ii iil i,.lll ,', ................................... It-

"FABLE OF CONTENTS

i i , , i,i, i, Hi i,i imll i, i, i_!l_,1,,i., ,i ..... i, H _L

SAFETY RULES ............................................................ 2

CUSTOMER RESPONSIBILITIES ...................... 3,14-16

PRODUCT SPECIFICATIONS ...................................... 3

WARRANTY .................................................................. 3

ACCESSORIES ............................................................. 5

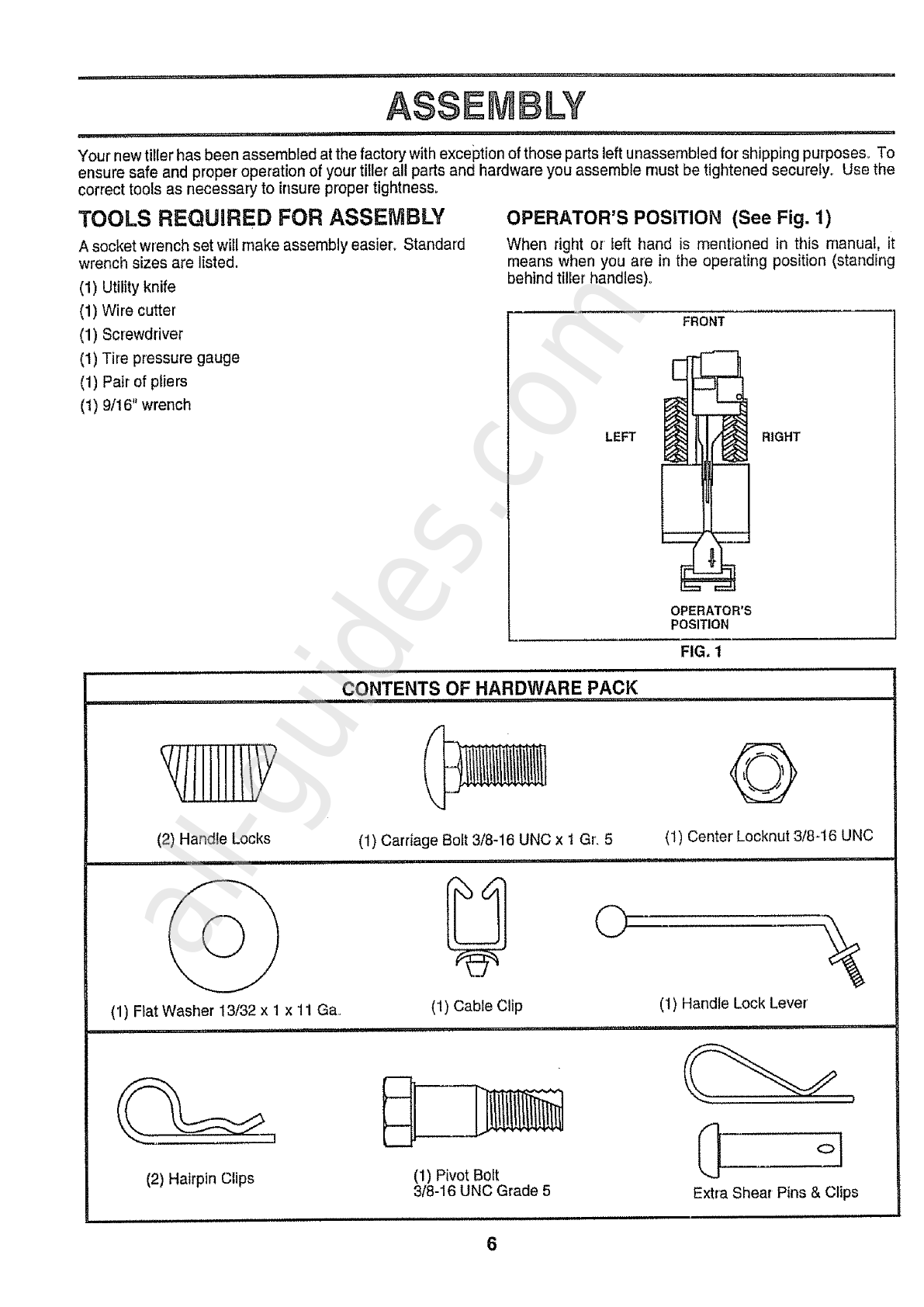

ASSEMBLY ............................................................... 6-8

OPERATION ............................................................ 9-13

MAINTENANCE SCHEDULE ..................................... 14

SERVICE & ADJUSTMENTS ................................. t6-19

STORAGE .................................................................... 20

TROUBLESHOOTING ................................................. 21

REPAIR PARTS=TILLER ....................................... 22-28

REPAIR PARTS-ENGINE ....................................... 29-33

SERVICE/PARTS ORDERING ............... BACK COVER

UNDEX

A

Accessories ..............................................5

Adjustments:

Carburetor ......................................19

Depth Stake .................................10

Handle Height ............................ 16

Side Shields ..................................11

Throttle ........................................ 1g

Tines ..................................................18

V-Belt (Ground Drive) ................17

Wheels .........................................13

Air Cleaner ...................................................15

B

Belt:Belt Guard .....................................17

Repair Parts ...................................23

V-Bett (Ground Drive) ................17

Cooling System .......................................15

Controls:

Choke ....................................................g

Throttle ....................................................9

Drive (Tines) ....................................9

Cultivating ....................................... 13

Customer Responsibilities:

Air Cleaner _...................................15

Cooling System ..............................15

Finish .......................................... 16

Maintenance Schedule ..............14

Muffler'. ............................................16

Oi! Change ..........................................15

Spark Plug ..................................16

Tines .....................................................18

Transmission ..................................16

V-Bett (Ground Drive) ................17

D

Depth Stake:

Adjustment ..................................!0

Repair Parts .............................. 26

E

Engine:

Air Cleaner. .....................................15

Cooling Systen'l ................................15

Fuel Type .....................................1t

Engine (cont'd)

Lubrication ........................................15

Oil Level ...........................................11

Oil Type ....................................11,t5

Spark Plug .....................................16

