Secabo TM2 User manual

EN

OPERATING MANUAL

for the heat press

Secabo TM2

Congratulations on the purchase of your Secabo heat press!

Please read this operating manual carefully to ensure a smooth production launch with your new

device.

Any type of reproduction of this operating manual requires the written permission of Secabo

GmbH. Modifications to and errors in the technical data and/or product characteristics are

reserved.

Secabo GmbH accepts no liability for any direct or indirect damages resulting from the use of this

product.

Version 1.1 (29.07.2019)

Secabo GmbH Hochstatt 6-8 85283 Wolnzach Alemania [email protected] www.secabo.com

Brief overview

Secabo TM2 Heat Press

The new TM2 mug press by Secabo is ideal for comfortably performing sublimation transfers on

ceramic mugs and other similar objects. The Secabo TM2 heat press is suitable for novice and

professional users, and equipped with a digital controller that allows for fast and safe operation.

Pressure can easily be adjusted via a hand wheel. Optionally, there are 4 different heating

elements available, including conical variants.

● digital controller for temperature, time and counter for keeping track of pressing operations

● varying heating sleeves available

● easily adjustable contact pressure

● suitable for sublimation on mugs

Safety Precautions

Please read the information and safety precautions carefully prior to first commissioning of the

device!

● Never reach inside the heat press with your hands when it is connected to the power

supply, especially if it is switched on and heated up – danger of burns!

● Never open the casing and do not make any modifications to the unit yourself.

● Should it be necessary to open the heat plate cover upon explicit request by Secabo's

customer service team, it is recommended you wear respiratory protection and only touch

the insulation wool located therein using gloves. Possible disposal of the insulation wool

should only be done inside a closed bag.

● Ensure that neither liquids nor metal objects reach the inside of the heat press.

● Make sure you use a grounded wall socket. Keep in mind that a heat press may only be

operated using a wall socket equipped with a ground fault circuit interrupter.

● Disconnect the heat press from the power supply when it's not in use.

● Always ensure that the heat press is out of reach of children during operation and never

leave the device unsupervised when switched on.

● Make sure the unit is only used in dry rooms.

If you cannot comply with one or more of the aforementioned safety rules, or if you are

unsure as to whether you're in compliance with all of the points, please contact our

technical support.

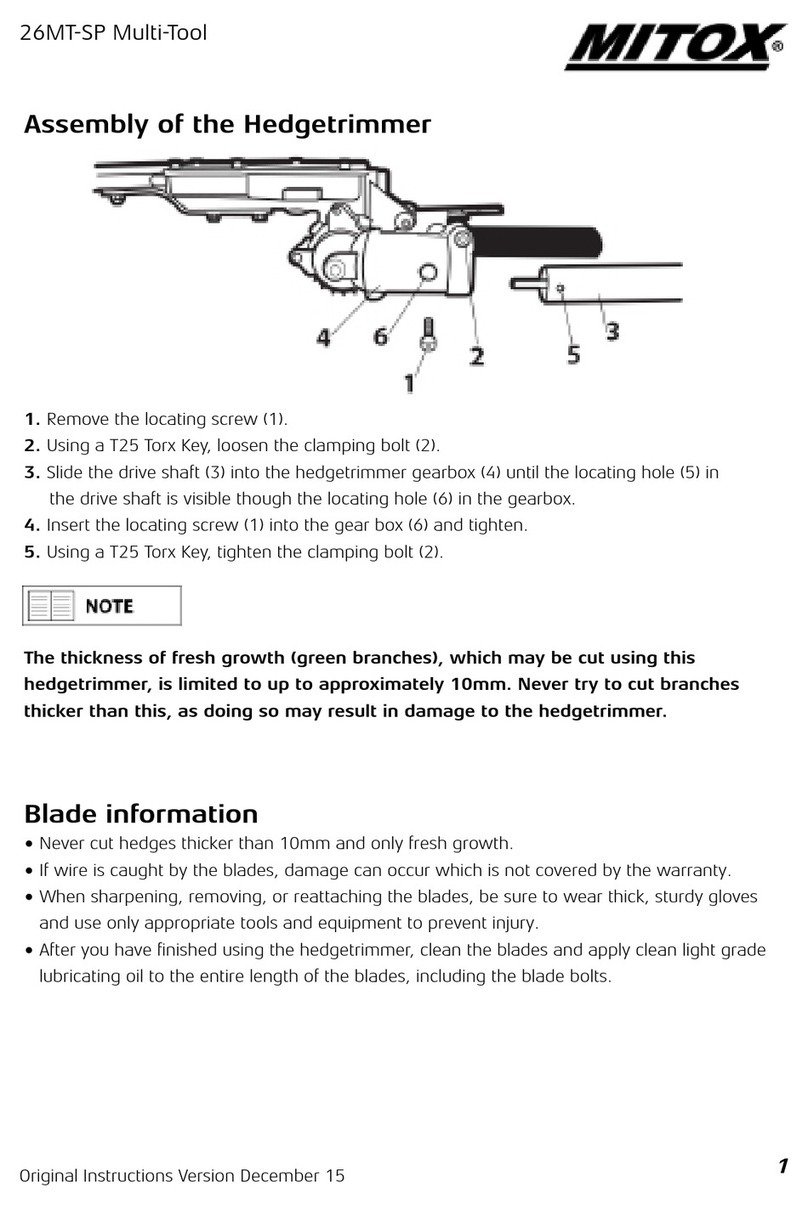

Machine description

Secabo GmbH Hochstatt 6-8 85283 Wolnzach Alemania [email protected] www.secabo.com

a. Heating element

b. Press lever

c. Digital controller for temperature and time as well as a counter

d. Switch

e. Power connection

Controller

The central controller allows for setting the desired temperature (° C and ° F), as well as the press

duration in seconds. The green digits because represent the target values, while the white

numbers reflect the current values. The counter is displayed at the lower right and indicates the

number of pressing operations carried out since the last reset.

