INSTRUCTIONS FOR:

EXHAUST FUME EXTRACTION SYSTEM

230V - 0.5hp - SINGLE HOSE & DOUBLE HOSE

MODEL No's: EFS100F & EFS101 & EFS102

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

Original Language Version EFS100F + EFS101 + EFS102 Issue No.1 - 02/12/11

3. CONTENTS

3.1. Unpack the equipment and check against the list below for

missing or damaged items. In the event of a fault contact the

supplier.

1. Extractor unit.

2. Extractor cone & flange inlet assembly.

3. Exhaust hosing (5mtr).

2. INTRODUCTION & SPECIFICATION

Wall mounted electric fan fitted with heat resistant hosing and

exhaust gas analyser port. Ideal for bikes, cars and car derived vans.

Requires installation onto workshop wall and ducting to appropriate

exhaust. Does not include electrical switch gear. Ideal for smaller

garages and workshops where space is limited.

Specification:

Motor ........................................................................ 0.5hp 230V 50Hz

Hose Size ......................................................................Ø75mm x 5mtr

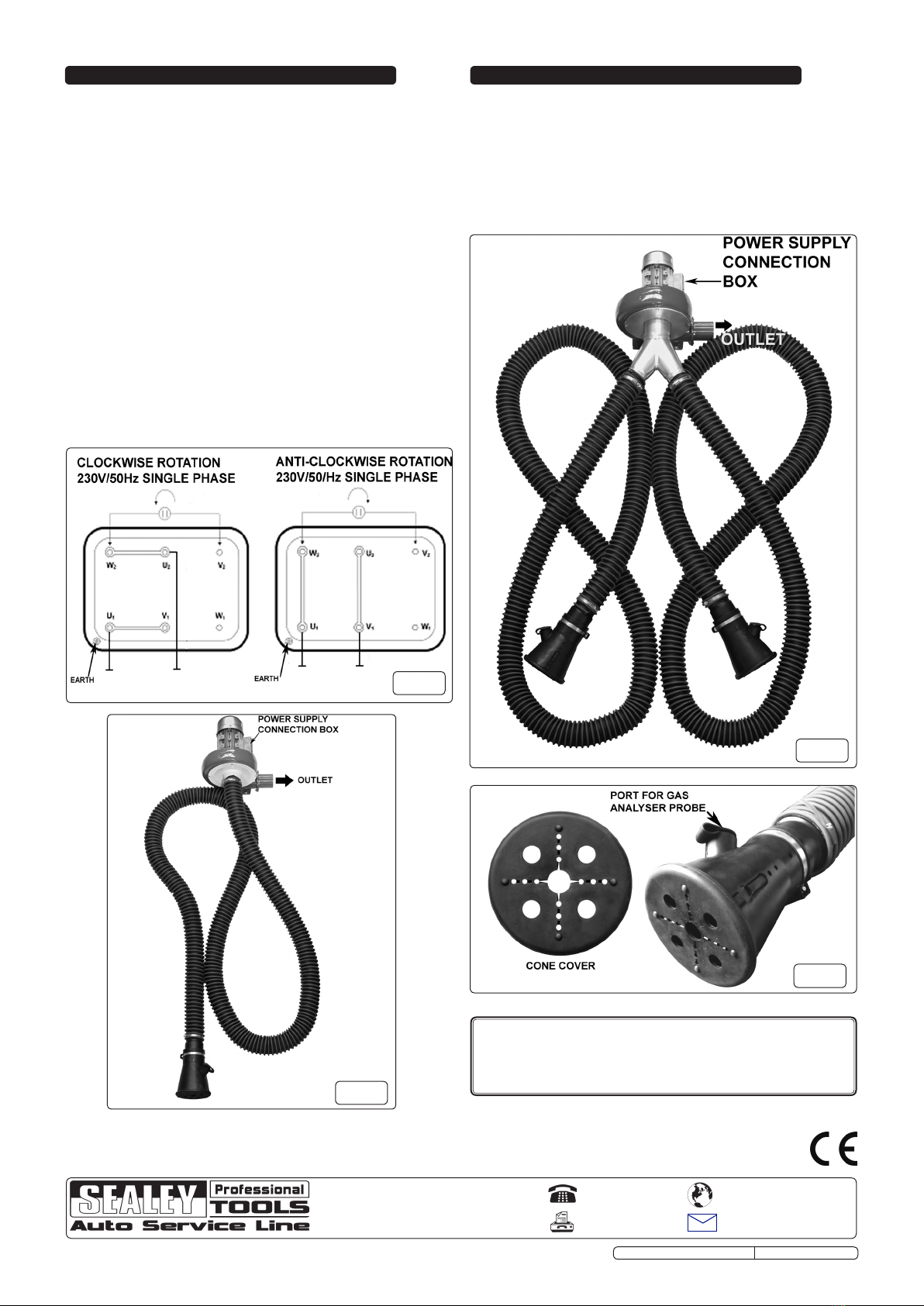

4. INSTALLATION

4.1. WE RECOMMEND THAT ELECTRICAL INSTALLATION

SHOULD ONLY BE CARRIED OUT BY A QUALIFIED

ELECTRICIAN.

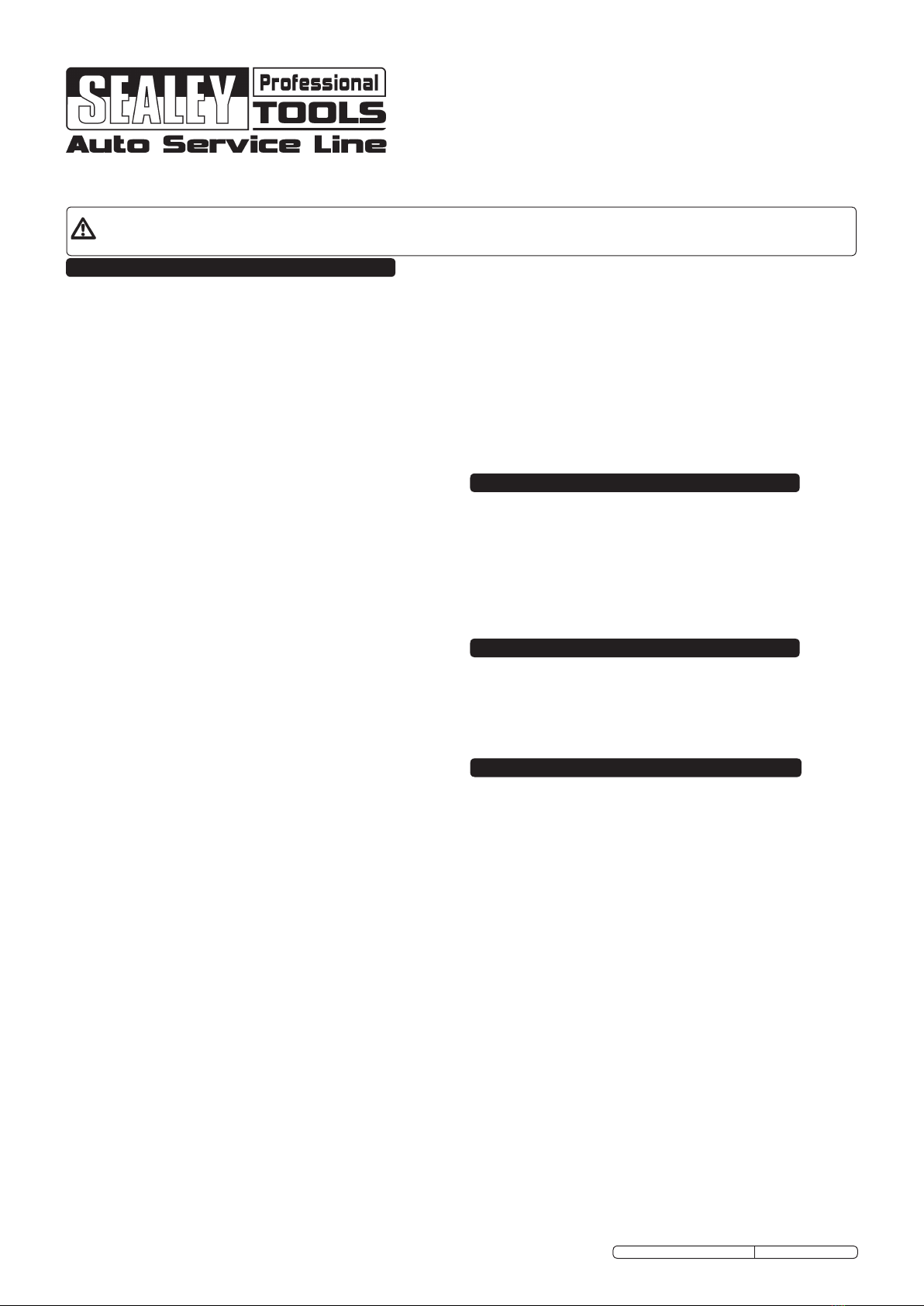

Note: This product is designed to be hard wired into a building

electrical circuit.

