Seepex BN 5-12 Series Manual

Progressive Cavity Pump Operation & Maintenance Manual

Supply of SEEPEX, Inc. pumps & accessories: consisting of engineering drawings,

descriptive literature, operating data and related information.

For the Supply of SEEPEX Pumps & Accessories

To:

W.M. Lyles Co. Contractors

42142 Roick Dr.

Temecula, CA 92590

Phone#: 661-301-7266

Attn: Grant Gourley, ggourley@wmlylesco.com

Project:

Orange County Sanitation District Sludge Dewatering & Odor Control-Plant #1

PO#: T1113-20

seepex Job#: 2115517

Specifications Section: 11309 Progressing Cavity Pumps

Equipment No:

Denomination: Pump Type: Commission#: Tag:

Active Dilute Polymer Pump BN 5-12 835294-296 15LPMP810, 820 & 830

Represented By:

Cortech Engineering

22785 Savi Ranch Pkwy.

Yorba Linda, CA 92887

Phone#: 714-779-0911, Fax#: 714-693-1715

By:

SEEPEX, Inc.

511 Speedway Dr.

Enon, OH 45323

Phone#: 937-864-7150, Fax#: 937-864-7157

January 2015

Page 1

General

Ausgabe

issue B / 02.01.2006 Dokument

document OM.GEN.01e Blatt

sheet 1(2)

1.0

General

1.1

Application

These operating instructions contain basic infor-

mation on the installation, commissioning and

maintenance of seepex machines. Compliance with

the work steps described in the individual sections is

essential.

1.2

Details of the seepex machines

1.2.1

Operating Instructions

The Commission Number (comm. no) assigns the

operating instructions to a particular seepex

machine. The operating instructions are produced in

relation to a specific job/commission and are valid

only for the machine whose comm. no. is identical

with that indicated on the cover sheet and

possessing the associated data sheet, Point 9.

1.2.2

Manufacturer

The machines were manufactured by seepex.

1.2.3

Range, Size, Version

of the machines are stated in the appended data

sheet, Point 9.

1.2.4

Machine Comm. No. and Year of Construction

are stated on the type plate at the machine.

1.2.5

Release Date of the Operating Instructions

is stated on the cover sheet of the operating

instructions.

1.2.6

Modifications, Notes of Modification

If modifications to the machines are

carried out in agreement with seepex, a new set

of operating instructions will be provided, or the

existing operating instructions will be supplemented by

an additional sheet together with a new cover sheet.

The date of modification and modification index will be

noted on the new cover sheet.

1.2.7

EEC Machine Directive

1.2.7.1

Manufacturer's Declaration

seepex Manufacturer's Declaration as required by the

EEC Machine Directive 89/392/EEC, Appendix II B:

The seepex machines delivered in accordance with

our design are intended to be fitted in one machine or

assembled together with other machines to form one

machine/plant. The commissioning of the machine is

forbidden until such a time as has been established

that the entire machine/plant satisfies the

requirements of the EEC Directive for Machines as

amended 91/368/EEC and 93/44/EEC.

Particular attention must be paid to the safety

requirements specified in EN809 (s and Equipment

for Fluids) as well as the information in these

operating instructions.

1.2.7.2

Declaration of Conformity

seepex machines possessing no safety accessories

do not fulfill the requirements of the EEC Machine

Directive 89/392/EEC as amended 91/368/EEC and

93/44/EEC.

For this reason, no Declaration of Conformity as

required by the EEC Machine Directive 89/392/EEC,

Appendix IIA can be issued before appropriate safety

devices have been installed/mounted on the machine

and/or plant with due regard to the information given

in these operating instructions.

The following harmonized standards are particularly

applicable:

EN 809, EN292T1, EN292T2

Applicable national standards and specifications must

be taken into consideration.

Following assessment of the conformity of the

machine/plant with the EEC Machine Directive,

customers may on their own initiative place on the

full machine/plant the EEC symbol 'CE' as defined in

Identification Directive 93/68/EEC.

CAUTION

This documentation must be kept available for at

least 10 years.

Page 3

General

Ausgabe

issue B / 02.01.2006 Dokument

document OM.GEN.01e Blatt

sheet 2(2)

1.2.8

Copyright and Industrial Property Rights

These operating instructions are copyrighted. The

reproduction, in particular by photocopying, of these

instructions is not permitted (§§ 54, 54 UrhG) and

constitutes a criminal offence (§ 106 UrhG).

Proceedings will be instituted if the copyright is

violated.

1.2.9

Specifications Required for Inquiries and Orders

The following information must be included when

inquiring about replacement parts or placing orders:

-comm. no.

- / machine type

This information is given on the type plate mounted

the machine.

1.2.10

Technical Data Sheet

see Point 9.

1.2.11

Performance Data, Load Index, Power

Consumption

are indicated in the associated data sheet, Point 9.

