SECOP P Series User manual

MOUNTING INSTRUCTIONS FOR

HERMETIC AC COMPRESSORS

GUIDELINE FOR P / T / X / D / N / F / S / G-SERIES & DELTA / KAPPA

WITH MORE THAN 60 YEARS OF

EXPERIENCE IN COMPRESSOR

TECHNOLOGY AND HIGHLY

DEDICATED EMPLOYEES, OUR

FOCUS IS ON DEVELOPING AND

APPLYING ADVANCED COMPRESSOR

TECHNOLOGIES TO ACHIEVE

STANDARD SETTING PERFORMANCE

FOR LEADING PRODUCTS AND

BUSINESSES AROUND THE WORLD.

www.secop.com SETTING THE STANDARD

2

1. Compressors ............................................................................................................3

1.1 Type label .............................................................................................................3

1.2 Denomination P / T / D / N / F / S / G-Series .....................................................4

1.3 Denomination variable speed .............................................................................6

1.3.1 Type label XV ........................................................................................................6

1.4 Denomination KAPPA/DELTA .............................................................................7

1.4.1 Type label KAPPA .................................................................................................7

1.4.2 Type label DELTA .................................................................................................7

1.5 Low and high starting torque ..............................................................................8

1.6 Motor protector ....................................................................................................8

1.7 Rubber grommets ...............................................................................................8

1.8 Minimum ambient temperature ..........................................................................8

1.9 SC Twin compressors ..........................................................................................8

2. Finding faults ............................................................................................................9

2.1 Winding protector cut out ...................................................................................9

2.2 PTC and protector interaction .............................................................................9

2.3 Check of winding protector and resistance ........................................................9

3. Opening the refrigerating system ...........................................................................10

3.1 Flammable refrigerants ....................................................................................10

4. Mounting .................................................................................................................11

4.1 Connectors ........................................................................................................11

4.2 Expanding connectors .......................................................................................12

4.3 Bending copper connectors ..............................................................................13

4.3.1 Spring benders ..................................................................................................13

4.3.2 Lever-type benders............................................................................................13

4.3.3 Tailor-made bending tools ................................................................................13

4.4 Tube adaptors ....................................................................................................14

4.5 Filler metal ........................................................................................................14

4.6 Brazing ..............................................................................................................14

4.7 Brazing on suction connectors(direct suction intake)......................................15

4.7.1 Temperature at socket TLX / NLE / NLU / NLV / DLE / DLX / DLV / XV ...........15

4.7.2 Temperature at socket SCE ...............................................................................15

4.7.3 Brazing on discharge connector. Temperature at socket DELTA ....................15

4.7.4 Heat protection ..................................................................................................15

4.8 Brazing methods and requirements .................................................................16

4.8.1 Filler Metal and Flux..........................................................................................16

4.8.2 Corrosion ...........................................................................................................16

4.8.3 Flame and heating .............................................................................................17

4.9 LOKRING® connections ....................................................................................17

4.10 Driers ..............................................................................................................18

4.11 Driers and refrigerants .....................................................................................19

4.12 Capillary tube in drier ........................................................................................19

5. Electrical equipment ..............................................................................................20

5.1 LST (RSIR) starting device .................................................................................20

5.2 LST (RSCR) starting device ...............................................................................20

5.3 PTC protection screen .......................................................................................21

5.4 HST (CSIR) starting equipment ........................................................................21

5.5 HST (CSR) starting equipment ..........................................................................21

5.6 Equipment for SC Twin compressors ...............................................................22

5.7 Connections .......................................................................................................22

5.8 Further reading ..................................................................................................22

6.- Single Pack Instructions .........................................................................................23

29. P / T / X / D / N / F / S / G-Series & DELTA / KAPPA. ..............................................53

30. Evacuation ..............................................................................................................54

30.1 Vacuum pumps .................................................................................................. 54

31. Charging of refrigerant ..........................................................................................55

31.1 Maximum refrigerant charge ............................................................................55

32. Testing ....................................................................................................................56

32.1 Testing of the appliance.....................................................................................56

33. Mounting accessories .............................................................................................57

TABLE

OF CONTENTS

3

If a compressor needs to be installed in new appliances normally there is enough time available to choose

the right compressor type from data sheets and perform sufficient testing. On the contrary, when a faulty

compressor needs to be replaced it can be impossible to get the same compressor type as the original in

many cases. That is why it is necessary to compare relevant compressor catalogue data.

A compressor can provide a long durability if service work is done in the right way and attention is paid

to keeping parts clean and dry. The service technician must observe the following when choosing a com-

pressor: type of refrigerant, voltage and frequency, application range, compressor displacement/capacity,

starting conditions, and cooling conditions. If possible use the same refrigerant type as in the faulty system.

The Secop hermetic refrigeration compressor programme consists of the types:

P / T / X / D / N / F / S / G-Series and DELTA / KAPPA

P T DELTA X D KAPPA N F S G

All compressors for 220-240 V have a yellow label with the type designation. Compressors for 115 V have a

green label with the type designation.

Direct current compressors and variable speed compressors have a gray label.

The label for “R404A R507” or “R404A R407C R507” has a lilac stripe. The label for “R134a” has a blue

stripe. The labels for “R290” and “R600a” both have a red stripe.

The labels for the DELTA, KAPPA, and XV compressors do not follow all rules.

The country of origin indicated on the com-

pressor paper label and on the compressor

varies depending on the place of manufac-

ture.

If the type label has been destroyed, the com-

pressor type and the code number can be found

on the engraving on the side of the compressor.

For information please refer to Product Bulletin

"Date Code Format & Country of Origin".

