TABLE

O

CONTENTS

SAFETY

RULES

...................................................................

2

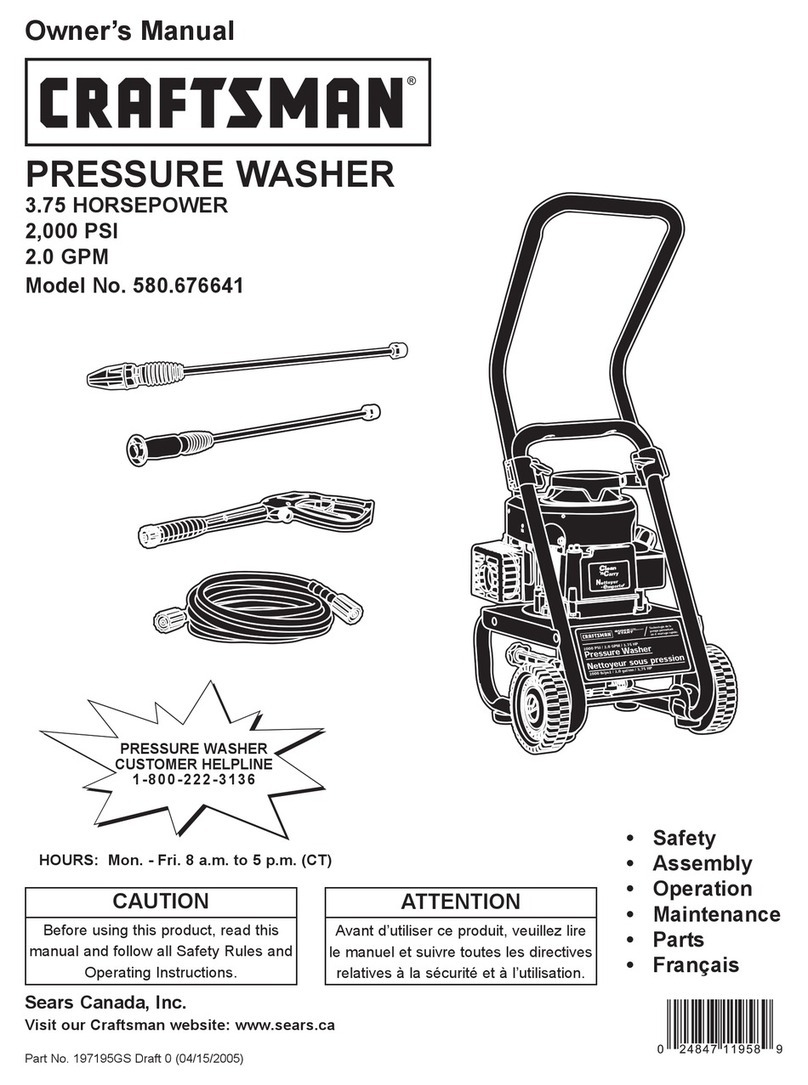

