SEC America SSV 1000-12 User manual

Please read this manual before operating your inverter.

PURE SINE WAVE

DC-AC INVERTER

MODELS: SSV 1000-12

SSV 1000-24

AC POWER SOURCE

OWNER'S MANUAL

INDEX

Safety Instructions ............................................................................................. 2,3

Inverters - General Information ...................................................................... 4,5,6

Characteristics of SinusoidalAC Power ............................................................... 7

Advantages of Sine Wave Inverters ...................................................................... 8

AC Power Distribution and Grounding ..................................................... 9,10,11

Limiting Electromagnetic Interference (EMI) .................................................... 11

Powering direct/embedded SMPS ...................................................................... 12

Principle of Operation ........................................................................................ 13

Layout ................................................................................................................. 13

Specifying Batteries, Chargers andAlternators ..............................14,15,16,17,18

Installation ......................................................................................19,20,21,22,23

Operation ....................................................................................................... 24,25

ProtectionAgainstAbnormal Conditions ...................................................... 25,26

Troubleshooting Guide .................................................................................. 27,28

Specifications...................................................................................................... 29

Warranty ............................................................................................................. 30

INDEX

Page 1

Page 2

SAFETY INSTRUCTIONS

Please read these instructions before installing or operating the inverter to prevent personal

injury or damage to the inverter.

GENERAL

Installation and wiring compliance

- Installation and wiring must comply with the local and national electrical codes and must

be done by a certified electrician

Preventing electrical shock

- Always connect the grounding connection on the inverter to the appropriate grounding

system

- Disassembly / repair should be carried out by qualified personnel only.

- Disconnect all AC and DC side connections before working on any circuits associated with

the inverter. Turning the on/off switch on the inverter to off position may not entirely

remove dangerous voltages

- Be careful when touching bare terminals of capacitors. The capacitors may retain high

lethal voltages even after the power has been removed. Discharge the capacitors before

working on the circuits

Installationenvironment

- The inverter should be installed indoor only in a well ventilated, cool, dry environment

- Do not expose to moisture, rain, snow or liquids of any type.

- To reduce the risk of overheating and fire, do not obstruct the suction and discharge

openings of the cooling fan

- To ensure proper ventilation, do not install in a low clearance compartment

Preventing fire and explosion hazards

Working with the inverter may produce arcs or sparks. Thus, the inverter should not be used

in areas where there are inflammable materials or gases requiring ignition protected equip-

ment. These areas may include spaces containing gasoline powered machinery, fuel tanks,

battery compartments

Precautions when working with batteries.

- Batteries contain very corrosive diluted sulphuric acid as electrolyte. Precautions should be

taken to prevent contact with skin, eyes or clothing

- Batteries generate hydrogen and oxygen during charging resulting in evolution of explosive

gas mixture. Care should be taken to ventilate the battery area and follow the battery

manufacturer’s recommendations.

- Never smoke or allow a spark or flame near the batteries.

- Use caution to reduce the risk of dropping a metal tool on the battery. It could spark or short

circuit the battery or other electrical parts and could cause an explosion.

- Remove metal items like rings, bracelets and watches when working with batteries. The

batteries can produce a short circuit current high enough to weld a ring or the like to metal

and thus cause a severe burn.

- If you need to remove a battery, always remove the ground terminal from the battery first.

Make sure that all the accessories are off so that you do not cause a spark

Page 3

INVERTER RELATED

Preventing paralleling of theAC output

The AC output of this inverter cannot be synchronised with another AC source and hence, it

is not suitable for paralleling. TheAC output of the inverter should never be connected

directly to an electrical breaker panel / load center which is also fed from the utility power /

generator. Such a connection may result in parallel operation of the different power sources

and AC power from the utility / generator will be fed back into the inverter which will

instantly damage the output section of the inverter and may also pose a fire and safety

hazard. If an electrical breaker panel / load center is fed from an inverter and this panel is

also required to be powered from additional alternate AC sources, the AC power from all

the AC sources like the utility / generator / inverter should first be fed to a manual selector

switch and the output of the selector switch should be connected to the electrical breaker

panel / load center.

To prevent possibility of paralleling and severe damage to the inverter, never use a simple

jumper cable with a male plug on both ends to connect the AC output of the inverter to a

handy wall receptacle in the home / RV.

Connecting to multi-wire branch circuits

Do not directly connect the hot side of the inverter to the two hot legs of the 120 / 240 VAC

electrical breaker panel / load centre where multi-wire ( common neutral ) branch circuit

wiring method is used for distribution of AC power. This may lead to overloading /

overheating of the neutral conductor and is a risk of fire.

A split phase transformer ( isolated or auto-transformer ) of suitable wattage rating ( 25 %

more than the wattage rating of the inverter ) with primary of 120 VAC and secondary of

120 / 240 VAC ( Two 120 VAC split phases 180 degrees apart) should be used. The hot and

neutral of the 120 VAC output of the inverter should be fed to the primary of this trans-

former and the 2 hot outputs ( 120 VAC split phases ) and the neutral from the secondary of

this transformer should be connected to the electrical breaker panel / load centre.

Preventing input over voltage

It is to be ensured that the input voltage of the inverter does not exceed 16.5 VDC for SSV

1000-12 or 33 VDC for SSV 1000-24 to prevent permanent damage to the inverter.

Please observe the following precautions:

- Ensure that the maximum charging voltage of the battery charger / alternator / solar

charge controller is below 16.5 VDC for SSV 1000-12 or 33 VDC for SSV 1000-24

- Do not use unregulated solar panels to charge a battery. Under cold ambient temperatures,

the output of the solar panel may exceed 18 VDC for 12 V system or 36 VDC for 24 V

system. Always use a charge controller between the solar panel and the battery.

