SECOP 101N2130 User manual

1/3 DES.I.101.T1.02 / 520N1301 June 2021

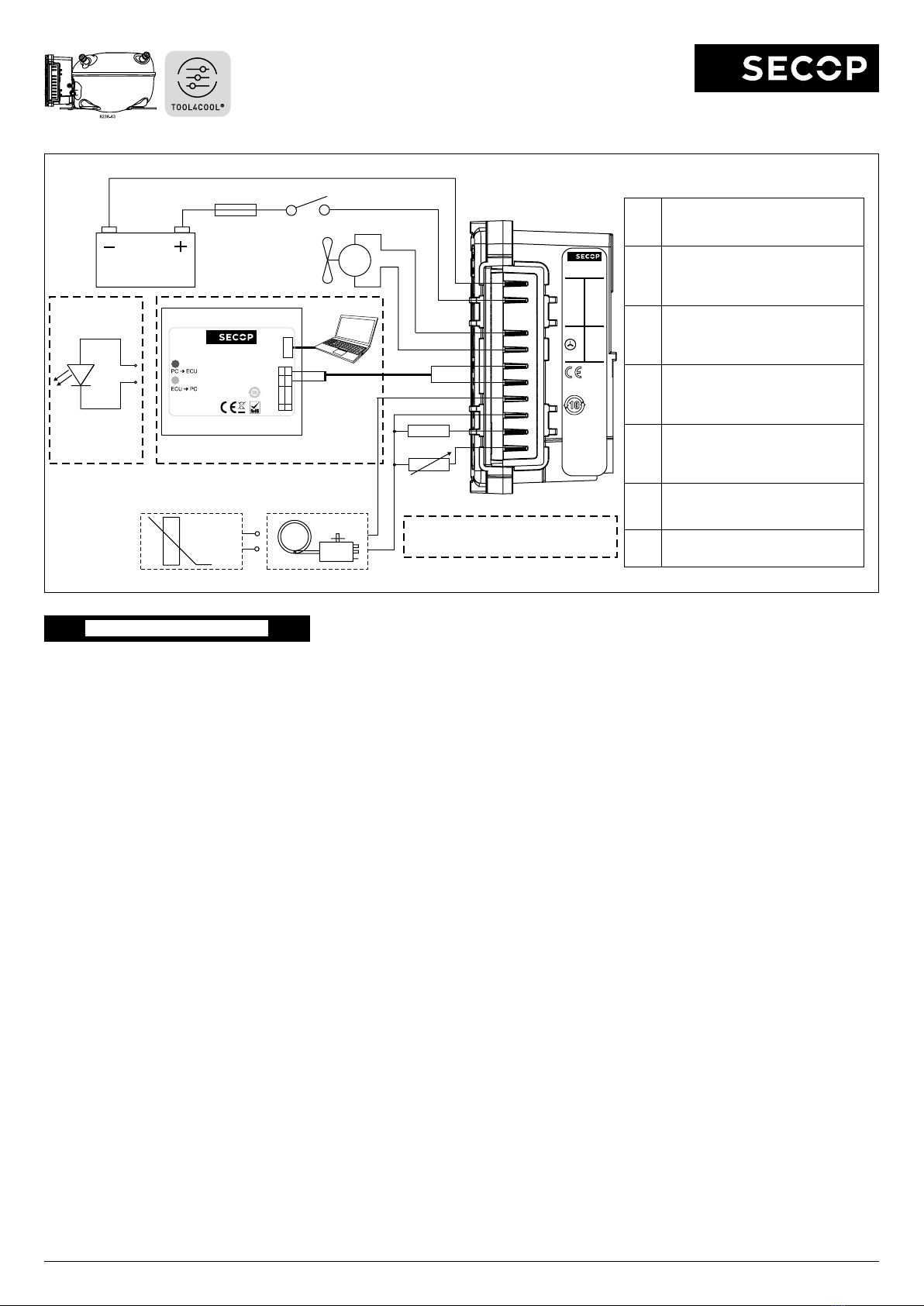

Fig. 1

ENGLISH

The electronic unit is a dual voltage device. This

means that the same unit can be used in 12V

or 24V power supply systems. Maximum volt-

age is 17V for a 12V system and 34V for a 24V

power supply system. Max. ambient temperature

is 55°C. The electronic unit has a built-in thermal

protection which is actuated and stops compres-

sor operation if the electronic unit temperature

gets too high (100°C/212°F on the PCB). It can

be connected to a PC through the Secop One

Wire/LIN Gateway communication interface on

the terminal D/I and C (Fig. 1). Communication

gateway modules incl. communication cables

can be ordered at Secop.