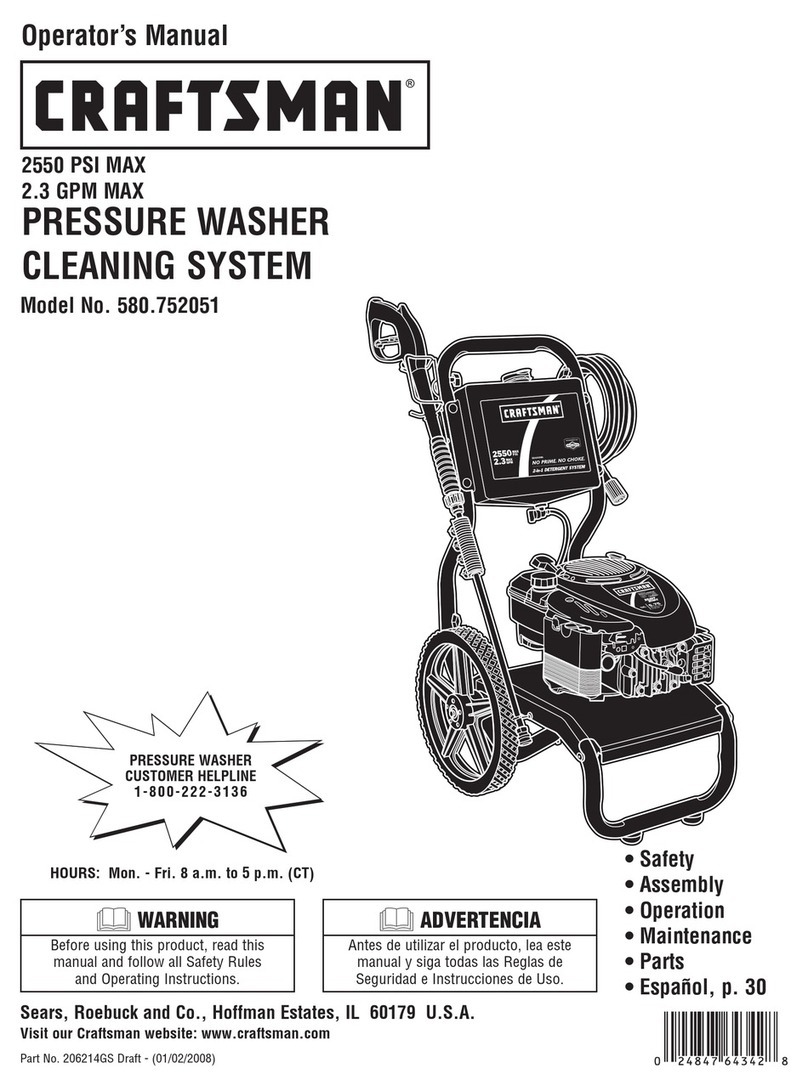

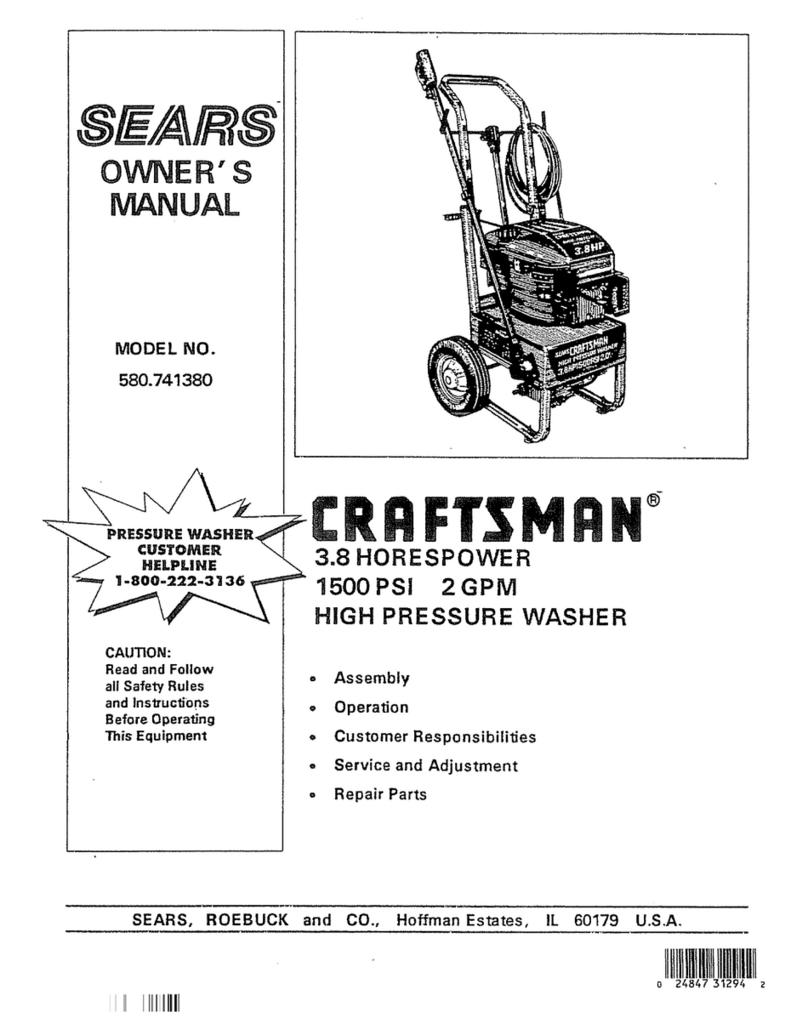

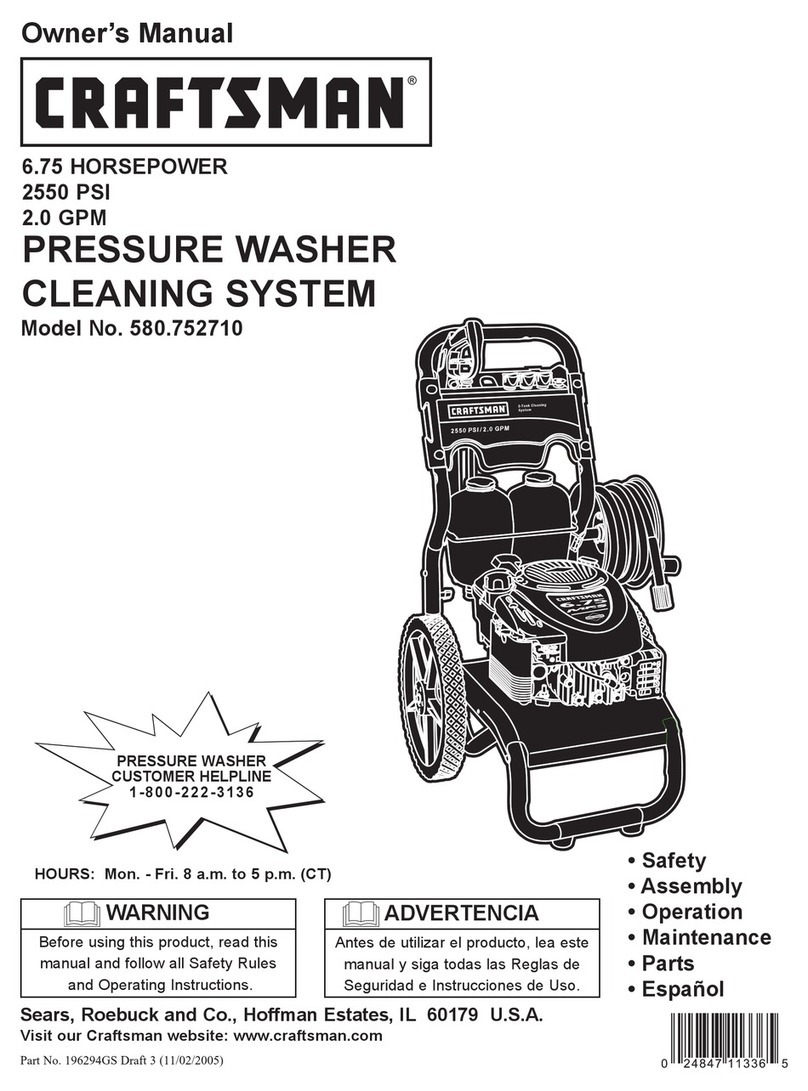

PRODUCT

SPECIFICATIONS

...........................................

3

CONTENTS

OF

HARDWARE

PACK

.................................