1.2.12

Sound Pressure Level

The sound pressure level and/or noise characteris-tics

of the seepex machines are ascertained in

accordance with DIN 45635. The measuring

guidelines are largely identical with the international

standards ISO 3740-1980 and ISO 3744-1981.

1.2.13

Operating Range

Employment of the machine is not permissible for

purposes other than those stated in the data sheet,

see Point 9. seepex cannot accept liability for damage

arising through failure to comply with this operating

range.

1.3

Supplementary Information

1.3.1

Accessories, Optional Extras

Please refer to the data sheet, Point 9.

1.3.2

Company Address, Service Addresses

see Point 11

Page 4

Safety

Ausgabe

issue C / 03.01.2006 Dokument

document OM.SAF.01e Blatt

sheet 1(2)

2.0

Safety

These operating instructions contain basic require-

ments to be observed during the installation, opera-

tion and maintenance of the machine. Therefore, the

instructions must be read by the mechanical fitter and

by the technical personnel/operator responsible for

the machine prior to assembly and commissioning,

and kept available at the operating site of the

machine/plant at all times.

Compliance is required not only with the general

safety instructions given in this section but also with

the detailed instructions, e.g. for private usage, given

under the other main headings in these operating

instructions.

2.1

Labeling of Advice in the Operating Instructions

In these operating instructions safety advice whose

non-observance could lead to danger for life or limb is

labeled with the following general hazard symbol:

safety symbol acc. to ISO 3864 - B.3.1

Warnings regarding electric power are labeled with:

safety symbol acc. to ISO 3864 - B.3.6

Safety instructions whose non-observance could

jeopardize the machine and its functions are labeled

by the word

CAUTION

Always comply with instructions mounted directly on

the machine, e.g.

-rotational direction arrow

-fluid connection indicators

and ensure that the information remains legible.

2.2

Personnel Qualifications and Training

Personnel charged with operation, maintenance,

inspection and assembly must be in possession

of the appropriate qualifications for the tasks.

The company operating the machine must define

exact areas of responsibility, accountabilities and

personnel supervision schemes. Personnel lacking

the required skills and knowledge must receive

training and instruction. If necessary, the opera-ting

company may commission the manufacturer/

supplier to conduct these training courses. Further-

more, the operating company must ensure that the

personnel fully understand the contents of the

operating instructions.

2.3

Dangers Resulting from Failure to Observe

Safety Instructions

Failure to comply with the safety instructions may

lead to hazards to life and limb as well as dangers

for the environment and the machine. Non-obser-

vance of safety instructions can invalidate the right of

claim to damages.

The following are just some examples of possible

dangers resulting from failure to comply with the

safety instructions:

-Failure of important machine/plant functions

-Failure of prescribed methods of service and

maintenance

-Danger to life and limb due to electrical,

mechanical and chemical influences

-Danger to the environment due to the leakage

of hazardous substances

2.4

Safety-conscious Working

Always comply with the safety instructions listed in

this document, the existing national accident

prevention regulations and any company-internal

work, operating and safety rules.

Page 5

Safety

Ausgabe

issue C / 03.01.2006 Dokument

document OM.SAF.01e Blatt

sheet 2(2)

2.5

Safety Instructions for the Operating

Company/Machine Operator

-Any potentially hazardous hot or cold machine

parts must be provided with protection against

accidental contact at the customer´s premises.

-Protective guards for moving parts (e.g. coupling)

must never be removed while the machine is in

operation.

-Leakages (e.g. in the shaft seal) of hazardous

conveying liquids (e.g. explosive, toxic, hot) must

be drained in such a way that no danger arises for

persons or for the environment. Always observe

the relevant statutory requirements.

-The risk of exposure to electrical power must be

eliminated (for details, see the VDE regulations, for

example, or those of the local power supply

company).

2.6

Safety Instructions for Maintenance, Inspection

and Assembly Work

The operator must ensure that all maintenance,

inspection and assembly tasks are carried out by

authorized and qualified personnel who have studied

the operating instructions closely and become

sufficiently familiar with the machine.

As a basic rule, the machine must be brought to

astandstill before work is carried out. Always comply

with the de-commissioning procedure described in

this document.

Any machiness or assemblies conveying media that

are detrimental to health must be decontaminated.

Immediately following completion of work, all safety

and protective devices must be replaced

in position and, where applicable, re-activated.

Before re-starting the machine, observe the points

listed under the heading "Initial Startup".

2.7

Unauthorized Modification and Manufacture of

Replacement Parts

Conversions or modifications of the machine are

permissible only in consultation with the manu-

facturers. Original manufacturer replacement parts

and manufacturer-approved accessories enhance

the operational safety of the machine. The usage of

unauthorized parts may lead to the nullification of the

manufacturer's liability for any resultant damages.

2.8

Impermissible Modes of Operation

The operational safety of the machines supplied is

warranted only for employment in accordance with

the intended use as defined in Section 1 - General -

of these operating instructions. Never allow the

threshold values specified in the data sheet to be

exceeded.

