Seepex BW 10 Manual

sc

Operating and Maintenance

Instructions

Progressive Cavity Pump

range size

BW 10

commission-No.

822812

Job # 2109552

This operating and maintenance instruction

includes important safety information and

instructions for installation, commissioning,

operation and maintenance of the seepex machinery.

It is essential therefore, that the responsible

specialist refers to it before starting any

work on the machinery as well as prior to

commissioning. Furthermore, this instruction

must always be available on site.

General

Ausgabe

issue A / 10.12.1994 Dokument

document OM.GEN.01e Blatt

sheet 1(2)

1.0

General

1.1

Application

These operating instructions contain basic infor-

mation on the installation, commissioning and

maintenance of seepex machines. Compliance with

the work steps described in the individual sections is

essential.

1.2

Details of the seepex machines

1.2.1

Operating Instructions

The Commission Number (comm. no) assigns the

operating instructions to a particular seepex

machine. The operating instructions are produced in

relation to a specific job/commission and are valid

only for the machine whose comm. no. is identical

with that indicated on the cover sheet and

possessing the associated data sheet, Point 9.

1.2.2

Manufacturer

The machines were manufactured by seepex.

1.2.3

Range, Size, Version

of the machines are stated in the appended data

sheet, Point 9.

1.2.4

Machine Comm. No. and Year of Construction

are stated on the type plate at the machine.

1.2.5

Release Date of the Operating Instructions

is stated on the cover sheet of the operating

instructions.

1.2.6

Modifications, Notes of Modification

If modifications to the machines are

carried out in agreement with seepex, a new set

of operating instructions will be provided, or the

existing operating instructions will be supplemented by

an additional sheet together with a new cover sheet.

The date of modification and modification index will be

noted on the new cover sheet.

1.2.7

EEC Machine Directive

1.2.7.1

Manufacturer's Declaration

seepex Manufacturer's Declaration as required by the

EEC Machine Directive 89/392/EEC, Appendix II B:

The seepex machines delivered in accordance with

our design are intended to be fitted in one machine or

assembled together with other machines to form one

machine/plant. The commissioning of the machine is

forbidden until such a time as has been established

that the entire machine/plant satisfies the

requirements of the EEC Directive for Machines as

amended 91/368/EEC and 93/44/EEC.

Particular attention must be paid to the safety

requirements specified in EN809 (s and Equipment

for Fluids) as well as the information in these

operating instructions.

1.2.7.2

Declaration of Conformity

seepex machines possessing no safety accessories

do not fulfill the requirements of the EEC Machine

Directive 89/392/EEC as amended 91/368/EEC and

93/44/EEC.

For this reason, no Declaration of Conformity as

required by the EEC Machine Directive 89/392/EEC,

Appendix IIA can be issued before appropriate safety

devices have been installed/mounted on the machine

and/or plant with due regard to the information given

in these operating instructions.

The following harmonized standards are particularly

applicable:

EN 809, EN292T1, EN292T2

Applicable national standards and specifications must

be taken into consideration.

Following assessment of the conformity of the

machine/plant with the EEC Machine Directive,

customers may on their own initiative place on the

full machine/plant the EEC symbol 'CE' as defined in

Identification Directive 93/68/EEC.

CAUTION

This documentation must be kept available for at

least 10 years.

4

General

Ausgabe

issue A / 10.12.1994 Dokument

document OM.GEN.01e Blatt

sheet 2(2)

1.2.8

Copyright and Industrial Property Rights

These operating instructions are copyrighted. The

reproduction, in particular by photocopying, of these

instructions is not permitted (§§ 54, 54 UrhG) and

constitutes a criminal offence (§ 106 UrhG).

Proceedings will be instituted if the copyright is

violated.

1.2.9

Specifications Required for Inquiries and Orders

The following information must be included when

inquiring about replacement parts or placing orders:

-comm. no.

- / machine type

This information is given on the type plate mounted

the machine.

1.2.10

Technical Data Sheet

see Point 9.

1.2.11

Performance Data, Load Index, Power

Consumption

are indicated in the associated data sheet, Point 9.

1.2.12

Sound Pressure Level

The sound pressure level and/or noise characteris-tics

of the seepex machines are ascertained in

accordance with DIN 45635. The measuring

guidelines are largely identical with the international

standards ISO 3740-1980 and ISO 3744-1981.