LST/HST mentioned both means that the start-

ing characteristics are depending on the electri-

cal equipment.

Barcode format

A Secop compressor type label contains two barcode lines. The first line is the full code number of the com-

pressor and the second line is the compressor serial number. These barcodes contain 8 characters each

and are printed in code 128.

Serial number

The compressor serial number will also be written in normal letters below the barcodes

The serial number contains 8 digits, written in characters 0–9 and A–Z, excluding I and O.

1.

COMPRESSORS

1.1

Type label

4

1 The first letter of the denomination (P, T, D, N, F, S or G) indicates compressor series

2 The second letter indicates motor protection placement.

3 E, Y, X, and U denote different energy optimization steps. S means semi-direct suction.

On all these mentioned types, the indicated suction connector has to be used. Using the wrong

connector as a suction connector will lead to reduced capacity and efficiency.

4 A number indicates the displacement in cm3, but for PL compressors, the number indicates the

nominal capacity.

5 The letter after the displacement indicates which refrigerant must be used as well as the field of

application for the compressor.

1.2

Denomination Key to AC-Compressor Type Designation (P / T / D / N / F / S / G-Series)

1 2 3

Compressor

design

Protector location Optimization level

Internal External

PTC

LST

Relay

HST

PTC Relay Low < Standard > High

P

L

L

Blank

Ea)

Semi-direct

intake

T

T

F

Eb)

S

Ya)/b) Xa)

D

Semi-direct or direct intake

NUa)

F R

S C C E

Direct

intake

G S

Semi-direct

intake

L = Low

Blank =

Standard

S= Semi-direct intake

E= Energy-optimized

Y= High energy-optimized +

X= High energy-optimized ++

U= High energy-optimized +++

5

5 LBP (Low Back Pressure) indicates the range of low evaporating temperatures, typically -10 °C / +14 °F down to -35 °C / -31 °F

or even -45 °C / -49 °F, for use in freezers and refrigerators with freezer compartments. MBP (Medium Back Pressure) indicates

the range of medium evaporating temperatures, typically -20 °C / -4 °F up to 0 °C / +32 °F , such as in cold cabinets, milk coolers,

ice machines, and water coolers. HBP (High Back Pressure) indicates high evaporating temperatures, typically -5 °C / +23 °F up to

+15 °C / +59 °F, such as in dehumidifiers and some liquid coolers.

T as an extra character indicates a compressor intended for tropical application. This means high ambient temperatures and

capable of working with more unstable power supply.

6 The next letter in the compressor denomination provides information on the starting torque. If, as principal rule, the compressor is

intended for LST (Low Starting Torque) and HST (High Starting Torque), the place is left empty.

The starting characteristics depend on the electrical equipment chosen. K indicates LST (capillary tube and pressure equalization

during idle periods) and X indicates HST (expansion valve or no pressure equalization).

7 The final letter (separated by a dot) mentions the generation of the compressor.

4 5 6 7

Compressor size Application range Refrigerant Code letter

for starting

characteristics

Generation

Capacity at

rating point

Displacement

20

30

35

50

C = LBP

CL = LBP

CM = LBP

CN = LBP/MBP

CNL = LBP

D = HBP

DL = HBP

DN = HBP

F = LBP/(MBP)

FT = LBP tropical

G = LBP/MBP/HBP

GH = Heat pump

GHH = Heat pump optimized

K = LBP/(MBP)

KT = LBP/(MBP) tropical

MF = MBP

MK = MBP

ML = MBP

MN = MBP

S = LBP/HBP (service)

ST = LBP tropical (service)

R22

R404A/R507

R22

R290

R290

R22

R404A/R507

R407C

R290

R134a

R134a

R134a

R134a

R134a

R600a

R600a

R134a

R600a

R404A/R507

R290

R426A

R401A/R401B

R409A/R409B

R426A

R401A/R401B

R409A/R409B

Blank >

universal

(principal rule)

K = LST

characteristics

(capillary tube)

X = HST

characteristics

(expansion valve)

Blank >

first

generation

.1 >

updated

first

generation

.2 >

second

generation

.3 >

third

generation

.4 >

fourth

generation

2.5, 3, 4

4.5, 4.8, 5

5.7, 6, 6.5

7, 7.5, 8

8.7, 9, 10

4, 4.8

5.7, 6.5

7.5, 8.7

9.4, 10

5.2, 5.5, 5.7

6, 6.1, 7, 7.3

8.0, 8.4, 8.8, 9

10, 11, 12.6

13, 13.3, 15

6

7.5

8.5

10

11

10

12

15

18

21

18

21

26

34

a) = Run capacitor compulsory

b) = Run capacitor optional

6

1.3

Denomination

variable speed

1.3.1

Type label XV

Key to AC-Compressor Type Designation (Variable Speed)

1 2 3 4 5 6

Compressor

design

Optimization

level

Compressor

size

Application range Refrigerant Code letter

for starting

characteristics

Generation

Low < Standard > High Displacement

XV L

Blank

5.0

7.2

8.0 F = LBP/(MBP)

K = LBP/(MBP)

EKT = LBP/(MBP)

extreme tropical

CL = LBP

ML = MBP

CN = LBP/MBP

CNL = LBP

MN = MBP

R134a

R600a

R600a

R404A/R507

R404A/R507

R290

R290

R290

X = LST & HST

characteristics

(capillary tube &

expansion valve)

Blank >

first

generation

.1 >

updated

first

generation

.2 >

second

generation

DLV 4.0

5.7 Blank >

universal

(principal rule)

