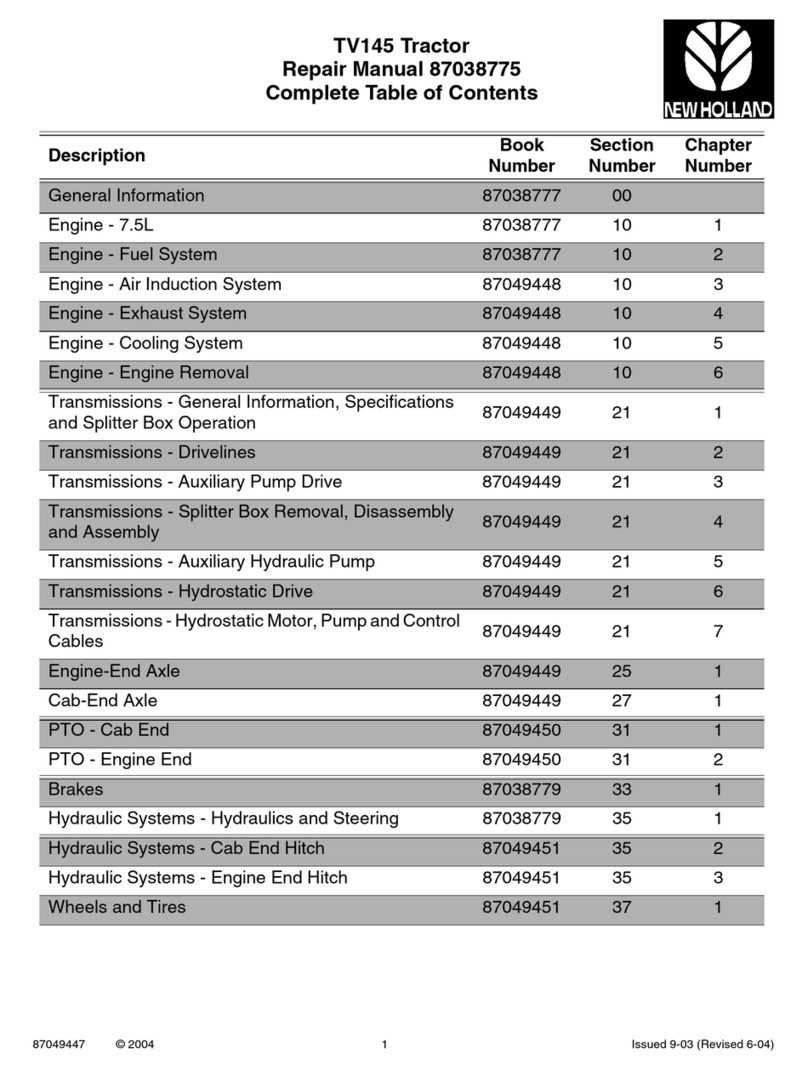

PowerTake-Off(PTO).................................................................31

[31.104]Rearelectro-hydrauliccontrol......................................................31.1

[31.110]One-speedrearPowerTake-Off(PTO)............................................31.2

[31.120]CentralPowerT ake-Off(PTO).....................................................31.3

Brakesandcontrols....................................................................33

[33.110]Parkingbrakeorparkinglock......................................................33.1

[33.120]Mechanicalservicebrakes.........................................................33.2

Hydraulicsystems.......................................................................35

[35.000]Hydraulicsystems..................................................................35.1

[35.104]Fixeddisplacementpump..........................................................35.2

[35.204]Remotecontrolvalves.............................................................35.3

[35.300]Reservoir,cooler,andlters........................................................35.4

Steering.....................................................................................41

[41.200]Hydrauliccontrolcomponents......................................................41.1

[41.206]Pump...............................................................................41.2

[41.216]Cylinders...........................................................................41.3

Cabclimatecontrol.....................................................................50

[50.100]Heating.............................................................................50.1

[50.104]Ventilation..........................................................................50.2

[50.200]Airconditioning.....................................................................50.3

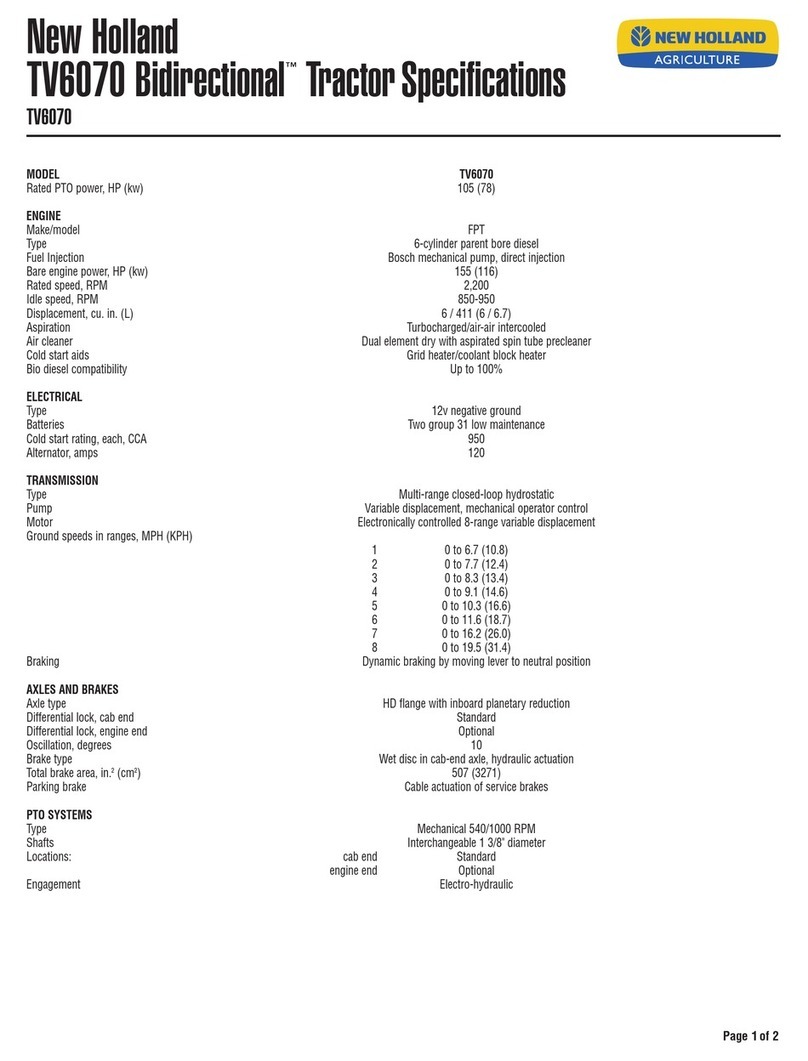

Electricalsystems.......................................................................55

[55.000]Electricalsystem...................................................................55.1

[55.010]Fuelinjectionsystem...............................................................55.2

[55.024]Transmissioncontrolsystem.......................................................55.3

[55.100]Harnessesandconnectors.........................................................55.4

[55.201]Enginestartingsystem.............................................................55.5

[55.301]Alternator...........................................................................55.6

[55.302]Battery..............................................................................55.7

47975091_06/07/2016