The PC interface allows you to create dierent

settings and reads out several measurements by

using the software tool TOOL4COOL® supplied

by Secop.

Installation (Fig. 3)

Mount the electronic unit directly on the compres-

sor plug and x it with screws.

Power supply (Fig. 1)

The electronic unit must always be connected

directly to the battery poles. Connect the plus to

+ and the minus to –, otherwise the electronic

unit will not work. The electronic unit is protected

against reverse battery connection. For protec-

tion during installation, a fuse must be mounted

in the + cable as close to the battery as possible.

A 15A fuse for 12V and a 15A fuse for 24V

circuits are recommended.

If a main switch is used, it should be rated to a

current of min. 20A.

The wire dimensions in Fig. 4 must be observed.

Avoid extra junctions in the power supply system

to prevent voltage drop from aecting the battery

protection setting.

Battery protection (Fig. 2)

The compressor stops and restarts again accord-

ing to the designated voltage limits measured on

the + and – terminals of the electronic unit. The

standard settings for 12V and 24V power supply

systems are shown in Fig. 2. (PC option)

Other settings are (Fig. 5) optional if a connec-

tion which includes a resistor (R1) is established

between terminals C and P (non PC option).

Thermostat (Fig. 1)

The thermostat is connected between the termi-

nals C and T. Either a NTC (electrical thermostat)

or a mechanical thermostat can be connected.

Three dierent thermostat modes can be chosen

in the software - Auto (both NTC and mechanical),

NTC or Mechanical. Standard setting is Auto. In

case of using a NTC the set point in the range

between -40ºC and 40ºC is set with the software

and the temperature can also be seen by using

the interface. When using the Auto setting in the

software it is not possible to obtain NTC failures,

so it is recommended to set the thermostat mode

to NTC when using a NTC.

Setpoint selection (Fig. 6)

In order to utilize the nally intergrated tempera-

ture control. You can connect a 10kΩ potentiom-

eter between S and C (R2). Via this resistor a

temperature setpoint between -20°C and 10°C

can be selected. The compressor will stop when

the set point is measured on the NTC and re-

start at set point +1kΩ or 3K (Kelvin) (non PC

option).

Speed selection (Fig. 5)

The compressor will run with a xed speed of

4,000 rpm when the thermostat is switched on.

Other xed compressor speeds and start speeds

in the range between 2,000 and 4,000 rpm can

be obtained when changing the speed settings

in the software (PC option) or with the resistor

(non PC option).

A start delay in the range from 0-240 sec. (factory

setting 4 sec.) after thermostat cut-in can also be

chosen. By default the compressor will start with

a speed of 2,500 rpm for the rst 30 seconds.

Fan (Fig. 1)

A fan can be connected between the terminals

+(F) and F. Connect the plus to +(F) and the mi-

nus to F. Since the output voltage between the

terminals +(F) and F is always regulated to 12V,

a 12V fan must be used for both 12V and 24V

power supply systems.

The fan output can supply a continuous power

of 6Wavg. A higher current draw is allowed for 2

seconds during start.

Fan settings can be adjusted via TOOL4COOL®.

The factory default setting in the controller is:

Detect missing fan - Disabled.

The unit has to be restarted when these settings

have been changed. If a fan is used without ad-

apting the TOOL4COOL® settings, the fan will

run but no error signal will be sent in case of fan

failure. It is also possible to set a start delay on

the fan in the range from 0 – 240 sec. but only if

a fan is connected and not running.

Factory default setting for a fan is 0 seconds.

Fan speed can be adjusted through the interface

from 40 – 100%.

Error handling (Fig. 7)

If the electronic unit records an operational error,

the error can be read out in the software

(PC op-

tion). Error codes are dened as shown in Fig. 7.

A 10mA light emitting diode (LED) can alterna-

tively be connected between the terminals D/I

and +. In case the electronic unit records an

operational error, the diode will ash a number of

times. The number of ashes depends on what

kind of operational error was recorded. Each

ash will last ¼ second. After the actual number

of ashes there will be a delay with no ashes,

so that the sequence for each error recording is

repeated every 4 seconds

(non PC option)

.

