Specication

Model No: ................................................................................................................................................. VS870.V2

Rubber Cone Diameter:.........................................................................10-45mm, 30-65mm, 50-85mm, 70-100mm

Power Supply: ....................................... ........................................................................................................ 12V dc

Air Supply: .............................................................................................................................................. 14psi (1bar)

Oil Type: .........................................................................................................................................Mineral (baby) oil

Oil Reservoir Capacity:.......................................................................................................................................75ml

Heating Duration:.....................................................................................................................................4¾ minutes

Hose Length: ................................................................................................................................................2600mm

Power Lead Length: ........................................................................................................................................... 4mtr

Machine Weight:................................................................................................................................................7.2kg

Smoke Output Pressure: ............................................................................................................. Approximately 1psi

4. OPERATION

WARNING: Wearglovestohandlethebreglasselement/wicktoguardagainstglassbrespenetratingtheskin.

4.1 Beforeinitialuse,soakthebreglasselement/wickinmineral(baby)oil.Failuretocarrythisoutwillleadtothebreglasselementburning

out immediately.

The breglass element is considered to be a consumable item and is not covered by warranty.

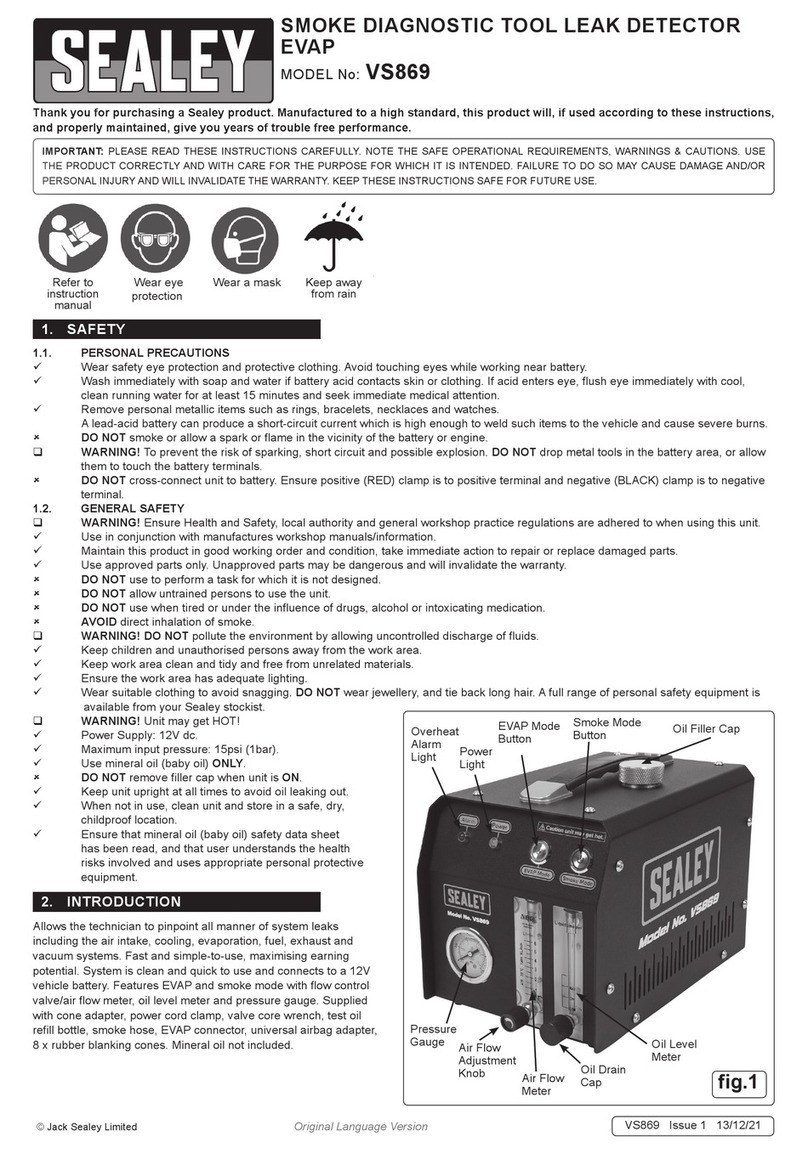

4.2 Taketopooilller(g.1)andllwithmineralbasedbabyoil(maximum:75ml).Thesightglassontheright-handsideoftheunitshows

the oil level.

4.3 Connecttoworkshopairsupplyusingthequickconnectorontheleft-handsideoftheunit(seeg.1).Theinletairpressureneedstobe

regulated to no more than 14psi (1bar).

4.4 Connect to 12V battery; green indicator light will show.

4.5 Press Heater Button on front of unit; red light will show indicating that the heater element is active. The heater element is timed to operate

for 4¾ minutes,afterwhichtimeitwillswitchoautomatically.

DO NOT removetheoilllercapwhilsttheunitisoperatingorisconnectedtoanairsupplyasthiswillcauseoil(whichcouldbehot)tobe

forcedfromthellerneck.

