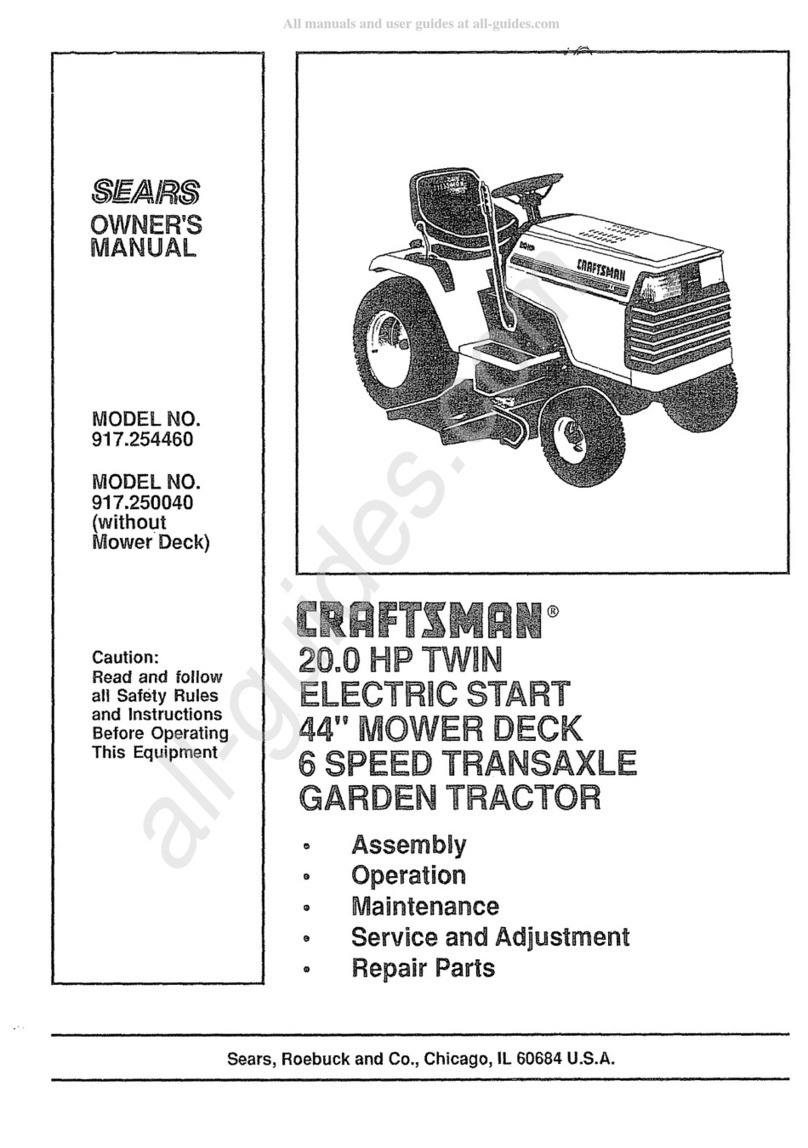

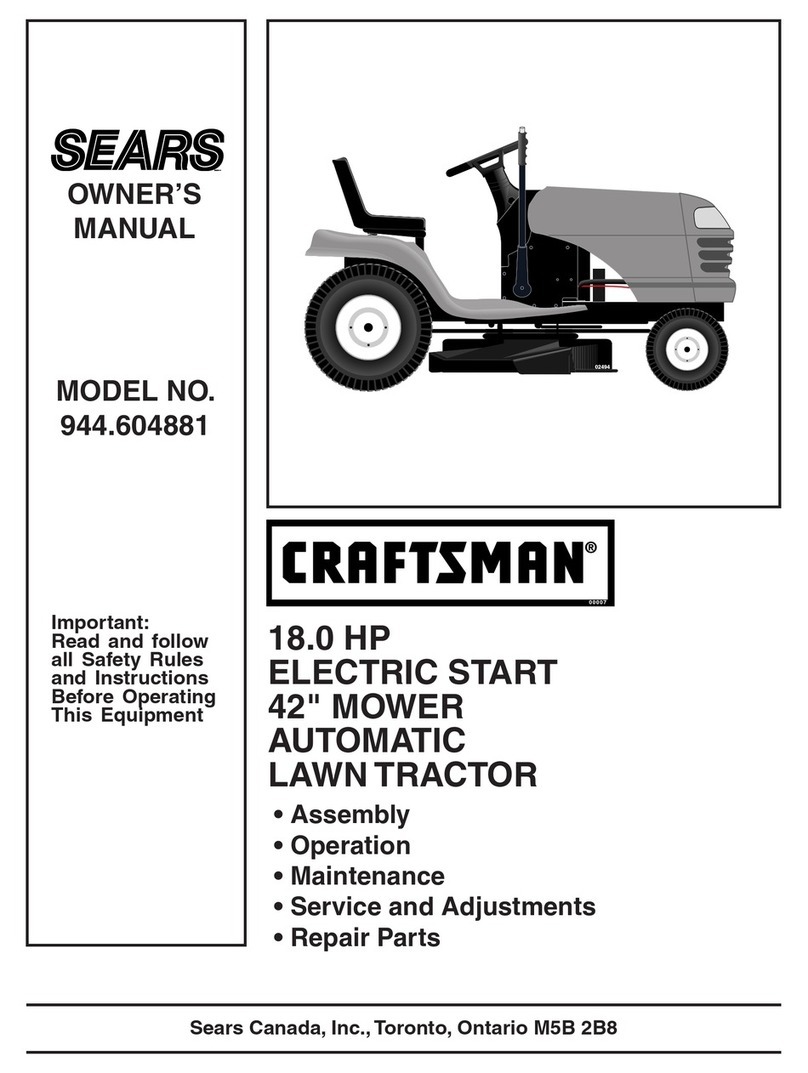

FULL ONE YEAR WARRANTY

ON ELECTRIC START GARDEN TRACTOR

For one year from the date of purchase, when this Garden Tractor is used for personal household purposes, Sears will repair any defect in

material orworkmanship in this Garden Tractor, except the battery, at no charge.

If this GardenTractor is used for commercial or rental purposes,thiswarrantyapplies for only 30 days from the date of purchase.

FULL 90-DAY WAR RANTY ON BATTERY

For 90 days from thedate of purchase, if anybatteryincludedwith theGarden Tractor proves defective in material or workmanship and will

not hold a charge, Sears will replace the battery, at nocharge.

LIMITED WARRANTY ON BATTERY

From the 91st day until one yearfromthe date of purchase, if any battery included with theGarden Tractor proves defective in material or

workmanship and will not hold a charge, Sears will replace the battery, charging 1/12th oftheprice of the new battery for each full month

from the date of purchase.

Warranty service is available at your home, at no charge, by simply contacting the nearest Sears storeor Service Center throughout the United

States.

Thiswarranty gives you specific legal rights,and you may also have other rights which vary from stateto state.

Sears, Roebuck and Co.

