Description of appliance ............................................................................. 2

Contents .............................................................................................. 3

Technical data ............................................................................................ 4

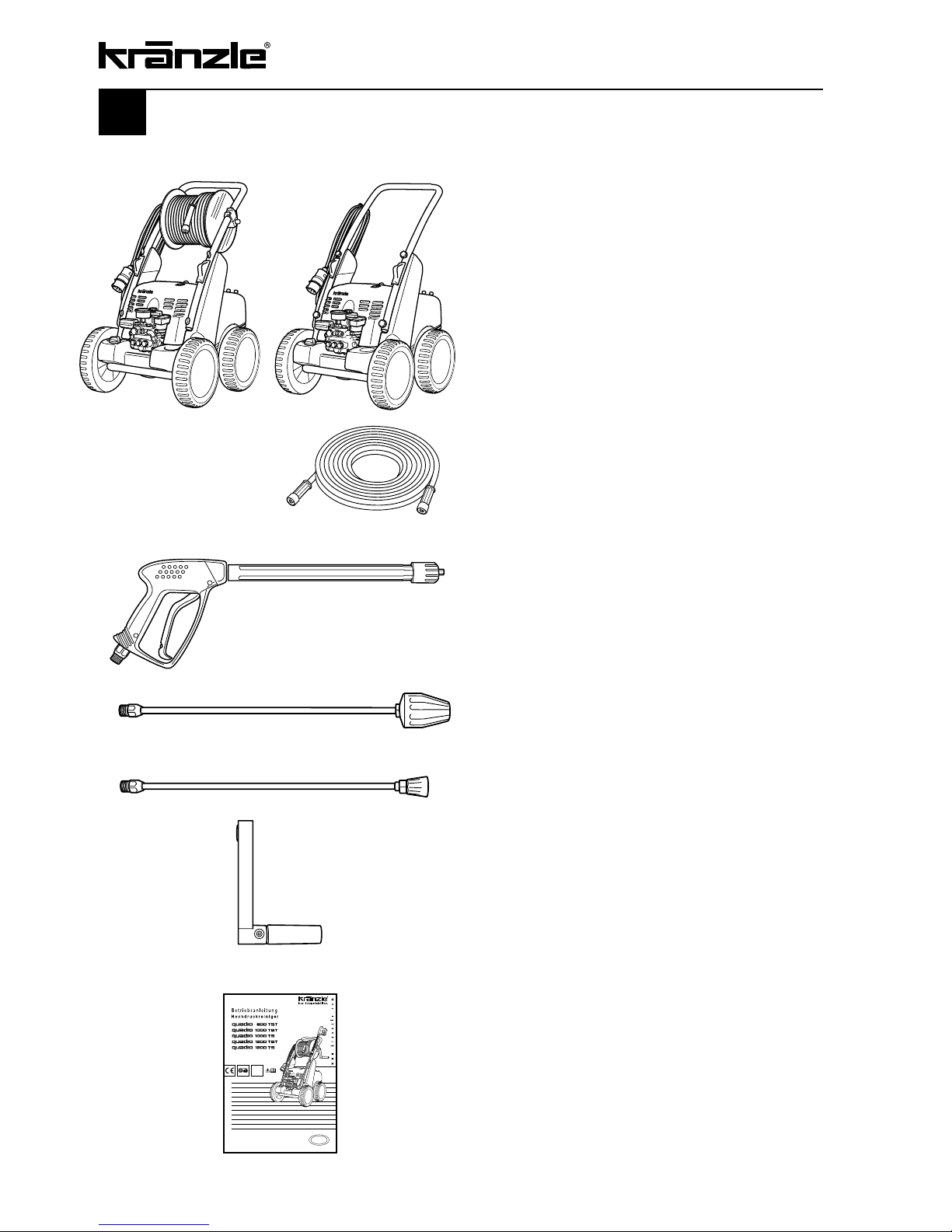

Overview 'This is what you have purchased' ................................................ 6

General rules ............................................................................................. 7