4.6 Fromcold,theheatermayneedtobeactivatedmorethanoncetoachievetherequiredtemperaturenecessaryforvaporisation.

4.7 Oncesmokeisstartingtoissuefromthehoseitmaybenecessarytotemporarilyincreasetheairowusingairowcontrol(g.1).Thiswill

clear any excess oil.

4.8 Therequiredvolumeofsmokecanbeachievedbyadjustingtheairowrate,usingtheairowcontrolandgaugeforreference.

4.9 The smoke produced can be used in many ways to indicate the presence of leaks in either pressure or vacuum systems. When smoke is

introducedintothelocalityofthesuspectedleak,itwillbecarriedbytheowofaireithertoorfromtheaperture,dependingonthesystem.

Observing the behaviour of the smoke will pinpoint the problem.

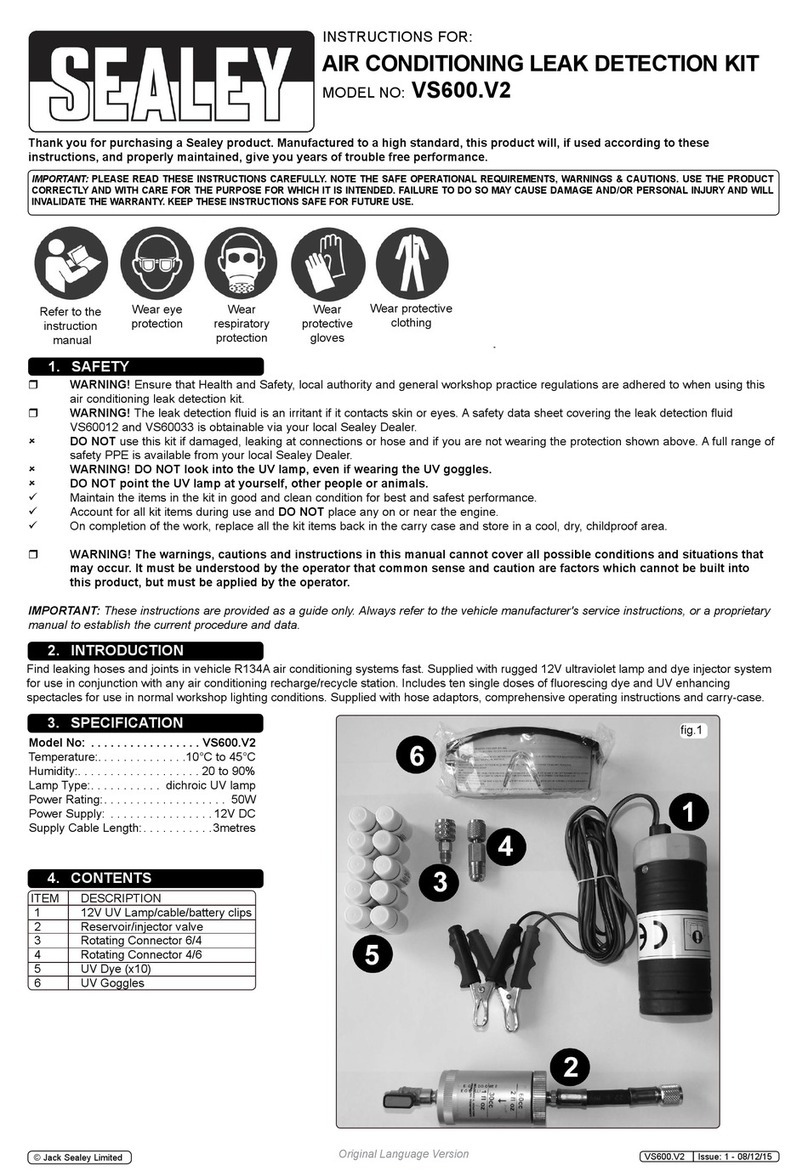

4.10 Alternatively, smoke can be introduced into ducting by unfastening one end of the duct and plugging with a suitable rubber cone from

thoseincludedinthekit(seeg.2).Thehosefromthemachinecanthenbecoupledtothebushintheconeandtheductlledwithsmoke.

Any leak will be displayed by a jet of smoke coming from it.

