Po er Assist for SeaStar Systems 1

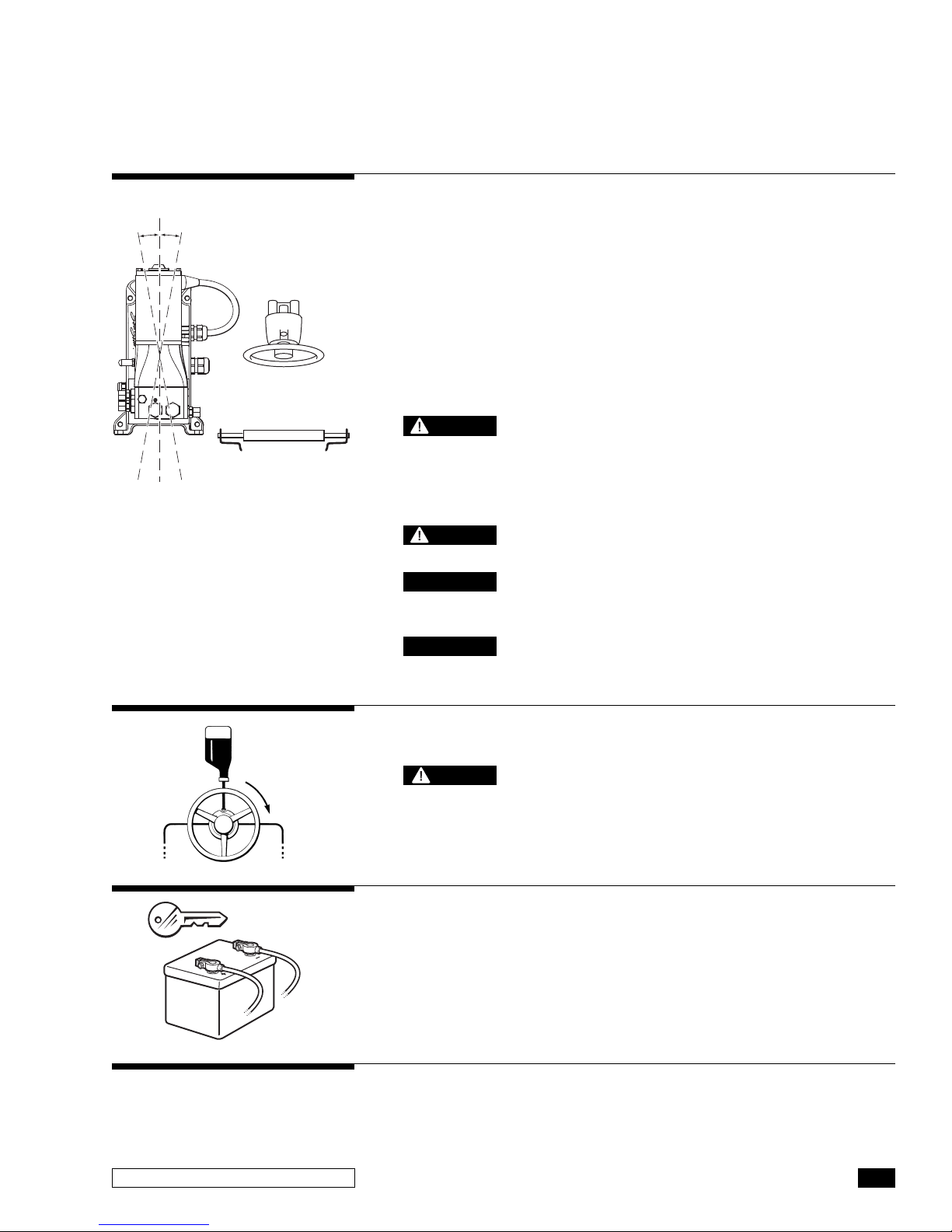

Ensure that the following he k list is arried out

1With the P/A unit "OFF" (ignition off) perform a system pressure

test by turning the helm all the way to hard over and then for ing

the helm another one quarter to one half turn past the stop point.

Inspe t the following areas for leaks.

- Inspe t helm fittings

- Inspe t P/A fittings

- Inspe t ylinder fittings

Look for eviden e of a leak. This test is to be done in BOTH

dire tions. Any leak that is noti ed will need to be repaired

before operating the boat.

2Confirm that extruded nylon tubing has NOT been

substituted for SeaStar/SeaStar PRO Hydraulic Steering hose.

3Confirm that there is no interferen e between the steering

ylinder and the transom, splashwell or ja kplate or any

ombination of these parts by performing these simple steps:

• If installed on an outboard engine, with the engine fully titled,

turn steering from hard over to hard over and onfirm that NO

interferen e o urs. If you are using a hydrauli ja k plate this

also must be performed at the top and bottom position of the

ja k plate. (If interference is present, it MUST be eliminated

with trim limiting switches and/or jack plate restrictors. Contact

Jack plate manufacturer for advice if required.)

• Confirm that the steering ylinder an be stroked fully in both

dire tions as well as full tilt and trim without stret hing and/or

kinking the hydrauli hoses.

• Confirm that the hydrauli hose/tube are not subje ted to hafing,

rubbing or stret hing. Stret hed, kinked or hafed hose/tube will

fail over a period of time leading to loss of steering ontrol.

BEFORE OPERATING

YOUR BOAT

Failure to comply with the above may result in loss of steering

control, leading to collision with obstacle(s), ejection from vessel

resulting in property damage and/or personal injury or death.

WARNING

The SeaStar P/A unit has been

designed and tested for use with

Marine Hydraulic Steering ONLY.

It is not recommended for any

other use. Not complying with

this warning may result in

property damage and/or

personal injury or death.

WARNING

Stretched, kinked or chafed hose will fail over a period of time.

WARNING

When working in an area where fumes from fuel are present, allow

the fumes to disperse completely BEFORE doing any electrical

connection to the battery. Failure to do so may result in an

explosion and or fire.

WARNING

If power to the unit is lost, the SeaStar Power Assist and SeaStar

Power Assist PRO will revert to manual steering, requiring substan-

tially more effort to turn the wheel.

CAUTION