8

Recheck the gap to make sure the distance

is equal across the length of the hold down.

BLADE ADJUSTMENT

The blade adjustment has been made at

the factory before shipment. However, you

may find it necessary to check the blade

adjustment before operation.

TO PERFORM THE BLADE SET UP:

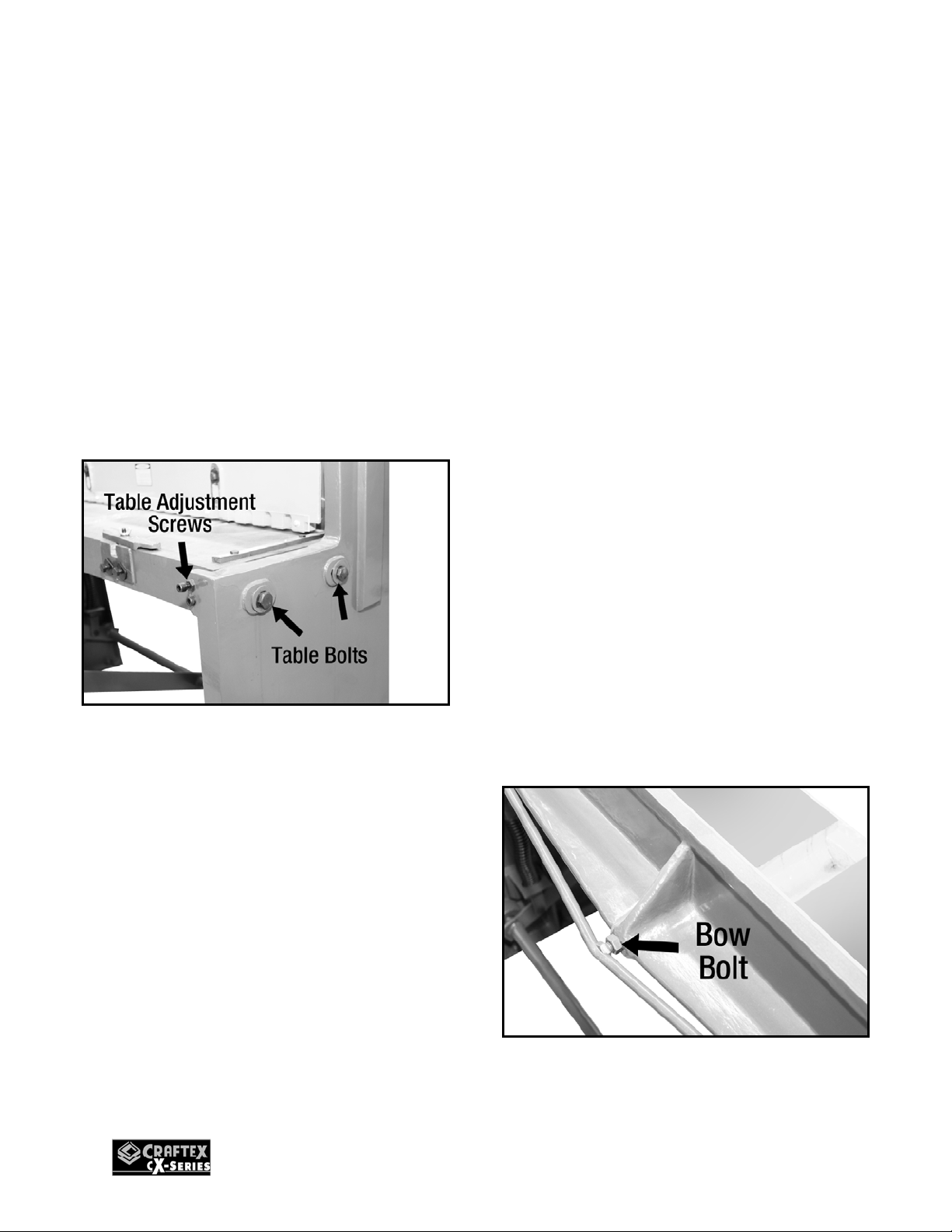

Loosen the two table bolts and table

adjustment screws on both sides of the

machine. See figure-5.