5

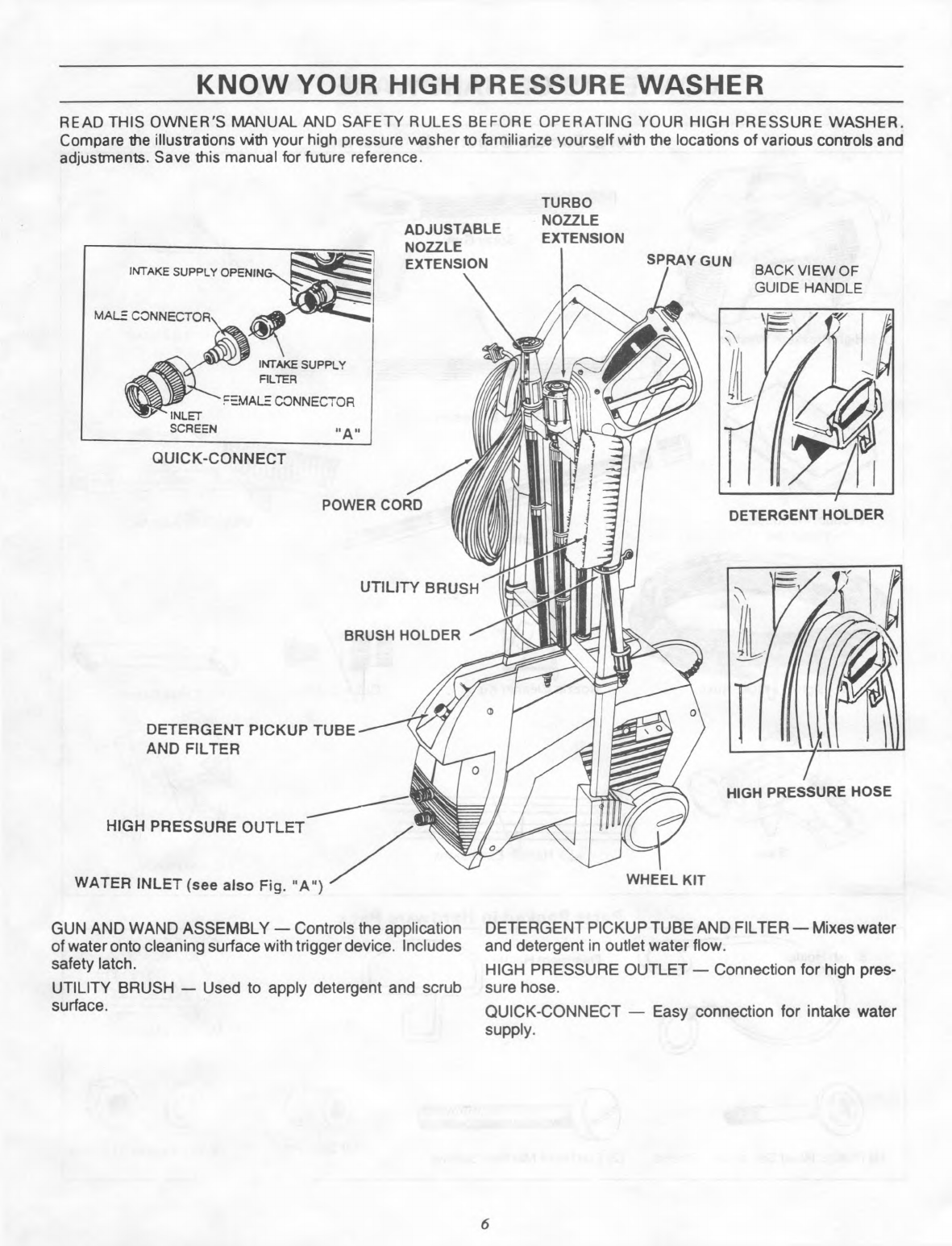

KNOW

YOUR

HIGH

PRESSURE

WASHER

....................

6

ASSEMBLY

.........................................................................

7-8

OPERATION

..................................................................

9

—

11

CUSTOMER

RESPONSIBILITIES

.............................

11-12

STORAGE

............................................................................

12

TROUBLESHOOTING

........................................................

13

REPLACEMENT

PARTS

..............................................

14-17

HOWTO

ORDER

PARTS

...................................

backpage

INDEX

-A-

-G

-

-R

-

Assembly

Checklist

..........................................

8

Remo ing

from

Carton

...................

7

SetUp

........................................

7,8

—

B

—

Before

starting

........................

9

Before

each

use

....................

10

-C

-

Cleaning

Tips

........................

10

Customer

Responsibilities

.

3,10

Check

washer

components

....

10

—

E

—

Electrical

supply

....................

10

Extension

cords

....................

