SealMaster MasterMix Bulk User manual

S:\Engineering\13-Operator Manuals\Current\BULK TANKERS_V2.0_OCT_2021.docx

MASTERMIX™BULK STORAGE TANKS

Owner’s Manual

Version 2.0

Issue Date: May 2021

Effective Date: October 2021

Version

Date

Changes

Approval

1.0

5/21

Original Issue

DS

2.0

10/21

Motor - Material

JG

Table of Contents

CORRESPONDENCE .......................................................................................................................................4

SealMaster® LIMITED WARRANTY................................................................................................................5

SAFETY PRECAUTIONS AND CAUTIONS ........................................................................................................6

PRECAUTIONS ...........................................................................................................................................6

CAUTIONS .................................................................................................................................................6

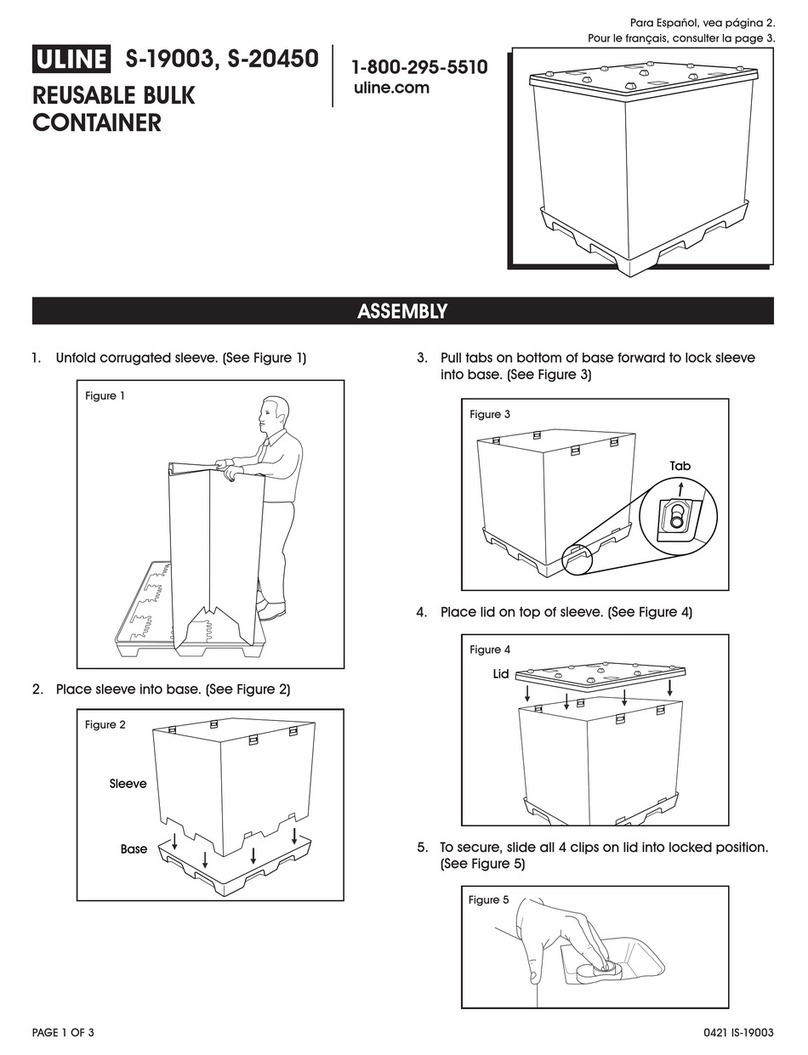

STARTUP........................................................................................................................................................7

1-STARTING THE ENGINE-HONDA.............................................................................................................7

2- BEFORE STARTING THE ENGINE-VANGUARD .......................................................................................8

3- STARTING THE ENGINE .........................................................................................................................8

4-AGITATOR ..............................................................................................................................................9

5-MATERIAL PUMP .................................................................................................................................10

MACHINE OPERATION ................................................................................................................................11

6-DISCHARGE MATERIAL OUT OF TANK..................................................................................................11

7-FILL MATERIAL IN TANK.......................................................................................................................12

