INSTRUCTIONS FOR

WHEEL REMOVAL TROLLEY 1200KG CAPACITY

MODEL NO: W1200T.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

9At least two people are required to assemble the trolley.

9Ensure that the vehicle to be worked on is safely supported on axle stands.

9Ensure that the trolley is in sound condition and good working order before use.

9Keep trolley clean for best and safest performance.

9Onlyusethetrolleyonrm,level,unobstructedsurfacewhichiscapableofsupportingthetrolleyandwheel.

9Ensure there is no risk of pinching in between moving parts.

9Ensure work area has adequate lighting.

9Keep work area clean and tidy and free from unrelated materials.

9Keep children and unauthorised persons away from the work area.

9Ensure all non essential personnel keep a safe distance when the trolley is in use.

8DO NOT overload the trolley - maximum capacity is 1200kg.

8DO NOT allow untrained persons to operate the trolley.

8DO NOT allow anyone to ride on the trolley.

8DO NOT use on tarmacadam as it may sink under load.

9DO NOTdrivetheunitoveredges,roughsurfacesetc.whenloaded,asthewholeunitmayoverturn.

8DO NOT use trolley for purposes other than for which it is designed.

8DO NOToperatethetrolleywhenyouaretiredorundertheinuenceofalcohol,drugsorintoxicatingmedication.

8DO NOT make any alterations to this device.

9AlwaysstandandoperatethewheeltrolleyfrombehindUprightTube(4),seeg.1.AlwaysmovetheWheelTrolleyusingoneHandle(20)

inthesocketonthelefthandside(asviewedintheg.1position)andtheotherHandle(19)intheSocketaboveLoweringPedal(A),see

g.2.

9Pushthewheelasfarontotherollersaspossible.

9Ensure that the load can not tilt whilst lowering or moving.

9Lower the wheel and secure it with the wheel support before transporting.

9It is of the greatest importance for safety that the wheel trolley is secured by the locking mechanism on the nearest hole before

manoeuvringtheunit.Ifthelockisnotused,thewheeltrolleycouldcomeapartwhilecarryingtheloadandthewheelcouldtipout.

9Maintaincorrectbalanceandfootingwhenmovingtrolleyandensurethattheoorisnotslippery.

9Wearsuitableclothingtoavoidsnagging.DO NOT wear loose jewellery and tie back long hair. A full range of personal safety equipment is

available from Sealey.

9Replace or repair damaged parts. Use only recommended parts. Unauthorised parts may be dangerous and will invalidate the warranty.

9Use a competent person to lubricate and maintain the trolley. DO NOTusebrakeuidtotopuphydraulicunit.Useapprovedhydraulicoil

only.

9Whennotinusestoretrolley,fullylowered,inasafe,dry,childproofarea.

WARNING!Failuretocomplywiththeseinstructionsmayresultinlossofload,damagetotrolleyorotherpropertyand/orpersonalinjury.

