ill iiii ii iiii ii

LIiiiiiilll,ll,,l••;•• • ••• _ illii

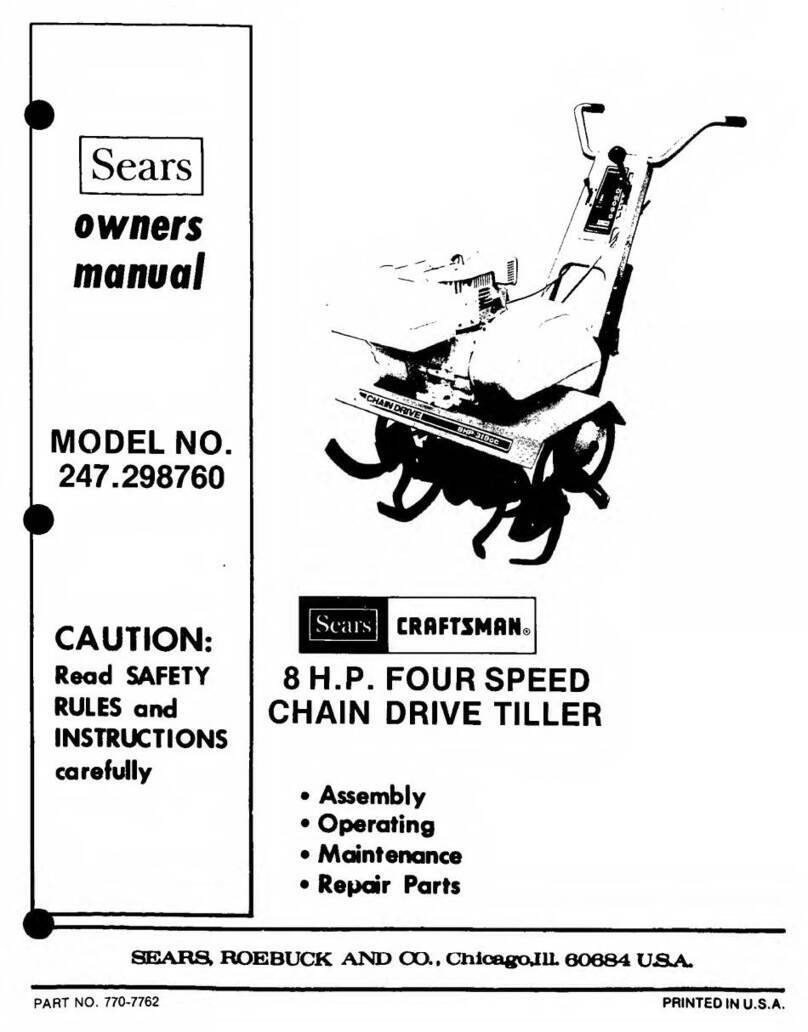

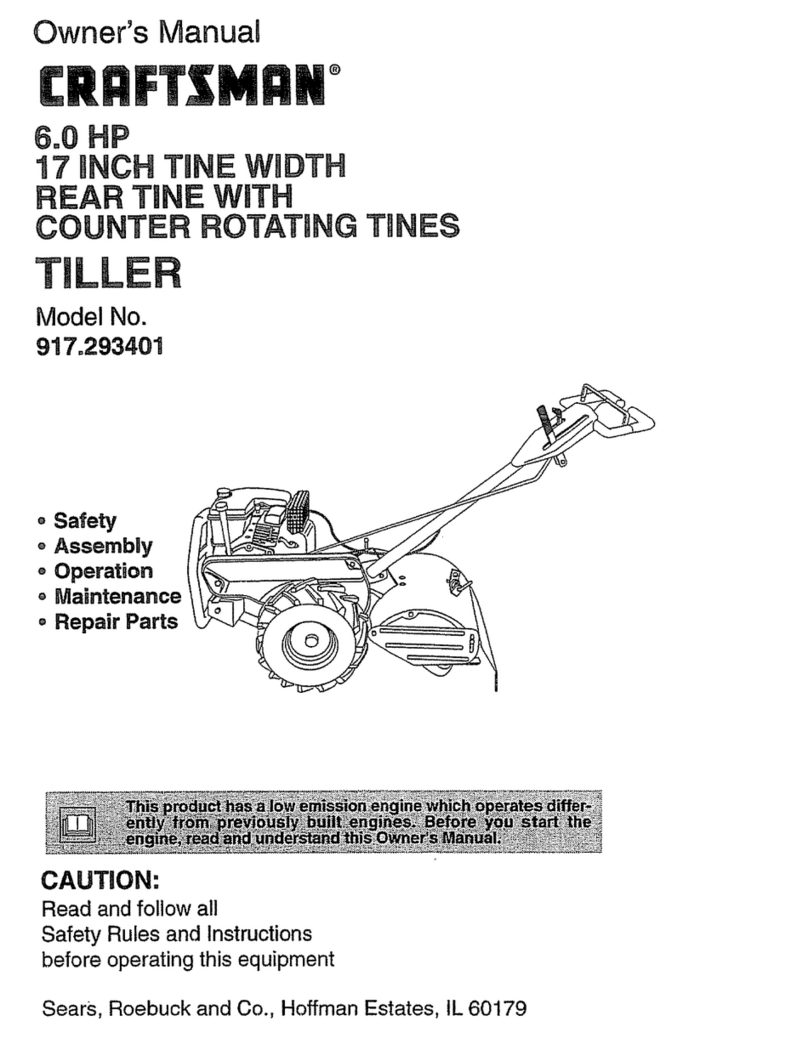

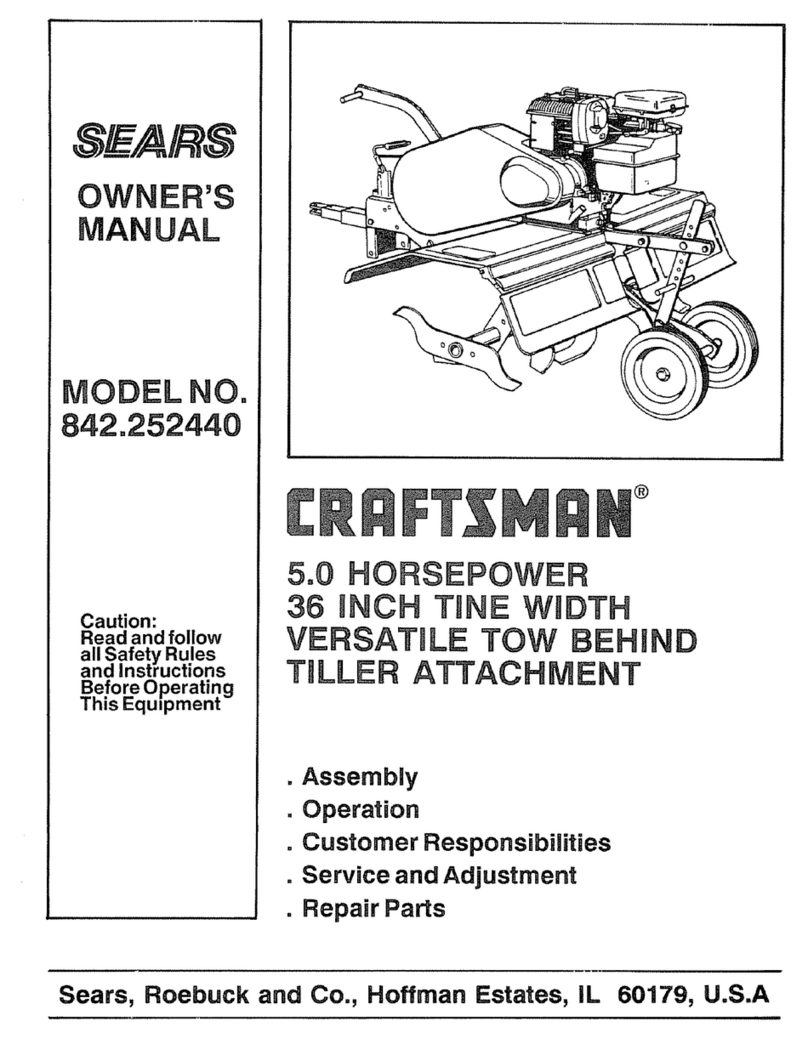

TABLE OF CONTENTS

ill iiilll iiiill,,i i iiiilll,llllll

SAFETY RULES ............................................................ 2

CUSTOMER RESPONSIBILITIES ...................... 3,13-15

PRODUCT SPECIFICATIONS ....................................... 3

WARRANT'/ ................................................................... 3

ACCESSORIES, ........................................................... 5

ASSEMBLY ................................................................ 6-8

OPERATION .......................................................... ..9-12

INDEX

MAINTENANCE SCHEDULE ...................................... 13

SERVICE & ADJUSTMENTS ................................. 15-18

STORAGE ..,................................................................. 19

TROUBLESHOOTING ;................................................ 20

REPAIR PARTS-TILLER ........................................ 21-26

REPAIR PARTS-ENGINE ....................................... 27-31

AEngine (cont'd)