K = LST

characteristics

(capillary tube)

X = HST

characteristics

(expansion valve)

NLV 12.6

SLV 12

15

7

1.4

Denomination

KAPPA / DELTA

1.4.1

Type label KAPPA

1.4.2

Type label DELTA

HXD55AA

F

S

0 001 00001234 0 1005

MADE IN AUSTRIA

TP

R600a

220-240 V ~ 50 Hz

Secop logo

Electrical characteristics

Suction tube indication

Compressor model

Background: white

Bar code

Background: yellow

Pantone 137

Symbol and text: black

Variant code

Production date

Check digit

Approval marks

Manufacturer &

version code

Serial number

Approval marks

1005 HKK12AA

SUCTION

9 052 1234567 0

MADE IN AUSTRIA

220-240 V ~ 50 Hz

TP

R600a

B

Secop logo

Electrical characteristics

Suction tube indication

Compressor model

Background: white

Variant code

Background: yellow

Pantone 137

Symbol and text: black

Bar code

Production date

Check digit

Serial number

Approval marks

Manufacturer &

version code

Key to AC-Compressor Type Designation (KAPPA/DELTA)

KAPPA 1 2 3 4 5 6 group

H X K 12 A T example

DELTA 1 2 3 4 5 6 group

H X D 55 A A example

Group#5: Application, starting characteristics

"A" for LBP, LST

"N" for LBP/(MBP), LST

"M" for LBP/MBP, LST

Group#4: Displacement in cm³

(values bigger than 20 have to be divided by 10)

Group#3: Platform

"K" for KAPPA, "D" for DELTA

Group#2: Performance level "M, T, K, X, Z"

(Medium Efficiency > Superior Efficiency)

Group#1: Refrigerant

"H" for R600a

"G" for R134a

Group#6: Nominal Voltage Range

"A" for 220-240 V~ 50 Hz

"E" for 115-127 V~ 60 Hz

"G" for 220-240 V~ 50 Hz and

208-230 V~ 60 Hz

"T" for 200-240 V~ 50 Hz

8

1.5

Low and high starting

torque

1.6

Motor protector and

winding temperature

1.7

Rubber grommets

1.8

Minimum ambient

temperature

1.9

SC Twin compressors

Description of the different electrical equipment shown can be found in the data sheets for the compressors.

See also chapter 4. Low starting torque (LST) compressors must only be used in refrigerating systems with

a capillary tube throttling device where pressure equalization is obtained between suction and discharge sides

during each idle period.

A PTC starting device (LST) requires that the idle time is at least 5 minutes, since this is the time necessary

for cooling the PTC.

The HST starting device, which gives the compressor a high starting torque, must always be used in refrig-

eration systems with an expansion valve, and for capillary tube systems without full pressure equalization

before each start. High stating torque (HST) compressors are normally using a relay and starting capacitor

as starting device.

The starting capacitors are designed for short time cut-in.“1.7 % ED”, which is printed on the starting ca-

pacitor. This means for instance max. 10 cut-ins per hour each with a duration of 6 seconds.

Most of the Secop compressors are equipped with a built-in motor protector (winding protector) in the motor

windings. See also chapter 2.1. At peak load, the winding temperature must not exceed 135 °C / 275 °F and

nderstable conditions, the winding temperature must not exceed 125 °C / 257 °F.

Refer to our data sheets for specific information.

Stand the compressor on the base plate until it is fitted. This reduces the risk of oil coatings inside the con-

nectors and associated brazing problems. Place the compressor on its side with the connectors pointing

upwards and then fit the rubber grommets and grommet sleeves on the base plate of the compressor. Do

not turn the compressor upside down. Mount the compressor on the baseplate of the appliance

Tightening torque for M6 bolt joint mountings should be 5 Nm ± 0,5 / 44 in-lb ± 4,4 (hand-tight).

Allow the compressor to reach a temperature above 10 °C / 50 °F before starting for the first time to avoid

starting problems.

The twin version consists of two SC compressors mounted on a common base plate. The two compressors

are joined by an oil-equalizing tube and also have an intake manifold with screw connector for a service valve

or a braze connector (these parts are supplied as accessories, please refer to data sheets for more info).

Each twin compressor is supplied with two sets of electrical equipment and mounting accessories.

9

2.1

Winding protector cut

out

2.2

PTC and protector

interaction

2.3

Check of winding

protector and

resistance

2.

FINDING FAULTS

If the compressor will not run, this may be due to a number of reasons. Before replacing the compressor,

make sure that it is defective. To easily determine the fault, please refer to Guideline

"Repair of Hermetic Refrigeration Systems".

If the winding protector cuts out while the compressor is cold, it can take approx. 5 minutes for the protector

to reset. If the winding protector cuts out while the compressor is warm (compressor housing above 80 °C /

176 °F) the resetting time is increased. Up to approx. 45 minutes may pass before reset.

The PTC starting unit requires a cooling time of 5 minutes before it can restart the compressor with full

starting torque. Short time power supply cut offs, not long enough to allow the PTC to cool down, can result

in start failure for up to 1 hour. The PTC will not be able to provide full action during the first protector resets,

as they typically do not allow pressure equalization. Thus, the protector trips until the reset time is long

enough. This can be solved by unplugging the appliance for 5 to 10 minutes typically.

In the event of compressor failure, a check is made by measuring resistance directly on the current lead-in

to see whether the defect is due to motor damage or simply a temporary cut out of the winding protector.

If tests with resistance measurement reveal a connection through the motor windings from point M to S of

the current lead-in, but a broken circuit between point M and C and S and C, this indicates that the winding

protector is cut out. If so, wait to reset.

