SealMaster SK300 User manual

S:\Engineering\13-Operator Manuals\Current\HANDAGITATOR_V2.0_JUNE2019.docx

HAND AGITATED MIXING TANK

Owner’s Manual

Version 2.0

Issue Date: June 2019

Effective Date: April 2019

Version

Date

Changes

Approval

1.0

Original Issue

2.0

6/19

New Format and Updates

DS

Table of Contents

CORRESPONDENCE ............................................................................................................. 2

SealMaster® LIMITED WARRANTY ..................................................................................... 3

SAFETY PRECAUTIONS AND CAUTIONS ............................................................................. 4

PRECAUTIONS................................................................................................................... 4

CAUTIONS......................................................................................................................... 4

MANUAL COVERAGE........................................................................................................... 5

HAND AGITATED MIXING TANK SKID AND TRAILER MOUNTED ...................................... 5

OPERATING INSTRUCTIONS................................................................................................ 6

CHECKLIST......................................................................................................................... 6

BEFORE STARTING THE ENGINE ....................................................................................... 6

STARTING THE ENGINE..................................................................................................... 7

ADDING MATERIAL........................................................................................................... 8

POURING MATERIAL......................................................................................................... 8

MACHINE MAINTENANCE................................................................................................... 9

MAINTENANCE SCHEDULE ............................................................................................... 9

TROUBLE SHOOTING ...................................................................................................... 10

WIRING DIAGRAMS .......................................................................................................... 11

ELECTRIC BRAKES AND RUNNING LIGHTS......................................................................11

TANK CAPACITY CHART .................................................................................................... 12

MATERIAL DEPTH AND GALLON VOLUME ..................................................................... 12

MACHINE PICTURES AND PARTS LIST ..............................................................................13

PARTS LIST PICTURE-1 .................................................................................................... 14

PARTS LIST PICTURE-2 .................................................................................................... 15

PARTS LIST PICTURE-2 .................................................................................................... 16

PARTS LIST PICTURE-3 .................................................................................................... 17

PARTS LIST PICTURE-4 .................................................................................................... 19

PARTS LIST PICTURE-5 .................................................................................................... 20

2

ThorWorks Industries, Inc.

Purchased by __________________________ Model NO. _______________________

Company Name _______________________ Serial NO. _______________________

Address ________________________________ Acceptance Date ________________

City _____________ State______ Zip _______

CORRESPONDENCE

All Correspondence regarding this equipment, as well as general correspondence should be addressed to:

ThorWorks Industries, Inc.

PO Box 2277

Sandusky, OH 44870

In referring to the equipment, kindly state the Model Number, Serial Number and any part number involved

`

3

SealMaster® LIMITED WARRANTY

SealMaster warrants that its products are of quality material and workmanship. SealMaster

agrees to replace, within a period of one (1) year from date of delivery, or at its option, repair,

without charge, any part of their manufacture which proved defective. The repair or

replacement will be free of charge F.O.B. Sandusky, Ohio, proving the damaged part or parts

are returned, freight prepaid, to SealMaster and investigation show such repair or replacement

is made necessary by an inherent defect of material or workmanship.

It is hereby understood that engines, motors, pumps, or other components purchased by

SealMaster for use on its equipment are not warranted by SealMaster and are sold only with

the standard warranty of the manufacturer of that component.

SealMaster will make no allowances for repairs or alterations completed by outside sources

unless authorization is in writing and approved by an authorized SealMaster representative.

Any claims for defective material or workmanship must be made prior to the expiration of thirty

(30) days from the date failure occurs, and in all cases prior to the expiration of the warranty

period of one (1) year. It is the intent of this paragraph to limit SealMaster’s liability solely to

the cost of replacement parts, F.O.B. factory, or at the option of SealMaster to repair of the

defective part or parts. No allowances for damages, lost time, or any other claim will be

recognized.

This warranty is null and void if other than genuine SealMaster parts are used.

SealMaster is constantly striving to improve their products. Changes in design and

improvement will be made whenever the manufacturer believes the efficiency of the product

will be improved, without incurring any obligation to incorporate such improvements in any

machines which have been shipped or are in service.

In an effort to continue to improve product quality, SealMaster reserves the right to change

specifications without notice.

Any modification or alteration of this machine without prior approval of the manufacturer may

void this warranty.

4

SAFETY PRECAUTIONS AND CAUTIONS

PRECAUTIONS

•Always wear eye and ear protection, and gloves.

•Be aware of all CAUTION, WARNING, DANGER signs on the unit.