- Do not connect the inverter to a battery system with a voltage higher than the rated

battery input voltage.

Preventing reverse polarity on the input side

When making battery connection on the input side, make sure that the polarity of battery

connection is correct (Connect the positive of the battery to the positive terminal of the

inverter and the negative of the battery to the negative terminal of the inverter). If the input

is connected in reverse polarity, DC fuse(s) inside the inverter will blow and may also cause

permanent damage to the inverter. DAMAGE CAUSED BY REVERSE POLARITY IS

NOT COVERED BY YOUR WARRANTY!

INVERTERS - GENERAL INFORMATION

Why an inverter is needed

The utility grid supplies you with alternating current (AC) electricity. AC is the standard

form of electricity for anything that “plugs in” to the utility power. Direct current (DC)

electricity flows in a single direction. Batteries provide DC electricity. AC alternates its

direction many times per second.AC is used for grid service because it is more practical

for long distance transmission. For more details read “Characteristics of SinusoidalAC

Power” on page 7.

An inverter converts DC to AC, and also changes the voltage. In other words, it is a

power adapter. It allows a battery-based system to run conventional AC appliances

directly or through conventional home wiring. There are ways to use DC directly, but for

a modern lifestyle, you will need an inverter for the vast majority, if not all of your loads

(in electrical terms, “loads” are devices that use electrical energy).

Incidentally, there is another type of inverter called grid-interactive. It is used to feed

solar (or other renewable) energy into a grid-connected home and to feed excess energy

back into the utility grid. This inverter is NOT grid interactive

Inverter should meet the application

To choose an inverter; you should first define your needs. Where is the inverter to be

used? Inverters are available for use in buildings (including homes), for recreational

vehicles, boats, and portable applications. Will it be connected to the utility grid in some

way? Electrical conventions and safety standards differ for various applications, so don’t

improvise.

ElectricalStandards

The DC input voltage must conform to that of the electrical system and battery bank. 12

volts is recommended for small, simple systems. 24 and 48 volts are the common

standards for higher capacities. Ahigher voltage system carries less current, which makes

the system wiring cheaper and easier.

The inverter’s AC output must conform to the conventional power in the region in order

to run locally available appliances. The standard forAC utility service in North America

is 120 and 240 Volts at a frequency of 60 Hertz (cycles per second). In Europe, South

America, and most other places, it is 230 volts at 50 Hertz.

Power capacity – “Continuous” and “Surge”

How much load can an inverter handle? Its power output is rated in Watts. Read details

under “Characteristics of SinusoidalAC Power” on page 7. There are two levels of

power rating -a continuous rating and a surge rating. Continuous means the amount of

power the inverter can handle for an indefinite period of hours. When an inverter is rated

at a certain number of Watts, that number generally refers to its continuous rating. The

“surge power” indicates the power to handle instantaneous overload of a few seconds to

provide the higher power required to start certain type of devices and appliances.

Page 4

Page 5

Loads that require “surge power” to start

Resistive types of loads (like incandescent lamps, toaster, coffee maker, electric range,

iron etc) do not require extra power to start. Their starting power is the same as their

running power.

Some loads like induction motors and high inertia motor driven devices will initially

require a very large starting or “surge” power to start from rest. Once they have started

moving and have attained their rated speed, their power requirement reduces to their

normal running power. The surge may last up to 5 seconds.

TVs and microwave ovens also require surge power for starting. The manufacturers’

specification of the appliances and devices indicates only the running power required.

The surge power required has to be guessed at best. See below under “Sizing of inverter

for loads that require starting surge”

If an inverter cannot efficiently feed the surge power, it may simply shut down instead of

starting the device. If the inverter’s surge capacity is marginal, its output voltage will dip

during the surge. This can cause a dimming of the lights in the house, and will sometimes

crash a computer.

Any weakness in the battery and cabling to the inverter will further limit its ability to start

a motor. A battery bank that is undersized, in poor condition, or has corroded connections,

can be a weak link in the power chain. The inverter cables and the battery interconnect

cables must be sized properly. The spike of DC current through these cables is many

hundreds of amps at the instant of motor starting. Please follow the instructions under

"Installation - DC side connections" on pages 20 & 21.

Sizing of inverter for loads that require starting surge

Observe the following guideline to determine the continuous wattage of the inverter for

powering loads that require starting surge. (Multiply the running watts of the device/

appliance by the Surge Factor)

*NOTE: The surge power rating specified for this inverter is valid for duration

of less than 1 second. This very short duration may not be sufficient to

start motor based loads which may require up to 5 seconds to complete

starting process. Hence, for purposes of sizing the inverter, use only the

continuous power rating of this inverter.

Type of Device orAppliance Surge Factor for Determining the Continuous *Wattage of the Inverter

(No. of times the running power rating of the device/appliance)

Refrigerator / Freezer 5

Air Compressors 4

Dishwasher 3

Automatic Washer 3

Sump pump 3

Furnace fans 3

Industrial motors 3

Portable kerosene / diesel fuel heater 2

Circular saw 3

Bench Grinder 3

Page 6

Power rating of Microwaves

The power rating of the microwave generally refers to the cooking power. The electrical

power consumed by the microwave will be approximately 2 times the cooking power. The

“surge power” of the inverter should be 2 times the electrical power (i.e., 4 times the

cooking power). Please note that the surge power of the microwave is not as long as the

motor load and hence, the surge power of the inverter can be considered to determine

adequacy of meeting the starting surge power

Powering a water supply pump

A water well or pressure pump often places the greatest demand on the inverter. It

warrants special consideration. Most pumps draw a very high surge of current during start

up. The inverter must have sufficient surge capacity to handle it while running any other

loads that may be on. It is important to size an inverter sufficiently, especially to handle

the starting surge (If the exact starting rating is not available, the starting surge can be

taken as 3 times the normal running rating of the pump). Oversize it still further if you

want it to start the pump without causing lights to dim or blink.