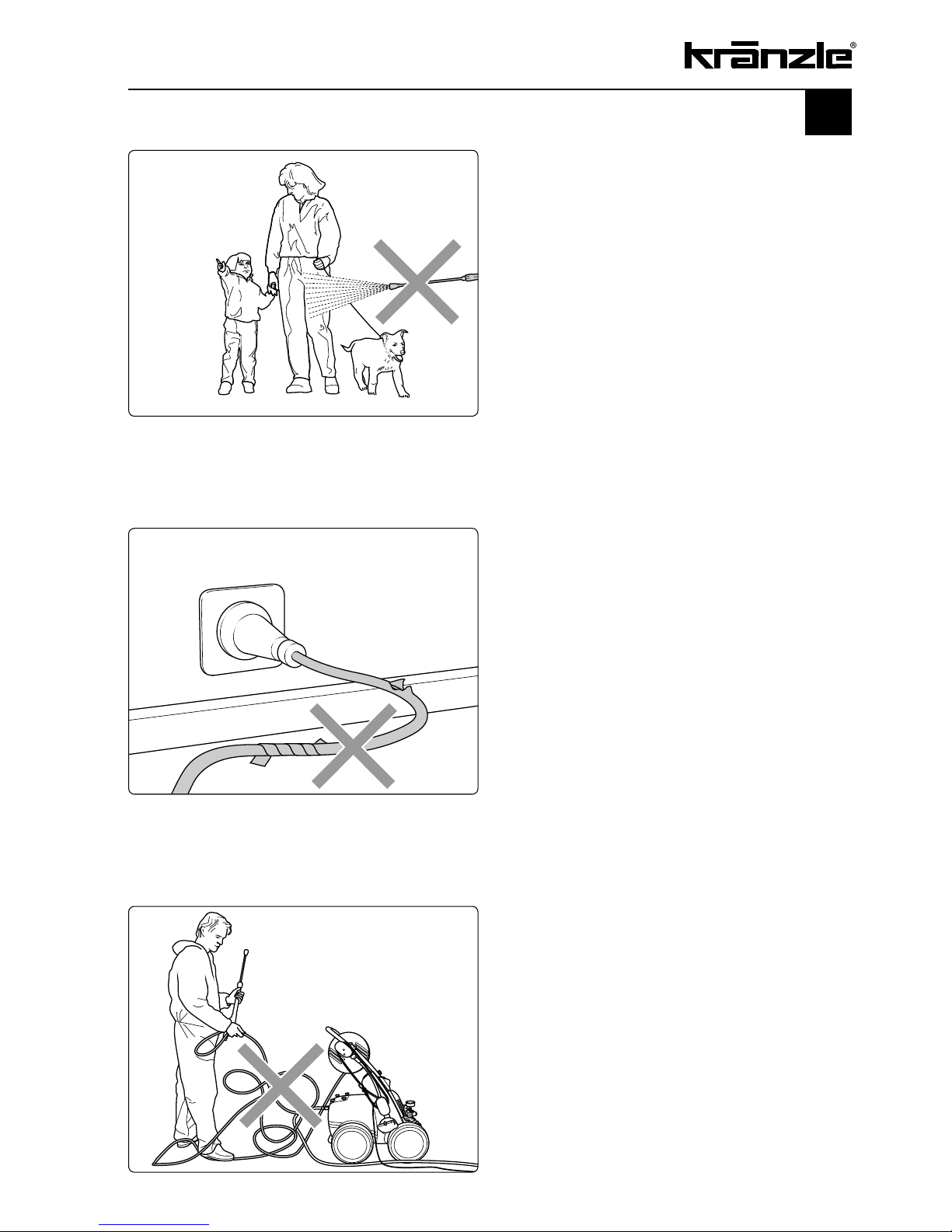

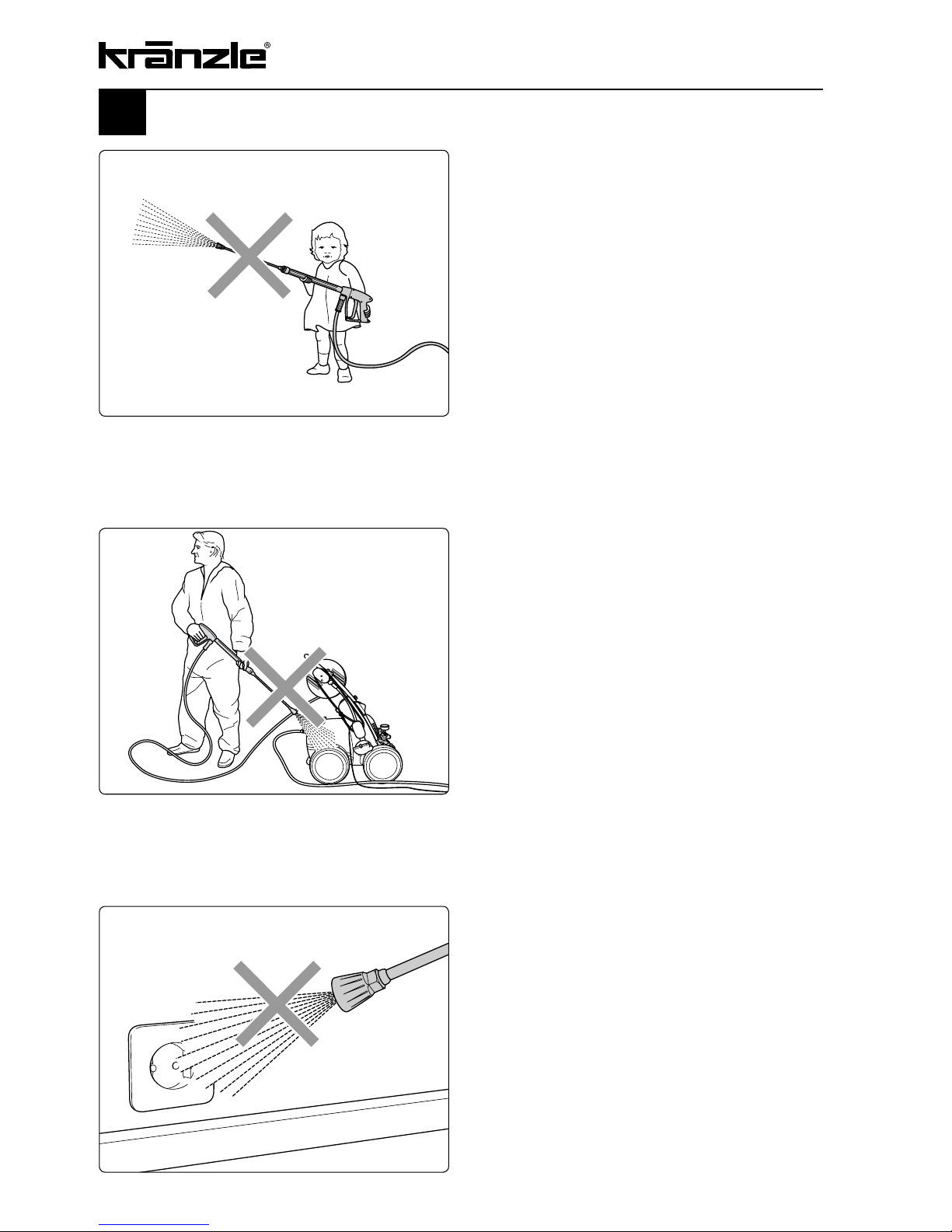

Safety precautions ...................................................................................... 8

That's what you have to observe ............................................................ 11

Kränzle- technology ................................................................................ 13

Water and cleaning system ...... ..............................................13