10

3.

OPENING THE REFRIGERATION

SYSTEM

3.1

Flammable

refrigerants

Never open a refrigerating system before all components for the repair are available. The compressor, drier,

and other system components must be sealed off until a continuous assembly can occur.

Opening a defect system must be done in different ways depending on the refrigerant used. Fit a service

valve to the system and collect the refrigerant in the correct manner.

R600a and R290 are hydrocarbons. These refrigerants are flammable and are only allowed for use in appli-

ances which fulfill the requirements laid down in the latest revision of EN/IEC 60335-2-24. (To cover poten-

tial risk originated from the use of flammable refrigerants). Consequently, R600a and R290 are only allowed

for use in household appliances designed for this refrigerant and fulfill the above-mentioned standard.

R600a and R290 are heavier than air and the concentration will always be highest at the floor.

R600a must only be stored and transported in approved containers and must be handled according to exist-

ing guidelines.

The flammability limits are approx. as follows:

Refrigerant R600a R290

Lower limit 1.5 % by vol. (38g/m³) 2.1 % by vol. (39 g/m³)

Upper limit 8.5 % by vol. (203 g/m³) 9.5 % by vol. (177 g/m³)

Ignition temperature 460 °C / 860 °F 470 °C / 878 °F

In order to carry out service and repair on R600a and R290 systems, the service personnel must be properly

trained to be able to handle flammable refrigerants. This includes knowledge on tools, transportng the

compressor and refrigerant, and the relevant regulations and safety precautions when carrying out service

and repair. Do not use open fire when working with refrigerants R600a and R290!

Secop compressors for flammable refrigerants are provided with a special warning sign. The maximal filling

capacity is 150 g per system, which equates to approximately 8 g/m³ in a 20 m³ kitchen and thereby around

25 % of the lower flammability limit. These precautions minimize the risk of ignition in case of a leakage.

Under favorable conditions however, exceeding these values is officially allowed.

All manufacturers of HC-systems have to follow these safety regulations. Customer service, as well as

the repair of R600a and R290 applications, should only be accomplished by highly trained and experienced

personnel. This implies also knowledge about tools, transporting compressors and refrigerants as well as

laws, regulations, and standards.

National safety regulations demand leakage simulations and strictly require the isolation of electrical com-

ponents close to the flow of refrigerants.

Yellow warning labels

Conversions from refrigerants R12 or R134a to R600a is not permitted, as the refrigerators are not approved

for operation with flammable refrigerants, and the electrical safety has not been tested according to existing

standards either. The same applies to conversions from refrigerants R22, R502, or R134a to R290.

The smaller R290 compressors, types T and N, are LST types. These often need a timer to ensure sufficient

pressure equalization time.

11

4.1

Connectors

4.

MOUNTING

Brazing problems caused by oil in the connectors can be avoided by placing the compressor on its base plate

some time before brazing it into the system. The compressor must never be placed upside down.

The system should be closed within 15 minutes to avoid moisture and dirt penetration.

The positions of connectors are found in the sketches. “C” means suction and must always be connected to

the suction line. “E” means discharge and must be connected to the discharge line. “D” means process and

is used for processing the system.

Most compressors are supplied with sealed connectors, which consist of a thick-walled copper plated steel

tube with great corrosion resistance and good braze ability. The connectors are welded in the compressor

housing and thus the weld cannot be destroyed by overheating during brazing operations. The seal is an

aluminum cap which gives a tight seal. Compressor with copper connectors are sealed with rubber plugs.

The aluminum cap sealing ("capsolut") offers a tight seali. The seal ensures that the compressors have not

been opened after leaving Secop´s production lines. In addition to that, the seal makes a protecting charge

of nitrogen superfluous.

220 V compressors are normally supplied with millimeter tubes, while 115 V compressors are supplied with

inch tubes. All connectors have a shoulder to provide optimal brazing conditions. Expanding the connectors

by more than 0.3 mm / 0.01 inch in is not allowed.

Compressors with an “S” in the model denomination and all NL/DL/SCE types have a direct intake system,

which means increased capacity. The suction connectors at these compressors must be connected to the

suction line to prevent capacity loss.

For the refrigerants R600a and R290, process tubes can be closed with a LOKRING® connection.

Brazing is not allowed on systems with flammable refrigerants.

12

4.2

Expanding connectors

The "capsoluts" are easily removed with an ordinary pair of pliers or a special tool as shown. The "capsolut"

cannot be remounted.

When the seals on the compressor connectors are

removed, the compressor must be mounted in the

system within 15 minutes to avoid moisture and dirt

penetration.

"Capsolut" seals on connectors must never be left in

the assembled system.

Oil coolers, if mounted (compressors from 7 cm3 displacement), are made of copper tube and the tube con-

nectors are sealed with rubber plugs. An oil-cooling coil must be connected in the middle of the condenser

circuit.

SC Twin compressors must have a non-return valve in the discharge line to compressor no. 2. If a change

in the starting sequence between compressor no.1 and no. 2 is desired, a non-return valve must be placed

in both discharge lines.

In order to create optimum conditions for braz-

ing and to minimize the consumption of filler

metal, all tube connectors on Secop compres-

sors have shoulders, as shown

It is possible to expand the connectors with in-

side diameters f 6.2 mm to 6.5 mm which suit

1⁄4” (6.35 mm) tubes, but we advise against ex-

panding the connectors by more than 0.3 mm

(0.01 inch). When expanding, it is necessary to

have a suitable counterforce on the connectors

so that they don’t break off.