4.1.1. The power cable (not supplied) is wired to the unit through the

power supply connection box (refer to Fig.2 & Fig.3). A wiring

diagram (Fig.1) is embossed inside the power supply

connection box cover as a guide to the correct connection of

the power cable.

4.2. WALL MOUNTING. The exhaust extractor should be mounted

in such a position that it will not cause an obstruction or

present a hazard in the work area.

4.2.1. The exhaust extractor should be fixed to a brick or concrete

wall through the wall mounting holes in the extractor main

body using fixings that will adequately support the weight of

the unit and the hosing. If in any doubt, seek professional

advice.

4.2.2. Suitable ducting (not supplied) should be used to pass the

exhaust gases from the outlet (refer to Fig.2 & Fig.3) to a safe

environment. The ducting should be kept as straight and level

as is practical to allow unrestricted egress of the exhaust

gases.

4.2.3. Attach the heat resisting hosing to the inlets (refer to Fig.2 &

Fig.3) and to the cones using the clamps supplied.

1.1. ELECTRICAL SAFETY

WARNING! It is the responsibility of the owner and the operator

to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they

are safe. You must inspect power cables, plugs, sockets and any

other connectors for wear or damage. You must ensure that the risk

of electric shock is minimised by the installation of appropriate safety

devices. A Residual Current Circuit Breaker (RCCB) should be

incorporated in the main distribution board. We also recommend that

a Residual Current Device (RCD) is used. It is particularly important

to use an RCD with portable products that are plugged into a supply

which is not protected by an RCCB. If in any doubt consult a

qualified electrician. You may obtain a Residual Current Device by

contacting your Sealey dealer. You must also read and understand

the following instructions concerning electrical safety.

1.1.1. The Health & Safety at Work Act 1974 makes owners of

electrical appliances responsible for the safe condition of

those appliances and the safety of the appliance operators. If

in any doubt about electrical safety, contact a qualified

electrician.

1.1.2. Ensure that the insulation on all cables and on the appliance

is safe before connecting it to the power supply.

1.1.3. Ensure that cables are always protected against short circuit

and overload.

1.1.4. Regularly inspect power supply cables and plugs for wear or

damage and check all connections to ensure that none is loose.

1.1.5. Important: Ensure that the voltage marked on the appliance

matches the power supply to be used.

1.1.6. DO NOT use worn or damaged cables, plugs or connectors.

Immediately have any faulty item repaired or replaced by a

qualified electrician.

1.2. GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and

general workshop practice regulations are adhered to when

using this equipment.

Familiarise yourself with the application, limitations and

potential hazards of the extractor.

WARNING! Disconnect the unit from the mains power

before servicing or performing any maintenance.

Maintain the extractor in good condition (use an authorised

service agent).

Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the

warranty.

Locate the extractor in a suitable working area, keep area clean

and tidy and free from unrelated materials. Ensure there is

adequate lighting.

Ensure there are no flammable or combustible materials near

the work area.

WARNING! The exhaust gases from the outlet of the fan

will be hot.

Ensure that ducting is not located close to any flammable

materials

Ensure that the material used for the ducting from the outlet is

heat resistant and flame retardant.

Ensure that the exhaust gases are released outside of the

workshop building.

Regularly check exhaust hosing and ducting for leaks.

Ensure that there is a vacuum at the extractor cone before

connecting to the vehicle exhaust pipe.

Keep children and unauthorised persons away from the working area.

DO NOT use the extractor for a task it was not designed to

perform.

.

DO NOT operate the extractor if any parts are damaged or

missing as this may cause failure or possible personal injury

DO NOT get the extractor wet or use in damp or wet locations

or areas where there is condensation.

DO NOT allow untrained persons to operate the extractor.

DO NOT operate the extractor when you are tired or under the

influence of alcohol, drugs or intoxicating medication.

DO NOT use the extractor where there are flammable liquids,

solids or gases such as paint solvents, etc.

DO NOT leave the extractor operating unattended.

When not in use switch the extractor off and disconnect

from the power supply.