Operation

Secabo GmbH Hochstatt 6-8 85283 Wolnzach Alemania [email protected] www.secabo.com

● Use the the supplied power cord to connect the heat press to a 230V socket.

● The red toggle switch turns the press ON.

● After a short self-test, dashes appear in the display.

● Press the OK button.

● Now you can use the arrow keys to choose between °C and °F. Confirm your selection by

clicking "OK".

● Now configure the desired temperature using the arrow keys and also confirm with OK.

● Next, use the arrow keys to set the desired pressing duration in seconds and again confirm

with OK.

● You're now ready to perform your first transfers. The clock starts counting as soon as the

press is closed with the press lever.

● 3 seconds before the set time elapses, a warning signal sounds, at which time you should

open the press again by folding back the press lever.

● You can regulate the contact pressure by turning the black handwheel between the lever

and the heating sleeve to the left or right.

● No settings can be changed during the press operation.

● With each completed pressing process, the counter displays increases by one, as soon as

the specified time has elapsed.

● The counter can be reset by pressing and holding RESET for approx. 5 seconds.

Note: Please keep in mind that it takes some time for the press to cool off after it is

switched off.

Note: Do not leave the press standing around in its heated up state. If you're no longer

using the press, always turn it off.

Heating elements

Heating elements are generally wearing parts and not covered by the warranty

To extend the service life, the following points should be noted:

● When heating up, it is recommended to insert a mug to protect the element, the same

advice applies to cooling down.

● It is advisable to turn the mug press off, even if it will not be used for just a short

period of time.

● All heating elements must be checked for their function on the day of receipt.

Maintenance and cleaning

All maintenance work must be carried out with the press switched off and cooled off, no

exceptions! First, remove the plug from the wall socket. Only perform maintenance work after

consultation with our technical support team.

The press should be cleaned regularly using a soft cloth and a mild household cleaner to remove

Secabo GmbH Hochstatt 6-8 85283 Wolnzach Alemania [email protected] www.secabo.com

adhesive residues, etc. Do not use scouring sponges, solvents or gasoline!

Recommended times and temperatures

These values should only be considered as guideline values, may vary depending on the material

and must be checked before pressing.

Material

temperature

Pressure

Press duration

Flock film

170°C - 185°C

low-medium

25s

Flex film

160°C - 170°C

medium-high

25s

Sublimation flex

180°C - 195°C

medium-high

10s - 35s

Sublimation on

mugs

200°C

medium-high

150s - 180s

Sublimation on tiles

200°C

high

120s - 480s

(depends on the thickness of the

material)

Sublimation on

puzzles

200°C

low-medium

25s

Sublimation on

mouse pads

200°C

medium

20s - 40s

Sublimation on

garments

200°C

medium-high

30s - 50s

Sublimation on

metal plates

200°C

high

10s - 50s

(depends on the thickness of the

material)

Important note: You should perform your own tests with the respective transfer materials

and carrier media prior to each production. The aforementioned values, as well as any

manufacturer's instructions only serve as indications. Washing resistance and behavior

during the transfer must be determined by performing your own tests.

No guarantee can be derived from the recommended values. It is always the user's

responsibility to determine and apply the correct settings for his specific conditions.

Note on garment finishing processes: After the press operation, garments must cool off

before any carrier media can be pulled off the transfer material. The hot glue in the transfer

material doesn't develop its adhesive strength until cooled off. If the glue does not stick in

Secabo GmbH Hochstatt 6-8 85283 Wolnzach Alemania [email protected] www.secabo.com

its cold state, this may indicate that the pressing procedure was too cold or too short.

Technical data

Heat press

Secabo TM2

Type

Mug press

Max. mug height

12.0cm

mug diameter

7.5cm - 9.5cm

Max. preset time

999s

Max. temperature

225°C

Pressure setting

Handwheel on press lever

Power supply

230V / 50Hz - 60Hz, 600W

Environment

+ 5°C - +35°C / 30% - 70% relative humidity

Weight

11kg

Dimensions (W x H x D)

59cm x 37cm x 52cm

Declaration of conformity - Statement of Conformity

We hereby declare under our sole responsibility that the product referred

to in "technical data" complies with the provisions of the following

directives and standards:

We herewith declare under sole responsibility that the under „technical

data“ mentioned product meet the provisions of the following EC

Directives and Harmonized Standards:

● EG-Richtlinien / EC Directives:

● 2014/35 / FG Establishment Directive

● 2014/35/EC Low Voltage Directive

● 98/37/EC Directive on machinery (2006/42/EC from 12/29/2009)

● 98/37/EC Directive on machinery (from 2009-12-29: 2006/42/EC)

● Norm / Standard: EN 60204-1:2006

Technische Dokumente bei / Technical documents at:

Secabo GmbH, Hochstatt 6-8, 85283 Wolnzach, Germany

Dipl. Ing. Fabian Franke

Dipl. Ing.(FH) Bernhard Schmidt

Secabo GmbH Hochstatt 6-8 85283 Wolnzach Alemania [email protected] www.secabo.com

Table of contents

Other Secabo Power Tools manuals

Secabo

Secabo TS5 Economy User manual

Secabo

Secabo TC D2 User manual

Secabo

Secabo TM5 User manual

Secabo

Secabo TCC Lite User manual

Secabo

Secabo TB7 User manual

Secabo

Secabo TC5 Smart User manual

Secabo

Secabo TS-38 User manual

Secabo

Secabo TC5 Smart User manual

Secabo

Secabo TMUG User manual

Secabo

Secabo TS7 User manual