10

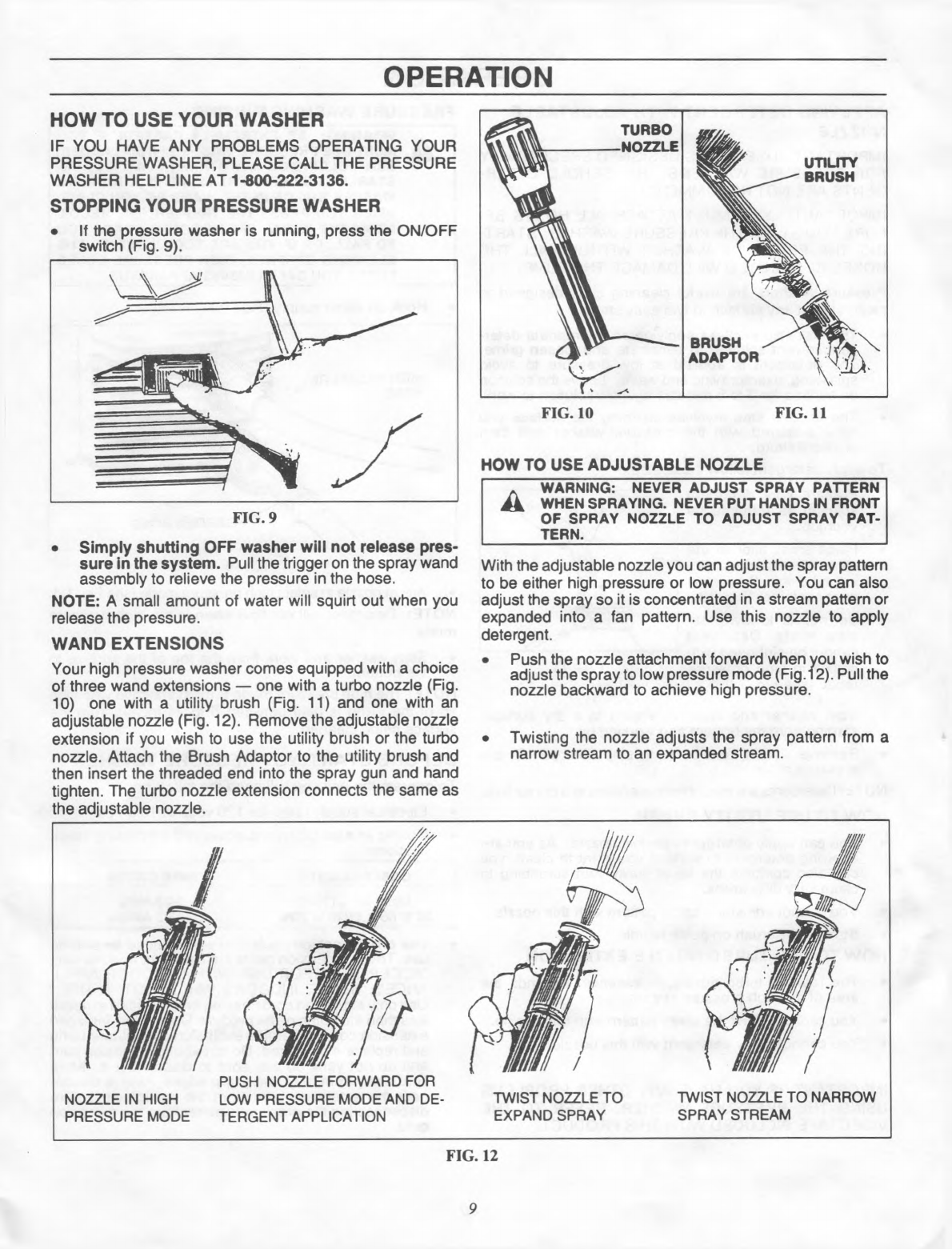

Extensions,

wand

....................

9

Gun

and

Wand

Assembly

..

6-8

-H

-

Hardware

Pack

..........................

5

High

Pressure

Hose

...............

6,

8

-M-

Maintenance

Agreement

.........3

-N

-

Nozzle,

adjustable

......................

9

-O

-

Operation

Detergent

Application

...............

10

Know

Your

Pressure

Washer

...

8

Stopping

........................................

8

To

Turn

on

Washer

........................

9

Order

Parts

.............

backpage

Replacement

Parts

...........

13-17

-S

-

Safety

Rules

.............................

2

Siphoning

.................................

10

Specifications

...........................

3

Storage

.....................................

11

-T

-

Troubleshooting

......................

13

—

u

—

Utility

brush

...............................

9

-W-

Warranty

....................................

3

ACCESSORIES

AND

ATTACHMENTS

These

accessories

and

attachments

were

a ailable

when

the

high

pressure

washer

was

purchased.

They

are

also

a ailable

at

most

Sears

retail

outlets

and

ser ice

centers.

Most

Sears

stores

can

order

these

items

for

you

when

you

pro ide

the

model

number

of

your

high

pressure

washer.

Some

of

these

accessories

may

not

apply

to

your

pressure

washer.

4