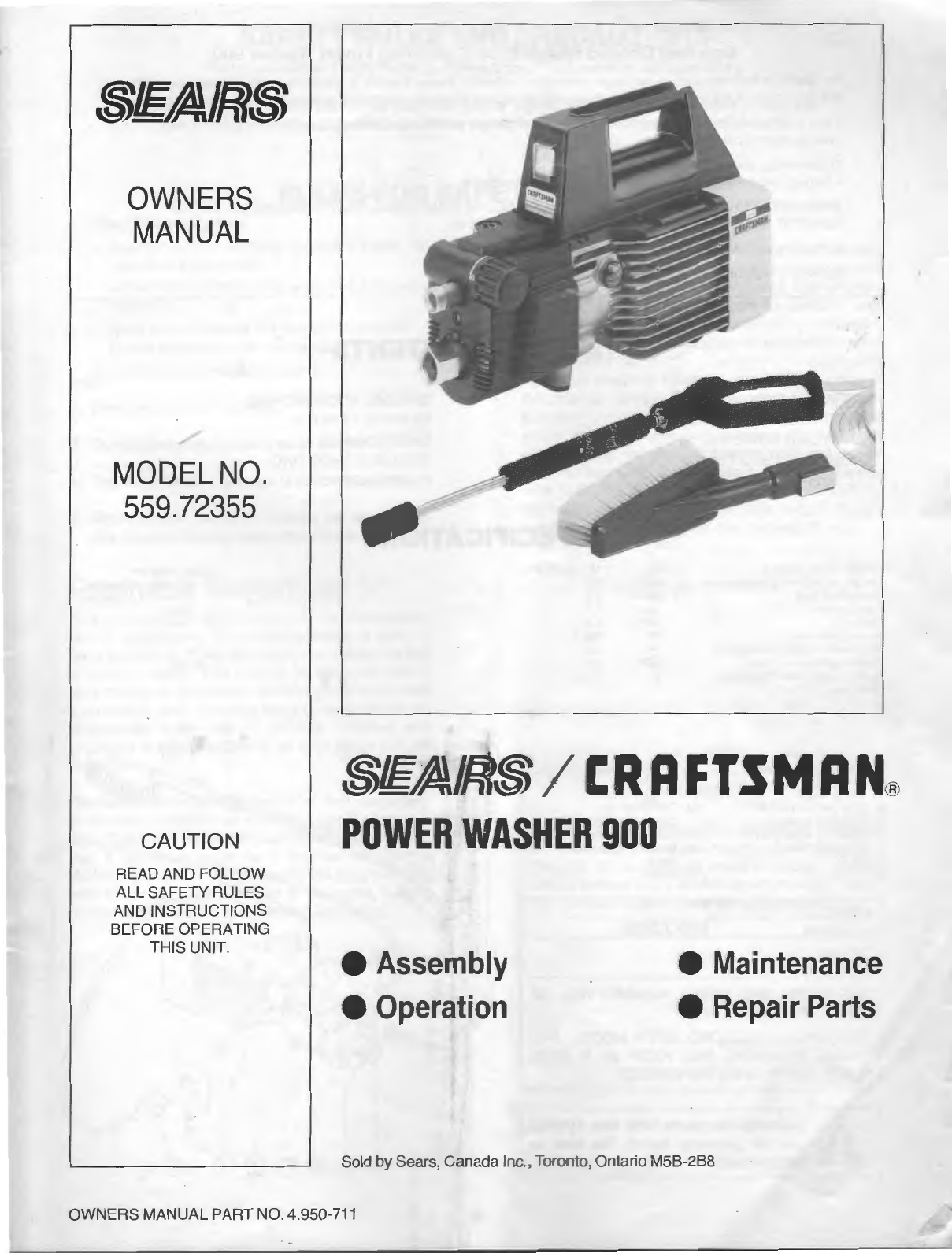

MAINTENANCE

Before servicing the Power Washer disconnect the

plug from the electrical power supply, and shut off

the water supply.

1.

Changing the oil

The oil should

be

changed once a year, or after

approx. 400 hours of operation. First the oil-level

sight glass

(8)

is

removed. The old oil

is

then

drained and 0.2 liter of new oil (15W-40, Order

No.

6.288-050 from service depots)

is

poured

in.

2.

Repairs

Any repairs that may

be

necessary should

be

en-

trusted to authorized service technicians. Please

send the unit with its accessories to the nearest

authorized service depot.

3.

Protection against Freezing

The Power Washer must

be

stored

in

such a way

as to protect it from freezing.

Do

not store the Power Washer outdoors

where the temperature

is

below 32°

F.

4.

High-pressure hose

The high-pressure hose must conform to safety

regulations, and must

be

marked with the max-

imum permissible operating pressure, the date of

manufacture and the name of the manufacturer.