Page 6

Transport and

Intermediate Storage

Ausgabe

issue C / 23.01.2006 Dokument

document OM.TRA.01e Blatt

sheet 1(1)

3.0

Transport and Intermediate Storage

3.1

Safety Precautions

Employ appropriate transport means, hoists and

tools when transporting and storing the machine,

always observing the safety instructions.

3.2

Transport

Depending on its weight, the seepex machine must

be transported manually or with appropriate trans-

port means. Comply with the transport instructions

on the packing.

3.3

Unpacking

The design of the packing is such that the equip-ment

can be removed manually or, if demanded by the

weight, by means of appropriate hoists.

Any screw fittings between the machine and the

packing must be undone. Comply with the attached

information notices and symbols.

3.4

Intermediate Storage/Preservation

Unless otherwise indicated in the data sheet, seepex

machines are provided with preservation only for the

duration of transport. If a long period of intermediate

storage is foreseen before the machine is

commissioned, it is necessary to pro-vide

supplementary preservation. If necessary,

the appropriate measures should be drawn up in

consultation with seepex.

Intermediate storage in extreme climatic conditions is

permissible only for machine whose design is

appropriate to the circumstances. If necessary,

seepex must be consulted.

CAUTION

Pumps of the range MAP

If the period from supply and subsequent storage until

the commissioning is more than 4 weeks, the hoses

should be dismantled, refer to Point 7.

3.5

Protection against Environmental Influences

To afford protection against environmental

influences, the intermediate storage location

must be dry, enclosed and free from frost.

Page 7

Description

Ausgabe

issue B / 02.01.2006 Dokument

document OM.DES.01e Blatt

sheet 1(1)

4.

Description of the seepex Progressive Cavity

Pump and Accessories

4.1

General Description, Design and Mode of Operation

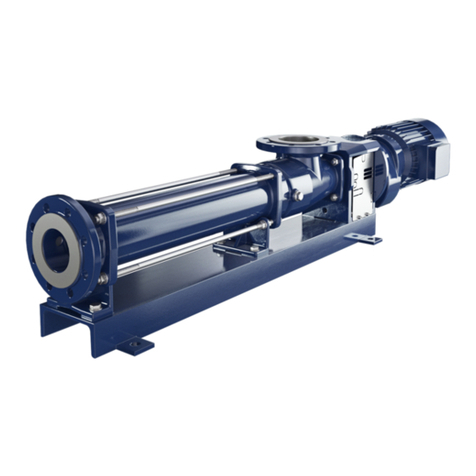

Like all progressive cavity pumps, seepex pumps

belong to the rotating positive-displacement pump

family. The characteristic attribute of these pumps is

the special formation and arrangement of the two

conveying elements, namely the rotor and the stator.

The difference in the number of threads possessed

respectively by the rotor and stator produces a

chamber that opens and closes alternately in line

with the constant turning motion of the rotor,

effecting the continuous transportation of the

conveying product from the suction side to the

pressure side.

The geometrical formation of the two conveying

elements combined with the constant contact that

exists between them result in sealing lines that effect

an airtight seal between the suction and pressure

side in every position of the eccentric screw, even

when the pump is stationary. The pump owes its

high suction capacity to this

sealing between the suction and pressure sides.

4.2

Mechanical Design

Please consult the sectional drawing, Point 9,

for the mechanical design of the pump. The data

sheet, Point 9, gives information on the design of the

pump housing, stator, rotor and rotating components.

Refer to document OM. SEA. __, for information on

the design of the shaft seal.

The data sheet, specifies details of the design of the

drive engine. Further details are

given in the appended manufacturer's documents,

Point 10.

4.3

Accessories

Consult the data sheet for information.

4.4

Dimensions, Weight

Consult the appended dimensional drawing,

4.5

Design Variants

Refer to the data sheet, Point 9, for the design of the

seepex progressive cavity pump. Other design

variants are possible, whereby seepex must first

check whether a particular pump is suitable for the

intended purpose.

4.6

Operating Site Specifications

Operating site specifications are listed in the data

sheet, Point 9. Details of the space required for

installation, operation and maintenance are given in

Point 5.2.1.

Page 8

Assembly and

Installation

Ausgabe

issue B / 02.01.2006 Dokument

document OM.INS.01e Blatt

sheet 1(2)

5.0

Assembly / Installation

5.1

Mounting Tools / Hoists

No special tools are required for the assembly and

installation of the pump.

The customer must check the dimensions and weight

of the seepex progressive cavity pump to ascertain

whether the available hoisting apparatus

is sufficient for the assembly and fitting of the pump.

5.2

Initial Assembly

5.2.1

Inspection Prior to Commencement of Assembly

5.2.1.1

Location

The place of installation for the pump must con-form

with the site stated in the data sheet in Point 9. Any

change of location must be checked and approved by

seepex.