In North America, most pumps (especially submersibles) run on 240 VAC, while smaller

appliances and lights use 120 VAC. To obtain 240 VAC from a 120 VAC inverter, use a

120 VAC to 240 VAC transformer. If you do not already have a pump installed, you can

get a 120 volt pump if you don’t need more than 1/2 HP.

Idle power

Idle power is the consumption of the inverter when it is on, but no loads are running. It is

“wasted” power, so if you expect the inverter to be on for many hours during which there

is very little load (as in most residential situations), you want this to be as low as

possible.

Phantom and idling loads

Most of the modern gadgets draw some power whenever they are plugged in. Some of

them use power to do nothing at all. An example is a TV with a remote control. Its

electric eye system is on day and night, watching for your signal to turn the screen on.

Every appliance with an external wall-plug transformer uses power even when the

appliance is turned off. These little loads are called “phantom loads” because their power

draw is unexpected, unseen, and easily forgotten.

A similar concern is “idling loads.” These are devices that must be on all the time in order

to function when needed. These include smoke detectors, alarm systems, motion detector

lights, fax machines, and answering machines. Central heating systems have a trans-

former in their thermostat circuit that stays on all the time. Cordless (rechargeable)

appliances draw power even after their batteries reach a full charge. If in doubt, feel the

device. If it’s warm, that indicates wasted energy.

Page 7

CHARACTERISTICS OF SINUSOIDAL AC POWER

Voltage, current, power factor, types of loads

The voltage waveform of 120 VAC, 60 Hz mains / utility power is like a sine wave. In a

voltage with a sine wave-form, the instantaneous value and polarity of the voltage varies

with respect to time and the wave-form is like a sine wave. In one cycle, it slowly rises in

the positive direction from 0 V to a peak positive value + Vpeak = 170 V, slowly drops to 0

V, changes the polarity to negative direction and slowly increases in the negative direction

to a peak negative value - Vpeak =170 V and then slowly drops back to 0 V. There are 60

such cycles in 1 sec. Cycles per second is called the “frequency” and is also termed “Hertz

(Hz.). If a linear load is connected to this type of voltage, the load will draw current which

will also have the same sine wave-form. However, the peak value of the current will depend

upon the impedance of the load. Also, the phase of the sine wave-form of the current drawn

by the linear load may be the same or lead / lag the phase of sine wave-form of the voltage.

This phase difference determines the “Power Factor (mathematically = the cosine of the

phase difference)” of the load. In a resistive type of load (like incandescent lamps, heaters

etc) the sine wave-form of the current drawn by the load has 0 phase difference with the sine

wave-form of the voltage of the AC power source. The Power Factor of a resistive load is

unity (1). The rated output power (in Watts) of the inverters is normally specified for

resistive type of loads that have unity (1) Power Factor. In a reactive type of load (like

electric motor driven loads, fluorescent lights, computers, audio / video equipment etc), the

phase of the sine wave-form of the current drawn by the load may lead or lag the sine wave-

form of the AC voltage source. In this case, the power factor of reactive loads is lower than

unity (1) – generally between 0.8 and 0.6. Areactive load reduces the effective wattage

that can be delivered by anAC power source

RMS and peak values

As explained above, in a sine wave, the instantaneous values of AC voltage (Volt, V) and

current (Ampere, A) vary with time. Two values are commonly used – Root Mean Square

(RMS) value and peak value. For simplicity, RMS value can be considered as an average

value. Mathematically, Peak Value = 1.414 x RMS value. For example, the 120 VAC, 60

Hz. mains / utility power is the RMS value. The peak value corresponding to this is = 1.414

x 120 = 170V.

The values of the rated output voltage and current of anAC power source are their

RMS values

AC power – Watts / VA

The power rating of an AC power source is designated in Volt Amperes (VA) or in Watts

(W)

Power in Volt Amperes (VA) = RMS Volts (V) x RMS Amps (A)

Power in Watts = RMS Volts (V) x RMS Amps (A) x Power Factor

NOTE : The rated power of the inverter in Watts (W) is normally designated for a linear,

resistive type of load that draws linear current at unity (1) power factor. If the load is

linear and reactive type, the rated power of the inverter in watts will be limited to its

normal rated power in watts (W) x Power Factor. For example, an inverter rated for

1000 W ( at unity power factor) will be able to deliver only 600 watts to a reactive type

of load with a power factor of 0.6

Page 8

ADVANTAGES OF A PURE SINE-WAVE INVERTER

OVER A MODIFIED SINE-WAVE INVERTER

The output voltage of a sine-wave inverter has a sine wave-form like the sine wave-form

of the mains / utility voltage. In a sine wave, the voltage rises and falls smoothly with a

smoothly changing phase angle and also changes its polarity instantly when it crosses 0

Volts. In a modified sine wave, the voltage rises and falls abruptly, the phase angle also

changes abruptly and it sits at 0 Volts for some time before changing its polarity. Thus,

any device that uses a control circuitry that senses the phase (for voltage / speed control)

or instantaneous zero voltage crossing (for timing control) will not work properly from a

voltage that has a modified sine wave-form.

Also, as the modified sine wave is a form of square wave, it is comprised of multiple sine

waves of odd harmonics (multiples) of the fundamental frequency of the modified sine

wave. For example, a 60 Hz. modified sine wave will consist of sine waves with odd

harmonic frequencies of 3rd(180 Hz), 5th (300 Hz.), 7th (420 Hz.) and so on. The high

frequency harmonic content in a modified sine wave produces enhanced radio interfer-

ence, higher heating effect in motors / microwaves and produces overloading due to

lowering of the impedance of low frequency filter capacitors / power factor improvement

capacitors.