A different solution to this problem would be to

reduce the diameter of the end of the connector

tube with special pliers.

13

4.3

Bending copper

connectors

4.3.1

Spring benders

4.3.2

Lever-type benders

4.3.3

Tailor-made

bending tools

Secop has changed most of its compressors to copper connectors to ensure easy brazing and handling.

Should additional extra handling or bending of connectors be required, it is the responsibility of the techni-

cian to choose the proper bending method. Bending is not recommended without the standard support tools

used for adjusting or bending normal tubes shown below.

The following tools may be used for bending.

Spring benders are an efficient low-cost method for bending copper tubes. They are available in different

sizes to fit over the copper tube. Please ensure that you choose the correct size. The spring must be placed

over the full length of the bend. If you have difficulties removing the spring after bending, do not use force to

pull on the spring, as this may damage the spring. Simply twisting the spring and “unscrewing” the spring

will usually work. This procedure is only recommended for small adjustments.

Lever-type benders are easy to use and are calibrated for accurate bending. Many have scales or markings

to repeat the bending accuracy.

In some cases, special bending tools are necessary

due to space issues or special angles. This requires

a special geometry to protect the tube against wear

and tear on the profile (effective flow diameter).

If you need further information, please get in contact

with a bending specialist.

14

4.4

Tube adaptors

4.5

Filler metal

4.6

Brazing

Instead of expanding the connectors or reducing the diameter of the connection tube, copper adapter tubes

can be used for service.

A 6/6.5 mm adapter tube can be used when a compressor with millimeter connectors (6.2 mm) is to be con-

nected to a refrigerating system with 1⁄4” (6.35 mm) tubes.

A 5/6.5 mm adapter tube can be used when a compressor with a 5 mm discharge connector is to be con-

nected to a 1⁄4” (6.35 mm) tube.

For brazing, the connectors and copper tubes filler metals with a silver content as low as 2% can be used.

This means that the so-called phosphor filler metals can also be used when the connecting tube is made

of copper.

If the connecting tube is made of steel, a filler metal with high silver content, which does not contain phos-

phor and which has a liquidus temperature below 740 °C / 1364 °F, is required. A flux is also needed for this

purpose.

The following are guidelines for brazing steel connectors whis is different to brazing copper connectors.

During heating, the temperature should be kept as close to the melting point of the filler metal as possible.

Overheating will lead to surface damage, so decreasing the chances of good brazing.

Use the “soft” heat in the torch flame when heating

the joint. Distribute the flame so at least 90 % of

the heat concentrates around the connector and

approx. 10 % around the connecting tube

When the connector is cherry-red (approx. 600 °C /

1112 °F) apply the flame to the connecting tube for

a few seconds.

Continue heating the joint with the “soft” flame and

apply filler metal.

Draw the filler metal down into the gap by slowly

moving the flame towards the compressor; then

completely remove the flame.

15

Secop uses telescope pipes or similar elements

inside the suction tube on some T- and N-Series

compressors, on all D- and X-Series compressors

and on the new SCE compressors to optimize energy

consumption.

You can identify the compressors by the thicker suc-

tion tube area near the compressor shell.

These telescope pipes are made out of plastic and

are sensitive to high heat exposure

Make sure when

brazing a tube into

the suction connec-

tor that the section

with the telescope

never exceeds 150 °C

/ 302 °F.

The new range of

SCE compressors

features a telescope

inside the compres-

sor on the suction

tube to optimize en-

ergy consumption.

These telescopes are

made of rubber and

are sensitive to high

heat exposure.

Make sure when brazing a tube into the suction con-

nector that the area with the telescope never ex-

ceeds 350 °C / 662 °F and do not braze longer than

30 seconds.

The DELTA compressor

uses a special discharge

connection element which

is directly connected to

the discharge tube to opti-

mize power consumption.

This element is made out

of plastic and are sensitive

to high heat exposure.

Make sure when brazing a

tube into the discharge connector that the area with

the telescope never exceeds 240 °C / 464 °F and do

not braze longer than 10 seconds.

Use a fork burner and/or a damp cloth, if necessary.

A protective plate can also serve to protect the tele-

scope from direct heat from a flame.

Telescope pipes or similar elements make it no

longer possible to select the process connector

as the suction connector or vice versa. You must

choose the correct connector for the suction line.

Please refer to the corresponding data sheets.

4.7

Brazing on suction

connectors

(compressors with

direct suction intake)

4.7.1

Temperature at socket

TLX / NLE / NLU / NLV

DLE / DLX / DLV / XV

4.7.2

Temperature at socket

SCE

4.7.3

Brazing on discharge

connector.

Temperature at socket

DELTA

4.7.4.

Heat protection

TLX compressor with copper connectors

NLU compressor copper-plated steel connectors

NLE compressor with copper connectors (NLV similar)

DLE compressor with copper connectors (DLX, DLV similar)

XV compressor with copper connectors

DELTA compressor with copper (suction, process) and

copper-plated steel (discharge) connectors

SCE compressor with copper connectors

16

4.8

Brazing methods and

requirements

4.8.1

Filler Metal and Flux

4.8.2

Corrosion

The refrigeration and air conditioning industries depend on brazed copper tubes as a leak proof carrier for

pressurized refrigerant. The common approach to brazing copper to copper or copper to steel is to use filler

metal (copper alloy). Torch brazing with oxygen/fuel gas (acetylene in most cases) is standard practice in

heating these connections.

Two brazing methods are used

• With filler metal and flux

• With filler metal only

Basic requirements to have a good brazing connection

• Filler metal flows easily when clearance uniform and tight, between 0.038 mm and 0.076 mm /

0.0015 inch and 0.003 inch

• The wide 0.5 mm / 0.02 inch clearance severely limits the flow.