MACHINE MAINTENANCE...........................................................................................................................13

MAINTENANCE SCHEDULE......................................................................................................................13

MAINTENANCE SCHEDULE –STEIN-O-GLAND ........................................................................................14

TROUBLESHOOTING GUIDE ....................................................................................................................15

TROUBLESHOOTING GUIDE-CHART........................................................................................................17

TANK CAPACITY CHART...............................................................................................................................18

MATERIAL DEPTH AND GALLON VOLUME..............................................................................................18

MACHINE PICTURES AND PARTS LIST .........................................................................................................20

PARTS LIST PICTURE-1 TANK...................................................................................................................20

PARTS LIST PICTURE-2 OPTIONAL ...........................................................................................................21

PARTS LIST PICTURE-3 STANDARD..........................................................................................................22

PARTS LIST PICTURE-4 STANDARD..........................................................................................................23

PARTS LIST PICTURE-5 OPTIONAL ...........................................................................................................24

PARTS LIST PICTURE-6 STANDARD & OPTIONAL.....................................................................................25

PARTS LIST PICTURE-7 PUMP W/ ELECTRIC MOTOR OPTIONAL.............................................................26

PARTS LIST PICTURE-8.............................................................................................................................27

PARTS LIST PICTURE-9.............................................................................................................................28

ROPER 2” PUMP 3617 HZ............................................................................................................................30

PARTS LIST...............................................................................................................................................30

3

PARTS LIST FOR 2” BOWIE PUMP OPTIONAL..........................................................................................31

PARTS LIST FOR 3” BOWIE PUMP OPTIONAL..........................................................................................33

PARTS LIST FOR 2” ARO PUMP OPTIONAL..............................................................................................34

PARTS LIST FOR SMALL-DIAPHRAGM PUMP...........................................................................................38

PARTS LIST FOR LARGE-DIAPHRAGM PUMP...........................................................................................40

PARTS FOR ELECTRICAL SET-UP ..................................................................................................................41

PARTS FOR PLUMBING..................................................................................................................................1

PICTURE-1 AGITATION ..............................................................................................................................1

PICTURE-2-CONTROL VALVES ...................................................................................................................2

PICTURE-3 3” BOWIE & HIGH SPEED MOTOR...........................................................................................3

PICTURE-4 FILTER PLUMBING ...................................................................................................................4

PICTURE-5 PUMP WITH C-FACE MOTOR ..................................................................................................5

PICTURE-6 PUMP WITH GAS ENGINE........................................................................................................6

4

ThorWorks Industries, Inc.

Purchased by __________________________ Model NO. _______________________

Company Name _______________________ Serial NO. _______________________

Address ________________________________ Acceptance Date ________________

City _____________ State______ Zip _______

CORRESPONDENCE

All Correspondence regarding this equipment, as well as general correspondence should be addressed to:

ThorWorks Industries, Inc.

PO Box 2277

Sandusky, OH 44870

In referring to the equipment, kindly state the Model Number, Serial Number and any part number involved

`

5

SealMaster® LIMITED WARRANTY

SealMaster warrants that its products are of quality material and workmanship. SealMaster

agrees to replace, within a period of one (1) year from date of delivery, or at its option, repair,

without charge, any part of their manufacture which proved defective. The repair or

replacement will be free of charge F.O.B. Sandusky, Ohio, providing the damaged part or parts

are returned, freight prepaid, to SealMaster and investigation shows such repair or

replacement is made necessary by an inherent defect of material or workmanship.

It is hereby understood that engines, motors, pumps, or other components purchased by

SealMaster for use on its equipment are not warranted by SealMaster and are sold only with

the standard warranty of the manufacturer of that component.

SealMaster will make no allowances for repairs or alterations completed by outside sources

unless authorization is in writing and approved by an authorized SealMaster representative.

Any claims for defective material or workmanship must be made prior to the expiration of thirty

(30) days from the date failure occurs, and in all cases prior to the expiration of the warranty

period of one (1) year. It is the intent of this paragraph to limit SealMaster’s liability solely to

the cost of replacement parts, F.O.B. factory, or at the option of SealMaster to repair of the

defective part or parts. No allowances for damages, lost time, or any other claim will be

recognized.

