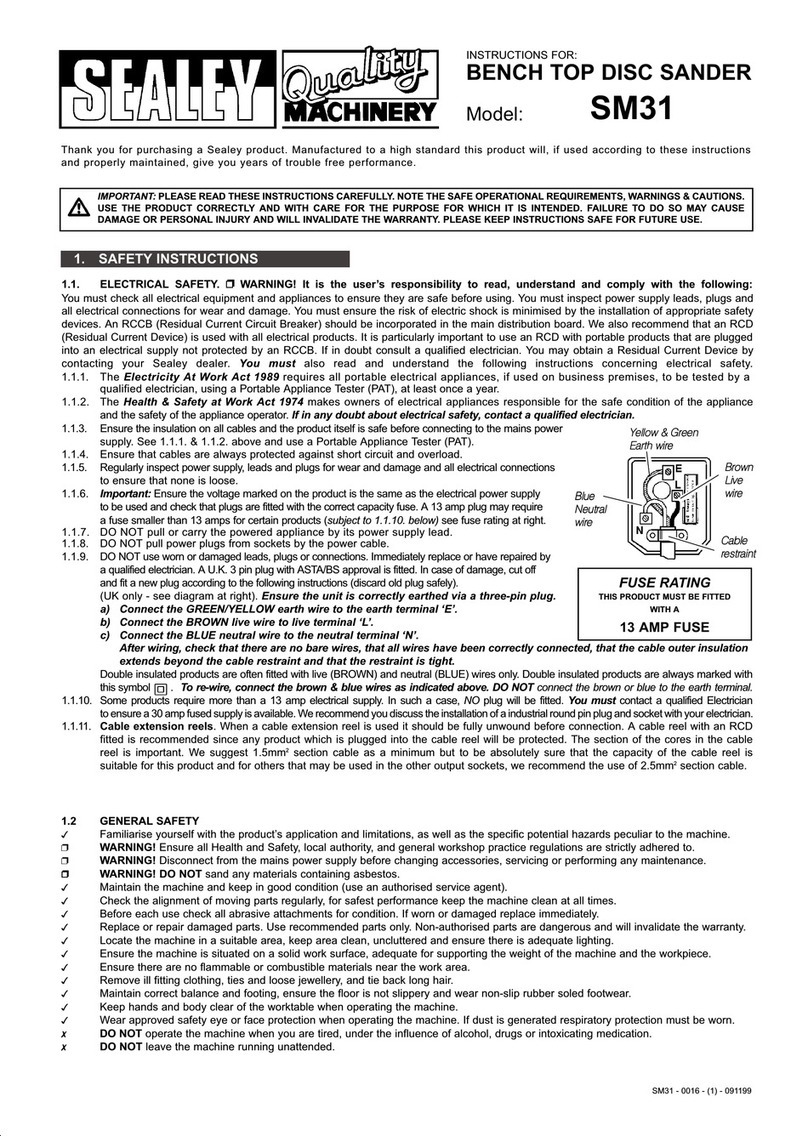

5.1 PREPARATION.

5.1.1 If the sander is to be used in a temporary work environment

ensure that the rubber feet are attached in order to keep it

stable in use. Wear suitable respiratory protection.

5.1.2 The sander can also be permanently installed in a workshop

environment by removing the feet and bolting the unit to a

bench using the same fixing holes as used for the feet. Ideally

the sander should be connected to a dust extraction system or

vacuum cleaner.

5.1.3 DO NOT allow two people to use the sander at the same

time.

5.2 OPERATION.

5.2.1 Adjust the angle of the appropriate table and/or guide as

required by the job in hand.

5.2.2 Plug the sander into the mains power supply.

5.2.3 Switch on the sander using the green ON button. See fig.1(12).

5.2.4 Remember that even though you are using only one of the

sanding facilities, the other is still turning and could

represent a hazard to you or other people nearby.

5.2.5 Allow the belt or disc to reach full speed before bringing the

workpiece into contact with it. Do not use excessive force to

remove material but allow the abrasive material to do its job.

5.2.6 Switch off the sander using the red OFF button. See fig.1(12).

5.2.7 Allow the disc and belt to come to a standstill before leaving

the sander.

5.2.8 DO NOT leave the sander running unattended.

5.2.9 Unplug the sander from the mains power supply when no

longer required.

4.6 Adjusting the sanding belt.

4.6.1 The sanding belt supplied with the machine is factory set to run

in alignment with the drive wheels. Should the belt begin to run

out of true it can be re-centred using the tracking knob shown

in fig.5(C). Turn the knob clockwise to move the belt to the

right, (when facing the machine). Turn the knob counter

clockwise to move the belt to the left.

4.4 Attaching the sanding belt table. (See fig.4).

4.4.1 Take the sanding belt table (A) in the orientation shown in fig.4

and allow the sanding belt to pass the through the slot and into

the hole in the middle of the disc. Lower the disc down until

the adjusting slot (B) is adjacent to the fixing nut on the corner

of the main casting.

4.4.2 Fix the table in position by passing the threaded portion of the

inner fixing (C) through the adjusting slot (B) and into the fixing

nut. Hand tighten at this stage.

4.4.3 Push the locking lever (D) onto the inner fixing (C) so that it

engages with the castellations on the end of the fixing.

4.4.4 Slide the spring (E) onto the plain portion of the socket capped

bolt (F) and insert the bolt into the hole in the locking lever (D).

Using a 3mm hex key, carefully screw the bolt into the end of

the inner fixing (C). Do not overtighten.

4.4.5 To overcome the limited arc of movement of the locking lever,

disengage it from the inner fixing by pulling it away from the

table and rotate it in the direction required. Release the lever

so that it re-engages with the inner fixing. You can now, further

tighten or loosen the fixing as required.

4.5 Setting the table at 90°to the belt. (See fig.1).

4.5.1 At the back of the belt table is a recessed, socket capped grub

screw which is used as a stop to quickly allow the table to be

returned to 90° having been set at another angle. See fig.1(14).

4.5.2 To set the stop, partially loosed the table and using a small set

square, set the table surface at 90° to the belt.

4.5.3 Using a 3mm hex key, screw the grub screw downwards until it

just touches the body of the unit without moving the table.

There is a nut on the grub screw on the underside of the table.

When you are satisfied that the stop is correctly positioned,

lock it in place by tightening the nut up to the underside of the

table.

5. OPERATING INSTRUCTIONS

fig.5

fig.4