5.2.1.2

Space Requirements

Customers are responsible for determining the

space requirements; the following factors must be

taken into consideration:

dimensions and weight of the machine

required transport and hoisting equipment

possible piping layout with allowance for the space

allowing disassembly of the rotor as defined in

5.2.1.3

freedom of movement to:

operate the drive /

speed regulation

read speed and pressure indicators

adjust a stator retensioning device, if fitted

operate a buffer fluid supply unit, if fitted

space required for lubrication / renewal of

lubricants

disassembly of mechanical protective devices, e.g.

V-belt or coupling protection

space required for handling the mounting tools, e.g.

sufficient wall clearance

5.2.1.3

Space Allowing Disassembly of Stator P

Aspecific space must be allowed for exchanging the

stator. The required dimension "P" is indicated in the

index of these operating instructions or in the

appended dimensional drawing, Point 9.

CAUTION

Ensure also that the pipe work can be dismounted at

this location too.

5.2.2

Installation of the Fully Assembled Pump

•Installation in conformity with data sheet

Installation of the pump is permissible only in

accordance with the data sheet specifications and

the associated basic drawing, see Point 9. Any

change in the position must be checked and

approved by seepex.

•Tension-free mounting of pump

This rule applies to pumps with and without drives,

to versions with and without baseplate, for

mounting on the foundation or other bearing

elements. The entire area of all bearing surfaces of

the machine must rest on the ground. Any

unevenness must be corrected by appropriate

supports.

Correct seating of drives

All drives have been aligned ready for operation

and mounted by seepex. However, displace-ments

may occur during transport or installation. For this

reason, check that the alignment and fastening of

the drive and coupling are correct.

•Protective devices

On completion of the assembly

and installation work, immediately

mount all safety and protective

devices in their proper locations

and set them in operation.

Page 9

Assembly and

Installation

Ausgabe

issue B / 02.01.2006 Dokument

document OM.INS.01e Blatt

sheet 2(2)

5.2.3

Protective and Controlling Equipment

Information on equipment of this nature, where fitted,

is provided in the data sheet, Point 9. Consult the

attached manufacturer's specifications, Point 10, for

instructions on assembly and installation.

5.2.4

Electric Connection of Electric

Motor and Frequency Converter

The electric connections must be

established in accordance with the

manufacturer's specifications,

Point 10, as well as the safety speci-

fications applying at the installation

site. The mains voltage and

frequency must match the ratings

indicated on the type and rating

plates.

•Switch on electric motor „direct-on-line“

CAUTION

An increased starting torque is necessary due

to the clamping between the rotor and stator

conveying elements. This means the electric motors

that drive the progressive cavity pumps must always

be switched on directly. As a rule, star-delta startup

is not possible unless special arrangements have

been made with seepex.

Three-phase cage motor

Delta connection Star connection

Terminal

board

low . . . high . . .

... voltage indicated on rating plate

•Speed regulation via frequency inverter

When progressive cavity pumps with frequency-

controlled drives are started up problems may occur

due to unsuitable or wrongly set frequency inverters.

For this reason we recommend the purchase of the

complete drive, including frequency inverter, from

seepex, so that the frequency inverter can be tuned

on the seepex test field along with a trial run.

Ensure that customer-supplied frequency inverters

comply with the starting torque and running power

specified in the appended data sheet, Point 9.

CAUTION

Consult the appended document TI.FRU.01, see

Point 9, for further information on the electric

connection and the setting of frequency inverter

and variable-speed motor.

5.2.5

Piping

5.2.5.1

Suction and Pressure Flanges

The position, nominal width and standard of the

suction and pressure flange of the progressive cavity

pump are specified in the dimension drawing, Point 9,

and data sheet, Point 9. Always observe the rotational

direction and flow direction defined in Point 6.2.5.

5.2.5.2

Piping Dimensioning

CAUTION

The pipe diameters on the suction and pressure sides

must be dimensioned in accordance with the

customer's pressure-loss calculation in such a way

that the pressures specified in the data sheet, Point 9,

are not exceeded. The nominal width of the suction

pipe should at least match that of the pump suction

flange.

5.2.5.3

Residue-free Piping

CAUTION

Prior to starting up the pump, ensure that all pipelines

are free from foreign bodies. Installation residues

(such as weld spatter, screws, steel chips etc.) will

lead to damage of the seepex pump for which

guarantee claims will not be accepted.

5.2.5.4

Tension-free Mounting

CAUTION

Pipelines and other components requiring to be

connected with the pump must be mounted without

stresses.

5.2.5.5

Fluid Connections for Optional Extras

Consult the data sheets, Point 9, for information

regarding the optional extras, if any, that are fitted.

The technical description is given under Point 9.

Page 10

Commissioning/

De-commissioning

Ausgabe

issue C / 02.01.2006 Dokument

document OM.COM.01e Blatt

sheet 1(3)

6.0

Commissioning/De-commissioning

6.1

Engineering Data

Details regarding all technical specifications and

operating conditions are given in these operating

instructions together with the data sheet, Point 9.

To guarantee the correct assignment of documen-

tation to pump, the commission number on the

cover sheet

and data sheet of these operating instructions

must match the commission number stated on

the nameplate of the pump.