Advantages of sine-wave inverters:

•The output wave-form is a sine-wave with very low harmonic distortion and

clean power like utility supplied electricity.

•Inductive loads like microwaves and motors run faster, quieter and cooler

•Reduces audible and electrical noise in fans, fluorescent lights, audio amplifi-

ers, TV, fax and answering machines

•Prevents crashes in computers, weird print outs and glitches in monitors

Some examples of devices that may not work properly with modified sine wave and may

also get damaged are given below:

•Laser printers, photocopiers, magneto-optical hard drives

•The built-in clocks in devices such as clock radios, alarm clocks, coffee

makers, bread-makers, VCR, microwave ovens etc may not keep time correctly.

•Output voltage control devices like dimmers, ceiling fan / motor speed control

may not work properly (dimming / speed control may not function)

•Sewing machines with speed / microprocessor control

•Transformer-less capacitive input powered devices like (i) Razors, flashlights,

night-lights, smoke detectors etc (ii) Re-chargers for battery packs used in hand

power tools. These may get damaged. Please check with the manufacturer

of these types of devices for suitability

•Devices that use radio frequency signals carried by the AC distribution wiring.

•Some new furnaces with microprocessor control / Oil burner primary controls

•High intensity discharge (HID) lamps like Metal Halide lamps. These may get

damaged. Please check with the manufacturerof these types of devices for

suitability

•Some fluorescent lamps / light fixtures that have power factor correction

capacitors. The inverter may shut down indicating overload

Page 9

AC POWER DISTRIBUTION AND GROUNDING

CAUTION! PLEASE NOTE THAT THEAC OUTPUT CONNECTIONS AND THE DC

INPUT CONNECTIONS ONTHIS INVERTERARE NOT

CONNECTED (BONDED) TO THE METAL CHASSIS OF THE

INVERTER. BOTH THE INPUTAND OUTPUT CONNECTIONSARE

ISOLATED FROM THE METAL CHASSISAND FROM EACH OTHER.

SYSTEM GROUNDING,AS REQUIRED BY NATIONAL / LOCAL

ELECTRICAL CODES / STANDARDS, IS THE RESPONSIBILITYOF THE

USER / SYSTEM INSTALLER.

Conductors for electrical power distribution

For single phase transmission of AC power or DC power, two conductors are required

that will be carrying the current. These are called the “current-carrying” conductors.A

third conductor is used for grounding to prevent the build up of voltages that may result

in undue hazards to the connected equipment or persons. This is called the “non current-

carrying” conductor (will carry current only under ground fault conditions)

Groundingterminology

The term “grounded” indicates that one or more parts of the electrical system are

connected to earth, which is considered to have zero voltage or potential. In some areas,

the term “earthing” is used instead of grounding.

A “grounded conductor” is a “current-carrying” conductor that normally carries current

and is also connected to earth. Examples are the “neutral” conductor in AC wiring and

the negative conductor in many DC systems. A“grounded system” is a system in which

one of the current-carrying conductors is grounded

An “equipment grounding conductor” is a conductor that does not normally carry current

(except under fault conditions) and is also connected to earth. It is used to connect the

exposed metal surfaces of electrical equipment together and then to ground. Examples are

the bare copper conductor in non-metallic sheathed cable (Romex ®) and the green,

insulated conductor in power cords in portable equipment. These equipment-grounding

conductors help to prevent electric shock and allow over-current devices to operate

properly when ground faults occur. The size of this conductor should be coordinated with

the size of the over-current devices involved

A “grounding electrode” is the metallic device that is used to make actual contact with the

earth. Other types of grounding electrodes include metal water pipes and metal building

frames.

A “grounding electrode conductor” is the conductor between a common single grounding

point in the system and the grounding electrode

“Bond” refers to the connection between the “grounded conductor”, the “equipment

grounding” conductors and the “grounding electrode” conductor. Bonding is also used to

describe connecting all of the exposed metal surfaces together to complete the equip-

ment-grounding conductors.

Page 10

Grounded Electrical Power Distribution System

The National Electrical Code (NEC) requires the use of a “grounded electrical distribu-

tion system”.As per this system, one of the two current-carrying conductors is required to

be grounded. This grounded conductor is called the “Neutral / Cold / Return”. As this

conductor is bonded to earth ground, it will be at near zero voltage or potential. There is

no risk of electrical shock if this conductor is touched. The other current carrying

conductor is called the “Line / Live / Hot”. The connection between the “Neutral” and the

grounding electrode conductor is made only at one point in the system. This is known as

the system ground. This single point connection (bond) is usually made in the service

entrance or the load center. If this connection is inadvertently made in more than one

place, then unwanted currents will flow in the equipment grounding conductors. These

unwanted currents may cause inverters and charge controllers to be unreliable and may

interfere with the operation of ground-fault detectors and over-current devices.

NOTE:Acurrent-carrying conductor that is not bonded to the earth ground cannot

be called a “neutral”. This conductor will be at an elevated voltage with respect to

the earth ground and may produce electrical shock when touched.

Polarity and color codes for power cords and plugs forAC devices and appliances

Single phase 120 VAC, 60 Hz AC devices and appliances use 2 pole, 3 wire grounding

configuration for connection to the AC power source. The plug of the power cord has

three pins – two flat pins ( also called poles ) that are connected to the two current-

carrying conductors and a round pin which is connected to a non-current carrying

conductor ( this will carry current only during ground fault conditions ) . One flat pin is

connected to a black current-carrying conductor which is also called “Line/Live/Hot”

pole. The other flat pin is connected to the white current-carrying conductor also called

the “Neutral / Return / Cold” pole. The third round pin is connected to the non-current

carrying green “equipment grounding conductor”. This green “equipment grounding

conductor” is bonded to the metal chassis of the device or appliance.

