9L MANUAL/AIR VACUUM OIL & FLUID

EXTRACTOR

MODEL NO: S01168

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are strictly adhered to when using this

equipment.

WARNING! Disconnect the extractor from the air supply before changing accessories, servicing or performing any maintenance.

WARNING!

Ensure that you wear protective clothing, gloves, goggles, face mask as appropriate for the fluid being extracted.

9Keep the extractor clean and maintain it in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Check extractor connections and fittings before use. When the extractor is turned on check that there are no leaks.

9Ensure that the extractor’s tank capacity exceeds the amount of fluid to be collected.

9Avoid unintentional starting of the extractor and ensure that the end of the suction tube is fully submerged in the fluid before operating.

9Keep the work area clean, uncluttered and ensure there is adequate lighting.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Keep children and unauthorised persons away from the working area.

9Dispose of waste fluids in accordance with local authority regulations.

9Use only to extract engine or transmission oils, or similar NON-corrosive fluids. Unit may also be used for the transfer of water.

WARNING! DO NOT allow uncontrolled discharge of fluids thus polluting the environment.

8DO NOT pull or yank any pipes or hoses and DO NOT attempt to move the extractor by pulling the hose.

8DO NOT leave the extractor operating unattended.

8DO NOT use to extract hazardous or harmful chemicals, solvents, petrol, diesel, kerosene, alkaline or acids. If by chance such fluids

are used in the unit, it must be immediately drained and thoroughly cleaned. Use with prohibited fluids will invalidate your warranty.

8DO NOT store fluids in the extractor’s tank. After extracting fluid, it must be emptied into an approved receptacle as soon as possible.

8DO NOT dismantle, tamper or adapt the extractor for any purpose other than for which it is designed.

8DO NOT store in areas of high temperature, direct sunlight, rain or snow.

8DO NOT leave the unit in a pressurised state.

WARNING! When the extractor’s tank contains liquid that is under pressure DO NOT remove or insert the extension tube connector into

the inlet/outlet fitting as this may result in a sudden discharge of liquid that could be dangerous.

9Always press the pressure relief button before connecting or disconnecting the extension tube.

DO NOT direct the air line at yourself or others.