6.1.1

See Point 7.2.2 for Lubricant Chart

6.2

Preparation for Operation

6.2.1

Bearing

6.2.1.1

See Point 7.2.1.4 for pump bearing.

6.2.1.2

See manufacturer's documents, Point 10, for drive

bearings.

6.2.2

Shaft Sealing

See document OM.SEA.__,.

6.2.3

Filling Up of Suction Side to Avoid Dry Running

at Startup

CAUTION

Before switching on the pump, fill the suction-sided

pump casing with fluid so that the first rotations will

lubricate the conveying elements immediately. A

small quantity of fluid is sufficient for lubrication; the

subsequent operation of the pump is self-priming,

even if an air column up to the liquid level remains.

6.2.4

Electric/Hydraulic Connections

The connections are listed in the

appended manufacturer's documents,

Point 10.

The risk of exposure to electrical

hazards must be ruled out. Always

observe the safety regulations valid

at the site of installation.

6.2.5

Checking Direction of Rotation

The rotational direction of the pump

determines the flow direction of the

conveying medium.

Flow direction

counter-clockwise

Flow direction

clockwise

Prior to commissioning the rotational direction of the

pump must be checked for compliance with the data

sheet specification and the rotational direction arrow

on the type plate of the pump.

6.3

Control and Monitoring Equipment

Where applicable, please refer to the associated

documents, Point 10, for information on

commissioning.

6.3.1

Performance Check

Any optional extras must be subjected to a

performance check in conformity with the

specifications by seepex or other manufacturers, see

manufacturer's documents.

6.3.2

Setting

Unless already performed in the factory, setting must

be carried out in accordance with the appended

manufacturer's specifications, Point 10. Pay attention

to the operating specifications in the data sheet.

Page 11

Commissioning/

De-commissioning

Ausgabe

issue C / 02.01.2006 Dokument

document OM.COM.01e Blatt

sheet 2(3)

6.4

Equipment for Protection of Persons

Machines must be fitted with mechanical

protective devices complying with DIN EN

809.

Moving or working parts must be

protected against accidental contact.

However, safety considerations demand

it be possible at all times

to check without hindrance whether the

shaft seal is fully functional.

Aprotective guard is necessary in this

area only if components are mounted on

the rotating, smooth shaft.

If pumps are operated with an open

suction flange/feed hopper, a suitable

protective guard complying with DIN EN

294 must be mounted.

Country-specific protective regu-lations

must be observed at the site of

installation.

Prior to activati

on of the pump, check the

proper function of all protective

equipment.

6.5

Commissioning

6.5.1

Initial Startup/Re-starting

CAUTION

Every seepex progressive cavity pump is designed

for the specific operating conditions documented in

the data sheet. Commissioning is permissible only if

the operating conditions conform with those

indicated in the data sheet. Although the potential

usages of the seepex pump are not confined to the

specified operating conditions, any change in the

original conditions must be checked and approved

by seepex.

The right to make claims under the warranty

agreement will be annulled if operating conditions

are changed without prior approval by seepex.

6.5.2

Avoid Dry Running of Pump

CAUTION

The dry running of a pump increases the friction

between rotor and stator, quickly causing an

unacceptably high temperature to develop on the inner

surface of the stator. This overheating leads

to burning of the stator material and the total

failure of the pump.

For this reason it is necessary to ensure that the

suction-sided flow never dries up completely.

If a continuous flow cannot be guaranteed for the

plant, it is essential to fit the seepex dry running

protection device TSE, available as an optional

accessory.

6.5.3

Check Pressure at Suction and Pressure Flanges

6.5.3.1

Safeguard Pump Against Excessive

Pressure at the Suction Flange

The seepex pump is designed to

operate with the pressure at the suction

flange (suction head or inlet pressure)

specified in the data sheet. Deviating

pressure conditions may lead to the

failure and/or destruction of the shaft

seal or entire pump.

For this reason the suction pressure

specified in the data sheet must be

guaranteed. Appropriate monitoring

devices are oil-filled contact mano-

meters that deactivate the pump.

6.5.3.2

Safeguard Pump Against Excessive Pressure at

the Pressure Flange

The seepex

pump operates according to

the positive displacement principle.

Operation of the pump against an

excessive pressure caused by closed

valves, by high pressure losses in the

piping or by product sedimentation will

lead to the destruction of the pump,

drive, pipe work and/or downstream

equipment. Every progressive cavity

pump must therefore be protected

against overpressure. Safety valv

es with

bypass pipes or oil-filled contact

manometers that disactivate the pump

are appropriate protective devices.

6.5.4

Drive Engine

Consult the attached manufacturer's

operating instructions, Point 10, for

information on commissioning the drive

engine.