This warranty is null and void if other than genuine SealMaster parts are used.

SealMaster is constantly striving to improve their products. Changes in design and

improvement will be made whenever the manufacturer believes the efficiency of the product

will be improved, without incurring any obligation to incorporate such improvements in any

machines which have been shipped or are in service.

In an effort to continue to improve product quality, SealMaster reserves the right to change

specifications without notice.

Any modification or alteration of this machine without prior approval of the manufacturer may

void this warranty.

6

SAFETY PRECAUTIONS AND CAUTIONS

PRECAUTIONS

Always wear eye and ear protection, and gloves.

Be aware of all CAUTION, WARNING, and DANGER signs on the

unit.

Read all Owners Manuals that come with this unit.

Make sure the operator is familiar with the units’ operation.

Replace any hoses that show signs of wear, fraying, or splitting.

Be sure all fittings and joints are tight and leakproof.

Check all the nuts and bolts for tightness. Bolts and nuts are

machined tightened before leaving the factory. However, some

loosening may occur during shipment.

Do not do maintenance work on the machine while in operation.

The machine should not be left unattended when running.

CAUTIONS

Keep hands, feet, and clothing away from moving parts.

Do not operate the machine without all guards in place.

Do not operate Agitator with the chain guard removed.

Do not operate Agitator with Manhole cover open.

Open Manhole cover before pumping material out. This Tank is

equipped with an Air Vent and operating a Pump with the lid

closed may create a vacuum if the vent is plugged.

7

MASTERMIX™STORAGE TANKS

EQUIPPED WITH HONDA ENGINE

STARTUP

1- BEFORE STARTING THE ENGINE-HONDA

Note: Make sure you check the appropriate oil level.

Check Hydraulic Oil –Maintain level at 4 inches below tank top,

when COLD. See Hydraulic Oil in this section for proper oil grade.

Make certain the shut-off valve on the tank is open.

Check gas supply.

Be sure all hydraulic valves are in a neutral position.

STARTING THE ENGINE

Set the fuel shutoff and choke levers to the on position.

Set the throttle lever at ½ open.

Turn the engine switch to the start position.

It is important that when you are done running the engine that

the fuel shutoff lever is turned to the off position. This keeps

gasoline from mixing with the oil.

ENGINE

SWITCH

CHOKE

FUEL

THROTTLE

8

MASTERMIX™STORAGE TANKS

EQUIPPED WITH VANGUARD ENGINE

OPERATING INSTRUCTIONS

STARTUP

2- BEFORE STARTING THE ENGINE-VANGUARD

Note: Make sure you check the appropriate oil level.

Check Hydraulic Oil –Maintain level at 4 inches below tank top, when COLD. See

Hydraulic Oil in this section for proper oil grade. Make certain the shut-off valve

on the tank is open.

Check gas supply.

Be sure all hydraulic valves are in a neutral position.

3- STARTING THE ENGINE

Set the throttle and choke levers to the on position.

Set fuel shut-off to the on position.

Set the engine on/off switch to run position.

Start the engine.

It is important that when you are done running the engine that the fuel shutoff

lever is turned to the off position. This keeps gasoline from mixing with the oil.

CHOKE

FUEL SHUT-OFF

ON/OFF

STARTER

SWITCH

FUEL TANK

ENGINE

CORD

HANDLE

THROTTLE

CONTROL

9

MASTERMIX™STORAGE TANKS

OPERATING INSTRUCTIONS

STARTUP

4-AGITATOR

The agitator can operate in either direction. The agitator control

hydraulic valve #19 meters oil flow, which means how far the

lever handle is moved, determines rotation speed. Material left in

the tank should be agitated 10 to 15 minutes. Do not leave a sand

and sealer mixture in the tank without agitation for more than

one day.

19 AGITATOR

CONTROL HYDRAULIC

VALVE

AGITATOR CONTROL

LEVER HANDLE

10

MASTERMIX™STORAGE TANKS

OPERATING INSTRUCTIONS

STARTUP

5-MATERIAL PUMP

The material flow hydraulic valve #19 meters oil flow also, so lever

handle movement determines gallons per minute output.