Sears Tower

SSC 41-3

Chicago,IL 60684

WARNING

This unit is equipped with an internal combustion engine and should not be used on or nearany unimproved forest-{;overed, brush-{;overed or grass-

covered land unless the engine's exhaust system is equippedwith a sparkarrester meetingapplicable local or state laws (if any).If a spark arrester is

used,it should be maintainedin effective working order by the operator.

In the State of California the above is required by law (Section4442 of the California PublicResources Code). Other states may have similar laws.

Federal laws apply on federal lands.See your S"ars Authorized Service Center for spark arrester muffler part number 6383R.

A

LOOKFOR THIS SYMBOL TO POINT OUT IMPORTANT

SAFETY PRECAUTIONS.IT MEANS-ATTENTION

BECOME ALERT YOUR SAFETYIS INVOLVED.

1.Know thecontrolsand how

OWNER'S MANUAL.

2.Do not allow childrento operatethevehicle. Do not allow

adults tooperate itwithout proper instruction.

3. Do not carry passengers. Keep childrenand pets a safe dis-

tance away.

4.Always wear substantial footwear. Donotwear loosefitting

clothing that could get caught in moving parts.

5.Keep your eyes and mind on your tractor, mower andthe

areabeing cut.Don't let other interests distract you.

6.Do notattemptto operate your tractor or mowerwhen

not indrivers seat.