Karcher high-pressure hoses meet these require-

ments.

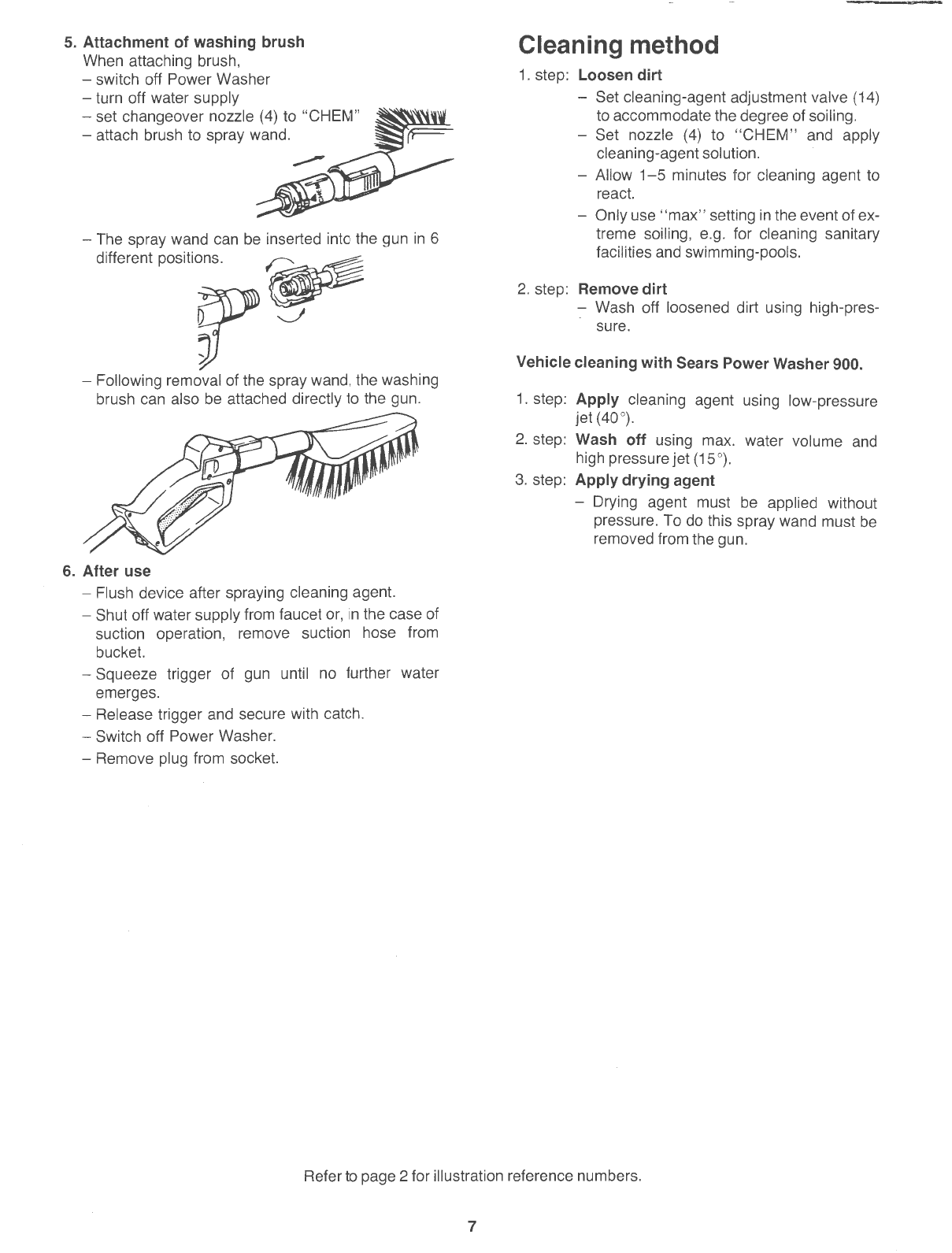

5.

Safety device

If

the pressure

is

excessive, the relief valve

on

the

pump opens a bypass on the pump intake side;

the factory setting must not be changed.

