8DO NOT operate sander if any parts are damaged or missing. This may cause failure and/or injury.

WARNING! DO NOT sand any materials containing asbestos.

8DO NOT carry the sander by the electrical cable.

8DO NOT use sander with water, get the sander wet or use in damp or wet locations, the sander is for dry use only.

8DO NOT operate sander if you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT use where there are flammable liquids, solids or gases such as paint solvents or waste wiping or cleaning rags.

8DO NOT leave the sander running unattended.

8DO NOT carry the sander with your finger on the power switch.

9 When not in use disconnect from power supply and store in a safe, dry, childproof area.

LEAD PAINT WARNING!

Paint once contained lead as a traditional ingredient. The dust from the removal of such paint is toxic if inhaled or ingested and must,

therefore, be avoided. The following action must be taken before using the sander on a surface that you suspect may have contained

lead in the paint.

1. User must determine potential hazard relating to age of paint to be removed. (Modern paints do not contain lead).

2. DANGER! Keep all persons and pets away from the work area. The following are particularly vulnerable to the effects of lead paint dust:

Expectant women, babies and children.

3. We recommend personal protection by using the following safety items:

a) Paint Spray Respirator (Sealey ref: SSP1699)

b) PE Coated Hooded Coverall (Sealey ref: SSP266)

c) Latex Gloves (Sealey ref: SSP24)

4. Take adequate measures to contain the paint dust, flakes, and scrapings.

5. Continue to wear safety equipment as in 3 above, and thoroughly clean all areas when task is complete. Ensure that paint waste is

disposed of, in sealed bags or containers, according to local authority regulations.

2. INTRODUCTION

5mm Orbit designed specically for use on car body work repairs. Six stage variable speed control from 4000-10000rpm. Ergonomic

rubberised gear head casing for added comfort and grip during use. Fitted with 5m mains cable. Supplied with Ø150mm hook and loop

backing pad, spare brushes and hex key.

3. SPECIFICATION

Model No: ..................................................................... OS400

Pad Size: ....................................................................Ø150mm

Motor Power: ................................................................... 400W

Supply: ............................................................................. 230V

No Load Speed: .............................................. 4000-10000rpm

Orbit Size:.......................................................................Ø5mm

Weight: ...........................................................................2.01kg

Thread size ....................................................................... M8

Noise power..............................................................88dB(A)

Noise pressure.......................................................... 77dB(A)

Vibration.....................................................................

3.6m/s²

Uncertainty ....................................................................1.5m/s²

4. OPERATION

WARNING! Before use, ensure that you have read and understood Section 1 Safety Instructions.

NOTE: The sander is designed for dry use only. DO NOT use with water or any other liqui

4.1. INSTALL HOOK AND LOOP BACKPLATE

4.1.1. With the tool unplugged from the power supply, place it on a tool rest with the spindle upright.

4.1.2. Firmly attach backplate to the machine spindle using bolt and hex key supplied while ensuring engagement of hexagonal spindle.

4.1.3. Attach sanding disc to backing plate ensuring it is centred. If using sanding discs with holes, align the holes on disc and backing

plate to aid dust extraction.