• The overlap need to be about 4 to 9 times of the tube thickness and is a function of the tube thickness

and required strength of the joint.

Filler metal

Two types of filler rods are used for brazing copper tubes. These fillers are:

• Phosphorus – copper brazing alloys with melting point around 704 °C / 1300 °F and this temperature

depends on the alloy composition.

When phosphorus content reaches 8.37%,

the melting point is 710 °C / 1310 °F.

Lower phosphorus content is needed when the clearance is greater than 0.127 mm / 0.005 inch.

Caution: Alloys containing phosphorus should not be used to braze copper – steel joints.

These alloys should not be used on Secop compressors with steel copper coated connecting tubes.

The joint will not have sufficient ductility for high vibration application (compressor).

• High silver filler metal should be used to braze the copper-steel joints or other ferrous base metals.

The best are 40%; 45% and 56% silver rods.

• With optimum clearance, many brazing filler metals are suitable. It is necessary to heat only the joint to

suitable temperature above filler metal melting point.

Flux

• Fluxes are not designed for the removing oxides, coatings (in our case – painting tubes), oil, grease, dirt,

or other foreign materials from the tubes to be brazed. Prior to brazing, all parts must be subjected to

appropriate cleaning operation. The main function of flux is to make sure that the filler metal flows freely

through the brazing joint.

• Oxides are the principal source of surface contamination. The dissolution and removal of oxides during

brazing are also a function of a flux.

• The flux must also be fluid and displace readily by the molten brazing filler metal So as not to impair

metal flow.

• Wetting ability and viscosity of a flux at brazing temperature, therefore, are important properties.

• Some filler metals such as silver and phosphorus are self-fluxing.

• Flux residue generally should be removed to avoid corrosion from the remaining active chemicals.

The residue obtained from the flux, particularly when considerable oxide removal has occurred, is a

form of glass. Less formation of glass makes for easier flux residue removal. Removing flux from

properly cleaned, brazed tubes can usually be accomplished by washing in hot water accompanied by

light brushing. Preferably, this rinse should be done immediately after brazing operation. drying is highly

recommended after rinsing.

The type of corrosion affecting brazed joints are often similar to those acting upon the base metal and their

alloys. Brazed joints experience corrosion caused by environment, geometric factors, microstructure, or

composition of the brazed joint. The basic corrosions are:

• Galvanic corrosion

• High temperature corrosion

• Cracking complicated by corrosion

Galvanic corrosion can be a major concern because the brazed joints consists often a bond between dis-

similar base and filler metal. If the braze is immersed in an electrolyte, galvanic corrosion may occur. The

electrolyte may be as simple as water. If flux is used and the customer is using water to clean the joint, they

create the electrochemical reaction. The distances between the anodic and cathodic reactions are on atomic

scale. The worst case scenario is using acid for cleaning the surface. We should remember that water is also

present in brazing fluxes either as water of hydration or separate addition for the purpose of making a paste

or liquid.

17

4.8.3.

Flame and heating

4.9

LOKRING® connections

(VULKAN Lokring

Rohrverbindungen GmbH

& Co. KG)

Flame

• The neutral flame should be used for copper-copper and copper – steel tubes.

When the oxygen addition reaches the ratio for the fuel gas to be completely combust, the feather that ex-

tended out from the bright inner cone disappears. This flame is used when the arc access of carbon in the

reducing flame is detrimental to the base metals or when maximum flame temperature is required.

Heating:

When brazing tubes type joints follow these steps for best results.

• First, heat the inside tube. Copper is a very excellent heat conductor and will draw the heat down inside

the joint.

• Then bring the torch to the fitting. Move the torch between the tube and fitting to ensure even heat, and

apply the filler metal. The phosphorus – copper brazing material will flow toward the heat into capillary

for a sound joint. Filler metal through the length of the capillary is desired.

• When copper is heated to the brazing temperature, surface oxides will flake off as the part cools. This

flaking can be detrimental inside the tube. In this application an inert gas such as nitrogen is bled through

the tube during and after brazing.

Systems containing the flammable refrigerants R600a or R290 must not be brazed. In such cases, a

LOKRING® connection as shown can be used.

Newly made systems can be brazed as usual, as long as they have not been charged with a flammable

refrigerant. Charged systems are never to be opened by using a flame. Compressors from systems with a

flammable refrigerant must be evacuated to remove the refrigerant residues from the oil.

Furthermore, those refrigeration systems must be opened with a pipe cutter. The brazing on HC-cooling

circuits is only allowed if the existing refrigerant has been disposed according to regulations and if the high

and low-pressure circuits are subsequently flushed separately with nitrogen. Even if the compressor is not

to be replaced, the brazing is only allowed under flowing nitrogen as a protective gas. On all other occasions,

the brazing close to flammable refrigerants is strictly forbidden.

When working on a system, the connections have to be established with pressure fitted connections. With

a solderless connection, this can be established for aluminum, copper, or steel pipes. The connection con-

sists of two rings and a connection piece to receive the two pipes, which is to be connected. Because of the

conical internal contour of the rings and the special external contour of the connection piece, the radius

of the connection piece will be reduced to the diameter of the pipes to generate a hermetic metal to metal

compound.

Torch

Inner cone

bluish white

Bluish

Bluish to orange

Neutral flame - No acetylene feather

Illustrations by kind permission of

VULKAN Lokring Rohrverbindungen GmbH & Co. KG

18

Prior to assembly, the pipe ends have to be cleaned thoroughly with fine steel wool or abrasive sheets, using

a rotating motion. Ths prevents scratches along the pipes, which could lead to an insufficent seal.