1.2.13

Operating Range

Employment of the machine is not permissible for

purposes other than those stated in the data sheet,

see Point 9. seepex cannot accept liability for damage

arising through failure to comply with this operating

range.

1.3

Supplementary Information

1.3.1

Accessories, Optional Extras

Please refer to the data sheet, Point 9.

1.3.2

Company Address, Service Addresses

see Point 11

5

Safety

Ausgabe

issue B / 21.04.1999 Dokument

document OM.SAF.01e Blatt

sheet 1(2)

2.0

Safety

These operating instructions contain basic require-

ments to be observed during the installation, opera-

tion and maintenance of the machine. Therefore, the

instructions must be read by the mechanical fitter and

by the technical personnel/operator responsible for

the machine prior to assembly and commissioning,

and kept available at the operating site of the

machine/plant at all times.

Compliance is required not only with the general

safety instructions given in this section but also with

the detailed instructions, e.g. for private usage, given

under the other main headings in these operating

instructions.

2.1

Labeling of Advice in the Operating Instructions

In these operating instructions safety advice whose

non-observance could lead to danger for life or limb is

labeled with the following general hazard symbol:

safety symbol acc. to ISO 3864 - B.3.1

Warnings regarding electric power are labeled with:

safety symbol acc. to ISO 3864 - B.3.6

Safety instructions whose non-observance could

jeopardize the machine and its functions are labeled

by the word

CAUTION

Always comply with instructions mounted directly on

the machine, e.g.

- rotational direction arrow

- fluid connection indicators

and ensure that the information remains legible.

2.2

Personnel Qualifications and Training

Personnel charged with operation, maintenance,

inspection and assembly must be in possession

of the appropriate qualifications for the tasks.

The company operating the machine must define

exact areas of responsibility, accountabilities and

personnel supervision schemes. Personnel lacking

the required skills and knowledge must receive

training and instruction. If necessary, the opera-ting

company may commission the manufacturer/

supplier to conduct these training courses. Further-

more, the operating company must ensure that the

personnel fully understand the contents of the

operating instructions.

2.3

Dangers Resulting from Failure to Observe

Safety Instructions

Failure to comply with the safety instructions may

lead to hazards to life and limb as well as dangers

for the environment and the machine. Non-obser-

vance of safety instructions can invalidate the right of

claim to damages.

The following are just some examples of possible

dangers resulting from failure to comply with the

safety instructions:

- Failure of important machine/plant functions

-Failure of prescribed methods of service and

maintenance

- Danger to life and limb due to electrical,

mechanical and chemical influences

- Danger to the environment due to the leakage

of hazardous substances

2.4

Safety-conscious Working

Always comply with the safety instructions listed in

this document, the existing national accident

prevention regulations and any company-internal

work, operating and safety rules.

6

Safety

Ausgabe

issue B / 21.04.1999 Dokument

document OM.SAF.01e Blatt

sheet 2(2)

2.5

Safety Instructions for the Operating

Company/Machine Operator

- Any potentially hazardous hot or cold machine

parts must be provided with protection against

accidental contact at the customer´s premises.

-Protective guards for moving parts (e.g. coupling)

must never be removed while the machine is in

operation.

- Leakages (e.g. in the shaft seal) of hazardous

conveying liquids (e.g. explosive, toxic, hot) must

be drained in such a way that no danger arises for

persons or for the environment. Always observe

the relevant statutory requirements.

- The risk of exposure to electrical power must be

eliminated (for details, see the VDE regulations, for

example, or those of the local power supply

company).

2.6

Safety Instructions for Maintenance, Inspection

and Assembly Work

The operator must ensure that all maintenance,

inspection and assembly tasks are carried out by

authorized and qualified personnel who have studied

the operating instructions closely and become

sufficiently familiar with the machine.

As a basic rule, the machine must be brought to

astandstill before work is carried out. Always comply

with the de-commissioning procedure described in

this document.

Any machines or assemblies conveying media that

are detrimental to health must be decontaminated.

Immediately following completion of work, all safety

and protective devices must be replaced

in position and, where applicable, re-activated.

Before re-starting the machine, observe the points

listed under the heading "Initial Startup".