4.2. STARTING AND STOPPING

4.2.1. Plug the sander into the power supply.

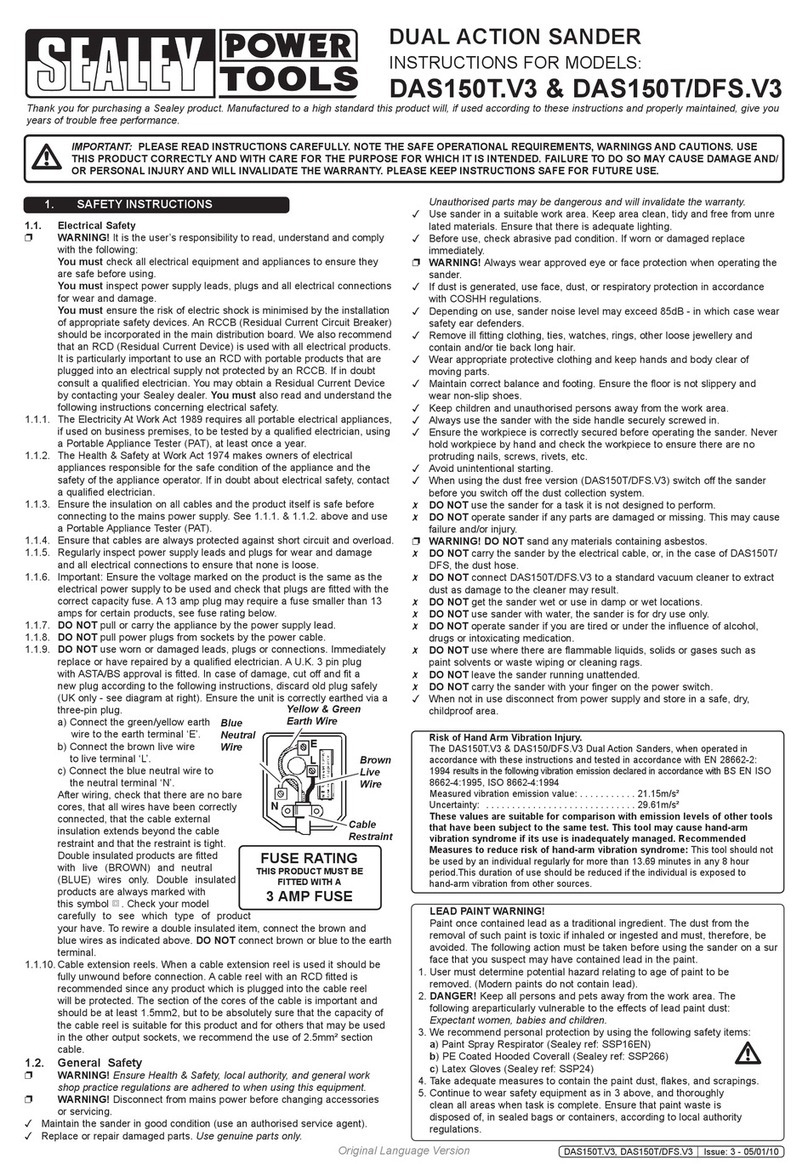

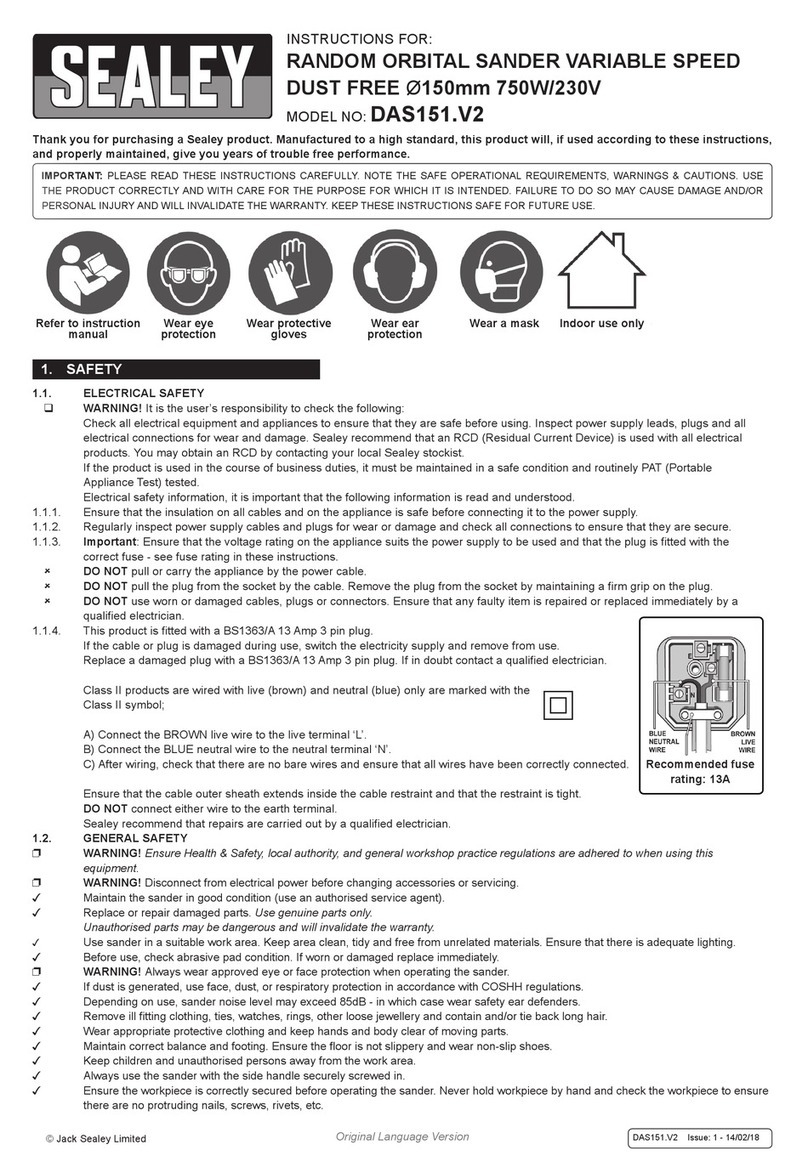

4.2.2. The sander has a six position speed controller numbered 1 to 6 oering speeds from 4000 to 10,000 RPM (g.1).

4.2.3. Set speed control to required value and pull the trigger to start. To stop the machine release the trigger.

4.2.4. For continuous operation press the switch lock button to lock the

trigger (g.1). Pull the trigger again to stop the tool.

4.3. DUST COLLECTION

4.4. The sander is equipped with a multi-holed backing plate.

4.4.1. Dust collection can be enhanced by use of sanding discs with

corresponding holes.

4.4.2. Align the holes when attaching sanding disc to the backing plate.

4.4.3. The sander has a self-vacuum function which, when connected

to either a dust collection bag or vacuum cleaner, can improve

dust collection. (Rubber connector supplied),

Original Language Version

© Jack Sealey Limited OS400 Issue 1 10/04/19

fig.1