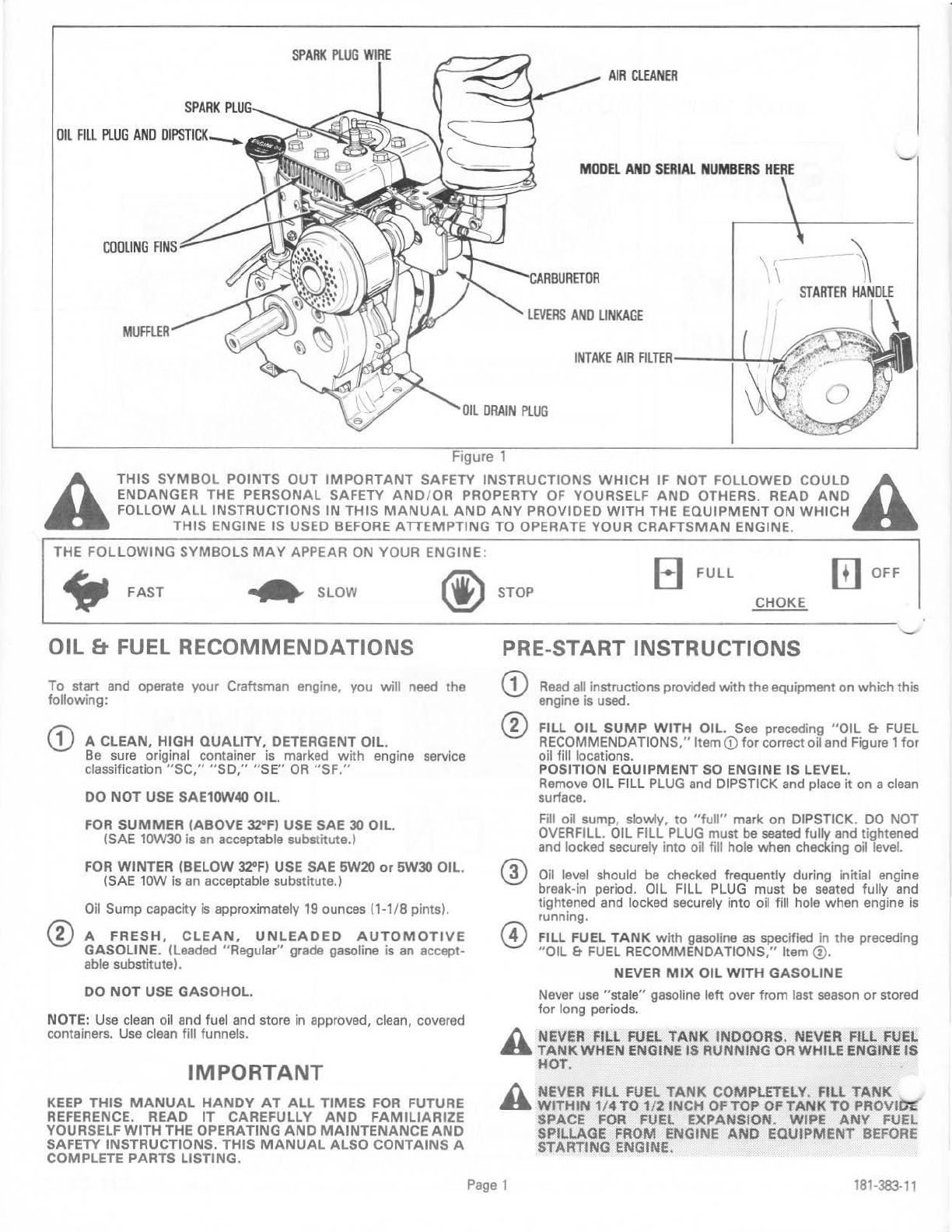

PRE-START INSTRUCTIONS tcontinuedl

®

"

CHECK

THE

FOLLOWING before attempting to start your

engine:

A.

BE

;

WRE

EOUIPMENT

~

:

iS.

.

iN

:

:

Ne

·

urt~AL

i

G~AR

WITH

.