Page 12

Commissioning/

De-commissioning

Ausgabe

issue C / 02.01.2006 Dokument

document OM.COM.01e Blatt

sheet 3(3)

6.5.5

Establish Clear Passage Through Pipelines

CAUTION

To prevent damage to the pump the unhindered flow

of liquid must be guaranteed between the points of

entry to and exit from the pipeline. For this reason,

open all relevant valves etc. prior to activation of the

pump.

6.6

De-commissioning

6.6.1

De-activation

The electric connections must be

switched off and protected against

accidental re-activation. Observe the

safety regulations applying to the plants.

6.6.2

Stationary Pump

The pump and all optional equipment must be

provided with the following protection modes while at

astandstill:

-Frost protection

-Protection against solid particle deposits

-Protection against sedimentation of the medium

-Corrosion protection for parts in contact with

the medium

We recommend that the pipeline and pump be

emptied for the duration of the plant standstill.

Following evacuation, the pump should be preserved.

6.6.3

Evacuation of the Pump

The pipeline must be evacuated on the

suction and pressure side or shut-off

directly behind the pump connections.

Drain any residual liquid in the pump

casing by opening/ removing the

screwed sealing plugs (705) and (502),

sealing rings (706) and (503). Casings

without screwed plug must be

evacuated by the connection branch

(SAG and DRS). Refer to the data

sheet and the sectional drawing of the

associated operating instruction, Point

9, for information on the pump design.

Conveying medium residues always

remain in the rotor/ stator chambers

and may run out during transport or

disassembly of the pump. If conveying

aggressive or hazardous media,

therefore, wear appropriate protective

gear during all installation work.

6.6.4

Disassembling the Pump

Dismantle the pipe work by removing the flange bolts

(SCH) and flange seals (DFL) or the threaded

connections (G).

Disassemble the pump together with the baseplate

(GPU) or, as applicable, without the baseplate (GPU)

following removal of the bolts (SCH) at the pump

feet.

Block-design pumps with direct flange-

mounted drive engine are liable to

become unstable during disassembly.

Stability can be restored by propping up

the drive engine.

6.6.5

Preservation/Storage

The pump must be preserved prior to storage.

Appropriate preservation measures must be agreed

with seepex.Always state the pump commission

number when making inquiries.

Page 13

TAB 1 – DEVICE DATA SHEETS

Engineering: JC/GS/ML Page 1 of 4

Inc.

seepex

Inc.

511 Speedway Drive

Enon, OH 45323

Phone (937) 864-7150

Fax (937) 864-7157

www.seepex.com

Data Sheet 835294-835296 Page 1

seepex

date 04/24/2013 commission no. 835294-835296

customer W.M. Lyles

seepex job no. 2115517 offer/item: 5383/0167 item 4 Amend. 1

project PO# T1113-20

3 of seepex progressive cavity pump

type BN 5-12 / A6-A7-A7-H0-IE-X

X=08E4, 20A7

conveying product U/495/CH

denomination active dilute polymer

rate of solids <0.5% viscosity ass. <500 cPs

size of solids no advice pH-value ass. 5-9

specific gravity ass. 1.0 temperature 32 to 113F

composition no advice

remarks thickening polymer feed pumps

performance data nom. min max

conveying capacity 12 24 GPM

pump speed 225 417 rpm

press in press. branch 104 104 psi

press in suct. branch Assumed Flooded

differential pressure 104 psi operating torque 36 lb. ft.

required drive power 3.59 Hp starting torque 60 lb. ft.

remarks Data according to Performance Curve

technical pump data

range BN kind of install. horizontal

size 5 direction of rot. counterclockwise

pressure stage 12 pos. of branch 2 @ pos. 3

1@pos.2

component material design/option

lantern grey cast iron GG25 standard

suction casing 1.4408 /AISI 316 SS standard

½” NPT gauge ports

suction connection DN 3” ANSI B16.5 150 lb. FF

pressure branch 1.4571 / AISI 316 SS ½” NPT gauge ports

pressure connection DN 3” ANSI B16.5 150 lb. FF

joint standard standard

grease 30322 high temp

joint seal FPM standard

coupling rod 1.4571 / AISI 316Ti standard

rotor 1.4571 / AISI 316Ti standard

stator FPM standard

mechanical seal 1.4408 / AISI 316 SS Double Acting Mechanical Seal

seal Chesterton 280 Double Seal 45MM

316/SC/SC/CBN/SC/Alfas

plug-in shaft 1.4571 / AISI 316Ti drilled 30x55

special designs

Page 25

Engineering: JC/GS/JP Page 2 of 4

Data Sheet 835294-835296 Page 2

general operating data

kind of operation continuous operation

site of installation indoors dry atmosphere

remarks

drive

type Gearbox

make SEW ratio i= 4.34

model RF47AM213RS nom./ min- max

mounting position M1 (B5) output speed 403 / 225 – 417 rpm

flange dia 160 mm motor speed 1750 / 977 – 1813 rpm

output shaft 716/0500-006B4 frequency 60 / 33 – 62 Hz

special w/ 4 point (QJ206) output bearing on the output shaft, w/ backstop

electric motor

manufacturer WEG

model 00718ET3E213TC-W22voltage 3x230/460 VAC

nominal power 7.5 Hp rated frequency 60 Hz.

