-4-

TableofContents

1.O ver v i e w ............................................................................................................................... 5

2.Model Explanation..................................................................................................................... 5

3.Shared Specifications................................................................................................................ 6

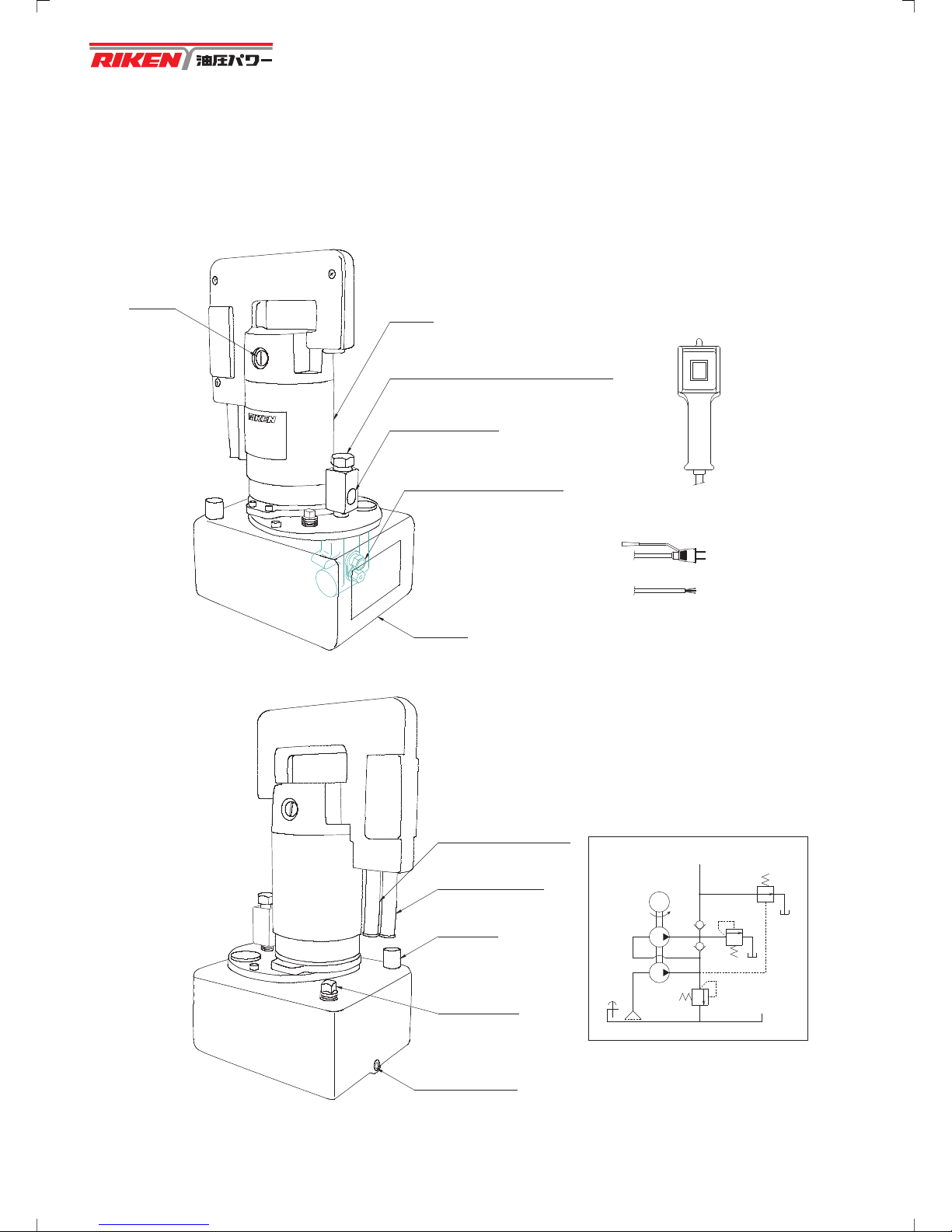

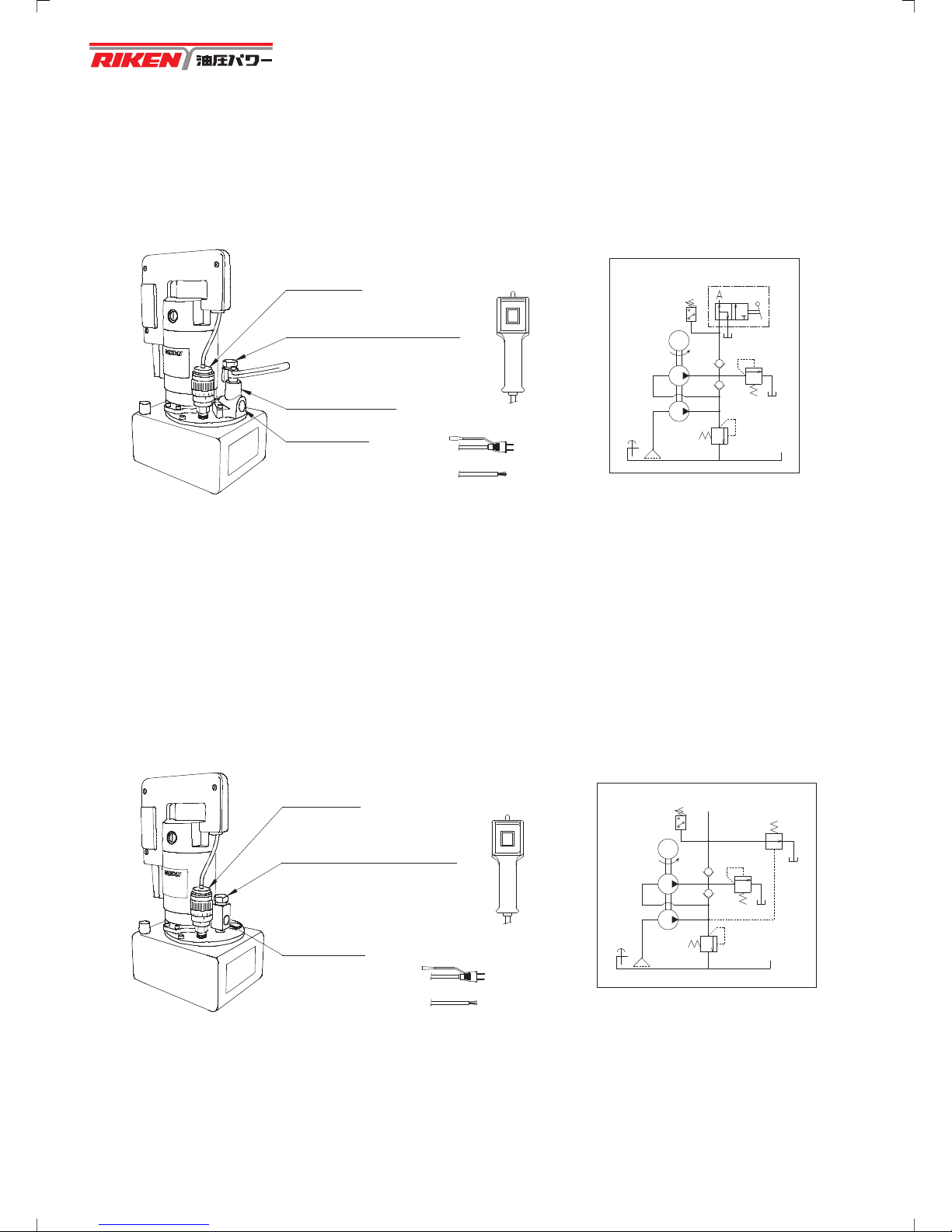

4.Explanation of Components ...................................................................................................... 7

5.Safety Cautions for Usage ...................................................................................................... 16

6.Fixed Installation Method ........................................................................................................ 18

7.Preparation Before Use........................................................................................................... 20

8.Preventive Maintenance.......................................................................................................... 21

(1) Inspection of Items Before Operation............................................................................... 21

(2) Inspection of Items During Operation............................................................................... 21

(3) Inspection Items After Operation ...................................................................................... 21

(4) Changing Hydraulic Oil .................................................................................................... 21

9.Explanation of Pressure Switch............................................................................................... 22

10.Operating Method.................................................................................................................... 23