AC output connections

The 120 VAC, 60 Hz version of the inverter uses NEMA 5-15R receptacles for connect-

ing the AC output of the inverter to devices and appliances fitted with a NEMA 5-15P

plug. The two rectangular slots are connected to the current-carrying conductors of the

AC power source inside the inverter. The round slot is the “equipment grounding”

connection and is internally connected to the metal chassis of the inverter.

CAUTION! : For the 120 VAC, 60 Hz NEMA 5-15R receptacles used in this inverter, the current

carrying conductor connected to the longer rectangular slot is isolated from the metal chassis of the

inverter. Hence, when the metal chassis of the inverter is connected to the earth ground, the longer

rectangular slot is not grounded to the earth ground. The longer rectangular slot is, therefore, not a

“neutral”. Do not touch this slot as it will be at an elevated voltage with respect to the metal chassis

/ earth ground and may produce an electrical shock when touched.

Page 11

Grounding to earth orto other designated ground

For safety, the metal chassis of the inverter is required to be grounded to the earth ground or

to the other designated ground (For example, in a mobile RV, the metal frame of the RV is

normally designated as the negative DC ground). An equipment grounding bolt with a wing

nut has been provided for grounding the metal chassis of the inverter to the appropriate

ground. (Located under the DC input terminals)

When using the inverter in a building, connect a # 8 AWG insulated stranded copper wire

from the above equipment grounding bolt to the earth ground connection ( a connection that

connects to the ground rod or to the water pipe or to another connection that is solidly

bonded to the earth ground ). The connections must be tight against bare metal. Use star

washers to penetrate paint and corrosion.

When using the inverter in a mobile RV, connect a # 8 AWG insulated stranded copper wire

from the above equipment grounding bolt to the appropriate ground bus of the RV (usually

the vehicle chassis or a dedicated DC ground bus ). The connections must be tight against

bare metal. Use star washers to penetrate paint and corrosion.

The inverter contains internal switching devices which generate conducted and radiated

electromagnetic interference (EMI).

The magnitude of EMI is limited to acceptable levels by circuit design but can not be

entirely eliminated. The effects of EMI will also depend upon a number of factors

external to the power supply like proximity of the inverter to the EMI receptors, types

and quality of connecting wires and cables etc. EMI due to factors external to the inverter

can be reduced as follows:

- Ensure that the inverter is firmly grounded to the ground system of the building or the

vehicle

- Locate the inverter as far away from the EMI receptors like radio, audio and video

devices as possible

- Keep the DC side cables between the battery and the inverter as short as possible.

- Twist the DC side cables. This will partially cancel out the radiated noise from the

cables

- Shield the DC side cables with metal sheathing / copper foil / braiding

- Use co-axial shielded cable for all antenna inputs (instead of 300 ohm twin leads)

- Use high quality shielded cables to attach audio and video devices to one another

- Do not operate other high power loads when operating audio / video equipment

LIMITING ELECTRO-MAGNETIC INTERFERENCE

(EMI)

Page 12

POWERING DIRECT / EMBEDDED SWITCHED

MODE POWER SUPPLY (SMPS)

Non-linear nature of current drawn by Switched Mode Power Supplies

Power supplies are used to convert AC voltages like 120 VAC to various DC voltages

like 3.3 V, 5 V, 12 V, 24 V, 48 V etc. Majority of modern day electronic devices use

embedded general purpose Switch Mode type of Power Supplies (SMPS) to drive the

electronic circuitry. General purpose Switch Mode Power Supplies (SMPS) ( excepting

those that have power factor correction ) have one major disadvantage – the current

drawn by them from the AC power source has a non linear waveform ( the waveform is

not sinusoidal as the input voltage waveform but is in the form of short, larger value pulses

around the area of + Vpeak and -Vpeak ). This is due to the charging of the input filter

capacitor(s) mostly around the positive and negative peak portions of the sinusoidal input

voltage. The degree of non-linearity is measured by the "Crest Factor":

Crest Factor = Peak Current / RMS Current

In a linear load, the Crest Factor is 1.414. However, in a general purpose SMPS, due to

its non linear nature, this factor will be much higher - in the region of up to 4. This will

mean that for a particular rated RMS current (applicable for a linear load), the general

purpose SMPS will draw much larger peak currents – approx. up to 4 times more than its

rated RMS current.

Inverters are protected against over current ( also called overloading ) by either clipping

the peaks of the output voltage ( this will result in a sine wave becoming a square wave,

reduction in the RMS value of the output voltage and generation of harmonics and

electrical noise ) or by shutting down the output voltage of the inverter completely. Thus,

if an inverter / generator is used to power a general purpose SMPS, it will be forced to

deliver higher peak currents resulting in premature triggering of the inverter’s /

generator's over current protection circuits. Thus, for safe operation, the continuous RMS

current rating of the inverter / generator should be at least 2.8 times the continuous RMS

current rating of the general purpose SMPS it is required to power:

Peak current of inverter = Peak current of SMPS

or

RMS current of inverter X 1.414 = RMS current of SMPS X 4

or

RMS current of inverter = 4/1.414 X RMS current of SMPS

or

RMS current of inverter = 2.8 X RMS current of SMPS)

Alternatively, the continuous power rating of the inverter / generator in Watts / VA

should be at least 2.8 times the continuous power rating of the SMPS in Watts / VA