2.7

Unauthorized Modification and Manufacture of

Replacement Parts

Conversions or modifications of the machine are

permissible only in consultation with the manu-

facturers. Original manufacturer replacement parts

and manufacturer-approved accessories enhance

the operational safety of the machine. The usage of

unauthorized parts may lead to the nullification of the

manufacturer's liability for any resultant damages.

2.8

Impermissible Modes of Operation

The operational safety of the machines supplied is

warranted only for employment in accordance with

the intended use as defined in Section 1 - General -

of these operating instructions. Never allow the

threshold values specified in the data sheet to be

exceeded.

7

Transport and

Intermediate Storage

Ausgabe

issue B / 14.08.1998 Dokument

document OM.TRA.01e Blatt

sheet 1(1)

3.0

Transport and Intermediate Storage

3.1

Safety Precautions

Employ appropriate transport means, hoists and

tools when transporting and storing the machine,

always observing the safety instructions.

3.2

Transport

Depending on its weight, the seepex machine must

be transported manually or with appropriate trans-

port means. Comply with the transport instructions

on the packing.

3.3

Unpacking

The design of the packing is such that the equip-ment

can be removed manually or, if demanded by the

weight, by means of appropriate hoists.

Any screw fittings between the machine and the

packing must be undone. Comply with the attached

information notices and symbols.

3.4

Intermediate Storage/Preservation

Unless otherwise indicated in the data sheet, seepex

machines are provided with preservation only for the

duration of transport. If a long period of intermediate

storage is foreseen before the machine is

commissioned, it is necessary to pro-vide

supplementary preservation. If necessary,

the appropriate measures should be drawn up in

consultation with seepex.

Intermediate storage in extreme climatic conditions is

permissible only for machine whose design is

appropriate to the circumstances. If necessary,

seepex must be consulted.

CAUTION

Pumps of the range MAP

If the period from supply and subsequent storage until

the commissioning is more than 4 weeks, the hoses

should be dismantled, refer to Point 7.

3.5

Protection against Environmental Influences

To afford protection against environmental

influences, the intermediate storage location

must be dry, enclosed and free from frost.

8

Description

Ausgabe

issue A / 10.01.1995 Dokument

document OM.DES.01e Blatt

sheet 1(1)

4.

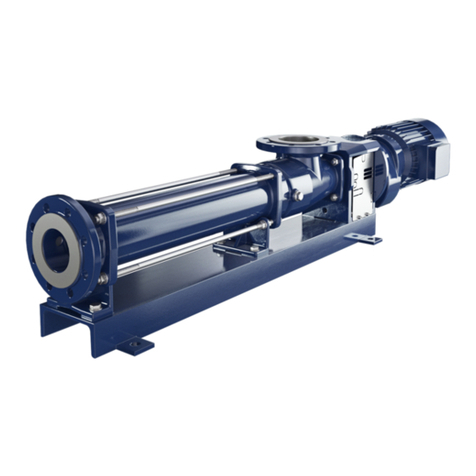

Description of the seepex Progressive Cavity

Pump and Accessories

4.1

General Description, Design and Mode of Operation

Like all progressive cavity pumps, seepex pumps

belong to the rotating positive-displacement pump

family. The characteristic attribute of these pumps is

the special formation and arrangement of the two

conveying elements, namely the rotor and the stator.

The difference in the number of threads possessed

respectively by the rotor and stator produces a

chamber that opens and closes alternately in line

with the constant turning motion of the rotor,

effecting the continuous transportation of the

conveying product from the suction side to the

pressure side.

The geometrical formation of the two conveying

elements combined with the constant contact that

exists between them result in sealing lines that effect

an airtight seal between the suction and pressure

side in every position of the eccentric screw, even

when the pump is stationary. The pump owes its

high suction capacity to this

sealing between the suction and pressure sides.

4.2

Mechanical Design

Please consult the sectional drawing, Point 9,

for the mechanical design of the pump. The data

sheet, Point 9, gives information on the design of the

pump housing, stator, rotor and rotating components.

Refer to document OM. SEA. __, for information on

the design of the shaft seal.

The data sheet, specifies details of the design of the

drive engine. Further details are

given in the appended manufacturer's documents,

Point 10.

4.3

Accessories

Consult the data sheet for information.

4.4

Dimensions, Weight

Consult the appended dimensional drawing,

4.5

Design Variants

Refer to the data sheet, Point 9, for the design of the

seepex progressive cavity pump. Other design

variants are possible, whereby seepex must first

check whether a particular pump is suitable for the

intended purpose.