.... _ Lubrication _.............................. 14

Accessories ....................... ............... 5

..... Oil Level ................................... 11

Adjustments: Oil Type .............................. 11 14

Carburetor ............................... 18 Spark Plug ............................... 15

Depth Stake .............................. 10 Starting. ................................... 12

Handle Height ...:.........: ........:..:15 .... Stopping .i................................ 10

Side Shields ............................. 11 Storage :................................... 19

Throttle .................................... 18 Winter Operation ..................... 14

:Tines ................................... _:_...17 .....

V-Belt (Ground Drive) .............. 16 .....

Air Cleaner .......... _.................... 14 _F

Fuel: .....

BFillingTank .............................. 11

Storage .................................... 19

Belt: Type ......................................... 11

R

Repair Parts:

Tiller .................................... 21-26

Engine ................................ 27-31

Rules for Safe Operation .................. 2

:S

Service & Adjustments:

Carburetor ............................... 18

Handle Height .......................... 15

Side Shields ............................. 11

Throttle .................................... 18

Tines ........................................ 17

V-Belt (Ground Drive) .............. 16

Wheels ..................................... 15

Belt Guard ............................... 16

Repair Parts ............................. 22

V-Be t (Ground Drive) .............. 16

Cooling System .............................. 14

Controls:

Choke ........................................ 9

Throttle ...................................... 9

Drive (Tines) .............................. 9

Cultivating. ..................................... 12

Customer Responsibilities:

Air Cleaner ............................... 14

Cooling System ....................... 14

Finish ....................................... 15

Maintenance Schedule ............ t3

Muffler .,..L.,..:..I:..._ ................. 15

Oil Change .......... :.................... 14

Spark Plug ............................... 15

TEnes........................................ 17

Transmission...; ....................... 15

V-Belt (Ground Drive) .............. 16

D

Finish: ^.

- _ervlce"

Ma ntenance ............................ 15 -.

:: _ : ..... Repair Parts ....................... 21-31

.......... _, ........ Sei_ice Record ........................ 13

n

Handle:

Height Adjustment.................. 115

Repair Parts ............................. 21

Shear Pins:

Operation .................... i............ 12

Repair Parts ............................. 26

Spark Plug:

LGap ............................................ 3

Lubrication: Maintenance ............................ 15

Storage:

Lubrication Chart .................... 13 Fuel System ............................. 19

Engine .................................. 14 Tiller._: ..................................... 19

M T

Muffler: Tilling ......................................... 10,12

Maintenance 15 Tines: i

Spark Arrester ........................... 3 Arrangement/Replacement ...... 17

Operation ................................. 10

Repair Parts ............................. 26

Shiraz:Pins ............................... 12

Transmission:

Maintenance ............................ 15

Repair Parts ............................. 24

O

Oil: Level ........................................ 11

Type .................................... t1,14

Operation:

Depth Stake: Cultivatin_l ................................ 12 Troubleshooting .........:................... 20

Adjustment ............................... 10 Fill Fuel "l_'ank........................... 11

Repair Parts ............................. 25 Starting Engine _....................... 12 Transporting ................................... 11

:: _:_Stopping Tines & Engine ......... 10

• : E_ ..... Tilling ...:.,...:..: ......................... 10 i :: .... i: W:

En;'ine" Tilling Hints .............................. 12 Warranty ............ ""i ............... :....""..3

_-" "-' 14 Tine Operation ............. 10

AsrL;teaner................................. "........... 1 Wheels: :

Coolinn System 14 Transporting T,Iler.................... 1

"....................... 11 :Winter Operation .... 14 Removal. ................................. 15

FueIType ............,.,,... .......... ........ : i :ii: ..... : T"!'=,'",":"" ..... Repair Parts............................. 23

: i

4