Page 13

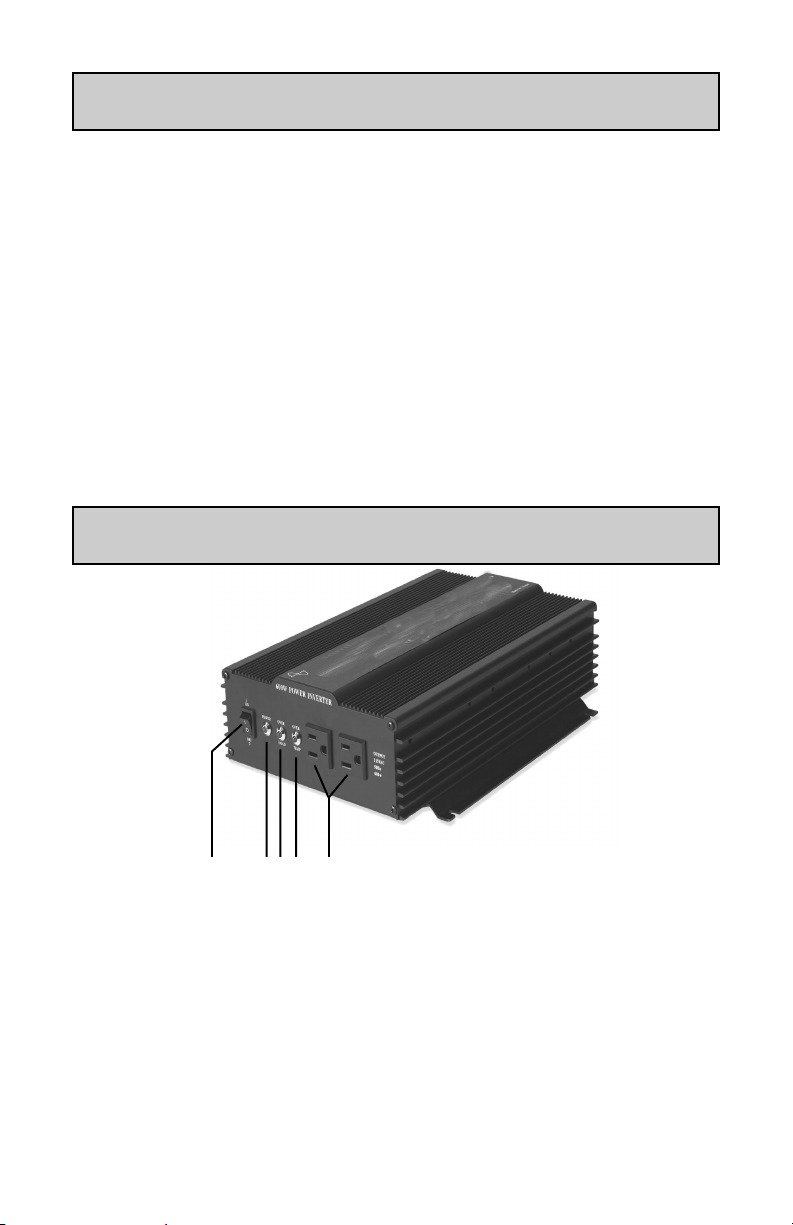

LAYOUT

PRINCIPLE OF OPERATION

The inverter converts the rated DC voltage of the battery to 120 V, 60 Hz. AC voltage.

The voltage conversion takes place in two stages. In the first stage, the rated DC voltage

of the battery is converted to a high voltage DC using high frequency switching and Pulse

Width Modulation (PWM) technique. In the second stage, the high voltage DC is

converted to 120 V, 60 Hz. sine-wave AC again using PWM technique. This is done by

using a special wave shaping technique where the high voltage DC is switched at a high

frequency and the pulse width of this switching is modulated with respect to a reference

sine-wave.

1 120V AC output receptacles

2 Power on/off Switch

3 Green L.E.D. - Power output status

4 Red L.E.D. - Overload

5 Red L.E.D. - Over temperature

6 Input terminals (back of unit -not shown)

RED - Positive (+)

BLACK or WHITE - Negative (-)

7 Cooling Fan (back of the unit - not shown)

8 Grounding lug (back of the unit - not shown)

9. Modular jack for optional Remote Control (bottom of the unit - not shown)

21345

SPECIFYING BATTERIES, CHARGERS

& ALTERNATORS

The inverter will require Deep Cycle LeadAcid Batteries of appropriate capacity.

Lead-acid batteries can be categorized by the type of application: automotive service -

Starting/Lighting/Ignition (SLI, a.k.a. cranking) and deep cycle service

SLI Batteries

Everybody is familiar with the SLI batteries that are used for automotive starting and

powering vehicular accessories. SLI batteries are designed to produce high power in short

bursts but must be constantly recharged (normally with an alternator while driving).

Vehicle starting typically discharges 1%-3% of a healthy SLI battery’s capacity.

The automotive SLI battery is not designed for repeated deep discharge where up to 80 %

of the battery capacity is discharged and then recharged. If an SLI battery is used for this

type of application, its useful service life will be drastically reduced

Deep Cycle Batteries

Deep cycle batteries are designed with thick-plate electrodes to serve as primary power

sources, to have a constant discharge rate, to have the capability to be deeply discharged

up to 80 % capacity and to repeatedly accept recharging. They are marketed for use in

recreation vehicles (RV), boats and electric golf carts – so they may be referred to as RV

batteries, marine batteries or golf cart batteries. There are two categories of deep cycle

lead acid batteries – wet and sealed. A wet cell battery has a high tolerance to overcharg-

ing. However, it will release hydrogen gas when charging that must be properly vented

and the water level must be checked frequently. Sealed batteries can either be Gel Cell or

AGM (Absorbed Glass Mat). Both the Gel Cell andAGM are maintenance free, have no

liquid to spill and gassing is minimal. The Gel Cell is the least affected by temperature

extremes, storage at low state of charge and has a low rate of self discharge. AnAGM

battery will handle overcharging slightly better than the Gel Cell

Units of Battery capacity

The battery capacity is the measure of the energy the battery can store and deliver to a

load. It is determined by how much current any given battery can deliver over a stipulated

period of time. The energy rating is expressed in Ampere Hours (AH). As a bench mark,

the battery industry rates batteries at 20 hour rate i.e. how many Amperes of current the

battery can deliver for 20 hours at 80 º F till the voltage drops to 10.5 Volts for 12 V

battery and 21 V for 24 V battery. For example, a 100 AH battery will deliver 5 Amperes

for 20 hours. Battery capacity is also expressed as Reserve Capacity (RC) in minutes.