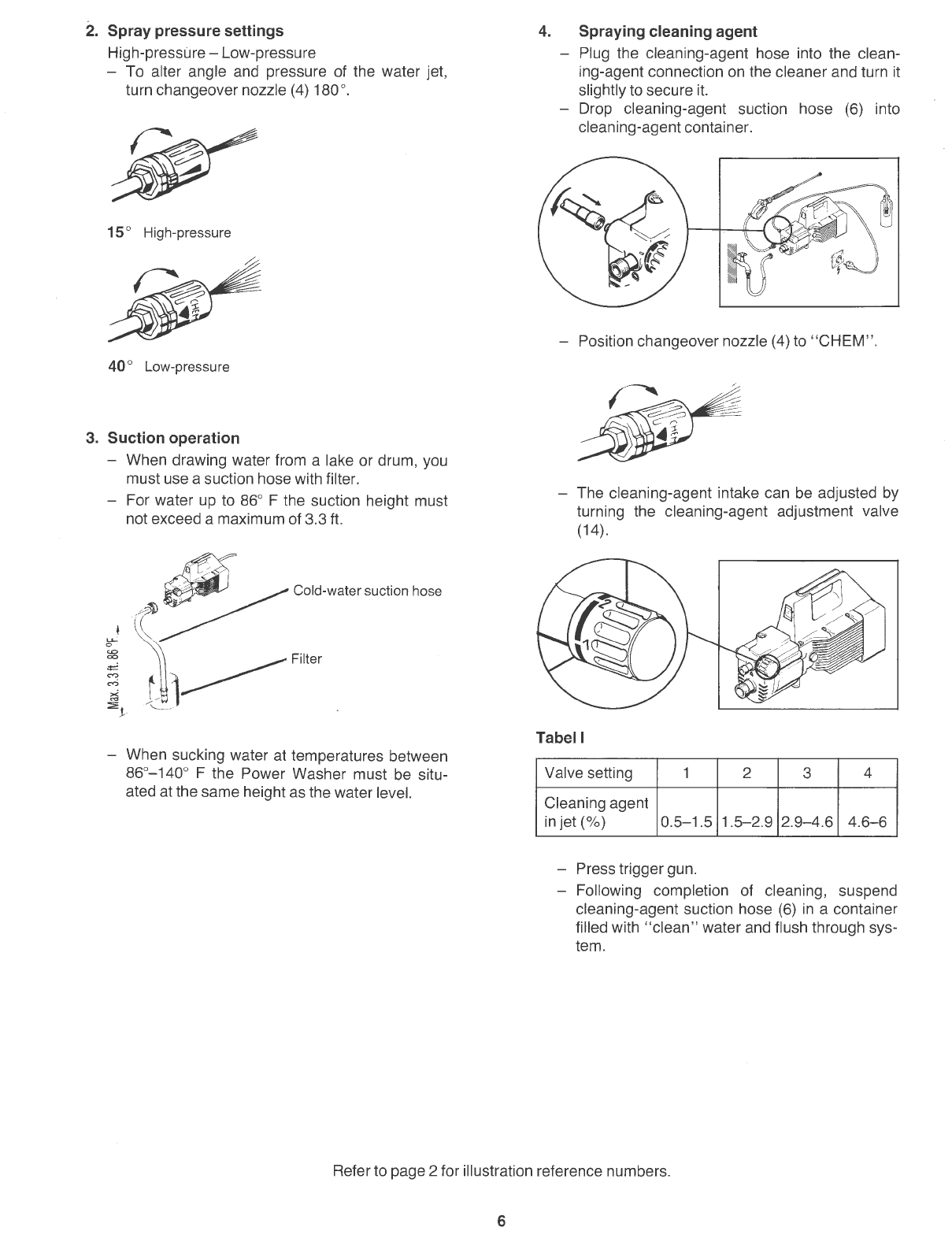

6. Cleaning changeover nozzle

Disconnect

th

e spray wand

(3)

from the trigger

gun

(2)

.

Remove dirt from nozzle bore with needle and

rinse with water from nozzle end.

In

the event of

stubborn dirt, disassemble changeover nozzle.

7.

Dismantling the changeover nozzle

Lift out the clip

(1

),

using a narrow screwdriver.

Pull off the cover

(2).

Unscrew the sleeve nut (3), using a 13/16" open-

ended wrench; use a

11

/16" open-ended spanner

to hold the end of the changeover nozzle.

Remove the sleeve nut; when doing this, hold the

spray wand with the nozzle uppermost to prevent

the ball

(4)

from becoming lost.

Press the nozzle tip

(5)

out of the sleeve nut

(4),

and clean

it.

Reassemble by proceeding

in

the reverse of the

above sequence.