7. Always get on oroffyour tractor from theoperators left

handside.

8.Clear the work area of objects which might be picked up

and thrown.

9. Disengage all attachment clutches and shift into neutral be-

fore attempting to start the engine.

10. Disengage power to attachments and stop the engine be-

fore leaving the operator's position.

11. Disengage power to mower, stopthe engine and disconnect

spark plug wire(s) from spark plug(s) before cleaning, mak-

ing an adjustment or repairs.

12.Disengage power to attachments when transporting or not

in use.

13. Take all possible precautions when leaving the vehicle un-

attended, such as disengaging the power-take-off, lowering

the attachments, shifting'into neutral,setting the parking

brake,stopping the engine, and removing the key.

14. Do not stop or start suddenly when going uphill or down-

hill. Mow up and down the face of slopes (not greater than

15°); never across theface.

15. Reduce speed on slopes and make turns gradually to pre-

vent tipping or loss of control. Exercise extreme caution

when changing direction on slopes.

16. Do not shift gears while going up or down slopes. Choose a

gear low enough tonegotiate the slope without stopping

and shifting gears.To reduce speed, move throttle lever

to slow.

17.Never mow in wet orslippery grass, when traction is un·

sure or at a speed which could cause a skid.

18. Stay alert for holes in the terrain and other hidden hazards.

19.Do not drive,too close to creeks, ditches and public high·

ways.

20. Exercise special care when mowing around fixed objects

in order to prevent theblades from striking them. Never

deliberately run tractor or mower into Or over any foreign

object.

21. Never shift gears until tractor comes to a stop.

22. Never place hands or feet under the mower,in the deflector

(discharge chute) or near any moving parts while tractor or

mower are running.Always keep clear of discharge chute.

RULES FOR SAFE OPERATION

to stopquickly.READ THE 23. Use care when pulling loads or using heavy equipment.

a. Use only approved drawbar hitch points.

b. Limit loads to those you can safely control.

c.Donot turn sharply. Use care when backing.

d. Usecounterweight or wheel weights when suggested in

this owner's manual.

24.Watch out for traff:: when crossing or near roadways.

25. When using any attachments, never direct discharge of

material toward bystanders nor allow anyone near theve-

hicle while in operation.

26. Handle gasoline with care - it is highly flammable.

a. Use approved gasoline containers.

b. Never remove the cap of the fuel tank or add gasoline to

a running or hot engine, or fill the fuel tank indoors.

Wipe up spilled gasoline.

c.Open doors if the engine is run in the garage - exhaust

fumes are dangerous. Do not run the engine indoors.

27. Keep the vehicle and attachments in good operating con-

dition, and keep safety devices in place.

28.Keep all nuts,bolts and screws tight to be sure the equip-

ment is in safe working condition.

29. Never store the equipment with gasoline in the tank inside

abuilding where fumes may reach an open flame orspark.

Allow the engine to cool before storing in any enclosure.

30.To reducefire hazard, keep the engine free ofgrass,leaves

orexcessivegrease.

31.Except for adjustment; DO NOT operate Engine if air

cleaner or cover directly over carburetor air intake is re-

moved. Removal of such part could create a fire hazard.

32. DO NOT OPERATE WITHOUTA MUFFLER OR TAM-

PER WITH THE EXHAUST SYSTEM. Damaged mufflers

or spark arresters couldcreate a fire hazard. Inspect period-

ically and replace if necessarv.

33. The vehicle and attachments should be stopped and inspect-

ed for damage after striking a foreign object,and the dam-

age should be repaired before restarting and operating the

equipment.

34. Do not change the engine governor settings or overspeed

the engine.

35. When using the vehicle with mower, proceed as follows:

a.Mow only in daylight or in good artificial light.

b. Never make a cutting height adjustment while the engine

is running if the operator must dismount to do so.

c. Shut the engine off when removing the grass catcher or

unclogging chute.

d.Check the blade mounting bolts for proper tightness at

frequent intervals.

36.Check the grass catcher bags frequently for wear or deterio-

ration. Replace with new bags for safety protection.

37.Do not operate the Mower without either the entire grass

catcher, on mowers so equipped, or the deflector shield in

place. ..

another free manual from www.searstractormanuals.com