To ensure a sealed connection, the pipe ends are treated with LOKPREP®. This evens out any irregularities

on the pipe’s surface and quickly hardens. After the insertion of the pipe end into the connection pieces,

the pipes should be rotated by 360°, to guarantee the sealant spreads evenly. Afterwards, the two rings are

compressed to the stop in the middle with a special pair of pliers for manual assembly.

Depending on the material and the environmental temperature, the LOKPREP® hardens in three to four

minutes, so that all necessary connections can be established alongside the replacement of the compressor

and filter dryer as well as the filling process. Due to maximal precision in the manufacturing process, the

connection can be established with minimal effort. It guarantees an absolutely clean, inseparable and purely

mechanical pipe connection with high durability regarding the hermetical seal.

Servicing and repair for R600a and R290 systems is possible for skilled and well trained service technicians.

Our video "Compressor Service for Isobutane (R600a) and Propane (R290) – Step by Step" can be used as a

reference (https://www.secop.com/solutions/compressor-qa-tools/compressor-service/)

Local laws and regulations must also be taken into account. Very careful handling is required due to the

flammability of the gas, which is a potential danger during work on the refrigeration system.

The disposal of R290 and R600a does not include the filling of a recycling cartridge. Due to the low GWP, the

flammable refrigerants are directed away from the workplace into the open through a tube. External ignition

sources must be avoided During the process.

Good ventilation of the room is necessary and the discharge of the vacuum pump must be lead to open air.

The equipment of the service technician must meet the requirements of R600a and R290 in terms of evacu-

ation quality and refrigerant charge accuracy. An electronic scale is recommended to control refrigerant

charge to within the needed accuracy.

The maximal filling capacity is 150 g / 5.3 oz. per system, which equates to approximately 8 g/m³ in a 20 m³

kitchen and thereby around 25 % of the lower flammability limit. These precautions minimize the risk of an

ignition in case of a leakage. Exceeding these values is officially allowed under favorable conditions.

All manufacturers of HC-systems have to follow these safety regulations. The customer service, as well as

the repair of R600a and R290 applications, should only be accomplished by highly trained and experienced

personnel.

Secop compressors are expected to be used in well dimensioned refrigerant systems including a drier con-

taining an adequate amount and type of desiccant and with a suitable quality.

The refrigerating systems are expected to have a dryness corresponding to 10 ppm. As a max limit 20 ppm

is accepted.

The drier must be placed in a way ensuring that the direction of flow of the refrigerant follows gravitation.

Thus the MS beads are prevented from moving among themselves and therefore creating dust and possible

blockage at the inlet of the capillary tube. For capillary tube systems this also ensures a minimal pressure

equalizing time.

Pencil driers should be especially chosen carefully to ensure proper quality. In transportable systems only

driers approved for mobile application are to be used.

A new drier must always be installed when a refrigeration system has been opened.

7469

4.10

Driers

19

Water has a molecular size of 2.8 Ångström. Accordingly, molecular sieves with a pore size of 3 Ångström

should be suitable for normally used refrigerants.

MS with a pore size of 3 Ångström can be supplied by the following:

Driers with the following amount of desiccants are recommended:

Compressor Filter drier

P and T 6 gram or more

F and N 10 gram or more

SC 15 gram or more

In commercial systems, larger solid core driers are often

used. These are to be used for the refrigerants according to

the manufacturers instructions. If a burn-out filter is needed

in a repair case, please contact the supplier for more detailed

information.

Special care should be taken when brazing the capillary tube. When mounting the capillary tube it should

not be pushed too far into the drier, thus touching the gaze or filter disc, causing a blockage or restriction.

If, on the other hand, the tube is only partly inserted into the drier, blockage could occur during the brazing.

This problem can be avoided by making a “stop” on the capillary tube with a pair of special pliers as shown:

4.11

Driers and refrigerants

4.12

Capillary tube in drier

UOP Molecular Sieve Division, USA

(earlier Union Carbide) 4A-XH6 4A-XH7 4A-XH9

R12 x x x

R22, R502 x x

R134a, R404A x x

HFC/HCFC blends x

R290, R600a x x

Grace Davision Chemical, USA 574 594

R12, R22, R502 x x

R134a x

HFC/HCFC blends x

R290, R600a x

CECA S.A., France NL30R Siliporite H3R

R12, R22, R502 x x

R134a x x

HFC/HCFC blends x

R290, R600a x

(3/16”)

20

5.

ELECTRICAL EQUIPMENT

5.1

LST (RSIR)

starting device

5.2

LST (RSCR)

starting device

The compressors are equipped with a single phase AC motor. The electrical equipment is classified as

“normal tight” (IP20). The motor protector is built into the motor (winding protector). Exceptions include

compressors with the denominations TF/TT, NF/NT, FF, some SCs and KAPPA and DELTA. Earth connec-

tions are located on the bracket around the current lead in of the compressor (exception KAPPA & DELTA).

No attempt must be made to start the compressor without a complete starting device.

Never use a starting device of an old compressor because this may cause a compressor failure. No attempt

must be made to start the compressor without the complete starting equipment.

For information on the right starting devices, please see Data Sheets for the compressor.

For safety reasons the compressor must always be earthed or otherwise additionally protected. Keep inflam-

mable material away from the electrical equipment. The compressor must not be started under vacuum.

R134a: With some exceptions, these compressors are designed with universal motors which means that

they can obtain a high (HST) or low starting torque (LST) depending on the external electrical

equipment used.