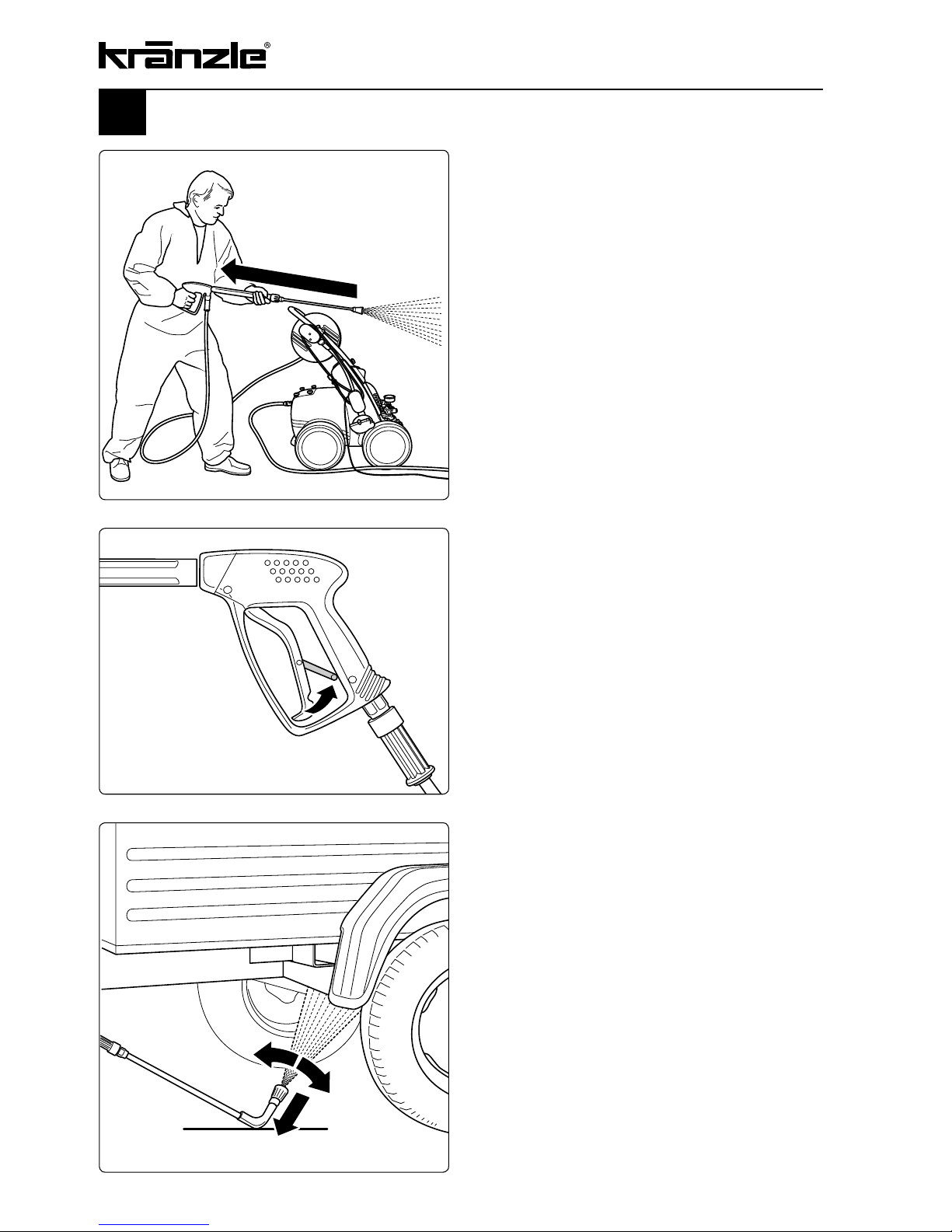

Lance and spray gun ............................................................. 13

Pressure control valve – safety valve ..................................... 13

Delayed motor cut-out ........................................................... 14

High pressure hose and spray device .................................... 14

Safety cut-out ....................................................................... 14

Putting into operation............................................................................. 15

Connection to water mains .................................................... 15

Direct suction ........................................................................ 20

When using detergents .......................................................... 21

To shut down the pump – frost protection .................................................. 22

Small repairs – do it yourself .................................................................... 23

EC – Declaration of Conformity ................................................................. 28

Guarantee ............................................................................................ 29

Accessories for high-pressure cleaners ..................................................... 30

Spare parts list ....................................................................................... 32

Complete assembly ............................................................... 32

Brake.................................................................................... 34

Water inlet ............................................................................ 35

Pump motor .......................................................................... 36

Pump transmission unit ......................................................... 38

Unloader valve and pressure switch ....................................... 40

Valve housing ....................................................................... 42

Hose drum ............................................................................ 44

Gun 'Starlet' with lance ......................................................... 46

Turbokiller with lance ............................................................ 47

Wiring diagramme .................................................................................... 48

Inspections – inspection reports ................................................................ 49

3

Contents Page