4.6

Operating Site Specifications

Operating site specifications are listed in the data

sheet, Point 9. Details of the space required for

installation, operation and maintenance are given in

Point 5.2.1.

9

5.0

Assembly/Installation

BW

Ausgabe

issue A / 23.01.07 Dokument

document OM.INS.08e Blatt

sheet 1(2)

5.1 Mounting tools/lifting gear

CAUTION

Pump falling over

Slight injury or damage to property may result.

!Adhere to the lifting tool’s starting point.

!Pay attention to the dimensions, weight and centre of gravity of the pump

!Use suitable mounting tools/lifting gear.

5.2 Required space

The required space should be determined by considering the following factors:

•Dimensions and weight.

•Requisite transport and lifting equipment.

•Pipe routing – dismantling (stator construction dimensions).

5.3 Stator construction dimensions (P)

•Refer to the dimensional drawing.

5.4 Erection of the complete mounted pump

!Erect in accordance with technical data (Chapter 3.0).

!Heed dimensional drawing.

Tension-free mounting of the pump

!Balance unevenness with suitable supports.

•Applies to mounting on foundations/load-bearing elements.

•Total areas of all pump bearing areas are resting on the surface.

Correct position of the drives

•All drives are set up ready for operation and mounted.

•Correct slipping of the drive during transport/installation of the pump by adjusting/fixing

the drive motor.

CAUTION

Safety protection equipment.

Slight injury or damage to property may result.

!Connect safety protection equipment and activate.

10

5.0

Assembly/Installation

BW

Ausgabe

issue A / 23.01.07 Dokument

document OM.INS.08e Blatt

sheet 2(2)

5.5 Energy supply to the seepex pump

DANGER

Supply voltage and power frequency

Death or serious injury will result.

!Heed type plate on the pump.

!Pay attention to manufacturer’s directions (Chapter 14.0).

!Pay attention to safety regulations.

5.6 Pipe work

5.6.1 Suction and pressure connection

•Refer to the dimension drawing for the position, nominal pipe size and norm.

•Heed rotational direction/direction of flow.

5.6.2 Dimensioning of pipe work

•Adhere to specifications regarding pressure in the pressure or suction connection.

•Heed technical data (Chapter 3.0).

•Nominal pipe size of suction pipe = nominal pipe size of suction connection of pumps

5.6.3 Residue-free pipe work

NOTICE

Damage to property through assembly residue

No claims under guarantee if violated.

!Keep all pipe work free of foreign objects.

!Remove weld spatters, screws, steel chips etc.

5.6.4 Tension-free mounting

!Assemble pipe work and other components in a tension-free manner.

11

Commissioning/

De-commissioning

Ausgabe

issue B / 06.01.1997 Dokument

document OM.COM.01e Blatt

sheet 1(3)

6.0

Commissioning/De-commissioning

6.1

Engineering Data

Details regarding all technical specifications and

operating conditions are given in these operating

instructions together with the data sheet, Point 9.

To guarantee the correct assignment of documen-

tation to pump, the commission number on the

!cover sheet

!and data sheet of these operating instructions

must match the commission number stated on

!the nameplate of the pump.

6.1.1

See Point 7.2.2 for Lubricant Chart

6.2

Preparation for Operation

6.2.1

Bearing

6.2.1.1

See Point 7.2.1.4 for pump bearing.

6.2.1.2

See manufacturer's documents, Point 10, for drive

bearings.

6.2.2

Shaft Sealing

See document OM.SEA.__,.

6.2.3

Filling Up of Suction Side to Avoid Dry Running

at Startup

CAUTION

Before switching on the pump, fill the suction-sided

pump casing with fluid so that the first rotations will

lubricate the conveying elements immediately. A

small quantity of fluid is sufficient for lubrication; the

subsequent operation of the pump is self-priming,

even if an air column up to the liquid level remains.

6.2.4

Electric/Hydraulic Connections

The connections are listed in the

appended manufacturer's documents,

Point 10.

The risk of exposure to electrical

hazards must be ruled out. Always

observe the safety regulations valid

at the site of installation.

6.2.5

Checking Direction of Rotation

The rotational direction of the pump

determines the flow direction of the

conveying medium.