19 MATERIAL FLOW

HYDRAULIC VALVE

MATERIAL CONTROL

LEVER HANDLE

3

11

MASTERMIX™STORAGE TANKS

MACHINE OPERATION

6-DISCHARGE MATERIAL OUT OF TANK

Open Main valve

Open Discharge valve

Close Return back valve

Close Recirculation valve

Start Engine. Pull Material control lever handle in forward

position.

WHEN FINISHED: Empty the discharge hoses. –Stein Pump Only

Close Main valve

Close Discharge valve

Open Return back valve

Open Recirculation valve

1

5

4

2

1

2

4

5

36 DISCHARGE VALVE

36 RECIRCULATION

VALVE

36 RETURN BACK

VALVE

36 MAIN VALVE

1

2

4

5

3

12

MASTERMIX™STORAGE TANKS

MACHINE OPERATION

7-FILL MATERIAL IN TANK

All valves should be closed.

Turn fill tube 3” gate valve #2 to open.

#2 3” GATE VALVE

13

MASTERMIX™STORAGE TANKS

MACHINE MAINTENANCE

MAINTENANCE SCHEDULE

Follow maintenance procedures listed in the engine and pump manuals.

MAINTAIN

8

HRS

1

WEEK

1

MONTH

6

MONTHS

1

YEAR

CHECK ENGINE

OIL LEVELS

CHANGE ENGINE

OIL

CHECK ENGINE

AIR FILTER

CHANGE ENGINE

AIR FILTER

CHECK HYDRAULIC

OIL LEVELS

CHANGE HYDRAULIC. OIL *

CHANGE HYDRAULIC. OIL

FILTER

CHECK MATERIAL PUMP *

GREASE LEVEL

GREASE AGITATOR*

BEARINGS

10 pumps

GREASE-ROUND HOUSING

FLANGE BEARINGS

CHECK TIRE PRESSURE

INSPECT ALL HOSES

* Use a good quality AW68 hydraulic oil with a rating of 352 SUS @100 F. Do not

use a 150 rated hydraulic oil as it is too light.

* The large hydraulic diaphragm pump, requires greasing of the center chamber.

With daily use, 4-5 pumps weekly. Use a #2 synthetic grease.

* The Agitator Bearings in Housing, need 10 pumps weekly of Bearing Grease.

14

MASTERMIX™STORAGE TANKS

MACHINE MAINTENANCE

MAINTENANCE SCHEDULE –STEIN-O-GLAND

MASTERMIX™STORAGE TANKS

15

MACHINE MAINTENANCE

TROUBLESHOOTING GUIDE

1. ENGINE

Refer to the engine owner’s manual for all specifications and

operating instructions.

Always move the fuel shutoff valve to the off position when finished.

Fuel can migrate down into the oil crankcase if the valve is left open. If

an electric motor is used, move the disconnect lever to the off

position.

2. MATERIAL PUMP

Material flow is reduced. The Basket Strainer or plumbing leading to

the pump is partially plugged. Or the pump could be worn internally

and needs new check balls and ball seats or replaced. Also, check the

rotation speed of the pump and hydraulic motor. Should the pump be

rotating slower than normal, the hydraulic motor and hydraulic pump

need to be tested for wear. Roper and Bowie Pumps could have worn

gears and also the center case. Before removing them for testing,

there is an adjustment that can be tried. On the side of the fwd.-rev

control valve, is a tiny plug that takes an Allen wrench, remove this

plug and there is an Allen head adjustment screw. Turn this clockwise

one full turn. If this doesn’t solve the problem then the hydraulic

pump and motor need testing or replacing.

The hydraulic motor turns but the pump doesn’t. Inspect the coupler

for wear or possibly a sheared key either on the pump shaft or

hydraulic motor shaft.

Material leaks from around the pump shaft. A Roper pump has

packing around the shaft. Remove the two nuts that are on either side

of the pump shaft and then remove the two-piece packing gland. The

gland will look like it is broken, ignore this as it is a casting that has

been snapped in half. Purchase Roper pump packing and add the

packing rings until the cavity is full. Replace the gland and snug the

nuts down. Do not overtighten as the shaft can be damaged. If the

pump will have to be disassembled to replace the ring seals.