4.11 The amount of smoke needed will vary with the capacity of the system being investigated.

4.12 If the smoke starts to dwindle, the heater element will need to be switched on for a further time.

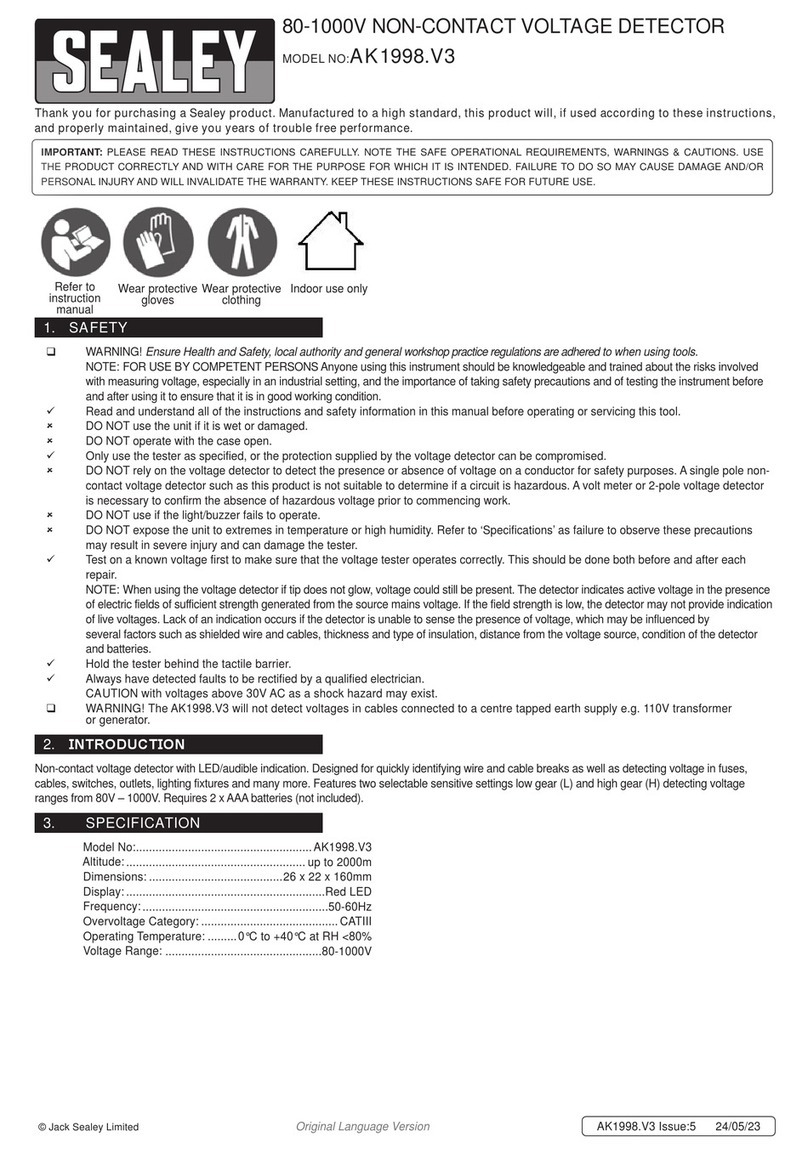

g.2 Rubber Cone Dimensions

● Allowsthetechniciantopinpointallmannerofsystem

leaks including air intake, cooling, evaporation, fuel,

exhaust and vacuum systems.

● Fastandsimpletouse,maximisingearningpotential.

● Featuressinglebuttonoperation,flowcontroland

auto power-off.

● Usesmineraloilandworkshopairsupplyto

generate smoke at low pressure whilst connected

to a vehicle.

● Systemiscleanandquicktouseandconnectstoa

12V vehicle battery.

● Fourrubberconesincluded.

● Mineraloilnotincluded.

2. INTRODUCTION

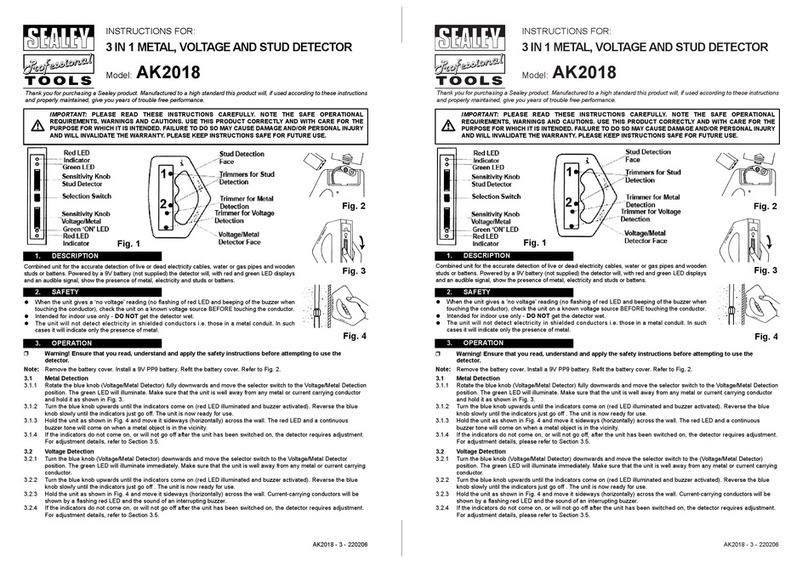

g.1

3. SPECIFICATION

VS870.V2 | Issue 2 (4) 21/03/18

Original Language Version

© Jack Sealey Limited