•Read all Owners Manuals that come with this unit.

•Make sure the operator is familiar with the units’ operation.

CAUTIONS

•Keep hands, feet, and clothing away from moving parts.

•Do not operate the machine without all guards in place.

•Stop the Agitator when opening the lid for any reason.

5

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

MANUAL COVERAGE

HAND AGITATED MIXING TANK SKID AND TRAILER MOUNTED

This manual cover model sizes 300 and 575 gallon tanks.

SealMaster® Hand-Agitated Sealcoat Mixing Tanks set the industry standard for

skid mount and trailer mount hand-agitated sealcoat mix tanks.

SealMaster Hand-Agitated Sealcoating Mixing tanks are available in several sizes

and configurations. SealMaster Hand-Agitated Mixing Tank can be carried in the

back of a truck (skid mounted) or towed behind (trailer mounted).

Ideal for gravity flow sealcoat applications or a pump can be attached for spray

applications. SealMaster sealcoating equipment has set the sealcoating

equipment industry standards for quality, performance and durability for over 40

years.

6

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

WITH OPTIONAL HYDRAULIC AGITATION

OPERATING INSTRUCTIONS

STARTUP

CHECKLIST

•Check engine oil level. Follow manufacturers guidelines as to

type and frequency of changes.

•Check hydraulic oil level. Use grade AW68 hydraulic oil.

•Fill fuel tank with gasoline for engine.

BEFORE STARTING THE ENGINE

Make sure the agitator control valve #6 is in the neutral position.

6AGITATOR

CONTROL VALVE

7

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

WITH OPTIONAL HYDRAULIC AGITATION

OPERATING INSTRUCTIONS

STARTUP

STARTING THE ENGINE

•Set the fuel shutoff and choke levers to the on position.

•Set the throttle lever at ½ open.

•Set the engine on/off switch to on position.

•Pull start the engine.

•It is important that when you are done running the engine

that the fuel shutoff lever is turned to the off position. This keeps

gasoline from mixing with oil as you are driving.

Refer to the engine manual.

ENGINE

PULL START

HANDLE

CHOKE

FUEL

THROTTLE

ON/OFF

SWITCH

8

OPERATING INSTRUCTIONS

APPLIES TO ALL SK300, SK575 & TR300

WITH OR WITHOUT OPTIONAL HYDRAULIC AGITATION

ADDING MATERIAL

1. Open the material tank lid and add pavement sealer with or

without sand. Close the lid.

2. Turn the hand crank lever #25, or engage the hydraulic

agitator, until the sealer is mixed thoroughly.

3. Mix periodically during the day, to keep material consistent.

POURING MATERIAL

4. Open valve #21 to pour out sealer.

5. Apply Sealer with a squeegee or brush.

25 HAND

CRANK

21 VALVE 2”

9

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

MACHINE MAINTENANCE

MAINTENANCE SCHEDULE

Follow maintenance procedures listed on the engine manual.

MAINTAIN

8

HRS

1

WEEK

1

MONTH

6

MONTHS

1

YEAR

2

YEARS

CHECK ENGINE OIL

LEVELS

CHECK HYDRAULIC OIL

LEVELS

CHANGE

HYDRAULIC OIL *

CHANGE HYDRAULIC OIL

FILTER

CLEAN HYDRAULIC

SUCTION STRAINER

CHECK BREAKAWAY BOX

BATTERY

CHECK TIRE PRESSURE

INSPECT ALL HOSES

* Use a good quality AW68 hydraulic oil with a rating of 352 SUS @100 F. Do not

use a 150 rated hydraulic oil as it is too light.