Flow direction

counter-clockwise

Flow direction

clockwise

Prior to commissioning the rotational direction of the

pump must be checked for compliance with the data

sheet specification and the rotational direction arrow

on the type plate of the pump.

6.3

Control and Monitoring Equipment

Where applicable, please refer to the associated

documents, Point 10, for information on

commissioning.

6.3.1

Performance Check

Any optional extras must be subjected to a

performance check in conformity with the

specifications by seepex or other manufacturers, see

manufacturer's documents.

6.3.2

Setting

Unless already performed in the factory, setting must

be carried out in accordance with the appended

manufacturer's specifications, Point 10. Pay attention

to the operating specifications in the data sheet.

12

Commissioning/

De-commissioning

Ausgabe

issue B / 06.01.1997 Dokument

document OM.COM.01e Blatt

sheet 2(3)

6.4

Equipment for Protection of Persons

Machines must be fitted with mechanical

protective devices complying with DIN EN

809.

!Moving or working parts must be

protected against accidental contact.

!However, safety considerations demand

it be possible at all times

to check without hindrance whether the

shaft seal is fully functional.

A protective guard is necessary in this

area only if components are mounted on

the rotating, smooth shaft.

!If pumps are operated with an open

suction flange/feed hopper, a suitable

protective guard complying with DIN EN

294 must be mounted.

!Country-specific protective regu-lations

must be observed at the site of

installation.

Prior to activation of the pump, check the

proper function of all protective

equipment.

6.5

Commissioning

6.5.1

Initial Startup/Re-starting

CAUTION

Every seepex progressive cavity pump is designed

for the specific operating conditions documented in

the data sheet. Commissioning is permissible only if

the operating conditions conform with those

indicated in the data sheet. Although the potential

usages of the seepex pump are not confined to the

specified operating conditions, any change in the

original conditions must be checked and approved

by seepex.

The right to make claims under the warranty

agreement will be annulled if operating conditions

are changed without prior approval by seepex.

6.5.2

Avoid Dry Running of Pump

CAUTION

The dry running of a pump increases the friction

between rotor and stator, quickly causing an

unacceptably high temperature to develop on the inner

surface of the stator. This overheating leads

to burning of the stator material and the total

failure of the pump.

For this reason it is necessary to ensure that the

suction-sided flow never dries up completely.

If a continuous flow cannot be guaranteed for the

plant, it is essential to fit the seepex dry running

protection device TSE, available as an optional

accessory.

6.5.3

Check Pressure at Suction and Pressure Flanges

6.5.3.1

Safeguard Pump Against Excessive

Pressure at the Suction Flange

The seepex pump is designed to

operate with the pressure at the suction

flange (suction head or inlet pressure)

specified in the data sheet. Deviating

pressure conditions may lead to the

failure and/or destruction of the shaft

seal or entire pump.

For this reason the suction pressure

specified in the data sheet must be

guaranteed. Appropriate monitoring

devices are oil-filled contact mano-

meters that deactivate the pump.

6.5.3.2

Safeguard Pump Against Excessive Pressure at

the Pressure Flange

The seepex pump operates according to

the positive displacement principle.

Operation of the pump against an

excessive pressure caused by closed

valves, by high pressure losses in the

piping or by product sedimentation will

lead to the destruction of the pump,

drive, pipe work and/or downstream

equipment. Every progressive cavity

pump must therefore be protected

against overpressure. Safety valves with

bypass pipes or oil-filled contact

manometers that disactivate the pump

are appropriate protective devices.

6.5.4

Drive Engine

Consult the attached manufacturer's

operating instructions, Point 10, for

information on commissioning the drive

engine.

13

Commissioning/

De-commissioning

Ausgabe

issue B / 06.01.1997 Dokument

document OM.COM.01e Blatt

sheet 3(3)

6.5.5

Establish Clear Passage Through Pipelines

CAUTION

To prevent damage to the pump the unhindered flow

of liquid must be guaranteed between the points of

entry to and exit from the pipeline. For this reason,

open all relevant valves etc. prior to activation of the

pump.

6.6

De-commissioning

6.6.1

De-activation

The electric connections must be

switched off and protected against

accidental re-activation. Observe the

safety regulations applying to the plants.