Reserve capacity is the time in minutes for which the battery can deliver 25Amperes at

80 º F till the voltage drops to 10.5 Volts for 12 V battery and 21 V for 24 V battery.

Approximate relationship between the two units is as follows:

Capacity inAH = Reserve Capacity in RC minutes x 0.6

Page 14

Typical battery sizes

Below is a chart of some battery sizes applicable for powering inverters:

BCI * Group Battery Voltage, V Battery AH

27 / 31 12 105

4 D 12 160

8D 12 225

GC2** 6 220

* Battery Council International

** Golf Cart

Reduction in usable capacity at higher discharge rates.

As stated above, the rated capacity of the battery in AH is applicable at a discharge rate of

20 Hours. As the discharge rate is increased, the usable capacity reduces due to “Peukert

Effect”. This relationship is not linear but is more or less according to the table below:

Table 1 Battery Capacity versus Rate of Discharge

Hours of Discharge Usable Capacity

20 100%

10 87%

8 83%

6 75%

5 70%

3 60%

2 50%

1 40%

Using the above table will show that a 100 AH capacity battery will deliver 100% (i.e.

full 100 AH) capacity if it is slowly discharged over 20 hours at the rate of 5Amperes.

However, if it is discharged at a rate of 50 Amperes then theoretically, it should provide

100 AH ÷ 50 = 2 hours. However, the Table above shows that for 2 hours discharge rate,

the capacity is reduced to 50% i.e. 50 AH. Therefore, at 50Ampere discharge rate the

battery will actually last for 50 AH÷50 Amperes = 1 Hour

Page 15

Depth of discharge and battery life

The more deeply a battery is discharged on each cycle, the shorter the battery life. Using

more batteries than the minimum required will result in longer life for the battery bank. A

typical cycle life chart is given at Table 2 below:

TABLE 2. – TYPICAL CYCLE LIFE CHART

Depth of Discharge Cycle Life Cycle Life Cycle Life

% ofAH Capacity Group 27 / 31 Group 8D Group GC2

10 1000 1500 3800

50 320 480 1100

80 200 300 675

100 150 225 550

It is recommended that the depth of discharge should be limited to 50 %

Loss of battery capacity at low temperatures.

Batteries lose capacity in low temperatures. At 32 º F, a battery will deliver about 70 to

80 % of its rated capacity at 80 º F. If the air temperature near the battery bank is lower

than 80 º F, additional batteries will be needed to provide the same usable capacity. For

very cold climates, an insulated / heated battery compartment is recommended.

Series and parallel connection of batteries

When two or more batteries are connected in series, their voltages add up but theirAH

capacity remains the same. For example, when two 12 V, 105 AH batteries are connected

in series, it becomes a 24 V, 105 AH battery. (Positive of the first battery is the positive

terminal of the series connection. The negative of the first battery is connected to the

positive of the second battery. The negative of the second battery is the negative of the

series connection)

When two or more batteries are connected in parallel, their voltages remain the same but

their capacities add up. For example, if two 12 V, 105 AH batteries are connected in

parallel, their voltage remains 12 V but their capacity becomes 105 × 2 = 210 AH

(Connect the positive terminal of the first battery to the positive terminal of the second

battery. These paralleled common positive terminals become the positive terminal of the

parallel combination. Connect the negative terminal of the first battery to the negative

terminal of the second battery. These paralleled common negative terminals becomes the

negative terminal of the parallel combination)

Page 16

Page 17

Sizing the Inverter Battery Bank

One of the most frequently asked question is, “how long will the batteries last?’. This

question cannot be answered without knowing the size of the battery system and the load

on the inverter. Usually this question is turned around to ask “How long do you want your

load to run?”, and then specific calculation can be done to determine the proper battery

bank size.

There are a few basic formulae and estimation rules that are used:

Formula 1 Power in Watts (W) = Voltage in Volts (V) x Current in Amperes (A)

Formula 2 For an inverter running from a 12 V battery system (PST-100S-12A),

the DC current required from the 12 V batteries is theAC power

delivered by the inverter to the load in Watts (W) divided by 10 & for

an inverter running from a 24 V battery system (PST-100S-24A), the

DC current required from the 24 V batteries is theAC power delivered

by the inverter to the load in Watts (W) divided by 20.

Formula 3 Energy required from the battery = DC current to be delivered (A) x

time in Hours (H)

The first step is to estimate the total AC watts (W) of load(s) and for how long the load(s)

will operate in hours (H). TheAC watts are normally indicated in the electrical nameplate

for each appliance or equipment. In case AC watts (W) are not indicated, formula 1 given

above may be used to calculate the AC watts by multiplying 120 VAC by the AC current in

Amperes . The next step is to derive the DC current inAmperes (A) from the AC watts as

per formulae 2 above. An example of this calculation for a 12V inverter is given below:

Let us say that the totalAC Watts delivered by the12 V inverter = 1000 W

Then, using formula 2 above, the DC current to be delivered by the 12 V batteries = 1000

W ÷10 = 100Amperes

Next, the energy required by the load inAmpere Hours (AH) is determined. For example,

if the load is to operate for 3 hours then as per Formula 3 above:

Energy to be delivered by the 12 V batteries = 100 Amperes × 3 Hours = 300 Ampere

Hours (AH)

Now, the capacity of the batteries is determined based on the run time and the usable

capacity. From Table 1, (on page 15), the usable capacity at 3 Hour discharge rate is 60%.