R600: Nearly all compressors for R600a are designed only for use with Low Starting Torque (LST).

R290: All compressors for R290 are designed for use with Low Starting Torque (LST) or

High Starting Torque (HST).

R404A/R507 All compressors for R404A/R507 and R407C are designed only for use with

and R407C: High Starting Torque (HST).

Compressors with the motor type Resistant Start Induction Run (RSIR) have a starting device for Low Start-

ing Torque (LST). The design of the electrical equipment depends on the actual compressor design. The

following designs of starting devices exist:

a) PTC + cord relief + cover, the motor protector is built into the motor (winding protector),

Mount the starting device on the current lead-in of the compressor. Pressure must be applied to the center

of the starting device so that the clips are not deformed. Mount the cord relief on the bracket under the

starting device.

Pressure must be applied to the center of the starting device when dismantling so that the clips are not

deformed. Place the cover over the starting device and screw it to the bracket.

b) Relay housing incl. motor protector + cord relief + cover (alternative: terminal board with cord relief)

Terminal board with cord relief: The relay is mounted by applying pressure on the center of the relay. The

cover is fixed with a clamp.

PTC with external protector: The protector is placed on the bottom terminal pin and the PTC on the 2 on the

top. The cover is fixed with a clamp. No cord relief is available for this equipment.

The PTC starting device requires pressure equalization before each start. This starting device is normally

used in well designed refrigerating systems with capillary tube as throttling device. The PTC needs a com-

pressor standstill period of 5 minutes to cool down before each start.

Compressors with the motor type Resistant Start Capacitor Run (RSCR) have a starting device for Low Start-

ing Torque (LST). This starting device consists of a PTC and a run capacitor.

The PTC starting device requires pressure equalization before each start. This starting device is normally

used in well designed refrigerating systems with capillary tube as throttling device.

The PTC needs a compressor standstill period of 5 minutes to cool down before each start.

This manual suits for next models

9

Table of contents

Popular Compressor manuals by other brands

Hitachi

Hitachi NEXT Series Service manual

EasyPro

EasyPro Compact Aeration Series instructions

Doosan

Doosan 7/205 Operation & maintenance manual

Champion

Champion R Series Operation & service manual

Ingersoll-Rand

Ingersoll-Rand N2 Series Installation and maintenance information

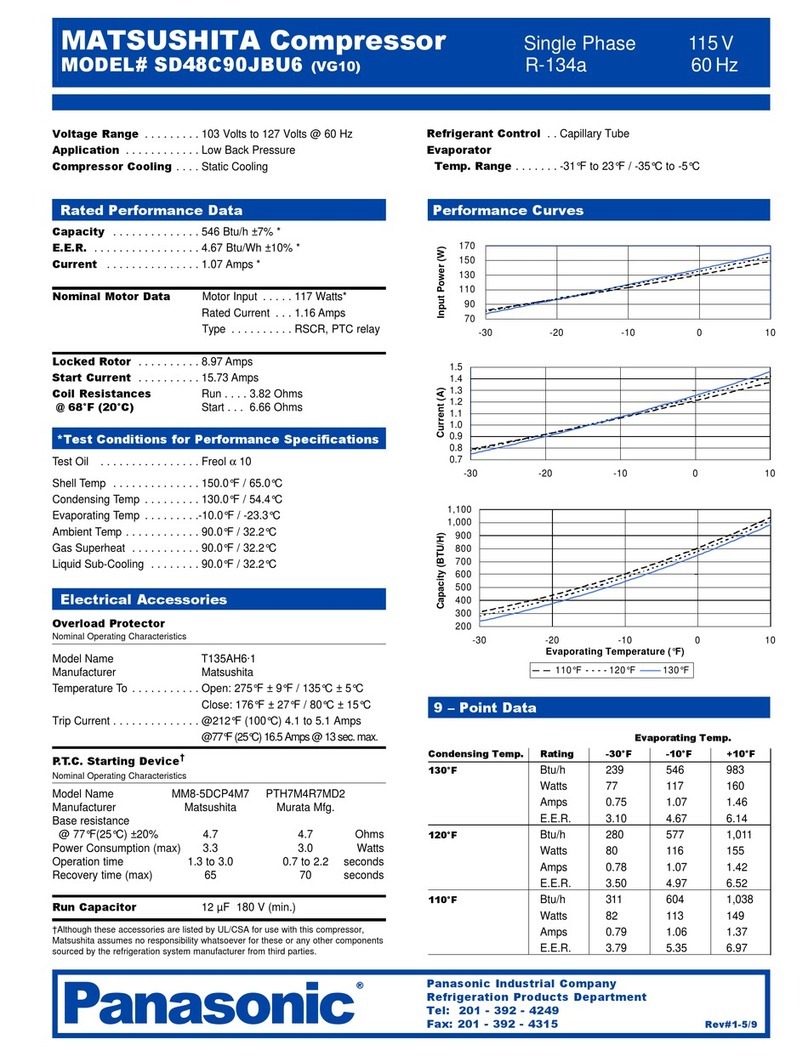

Panasonic

Panasonic Matsushita SD43C77JBU6 Specification sheet

BENDIX

BENDIX BA-921 COMPRESSOR-STD-CLOSED ROOM Service data sheet

Sherwin-Williams

Sherwin-Williams GTS-ProCart 283-584 owner's manual

Becker

Becker KDT 3.140 operating instructions

Panasonic

Panasonic Matsushita SD48C90JBU6 Specification sheet

American Eagle

American Eagle 70P manual

EKOM

EKOM DK50-10 Series user manual