10

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

MACHINE MAINTENANCE

TROUBLE SHOOTING

PROBLEM

ENGINE

ISSUES

CHAINS NOT CONTACTING

SPROCKETS PROPERLY

OPTIONAL HYDRAULIC

AGITATION

DOES NOT ROTATE

POSSIBLE CAUSES/SOLUTIONS

OIL SPECIFICATIONS / REFER TO OWNER’S MANUAL

OPERATING INSTRUCTIONS / REFER TO OWNER’S MANUAL

FUEL IN OIL CRANKCASE / FUEL SHUT-OFF VALVE IN

OFF POSITION WHEN FINISHED

CHAIN TENSION IMPROPERLY ADJUSTED / ADJUST CHAIN TIGHTENER

SPROCKET TEETH BROKEN / REPLACE SPROCKET

SHUTOFF VALVE IS CLOSED / OPEN VALVE

HYDRAULIC OIL LOW / FILL OIL LEVEL 4” FROM TOP OF TANK

HYDRAULIC AGITATOR MOTOR NOT WORKING / REPLACE AGITATOR MOTOR

COUPLER KEY / REPLACE THE SHEARED KEY

CHAIN BROKEN / REPLACE THE CHAIN

HYDRAULIC PUMP NOT WORKING / HAVE TESTED OR REPLACED

11

WIRING DIAGRAMS

ELECTRIC BRAKES AND RUNNING LIGHTS

WHITE

BLUE

BLUE

BLUE

BLUE

BLUE / BLACK

GREEN / BROWN

BROWN

YELLOW / BROWN

BROWN

GREEN / BROWN

BROWN

YELLOW / BROWN

BROWN

WHITE

WHITE

12

TANK CAPACITY CHART

GALLONS ARE APPROXIMATE AND MAY VARY SLIGHTLY TANK TO TANK

MATERIAL DEPTH AND GALLON VOLUME

MATERIAL

DEPTH

300

GALLONS

41"x54"

575

GALLONS

48"x74"

MATERIAL

DEPTH

300

GALLONS

41"x54"

575

GALLONS

48"x74"

INCHES

GALLONS

GALLONS

INCHES

GALLONS

GALLONS

1

2

3

25

197

305

2

6

8

26

206

321

3

10

15

27

216

336

4

15

23

28

225

351

5

21

32

29

233

366

6

28

42

30

242

381

7

35

52

31

250

396

8

42

64

32

258

411

9

50

75

33

266

425

10

58

87

34

274

439

11

67

100

35

281

453

12

75

113

36

287

466

13

84

127

37

293

479

14

93

141

38

298

492

15

102

155

39

303

504

16

112

169

40

307

516

17

121

184

41

309

527

18

130

199

42

538

19

140

214

43

548

20

150

229

44

557

21

159

244

45

565

22

169

259

46

571

23

178

274

47

577

24

188

290

48

580

13

HAND AGITATED MIXING TANK

MODEL TR300

MACHINE PICTURES AND PARTS LIST

PICTURE-1

4/5 TAIL LIGHTS

6TORSION AXLE

12 MARKER

LIGHTS

1MANHOLE

COMPONENTS

7TIRE & WHEEL

ASSEMBLY

10 PINTLE EYE COUPLER

11 BALL COUPLERS

13 SAFETY CHAIN

14 HOOK

9TRAILER JACK

8SAFETY

BREAK AWAY

15 PLUG

2AGITATOR

RUBBER

3BACKING

STRIP

14

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

PARTS LIST

PARTS LIST PICTURE-1

ITEM #

PART#

QTY.

DESCRIPTION

MANHOLE COMPONENTS

1

P639B004

1

RETAINING RING WITH SPLASH GUARD

P639B005

1

LID MANHOLE WITH VENT –DRIP EDGE

P639A009

1

GASKET-MANHOLE LOW TEMPERATURE

P639A006

1

LATCH &HARDWARE

2

P459A013

3

SK 575 AGITATOR RUBBER

P459A017

2

SK 300 AGITATOR RUBBER

3

P72000B012

2/3

BACKING STRIP

PARTS LIST –TRAILERS ONLY

* DENOTES YOUR CHOICE

ITEM #

PART#

QTY.

DESCRIPTION

4

P516A025

1

LEFT SIDE TAIL LIGHT

5

P516A024

1

RIGHT SIDE TAIL LIGHT

6

P511A013

1

TORSION AXLE

7

P514A017

2

TIRE AND WHEEL ASSEMBLY

8

P518A004

1

SAFETY BREAK AWAY KIT

9

P551A008

1

JACK SCREW ASSEMBLY

10

P646A003

*

PINTLE EYE COUPLER

11

P553A008

*

2-5/16” BALL COUPLER

12

P467A016

2

AMBER MARKER LIGHTS

13

P531A004

2

SAFETY CHAIN

14

P517A002

2

HOOK (PART OF SAFETY CHAIN)

15

P519A007

1

TRAILER PLUG

15

HAND AGITATED MIXING TANK

MODEL SK 575

MACHINE PICTURES AND PARTS LIST

PARTS LIST PICTURE-2

ITEM #

PART#

QTY.