6.6.2

Stationary Pump

The pump and all optional equipment must be

provided with the following protection modes while at

astandstill:

- Frost protection

- Protection against solid particle deposits

- Protection against sedimentation of the medium

-Corrosion protection for parts in contact with

the medium

We recommend that the pipeline and pump be

emptied for the duration of the plant standstill.

Following evacuation, the pump should be preserved.

6.6.3

Evacuation of the Pump

The pipeline must be evacuated on the

suction and pressure side or shut-off

directly behind the pump connections.

Drain any residual liquid in the pump

casing by opening/ removing the

screwed sealing plugs (705) and (502),

sealing rings (706) and (503). Casings

without screwed plug must be

evacuated by the connection branch

(SAG and DRS). Refer to the data

sheet and the sectional drawing of the

associated operating instruction, Point

9, for information on the pump design.

Conveying medium residues always

remain in the rotor/ stator chambers

and may run out during transport or

disassembly of the pump. If conveying

aggressive or hazardous media,

therefore, wear appropriate protective

gear during all installation work.

6.6.4

Disassembling the Pump

Dismantle the pipe work by removing the flange bolts

(SCH) and flange seals (DFL) or the threaded

connections (G).

Disassemble the pump together with the baseplate

(GPU) or, as applicable, without the baseplate (GPU)

following removal of the bolts (SCH) at the pump

feet.

Block-design pumps with direct flange-

mounted drive engine are liable to

become unstable during disassembly.

Stability can be restored by propping up

the drive engine.

6.6.5

Preservation/Storage

The pump must be preserved prior to storage.

Appropriate preservation measures must be agreed

with seepex. Always state the pump commission

number when making inquiries.

14

9.1

Demontage/

Wiedermontage

Pumpe

Ausgabe

issue A / 23.01.07 Dokument

document OM.MAI.99e Blatt

sheet 1(4)

Range: BW

Size: 5-10

9.1.1 Prepare the pump for dismantling

DANGER

Dangerous voltage.

Death or serious injury will result.

!Heed safety regulations.

!Disconnect pump from all sources of energy.

!Secure electrical connections against restarting.

!Empty pipes.

!Allow pipes to cool down.

!Remove pipe connections (suction

side/pressure side).

!Heed decommissioning (Chapter 6._).

9.1.2 Demontage

WARNING

Tilting or falling pump

Injuries and/or damage to equipment. Death or

serious injury can result.

!Secure the pump.

9.1.2.1 Druckstutzen (700) – Demontage

!Dismantle pressure branches (700).

602 606 604700

9.1.2.2 Stator (601) – dismantling

Remove stator (601) from suction casing (500).

601 500

15

9.1

Demontage/

Wiedermontage

Pumpe

Ausgabe

issue A / 23.01.07 Dokument

document OM.MAI.99e Blatt

sheet 2(4)

9.1.2.3 Suction Casing (500) – dismantling

!Dismantle suction casing (500).

!Remove casing gasket (501).

500 501212210

9.1.2.4 Rotor (600) – dismantling

!Remove Rotor (600) from plug in shaft (307).

!Dismantling of joint (G)

- Rotating unit – individual parts (Chapter 9_)

600 307G

9.1.2.5 Mechanical Seal (SEA) – dismantling

!Detasch set screws (378).

!Dismantle set collar (372), Mechanical seal

(SEA) and mechanical seal retainer (333).

!Dismantle shaft sealing (Chapter 9._)

SEA

378372 333

9.1.2.6 Plug in Shaft (307) – dismantling

Tool (W26/assembly

mandrel)

!Remove plug in shaft pin (309) from plug in

shaft (307) with tool (W26).

!Remove plug in shaft (307).

309307

W26

16

9.1

Demontage/

Wiedermontage

Pumpe

Ausgabe

issue A / 23.01.07 Dokument

document OM.MAI.99e Blatt

sheet 3(4)

9.1.3 Reassembly

WARNING

Tilting or falling pump/pump parts

Injuries and/or damage to equipment. Death or series

injury may result.

!Secure the pump.

CAUTION

Danger of fingers being crushed

Slight injury may result.

!Do not grasp between connections.

9.1.3.1 Plug in Shaft (307) – reassembly

!Clean the flange mechanism surfaces (FLS) and

output pivots of the drive (ANT).

FLS

ANT

!Slide on plug in shaft (307).