Hence, the actual capacity of the 12 V batteries to deliver 300 AH will be equal to 300AH

÷ 0.6 = 500 AH

And finally, the actual desired rated capacity of the batteries is determined based on the

fact that normally only 80% of the capacity will be available with respect to the rated

capacity due to non availability of ideal and optimum operating and charging conditions.

So the final requirements will be equal to:

500 AH ÷0.8 = 625 AH (note that the actual energy required by the load was 300AH)

It will be seen from the above that the final rated capacity of the batteries is almost 2 times

the energy required by the load inAH

Thus, as a thumb rule, theAH capacity of the batteries should be twice the energy

required by the load inAH

For the above example, the 12 V batteries may be selected as follows:

- Use 6 Group 27/31, 12 V, 105 AH batteries in parallel to make up 630 AH, or

- Use 3 Group 8D, 12 V, 225 AH batteries in parallel to make up 675 AH

Charging Batteries

The batteries can be charged by using good qualityAC powered battery charger or from

alternative energy sources like solar panels, wind or hydro systems. Make sure an

appropriate battery charge controller is used. It is recommended that the batteries may be

charged at 10% to 13 % of the Ampere Hour capacity (20 hour discharge rate). Also, for

complete charging (return of 100 % capacity ), it is recommended that a 3 stage charger

may be used (Constant current bulk charging followed by constant voltage boost /

absorption charging followed by constant voltage float charging )

Batteries, alternators and isolators on vehicles / RVs

It is recommended that for powering the inverter, one or more auxiliary deep cycle

batteries should be used that are separate from the SLI battery. The inverter should be

powered from the deep cycle batteries. For charging the SLI and the auxiliary deep cycle

batteries, the output from the alternator should be fed to these two sets of batteries

through a battery isolator of appropriate capacity. The battery isolator is a device that will

allow the alternator to charge the two sets of batteries when the engine is running. The

isolator will allow the inverter to be operated from the auxiliary batteries and also prevent

the SLI battery from charging the auxiliary deep cycle batteries when the engine is not

running. Battery isolators are available from auto / RV / marine parts suppliers

A majority of smaller vehicles have 40 to 105 Ampere alternator and RVs have 100 to

130 Ampere alternator. When in use, the alternators heat up and their output current

capacity can drop by up to 25%. When heated up, their charging voltage may also not

reach the desired absorption voltage and will result in return of only about 80% of the

battery capacity. In case the current output of the standard alternator is not adequate to

charge the two sets of batteries rapidly and fully to 100% of their capacity, use heavy duty

alternator that can produce higher current and voltage required to charge multiple battery

systems. These alternators are available with auto / RV parts suppliers.

Page18

INSTALLATION

Page 19

GENERAL

Installation and wiring compliance

- Installation and wiring must comply with the local and the national electrical codes and

must be done by a certified electrician

- In building / residential applications, electrical codes do not allow permanent connection

of AC distribution wiring to the inverter’s AC output receptacles. The receptacles are

intended for temporary (as needed) connection of cord connected loads only. Read

details under “AC Power Distribution and Grounding” on page 9.

- The inverter does not have integral over current protection for the AC output side.

Protection should be provided by the installer

- Over current protection of the cables from the battery to the inverter has to be provided

by the installer

- The DC input positive and negative terminals are isolated from the chassis. Similarly, the

neutral pole of the AC receptacles / the neutral wire is not bonded to the chassis. System

grounding to suit the national / local electrical codes is to be undertaken by the installer.

Read details under“AC Power Distribution and Grounding” on page 9.

Preventing electrical shock

- Always connect the grounding connection on the inverter to the appropriate grounding

system. Read details under“AC Power Distribution and Grounding” on page 9.

Installationenvironment

- The inverter should be installed indoor only in a well ventilated, cool, dry environment

- Do not expose to moisture, rain, snow or liquids of any type.

- To reduce the risk of overheating and fire, do not obstruct the suction and discharge

openings of the cooling fans.

- To ensure proper ventilation, do not install in a low clearance compartment

- Working with the inverter may produce arcs or sparks. Thus, the inverter should not be

used in areas where there are inflammable materials or gases requiring ignition protected

equipment. These areas may include spaces containing gasoline powered machinery, fuel

tanks, battery compartments

Mounting position of the inverter

-The inverter may be mounted horizontally on the top of a horizontal surface or under a

horizontal surface. The inverter may be mounted on a vertical surface only horizontally

(the fan axis should always be horizontal i.e. the fans should not be pointing up or down)

Cooling by forced airfan ventilation

The inverter produces heat when operating. The amount of heat produced is proportional to

the amount of power supplied by the inverter. ADC fan is used to provide forced air

cooling of this inverter. The fan is thermostatically controlled and will be switched on only

if the temperature of certain hot spot inside the inverter rises above a certain temperature.

At lower loads and / or at lower ambient temperatures, the fan may not switch on at all. This is

normal. The unit is protected against over-temperature due to failure of the fan / inadequate

heat transfer. The AC output will be shut-down if the hot spot inside the inverter reaches a

certain higher temperature.

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

Mitsubishi Electric

Mitsubishi Electric FR-V500 instruction manual

WarmPool

WarmPool OPTIMUS 9 Installation and user guide

Grundig

Grundig GHP-MM08 Service manual

DAB

DAB MCE/C Series Instruction for installation and maintenance

Xantrex

Xantrex Freedom Xi 1000 owner's manual

Osram

Osram POWERinvert PRO OEINVPAR6 manual