DESCRIPTION

16

P432A002

2

FLANGE BEARING 1” BORE

17

P426A001

1

SPROCKET 1” BORE

18

P1038A000

1

#40 CHAIN ROLLER (SOLD PER FOOT)

P1035A001

1

#40 MASTER LINK

19

P426A011

1

SPROCKET 1-1/2” BORE WITH 1/2" KEY

20

P50000A004

1

HAND CRANK ASSEMBLY (SPROCKET)

16 FLANGE

BRG. 1” BORE

16 FLANGE

BRG. 1” BORE

17 SPROCKET

1” BORE

17 SPROCKET

1” BORE

18 CHAIN AND

MASTER LINK

18 CHAIN AND

MASTER LINK

20 HAND

CRANK

22 HAND

CRANK

19 SPROCKET

1-1/2” BORE

17 SPROCKET

1” BORE

16

HAND AGITATED MIXING TANK

MODEL SK 575

PARTS LIST

PARTS LIST PICTURE-2

ITEM #

PART#

QTY.

DESCRIPTION

21

P397A002

1

2” VALVE

22

P50137B003

1

BEARING PLATE

23

P50137B002

1

BEARING SEAL

24

P434A003

2

4-HOLE FLANGE BEARING 1-1/2” BORE

22 BEARING

PLATE

24 FLANGE

BEARING

23 BEARING

SEAL

17

HAND AGITATED MIXING TANK

MODEL SK 300 & TR 300

MACHINE PICTURES AND PARTS LIST

PICTURE-3 SHOWN WITH DIRECT HAND CRANK

PARTS LIST PICTURE-3

ITEM #

PART#

QTY.

DESCRIPTION

25

P50000D001

1

HAND CRANK (DIRECT)

26

P50137B008

1

BEARING PLATE

27

P50137B009

1

BEARING SEAL

28

P432A003

2

2-HOLE FLANGE BEARING 1-1/4” BORE

25 HAND

CRANK

26 BEARING

PLATE

28 FLANGE

BEARING

27 BEARING

SEAL

18

HAND AGITATED MIXING TANK

APPLIES TO ALL SK300, SK575 & TR300

MACHINE PICTURES AND PARTS LIST

WITH OPTIONAL HYDRAULIC AGITATION

PICTURE-4

1Y-MOUNT

3HYD.

AGITATOR

MOTOR

2ENGINE

4HYD. OIL TANK

7HYDRAULIC

PUMP

6AGITATOR

CONTROL

VALVE

31 COUPLING

8JAW COUPLERS

& INSERT

9SUCTION STRAINER

10 PUMP MOUNT

BRACKET

5CLAMP

COUPLING

Other manuals for SK300

1

This manual suits for next models

2

Table of contents

Popular Other manuals by other brands

resi-linx

resi-linx HD-4001 digi-mod User guide and installation manual

Osaka

Osaka TERMOLOGGER USB-THR Installation and operation guide

NEC

NEC Slot-In PC with Intel Celeron 2 x 1.6 GHz CPU STv2 (Sandy... installation instructions

VLX

VLX 2911SR Operator's manual

DAHON

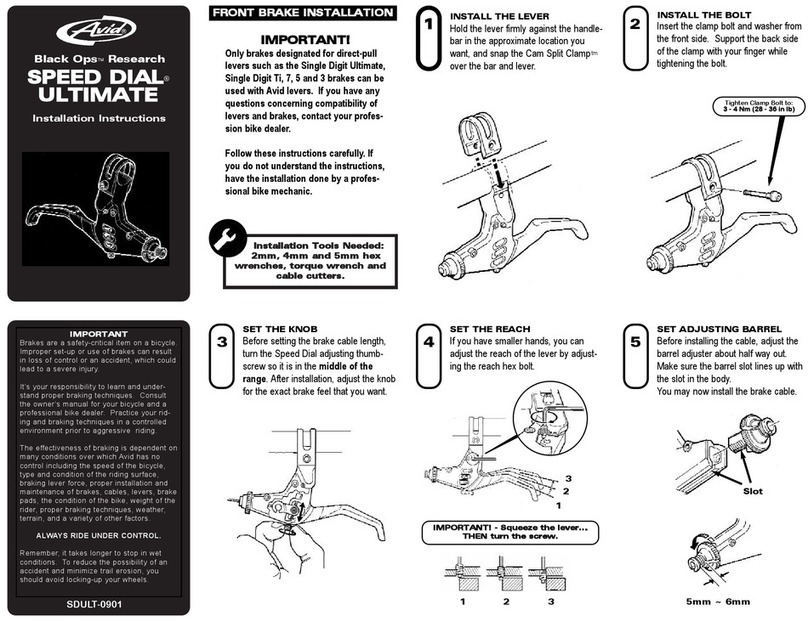

DAHON SPEED DIAL ULTIMATE installation instructions

Cress

Cress E1814 owner's manual