¢(QTCHIS

.s,

BELtS

}

CHAINS,

··

ere

:,

blS!NGAGEO

,

{fOLLOW

EOUif:iM£Nt ·

MANUFACTURER'S

IN

·

STRUCTIONS.} THIS

SHOULD

PLACE.

ANV

SAFETY

SWITCHES

IN

SAfE

STARTING POSITION.

B.

Be

sure SPARK

PLUG

WIRE is attached to SPARK PLUG.

(see

Figure

1)

C.

Be

sure

any ignition switch on engine

or

equipment

is

in ON,

RUN

or START position.

D.

Be

sure

FUEL

FILL

CAP air vent is open.

STARTING INSTRUCTIONS

h NEVER. RUN ENGlNE

lNDOORS

OR

IN

ENCLOSED,

..

POOf\tYVEN'f'ILATED

AREAS. ENGINE EXHAUST CON-

TAINS

CARBON

MONOXIDE,

AN

ODORl.ESS

AND

DEADLY GAS. . ..

h KEEP

HANDS,

FEET,

HAIR

AND

LOOSE CLOTHING

..

AWAY

FROM

ANY

MOV!NG

PARTS

ON

.ENGINE

AND

EQUIPMENT.

h

WARNING

-TEMPERATURE

OF

MUFFlER

AND

NEAR-

..

BY

AREAS

MAY

EXCEED

1SOOF

(OO'Cl.

AVOID

THESE

AREAs.

..

.

G)