mounting position F1 (C-face/footed) protection IP55

starting DirectatVFD thermal class F

special 213TC, custom options per quote # 3282014-rev1

baseplate

standard BN-ST-LA-EM-GH-TR-RC material carbon steel

drawing no. 801-200/0050-C-141B2 surface painted

special/accessories extended for motor support w/ round corners, drain pan, 1/2" ANSI B16.5

150lbs drain connection, grout holes, & 4 lifting lugs, mounting of base to

be within the confines of the base.

painting

execution standard

color RAL 5013 (blue)

remarks surface prep carbon steel only to SSPC SP6

surface prep all to SSPC SP1

primer coat - Macropoxy 646 - 3 mils dft

intermediate coat - Acrolon 218 HS - 4 mils dft

top coat - Acrolon 218 HS - 3 mils dft

total DFT = 10mils

note: stainless steel components are not to be painted

packing

packing type Crate

marking 2115517

documentation

dimensional drawing no. 140949 140950 operating manual 1 copy English

sectional drawing no. 062-004_1

shaft sealing sect. view 262-0GC/0050-0-009A2

remarks

additional accessories / special designs / remarks

pressure relief valve

manufacturer Kunkle model 171S

body material 316SS including spring flange size 1.5” NPT

pressure range 120-180 psi set point 130 psi

remarks pressure-tight hood

Page 26

Engineering: JC/GS/JP Page 3 of 4

Data Sheet 835294-835296 Page 3

pressure switch and gauge assembly (suction) quantity 1 per pump

diaphragm seal

manufacturer Onyx model K

top material 316 SS connection size 1” NPT

bottom material 316 SS fill fluid silicone instrument oil

diaphragm material Viton w/ Teflon coating special features flush port, ¼” NPT

pressure switch

manufacturer Ashcroft model B4-50-B-X06-Compound

switch type SPDT range -30in.Hg/15psi

enclosure NEMA4x set pressure 12psi

pressure gauge

manufacturer Ashcroft model Duragauge

type 1279 range -30in.Hg/15psi (compound)

diameter 4.5” connection ½”NPT

fill glycerin tube / socket bronze / brass

special: assembled per customers drawing #D-42924 Rev.C, with isolation and flushing port ball valves. 1” NPT

connection.

pressure switch and gauge assembly (discharge) quantity 1 per pump

diaphragm seal

manufacturer Onyx model K

top material 316 SS connection size 1” NPT

bottom material 316 SS fill fluid silicone instrument oil

diaphragm material Viton w/ Teflon coating special features flush port, ¼” NPT

pressure switch

manufacturer Ashcroft model B4-50-B-X06-200psi

switch type SPDT range 0-200psi

enclosure NEMA4x set pressure 150psi

pressure gauge

manufacturer Ashcroft model Duragauge

type 1279 range 0-200psi

diameter 4.5” connection ½”NPT

fill glycerin tube / socket bronze / brass

special: assembled per customers drawing #D-42924 Rev.C, with isolation and flushing port ball valves. 1” NPT

connection.

spare parts

_1_ rotor

_1_ stator

_1_ plug-in shaft

Page 27

Engineering: JC/GS/JP Page 4 of 4

Data Sheet 835294-835296 Page 4

Seismic calculations provided under separate informational submittal.

anchor bolts Hilti HAS-R 316 ¾”x9-5/8” anchor rod (2045010), quantity 6 (each pump).

Seal flush parts to be supplied loose: (installed in the field by contractor)

Qty. Qty. per pump Part no. Description Manufacturer

9 3 1839-005 True union 2000 industrial ball

valve, PVC, Viton elastomers, ½”

socket

Spears

3 1 8210G007 120/60 Solenoid valve, 2W, NC, brass

body, 120/60 AC, ½”NPT, 300psi ASCO

3 1 BVO-6116 Flowmeter with N/O switch, brass

body, NBR elastomers, glass

tube, 1-5 GPM range, ½”NPT

fittings

Kobold

1 1 for all 3 pumps D83SS-40-04-LA130 gauge, pressure, 0-200 PSI,

glycerin filled, SS casing, 4" dia

face, 1/2"MNPT lower mount

Trerice

3 1 5304K9 Hose with brass 3/8" Male x

Female, 3/8" ID, 300 PSI, 12” long McMaster Carr

Provide 316ss pump tags mounted to pump; tags to read commission no., tag no., type, date of

manuf., capacity, job no., TDH, speed.

TAG#'s:

“15LPMP810” - pos. 3

“15LPMP820” - pos. 3

“15LPMP830” - pos. 2

Concentric reducer, Proco style RC expansion joint, single filled arch, flanges drilled to ANSI 125/150#,

Viton elastomer, stainless steel hardware (per quote #239128):

Location Qty. Part no. Description Manufacturer

Suction 3 EJRCFA151/VV 4" ID X 3" ID X 6" F/F - RCFA-151/VV VITON

TUBE AND COV ER Proco

Suction 3 RNG4810300 SET, #481 150# RETAINING RINGS Proco

Testing:

-Hydrostatic per FO.QA.25e

-Performance test per FO.QA.42e with 5 recorded test points from shutoff head to 125% of maximum

design capacity.