2. INTRODUCTION

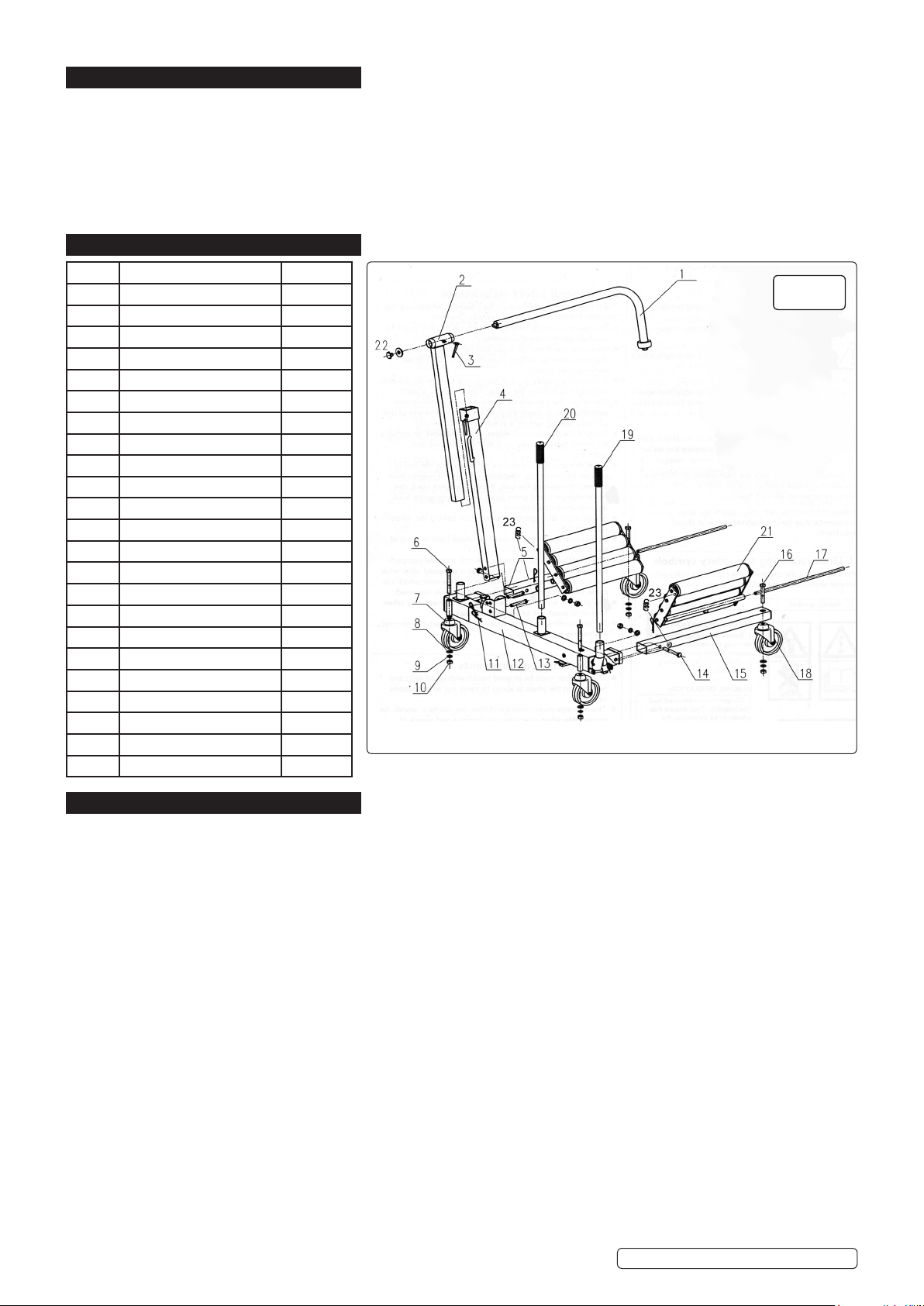

Eight adjustable rollers (4 each side) allow for easy turning of large deep tread tyres. Extra large jacking handle and hydraulic foot pedal allows

for one man operation. Safety bar with composite guard goes around wheel to ensure stability during transportation. Locking mechanism allows

rollerstobexedateightpre-setpositions.Mountedontwolockingcastersandtwonon-lockingforimprovedstabilityandeasymanoeuvrability.

Ideal for use on agricultural and commercial wheels and tyres.

BEFORE OPERATION

Beforeoperating,adjusting

orservicingthemachine,

it is important that each

operator carefully reads the

operating instructions.

DURING OPERATION

Always use the locking

mechanism which locks

the lifting rollers in position

before manoeuvring the

loaded wheel changer.

DURING OPERATION

Danger from unsecured

load. The operator must

ensure that wheels to be

carried by the machine are

correctly loaded and

supported in accordance

with the operating

instructions.

DURING OPERATION

Potentialslip/fallhazard.

Never stand or ride on the

wheel changer when

working with the machine.

W1200T.V2|Issue3(I)23/08/16

Original Language Version

© Jack Sealey Limited