2. INTRODUCTION

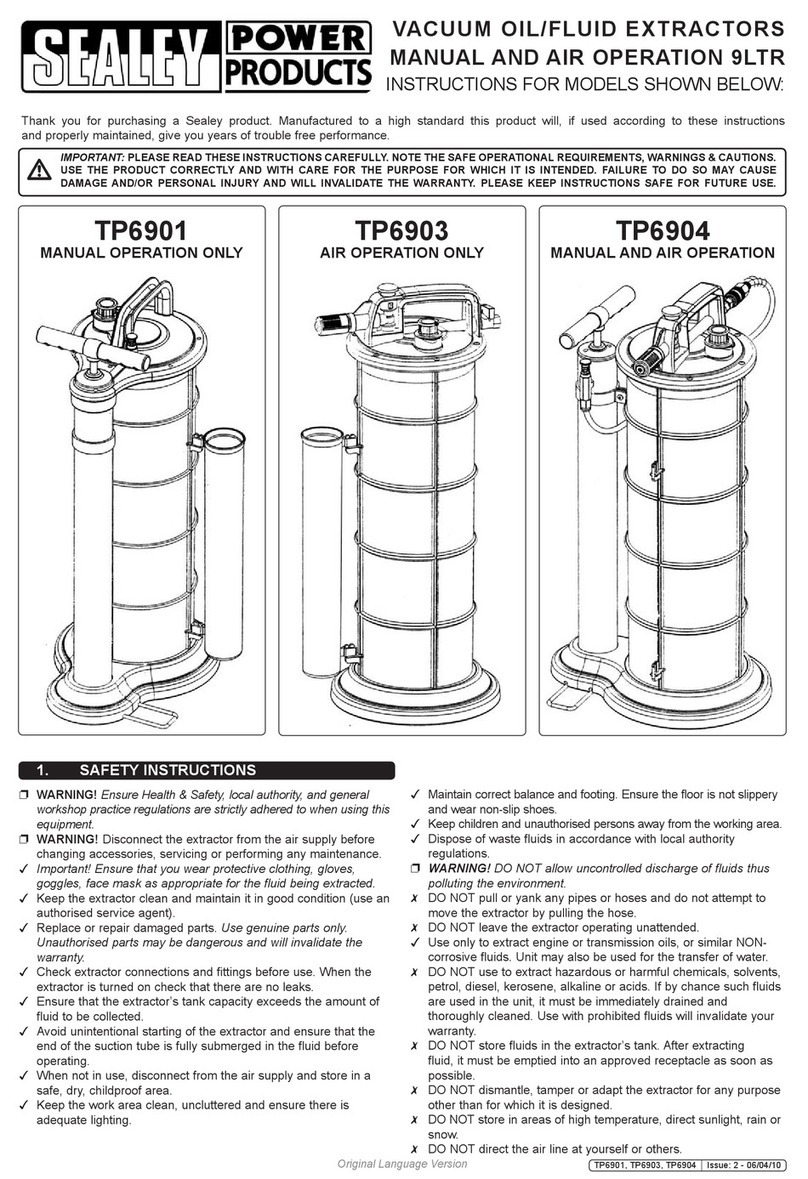

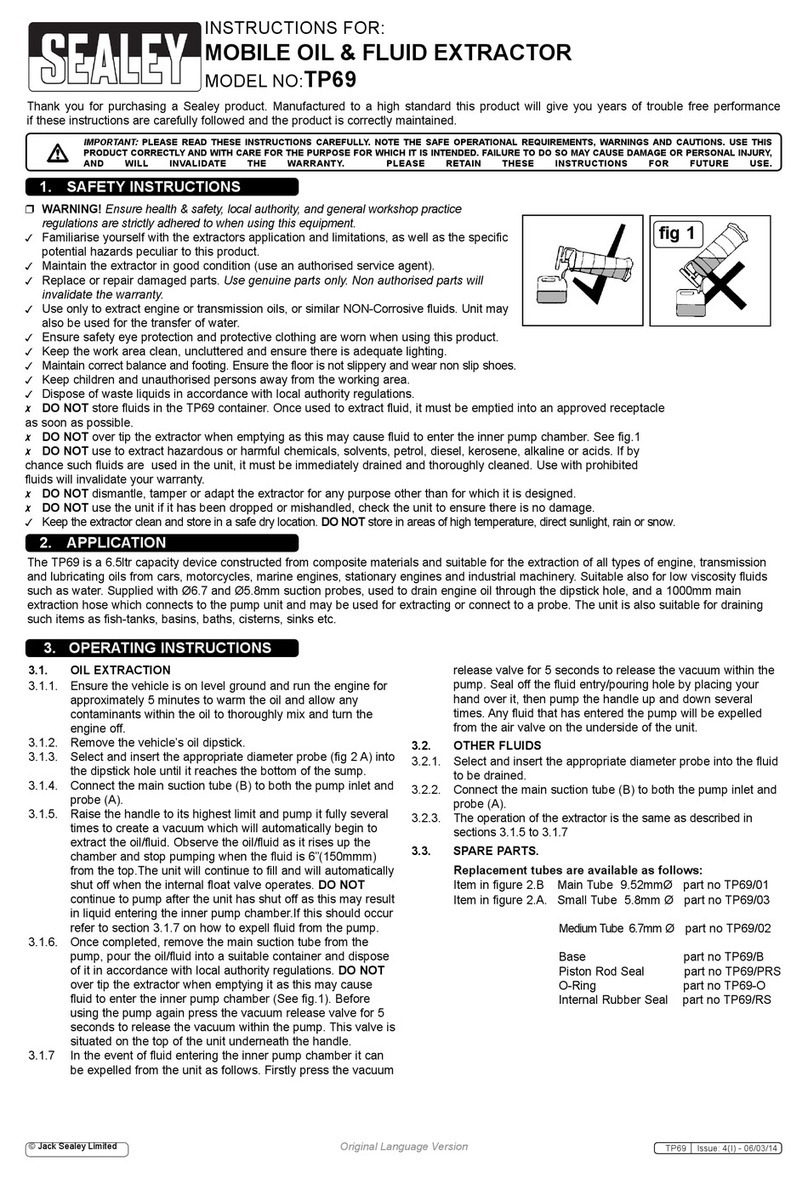

9L Capacity device constructed from composite materials. Uses manual pump or compressed air supply to generate vacuum.