-Certified pump curves showing head vs. flow, bhp, efficiency, and NPSH curves. NPSH required shall

be at least 5 feet of water absolute greater than NPSH available.

-Certification that the pump hp demand will not exceed the rated motor hp beyond the 1.0 service

rating at any point on the curve.

-Written acceptance of test results is required before shipment.

Page 28

TAB 2 – APPROVED SUBMITTAL

Motors | Automation | Energy | Transmission & Distribution | Coatings

USAW22SEVDUTY

Severe Duty is Standard

with WEG W22 motors.

You do not need a special motor for severe duty. Severe Duty is standard with WEG W22 motors.

1-800-ASK-4WEG

www.weg.net

2 |

You do not need a special motor for severe duty.

Severe Duty is standard with WEG.

Features that make a difference:

gReduced temperature on windings

and bearings

gNoise level reduction

gTerminal box position outlet on top

Pad for vibration sensor

gDisplaced 900from each other

Enhanced Lifting Provisions

gEasier handling - horizontal & vertical

gHigher mechanical strength and

handling safety

Solid feet

gMore impact resistance

gIdeal for high vibration level applications

Fan Cover

gAerodynamic design

gNoise level reduction

gBetter air flow distribution over frame

gIncreased mechanical strength

Fan

gReinforced fan hub structure

gNoise level reduction

gIncreased air flow

gFan with higher stiffness

gBetter connection quality

gEasier cable handling

during installation

gMore space available for

accessory installation

gEasier Maintenance

gMounting F1/F2/F3

gRotation on 90°stages

gIncreased dust and

moisture protection

gIncreased protection

to high-pressure

cleaning

External

gFinned surface for

improved bearing

heat dissipation

Internal

gChange of grease

path for positive

lubrication

gBearing lubrication

quality improvement

gReduced bearing

temperature

New Cooling System

Frame

DE (Drive Endshield)

gNew fin design

gBearing moved outwards for better load support

gImproved bearing heat dissipation for reduced bearing

temperature

gReinforced endshield structure

NDE (Non-Drive Endshield)

gNew design with smooth exterior surface

gImproved air flow

gNoise level reduction

gImproved structural rigidity for low vibration

Endshields Subsystem

Terminal Box

Bearing Caps

Seal Subsystem

g All NEMA Premium ratings have a 1.25 service factor (up to 100 HP) resulting in cooler operation and extended life of the motor

g All Cast Iron Construction, including Terminal Box and Fan Cover (*)

g Solid feet for reduced vibration levels and impact absortion

g Optimized ventilation system for cooler operation and extended life

g High Grade FC200 cast iron provides superior mechanical strength and heat dissipation

g All WEG W22 motors are Totally Enclosed Fan Cooled with a true IP55 rating against dust and moisture. (IPW56, IPW65 and

IPW66 available as optional)

g Exclusive W-Seal 364T and larger provides superior bearing protection

g Taconite Labyrinth seal 586 Frame and larger

g Exclusive WEG painting system exceed 200hrs ASTM 117 corrosion test (Exceeds IEEE841 standard)

g Balanced to 0.08 inches per second vibration limits (Meets IEEE841 standard)

g Four Bolt Conduit Cover with glued Neoprene Gasket

g Impregnation Resin and magnet wire are insulation class H

g Stainless Steel Nameplate - Laser edged with high contrast background

g Corrosion Proof Drains

g Inverter Duty per NEMA MG1, Part 31

g Certified Class I Div 2, Groups A, B, C & D; Class II, Div 2, Groups F & G

*cast iron fan cover available as an option on 143-215T frames

Table of contents

Other Seepex Water Pump manuals

Seepex

Seepex BN 52-6LS Product guide

Seepex

Seepex BN 2-12S Product guide

Seepex

Seepex BCSB Series Product guide

Seepex

Seepex BW 10 Manual

Seepex

Seepex BTVE 10-12 Product guide

Seepex

Seepex BTQ Series Product guide

Seepex

Seepex BN 2-12S Product guide

Seepex

Seepex BCSO 025-24 to 130-6L Product guide

Seepex

Seepex Macerator 110 Series Product guide

Popular Water Pump manuals by other brands

Kodiak

Kodiak PWP3HX Technical manual

Pentair Pool Products

Pentair Pool Products Hydromatic SK60 Installation and service manual

Pentair Hydromatic

Pentair Hydromatic HTP50 owner's manual

Seko

Seko Tekna Evo TPG series installation manual

Wilo

Wilo Stratos ECO Series Installation and operating instructions

IWAKI WALCHEM

IWAKI WALCHEM EHC Series instruction manual