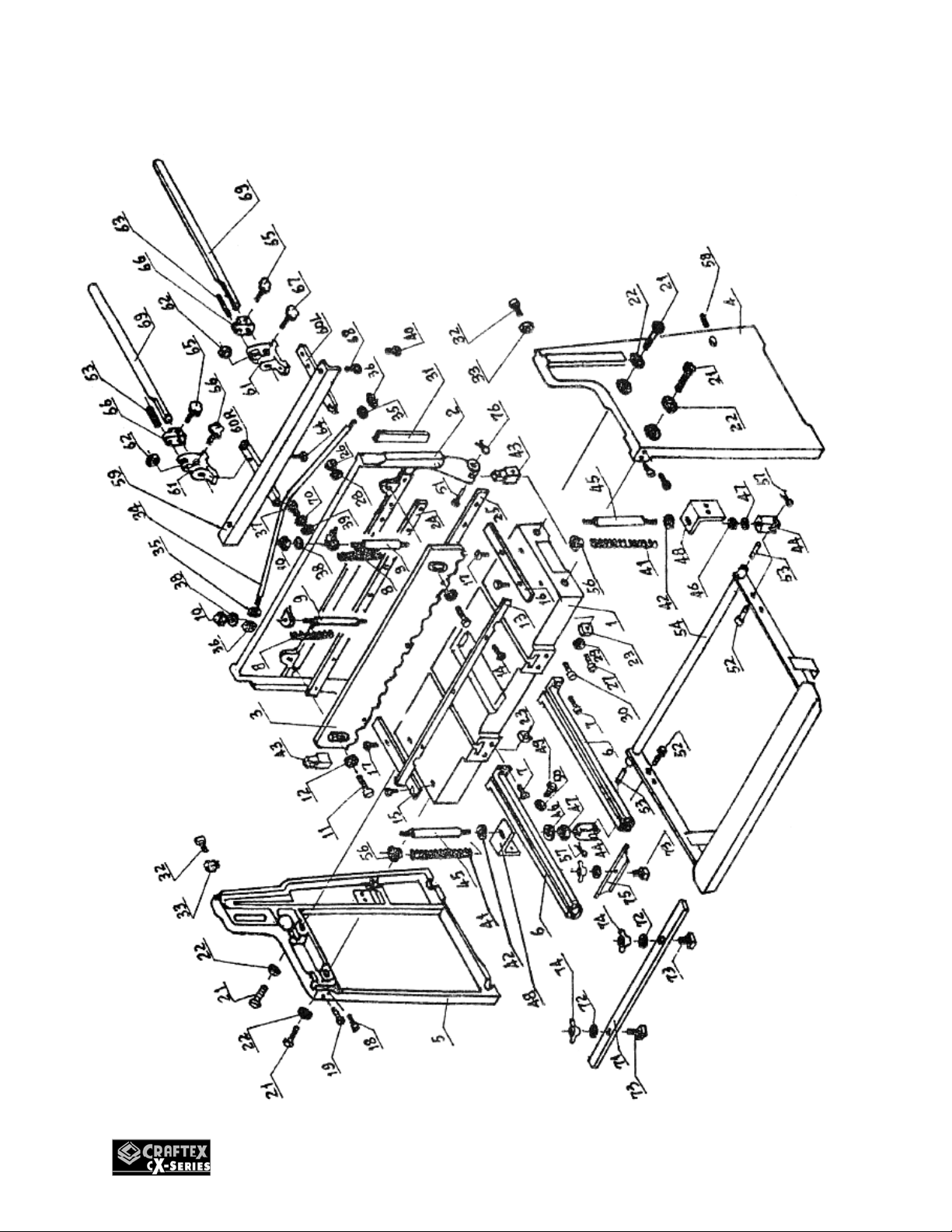

Figure-5 Table adjustment

Lower the blade and hold it in position using

the foot pedal.

Now, turn the table adjustment screws to

move the table and fixed blade until the

fixed blade makes light contact with the

moving blade all the way across the length.

Make sure the moving blade does not

overlap the fixed blade or it will cause

damage.

Use a sheet of paper and make several

cuts along the length of the blade. The

shear should cut through the paper cleanly.

Turn the table adjustment screws moving

the fixed blade away from the moving blade

so that you have a gap of 0.002". Check

this measurement with a feeler gauge.

Repeat the same step on the other side of

the machine so that gap is even across the

length of the blade.

Tighten the four leg bolts and make sure it

has not changed.

ADJUSTING BLADE BOW

The bow of the moving blade is adjusted by

loosening or tightening the bow bolt at the

center of the straightening rod. Check if

there is a change in the gap when the

moving blade is just below the top of the

fixed blade. After making adjustments to the

bow, repeat the blade adjustment section.

If the shear cuts paper on the ends

but not the center, turn the bow bolt

clockwise until paper is cut across

the length.

If the shear cuts paper at the center

but not the ends, turn the bow bolt

counter-clockwise until the paper is

cut across the length.

Figure-6 Adjusting the bow bolt