101N2130

IN

12/24V

FAN OUT

D/I

C

T

C

P

S

F

F

+

-

-

+

One Wire LIN Gateway

USB

USB C

U+* D/I

C

U

C

1

2LIN

BAT

105N9518 – V01.00

www.secop.com

Made in Germany

* Don‘t connect when

using D/I on BD-Products

Secop LIN/One-Wire

Gateway

Code no.:105N9516

Comm.

PC option (TOOL4COOL®)

Gateway connected to ,,andU D/I C

BAT

8910-2

Main switch

Fuse

Power supply

NTC resistor

–t°

option 1option 2

mech. Thermostat

Fan

-

+

R1

R2

+

+

-

-

LED

R1 = speed/battery protection

R2 = setpoint

non PC option (resistors)

non PC option

LED connected to

and+ D/I

Spade connectors

6.3 mm | 1/4 in.

Fig. 7

Operational errors (PC or non PC option)

Error

code

or LED

ashes

Error type

Can be read out in the software

TOOL4COOL®

6Thermostat failure

(If the NTC thermistor is short-circuit or has

no connection, the electronic unit will enter

manual mode).

5Thermal cut-out of electronic unit

(If the refrigeration system has been too hea-

vily loaded, or if the ambient temperature is

high, the electronic unit will run too hot).

4Minimum motor speed error

(If the refrigeration system is too heavily

loaded, the motor cannot maintain minimum

speed at approximately 1,850 rpm).

3Motor start error

(The rotor is blocked or the dierential

pressure in the refrigeration system is too

high (>5 bar)).

2Fan over-current cut-out

(The fan loads the electronic unit with more

than 0.65Apeak).

1Battery protection cut-out

(The voltage is outside the cut-out setting).

Instructions

Electronic Unit for BD1.4F-VSDx

Compressor, 101N2130, 12-24V DC

2/3 DES.I.101.T1.02 / 520N1301 June 2021

Instructions

Electronic Unit for BD1.4F-VSDx

Compressor, 101N2130, 12-24V DC

Fig. 3

Fig. 4

Fig. 2

Wire Dimensions DC

Size Max. length* Max. length*

Cross AWG 12V operation 24V operation

section

[mm2] [Gauge] [m] [ft.] [m] [ft.]

2.5 12 2.5 8 5 16

412413826

6 10 6 20 12 39

10 8 10 33 20 66

*Length between battery and electronic unit

Battery protection settings

Voltage (0.1 steps) Min. value Default Max. value

12V ± 0.3V DC,

all values

Cut out V DC 9.6 10.4 17

Cut in di. V DC 0.5 1.3 10

24V ± 0.3V DC,

all values

Cut out V DC 19 21.3 27

Cut in di. V DC 0.5 1.3 10

Fig. 5

R1

[kΩ]

Duty Cycle

[%]

Speed

[RPM]

Cut in level

[V]

Cut out level

[V]

Cut in level

[V]

Cut out level

[V]