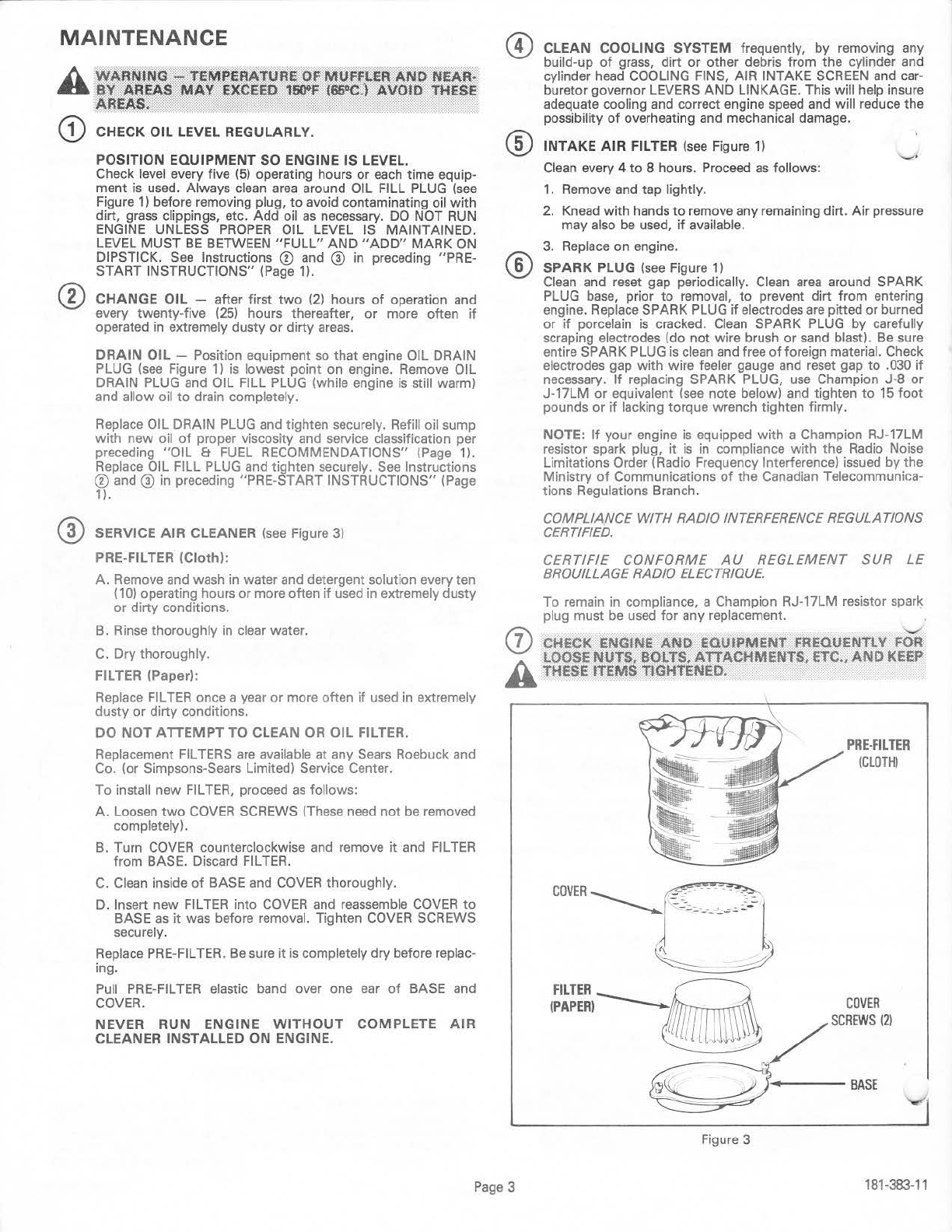

COLD ENGINE START (Engine has not

been

run recently).

A. Move remote control on equipment to

CHOKE

(see

equip-

ment manufacturers instructions).

B.

START

ENGINE

1.

Grasp

STARTER

HANDLE

(see

Figure

2)

and pull rope

out, slowly, until

it

pulls harder dueto engine compres-

sion. Let rope rewind slowly.

2.

Pull rope with arapid continuous full arm stroke. Let rope

rewind SLOWLY. Don't let

STARTER

HANDLE snap

back against starter.

3.

Repeat

preceding Instructions 1 and 2 until engine fires

and when engine starts, move equipment control to

FAST position.

Ifenginefalters, move equipment control

to

CHOKE

untill

engine runs smoothly and then

to

FAST.

NOTE: If engine fires, but fails to start, move equipment

control to FAST and repeat preceding Instructions 1 and

2 until engine starts.

If

engine fires, butfails to start again, repeat preceding

In

-

structions

1,

2 and 3 until engine starts.

®

WARM

ENGINE START (Engine still warm from recent

running).

NOTE -Warm engine may start without choking.

A. Move remote control on equipment to FAST.

B.

START

ENGINE

1.

Grasp

STARTER

HANDLE

(see

Figure

2)

and pull rope

out, slowly, until it pulls harder due to engine compres-

sion. Let rope rewind slowly.

2.

Pull rope with arapid continuous full

arm

stroke. Let rope

rewind SLOWLY. Don't let

STARTER

HANDLE

snap

back against starter.

3.

Repeat

preceding Instructions 1 and 2 until engine starts.

Ifenginefalters, move equipment control

to

CHOKE

untill

engine runs smoothly and then

to

FAST.

NOTE: If engine fails to start after a reasonable number

of

starting attempts, follow preceding "

CD

COLD

ENGINE

START" instructions.

TO STOP ENGINE

G)

®

Move remote control

on

equipment or any ignition stop switch

on engine to

STOP

or

OFF

position

(see

equipment manu-

facturer's instructions).

AFTER ENGINE IS STOPPED:

h

A.

DISCONNECT SPARK PLUG WIRE FROM

SPARK

..

PLUG

AND

PLACE

IT

WHERE

IT

CAN

NOT

CONTACT

SPARK PLUG. . ·

h B. TURN

IGNITION

SWITCH KEY

If

SO

EQUIPPED. TO

..

''

OFF" POSITION

AND

REMOVE KEY FROM SWITCH.

THIS

WILL

REDUCE

THE

POSSIBILITY

OF

UNAUTHORIZED STARTING OF ENGINE

WHILE

EQUIPMENTfS

NOT

IN

USE.

h C. NEVER STORE ENGINE WJTH FUEL IN

TANK

IN~

..

DOORS OR

IN

ENClOSED, POORLY VENTILATED

ENCLOSURES,WHERE

~UEL

fUMES

MAY

REACH

AN

OPEN FLAME,

SPARK

OR

PILOT LIGHT

AS

ONA

FURNACE, WATER HEATER. CLOTHES DRYeR, ETC.

Figure 2

Page2

181-383-11

another free manual from www.searstractormanuals.com