16

MASTERMIX™STORAGE TANKS

MACHINE MAINTENANCE

TROUBLESHOOTING GUIDE

3. AGITATION SYSTEM

The Agitator will not rotate or moves extremely slow. Does the

material pump turn at the proper speed? If yes, try the adjustment

listed above. The Agitator should now rotate properly. If it doesn’t,

then the agitator motor needs replacing. Does the motor shaft turn

but the sprockets do not? Check the motor for a sheared key. If the

material pump doesn’t rotate at the proper speed either, have the

hydraulic pump tested.

Hydraulic oil level. The level should be 4” down from the tank top. Use

grade AW68, SAE 10w20, or 10w30 hydraulic oil.

If sealer leaks from around the shaft. If the sealer is leaking from the

sprocket end of the shaft, the seal needs replaced. As long as the

sealer hasn’t been allowed to get into the bearing, it will not need

replacing. If rear bearing needs replacing, clean shaft well with emery

cloth before attempting to install new seals and bearing.

If the tank has a packing gland. Packing needs to be added.

17

MASTERMIX™STORAGE TANKS

MACHINE MAINTENANCE

TROUBLESHOOTING GUIDE-CHART

SURGE TANK –NOTE: WEARING OF A FACE SHIELD IS RECOMMENDED

PRESSURE CAN BE RELIEVED FROM THE SYSTEM BY OPENING THE

RECIRCULATION VALVES.

KEEP IN MIND THE PLUMBING CONNECTING THE PUMP TO THE SURGE TANK

COULD ALSO BE PLUGGED, AND THERE MAY BE RESIDUAL PRESSURE STILL IN THE

SYSTEM.

PROBLEM

AGITATOR

DOES NOT ROTATE

ENGINE

MATERIAL PUMP

MATERIAL FLOW

IS REDUCED

SURGE TANK - NOTE

EXCESSIVE PULSATION

BASKET STRAINER

EXCESSIVE PLUGGING

POSSIBLE CAUSES/SOLUTIONS

SHUTOFF VALVE IS CLOSED / OPEN

HYDRAULIC OIL LOW / OIL LEVEL 4” FROM TOP OF TANK

COUPLER / REPLACE THE SHEARED KEY

HYDRAULIC PUMP / HAVE TESTED OR REPLACED

OIL SPECIFICATIONS / REFER TO OWNER’S MANUAL

OPERATING INSTRUCTIONS / REFER TO OWNER’S MANUAL

FUEL IN OIL CRANKCASE / FUEL SHUT-OFF VALVE IN

OFF POSITION WHEN FINISHED

BASKET STRAINER IS PLUGGED / UNPLUG

PLUMBING LEADING TO PUMP IS PLUGGED / UNPLUG

PUMP WORN / NEEDS NEW BALLS AND BALL SEATS REPLACED

MATERIAL TOO THICK/ THIN WITH WATER

TANK PLUGGED / CLEAN OUT TANK

MATERIAL CHUNKS/ EMPTY TANK-FLUSH WITH WATER

EXCESSIVE SAND / LACK OF SEALER VISCOSITY MODIFIER

MATERIAL / TOO MUCH WATER HAS BEEN ADDED

18

TANK CAPACITY CHART

GALLONS ARE APPROXIMATE AND MAY VARY SLIGHTLY TANK TO TANK

MATERIAL DEPTH AND GALLON VOLUME

MATERIAL

DEPTH

6000

GALLONS

96"x196”

8000

GALLONS

96"x261"

10000

GALLONS

120"x217"

MATERIAL

DEPTH

6000

GALLONS

96"x196”

8000

GALLONS

96"x261"

10000

GALLONS

120"x217"