open 0 Maintain Maintain current value. Can be changed via Modbus

220 3 - Maintain current value. Can be changed via Modbus

130 6 - Maintain current value. Can be changed via Modbus

91 9 - Maintain current value. Can be changed via Modbus ECO

68 12 - Maintain current value. Can be changed via Modbus ECO o

51 15 9.6 - 34 V DC Solar

43 18 Default Solar o

36 21 Reset battery only

30 24 Reset battery and speed to default value

27 27 4000 Maintain current value. Can be changed via Modbus

22 30 4000 10.9 9.6 22.6 21.3

20 33 4000 11.4 10.1 23.6 22.3

18 36 4000 12.4 11.1 24.6 23.3

15 39 4000 13.4 12.1 25.6 24.3

13 42 3500 Maintain current value. Can be changed via Modbus

12 45 3500 10.9 9.6 22.6 21.3

11 48 3500 11.4 10.1 23.6 22.3

9.1 51 3500 12.4 11.1 24.6 23.3

8.2 54 3500 13.4 12.1 25.6 24.3

7.5 57 3000 Maintain current value. Can be changed via Modbus

6.2 60 3000 10.9 9.6 22.6 21.3

5.6 63 3000 11.4 10.1 23.6 22.3

5.1 66 3000 12.4 11.1 24.6 23.3

4.3 69 3000 13.4 12.1 25.6 24.3

3.9 72 2500 Maintain current value. Can be changed via Modbus

3.3 75 2500 10.9 9.6 22.6 21.3

2.7 78 2500 11.4 10.1 23.6 22.3

2.2 81 2500 12.4 11.1 24.6 23.3

1.8 84 2500 13.4 12.1 25.6 24.3

1.5 87 2000 Maintain current value. Can be changed via Modbus

1.0 90 2000 10.9 9.6 22.6 21.3

0.68 93 2000 11.4 10.1 23.6 22.3

0.36 96 2000 12.4 11.1 24.6 23.3

0.051 99 2000 13.4 12.1 25.6 24.3

Fig. 6

Set point

[°C]

R2

[Ω]

-20 0

-19 330

-18 670

-17 1000

-16 1330

-15 1670

-14 2000

-13 2330

-12 2670

-11 3000

-10 3330

-9 3670

-8 4000

-7 4330

-6 4670

-5 5000

-4 5330

-3 5670

-2 6000

-1 6330

0 6670

1 7000

2 7330

3 7670

4 8000

5 8330

6 8670

7 9000

8 9330

9 9670

10 10000

3/3 DES.I.101.T1.02 / 520N1301 June 2021

Secop accepts no responsibility for possible errors in catalogs, brochures, and other printed material. Secop reserves the right to alter its products without notice. This also applies to products already

on order provided that such alterations can be made without subsequential changes being necessary to specications already agreed. All trademarks in this material are the property of the respective

companies. Secop and the Secop logotype are trademarks of Secop GmbH. All rights reserved. www.secop.com

The communication port of the electronic unit

(terminal D/I and C) has two functions:

1. Communication mode (PC option):

The rst 15 seconds after power up/wake up, both

devices (compressor & PC) try to communicate.

In case a successful connection is made, the port

will stay in communication mode until next power up/

wake up.

2. Diode output mode (non PC option):

After 15 seconds with no communication link suc-

cessful established, the unit switches to diode output

mode.

No communication is possible until next power up/

wake up.

To ensure a trouble free connection using

TOOL4COOL®, the following method is recom-

mended:

Change the default TOOL4COOL® network setup

to allow TOOL4COOL® to search for the electronic

unit every 3 seconds. While TOOL4COOL® is sear-

ching, power up the electronic unit and wait for a

connection.

The following shows how to arrange this setup.

Preconditions:

The electronic unit is physically connected via the

gateway to the PC, but the power to the electronic

unit is not yet switched on.

In the example to the right, the electronic unit is con-

nected to the COM1 network.

Note:

Next to the USB connector of the gateway, there are

also two LED’s visible:

RED LED: blinks when TOOL4COOL® sends a

command to the electronic unit.

This must blink every second while TOOL4COOL®

is trying to establish a connection with the electronic

unit.

GREEN LED: blinks when the electronic unit re-

sponds to a TOOL4COOL® command.

The node address of the electronic unit must match

the command from TOOL4COOL®

(The network setting above tells TOOL4COOL® to

search for unit node address 1 every 3 sec.).

Instructions

Connecting TOOL4COOL®

to Electronic Unit 101N2130

Step Description / Display

1Do not power up the electronic unit at this stage.

2Start TOOL4COOL®

3In case the network is already connected, disconnect

it rst using on screen network option.

4Wait a few seconds, then select Connect Network

(below the File menu).

5Select the correct port, in this example COM1 is used.

6Cick Congure.

7Change Last network node address to 1and

change Refresh rate to 3.

Leave the other settings at their default value and

click OK twice.

Now TOOL4COOL® will only look for an electronic

unit with address 1, but every 3 seconds. This will

ensure that the connection is established within the 15

second time limit after powering up the unit.

Leave all other options unchanged.

8Power up the electronic unit

9The rst time the unit is connected, TOOL4COOL®

needs to obtain the parameter le from the unit before

a connection is shown by the red arrow. Allow a few

minutes for this task to complete.

You also can read the current status by selecting the

network and then select the tab Unit Status.

10 Look under Error/Message

In this example, no errors or messages appear and the unit is working properly.

11

If the parameter le was already loaded into

TOOL4COOL®,

a connection should be visible in less

than 10 seconds.

A red arrow is added before the network name to

indicate that a unit is ready.

Click the red arrow to open

the menu of the electronic

unit.

Other SECOP Industrial Equipment manuals