Suitable for the extraction of all types of engine, transmission and lubricating oil from cars, motorcycles, marine engines, stationary

enginesandindustrialmachinery.Alsosuitableforlowviscosityuidssuchaswater.SuppliedwithØ4,Ø6,Ø8x1000mmsuction

probes,Ø10x1000mmextensiontubeand1200mmbrakebleedtube.Usesprobestoextractengineoilthroughthedipsticktube.

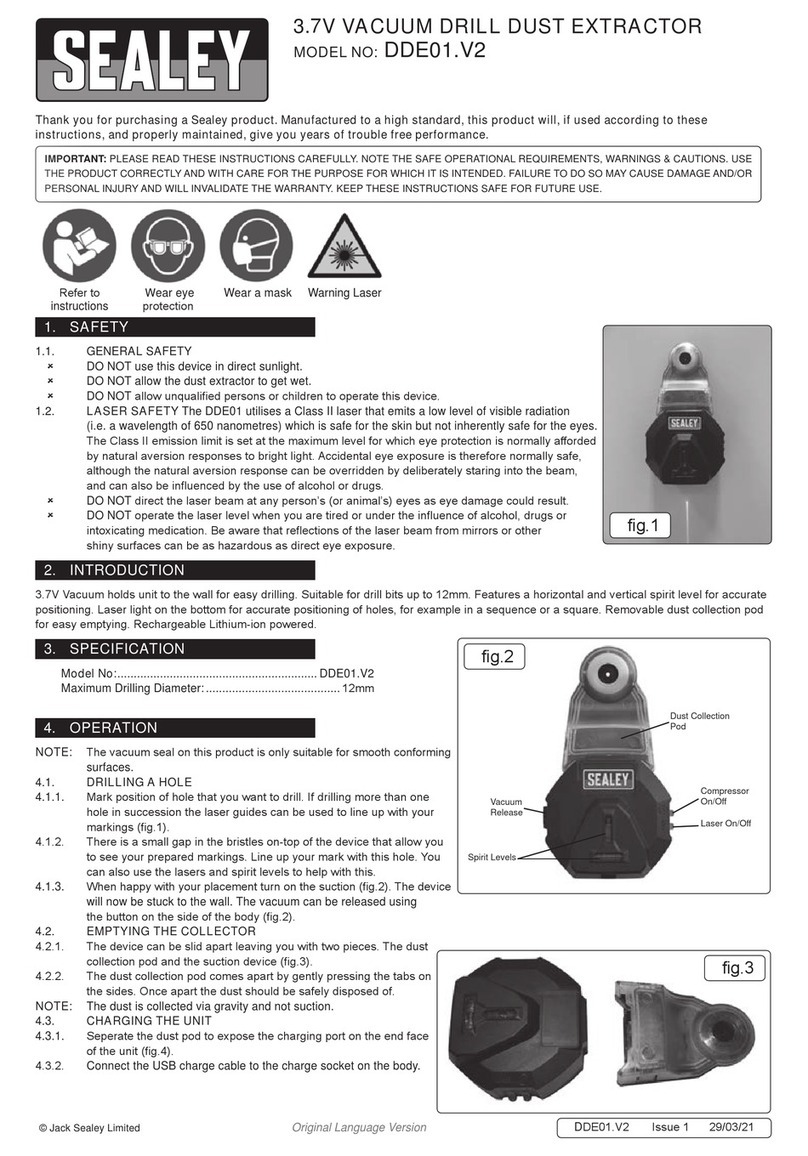

3. SPECIFICATION

Model: ........................................................................ S01168

Capacity:........................................................................... 9 L

Suction probes: Ø4x1000,Ø6x1000,Ø8x1000mm,1200mmBrakebleedtube

Extension hose: .............................................Ø10x1000mm

Supply:................................................................ 90psi(5cfm)

4. AIR SUPPLY

When using a workshop air supply, the recommended hook-up is shown below.

4.1. Ensure that the air valve (see fig.3) is in the “off” position before connecting to the air supply.

4.1.1. You will require an air pressure and an air flow (cfm) according to the specification.

WARNING! Ensure the air supply is clean and does not exceed the pressure quoted.

WARNING! Too high an air pressure and/or unclean air will shorten the life of the extractor due to excessive wear and may be

dangerous, causing damage and/or personal injury.

S01168Issue125/10/19

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear eye

protection

Wear protective

gloves