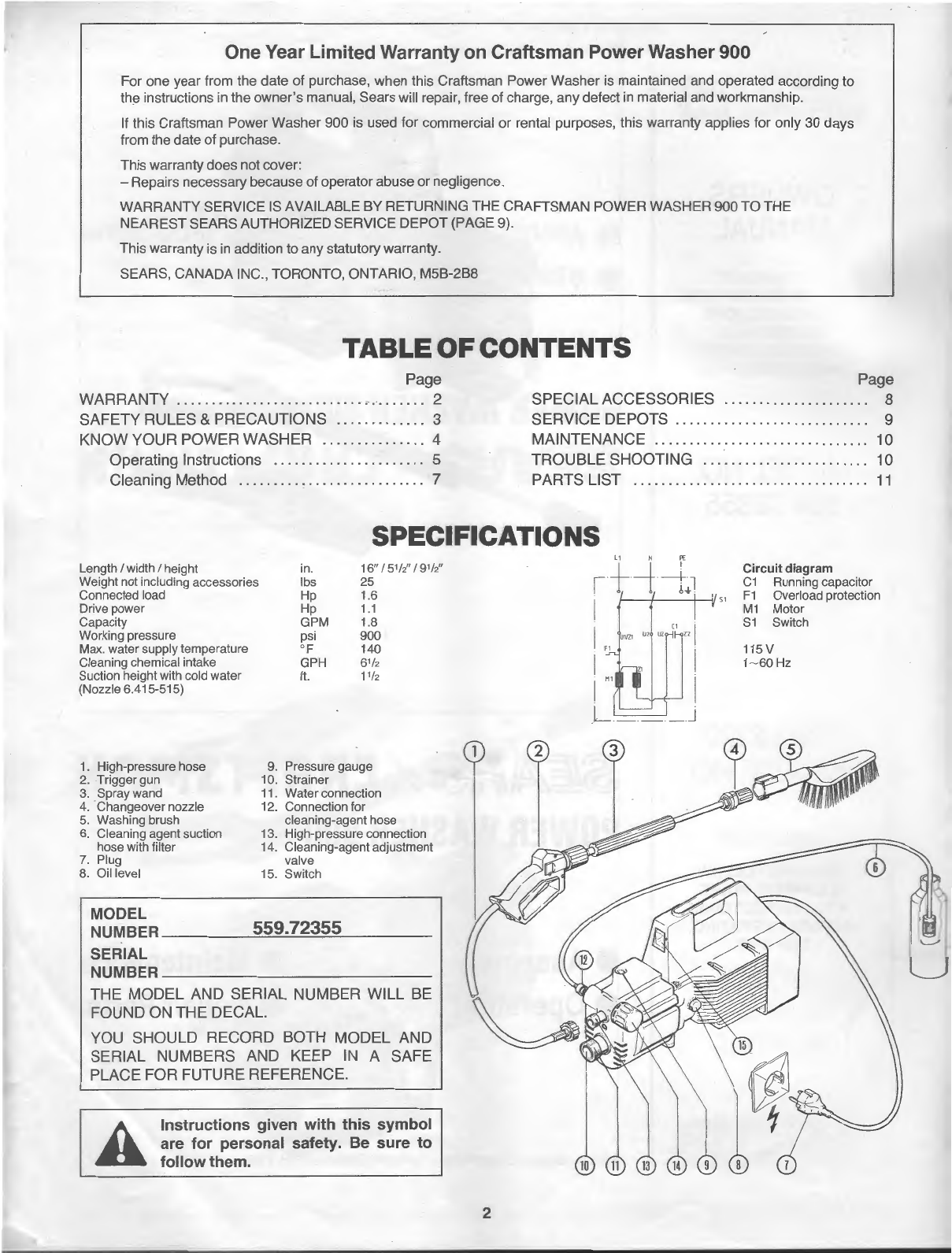

TROUBLE SHOOTING

Symptom

Problem

Correction

1.

Device will not start 1. No electrical power supply available ChecK cable, plug, power socket and fuse

2.

Motor overheats Press trigger of gun;after approx. 2 minutes the thermal

protection switch will switch the motor back on

3.

Low voltage

4. Trigger not open Open trigger

5. Electrical defect Have device repaired by service depot

2.

Device does not come 1. Pump is sucking air Check water hose, turn on water supply

up to pressure 2. Water filter clogged Clean filter

3.

Pump not bled to remove air Switch off device, press trigger of gun, switch on

device while pressing the trigger; repeat

if

necessary

4. Pump or relief valve defective Have device repaired by service depot

3. Water jet irregular 1

. Nozzle clogged Clean nozzle

2.

Water supply inadequate Use device in suction operation with open container

3. Relief valve incorrectly set Have device repaired by service depot.

4.

Water jet cannot be

1.

Ball in changeover nozzle stuck Tap changeover nozzle lightly;

varied degrease the nozzle

5.

No intake of cleaning

1.

Suction filter clogged Clean filter

in

suction nozzle

agent

2.

Nozzle blocked Clean changeover nozzle

3,

Ball

in

cleaning agent non-return Disconnect suction hose (6), and insert a piece of thin wire into the

valve jammed intake aperture until the ball in the valve is freed; reassemble device

4.

Wrong nozzle setting Switch the changeover nozzle to low pressure

10