INCHES

GALLONS

GALLONS

GALLONS

INCHES

GALLONS

GALLONS

GALLONS

1

11

15

14

34

1947

2592

2476

2

31

41

39

35

2025

2696

2578

3

57

76

71

36

2104

2801

2681

4

88

117

109

37

2183

2906

2784

5

122

162

151

38

2262

3012

2889

6

160

213

199

39

2342

3119

2994

7

201

267

250

40

2422

3225

3100

8

244

325

304

41

2503

3333

3207

9

291

387

362

42

2583

3440

3314

10

339

452

423

43

2664

3548

3422

11

390

520

487

44

2745

3656

3530

12

443

590

553

45

2827

3764

3639

13

498

663

622

46

2908

3872

3748

14

555

738

693

47

2989

3981

3858

15

613

816

766

48

3071

4089

3968

16

673

896

842

49

3152

4198

4079

17

734

978

920

50

3234

4306

4190

18

797

1062

999

51

3315

4414

4301

19

861

1147

1081

52

3396

4522

4413

20

927

1234

1164

53

3477

4630

4525

21

994

1323

1249

54

3558

4738

4637

22

1062

1414

1335

55

3639

4846

4749

23

1131

1506

1423

56

3719

4953

4862

24

1201

1599

1513

57

3800

5060

4974

25

1272

1693

1604

58

3879

5166

5087

26

1344

1789

1696

59

3959

5272

5199

27

1416

1886

1789

60

4038

5377

5312

28

1490

1984

1884

61

4117

5482

5425

29

1565

2083

1980

62

4195

5586

5538

30

1640

2183

2077

63

4272

5689

5650

31

1716

2284

2175

64

4349

5792

5763

32

1792

2386

2274

65

4426

5894

5875

33

1869

2489

2375

66

4502

5995

5987

19

TANK CAPACITY CHART

GALLONS ARE APPROXIMATE AND MAY VARY SLIGHTLY TANK TO TANK

MATERIAL DEPTH AND GALLON VOLUME

MATERIAL

DEPTH

6000

GALLONS

96"x196”

8000

GALLONS

96"x261"

10000

GALLONS

120"x217"

MATERIAL

DEPTH

6000

GALLONS

96"x196”

8000

GALLONS

96"x261"

10000

GALLONS

120"x217"

INCHES

GALLONS

GALLONS

GALLONS

INCHES

GALLONS

GALLONS

GALLONS

67

4577

6095

6099

99

9376

68

4651

6194

6211

100

9460

69

4725

6292

6323

101

9544

70

4798

6389

6434

102

9625

71

4870

6485

6545

103

9705

72

4941

6579

6656

104

9782

73

5011

6673

6766

105

9858

74

5080

6765

6876

106

9931

75

5148

6855

6985

107

10002

76

5215

6944

7094

108

10071

77

5280

7031

7203

109

10138

78

5344

7117

7310

110

10201

79

5407

7200

7418

111

10262

80

5469

7282

7524

112

10320

81

5529

7362

7630

113

10375

82

5587

7440

7735

114

10426

83

5644

7515

7840

115

10473

84

5698

7588

7944

116

10516

85

5751

7659

8047

117

10554

86

5802

7726

8149

118

10586

87

5851

7791

8250

119

10611

88

5897

7853

8350

120

10624

89

5941

7911

8449

90

5982

7965

8547

91

6020

8016

8644

92

6054

8062

8740

93

6085

8102

8835

94

6110

8137

8929

95

6130

8164

9021

96

6142

8178

9112

97

9201

98

9289

Table of contents

Popular Storage manuals by other brands

Transcend

Transcend StoreJet 2.5 SATA Series user manual

dellonda

dellonda DG113 manual

Seagate

Seagate Momentus Thin ST500LT012 product manual

XBOX

XBOX B4Q-00002 - 360 Hard Drive 20 GB Removable user guide

Cms Products

Cms Products Automatic Backup System CMS ABS Specifications

Freecom

Freecom Mobile Drive Secure user manual

Sun Microsystems

Sun Microsystems ZFS installation guide

U-Line

U-Line S-19003 manual

Western Digital

Western Digital Caviar WD1001FALS Specifications

QNAP

QNAP TS-963X user guide

SIIG

SIIG Dual 2.5" SATA MobileRack Quick installation guide

D-Link

D-Link DSN-3200 - xStack Storage Area Network Array Hard... Service manual