(1) SMP-30NV、SMP-40NV ............................................................................ 23

(2) SMP-30B、SMP-40B ................................................................................... 23

(3) SMP-30AR、SMP-40AR ............................................................................ 24

(4) SMP-30SK、SMP-40SK ............................................................................ 25

(5) SMP-30BR、SMP-40BR ............................................................................ 26

(6) SMP-30NE、SMP-40NE ............................................................................ 27

(7) SMP-30RK、SMP-40RK ............................................................................ 28

(8) SMP-30C、SMP-40C ................................................................................... 29

(9) SMP-30DCB、SMP-40DCB ..................................................................... 30

(10) SMP-30DVH、SMP-40DVH ..................................................................... 31

(11) SMP-30CR、SMP-40CR ............................................................................ 32

(12) SMP-30SW、SMP-40SW ............................................................................ 33

(13) SMP-30SP、SMP-40SP ............................................................................ 34

(14) SMP-30SL、SMP-40SL ............................................................................ 35

11.Adjusting the High Pressure Safety Valve ............................................................................... 36

12.COMMON FAULTS AND SOLUTIONS ................................................................................... 37

13.Internal Structure Diagram ...................................................................................................... 38

14.Electrical Wiring, Terminal Connection List ............................................................................. 44

15.Handling the High Pressure Hose........................................................................................... 45