Starting ...........................................12

Stopping .........................................10

Storage .............................................20

Winter Operation ..........................15

F

FueI:

Filling Tank ...................................11

Storage ........................................20

Type ...................................................11

Finish:

Maintenance ...............................16

H

Handle:

Height Adjustment .....................16

Repair Parts ...................................22

L

Lubrication:

Lubrication Chart .................... 14

Engine .................................................15

M

Muffler:

Maintenance .......................................16

Spark Attester ...................................3

O

Oil: Level .................................................11

Type ..............................................11,!5

Operation:

Cultivating ........................................13

Fill Fuel Tank ................._................11

Starting Engine ...........................12

Stopping Tines & Engine ...........10

Tilling .........................................10

Tilling Hints .............................. 12

Tine Operation ............................10

Transporting Tiller. ......................11

Winter Operation ...........................15

4

R

Repair Parts:

Titler. ................................................22-28

Engine ...............................................29-33

Rules for Safe Operation ........................2

Service & Adjustments:

Carburetor .....................................19

Handle Height ..................................16

Side Shields ...................................11

Throttle ...........................................................19

Tines..........................................................18

V-Belt (Ground Drive) .............. 17

Wheels ...............................................13,16

Service:

Repair Parts .................................22-33

Service Record ..............................14

Shear Pins:

Operation ..........................................12

Repair Parts ....................................27

Spark Plug:

Gap ..........................................................3

Maintenance .......................................16

Storage:

Fuel System ......................................20

Tiller...................................................20

T

Tilling.................................................10,12

"Tines:

Arrangement/Replacement ...... 18

Operation ..............................................10

Repair Parts ....................................27

Shear Pins ...................................12

Transmission:

Maintenance ....................................16

Repair Parts ......................................25

Troubleshooting..........................................21

Transporting ...............................................t 1

W

Warranty ......................................................3

Wheels:

Adjustment .........................................13

Removal ..............................................16

Repair Parts .................................24