Tool (W26/assembly

mandrel)

!Insert the plug in shaft pin (309) into the plug in

shuft with tool (W26).

309307 W26

9.1.3.2 Mechanical Seal (SEA) - reassembly

Tool (W27/Mounting sleeve with

assembly mandrel)

!Gleitringdichtungs-Aufnahme (333),

Gleitringdichtung (SEA) und Stellring (372) auf

Steckwelle (307) schieben.

!Secure Mechanical Seal (SEA) with tool (W27)..

SEA372 307W27 333

!Tighten the set collar (372) with set screws (378).

378 372

17

9.1

Demontage/

Wiedermontage

Pumpe

Ausgabe

issue A / 23.01.07 Dokument

document OM.MAI.99e Blatt

sheet 4(4)

Tool (W27/Mounting sleeve with

assembly mandrel)

!Dismantle tool (W27).. W27

9.1.3.3 Rotor (600) – reassembly

!Assmble rotor (600).

!Joint (G) reassembly

- Rotating unit – individual parts (Chapter 9_).

600 G

9.1.3.4 Sauggehäuse (500), Sauggehäusedichtung (501) – reassembly

!Provide rotor (600) with protective cover (SH).

!Slide on casing gasket (501).

!Assemble and adjust the pressure casing (500)

(water level).

SH

500 501212210 600

9.1.3.5 Stator (601) – reassembly

!Support rotor (600) with base (S) to prevent it falling

down.

!Add lubricant (liquid soap) to the opening on the

pressure branch side between the rotor (600) and

stator (601).

!Turn rotor (600) in the “right” rotating direction.

!

!

!Add lubricant (liquid soap) to the opening on the

pressure branch side between the rotor (600) and

stator (601).

!Turn Stator (601) in the „right“ rotating direction and

slide on the rotor (600).

!Slide on the Stator (601) up to the collar of the

pressure casing (500).

601 500600

9.1.3.6 Suction branch (700) – reassembly

!Assemble suction (700) branch.

602 606 604700

18

9.2

Rotating Unit

Individual Parts

Ausgabe

issue A / 21.03.07 Dokument

document OM.PJT.16e Blatt

sheet 1(3)

9.2.1 Dismantling

9.2.1.1 Dimantling of holding band (406, 407)

CAUTION

Danger of injury

Possible ejection of parts.

Slight injury or damage to property may result.

!Wear protective goggles.

!Detach holding band strap (SCL).

-Use suitable tool (WM).

!Push out strap part of holding band

(SCL).

!Remove holding band (406, 407).

9.2.1.2 Universal joint sleeve (405) – dismantling

!Pull back universal joint sleeve (405).

9.2.1.3 Retaining sleeve (401) – dismantling

!Knock back retaining sleeve (401).

-Use suitable tool (WM).

9.2.1.4 Detach joint

!Eject coupling rod pins (402).

!Remove Rotor (600).

Tool (W5/ Drift)

!Knock guide bushing (403) out with

tool (W5).

407 406 SCL WM

405

WM401

W5403

403 402

600

A

19

9.2

Rotating Unit

Individual Parts

Ausgabe

issue A / 21.03.07 Dokument

document OM.PJT.16e Blatt

sheet 2(3)

9.2.2 Rotating unit (RTE) – prepare individual parts for reassembly

9.2.2.1 Rotor (600)

!Remove existing damage.

!Clean the rotor (600).

Tool (W4/assembly

mandrel)

!Press in the guide bushing (403)

-Use tool (W4).

9.2.2.2 Plug-in shaft (307)

!Remove existing damage.

!Clean the plug-in shaft (307).

Tool (W4/assembly

mandrel)

!Press in the guide bushing (403)

-Use tool (W4).

9.2.3 Rotating unit (RTE) – individual parts – reassembly

HINWEIS

Faulty functioning of joints

Malfunctioning and/or destruction of joints.

Damage to property may result.

!Replace the coupling rod pins (402) and guide bushing (403) jointly.

9.2.3.1 Rotor (600) / Plug in shaft (307) – reassembly

!Slide the universal joint sleeve (405)

onto the Rotor (600).

!Fill the joint head with seepex joint

grease.

!Side on retaining sleeve (401).

!Insert coupling rod pins (402).

!Connect the Rotor (600)/plug in

shaft(307).

!Slide in coupling rod pins (402).

!Knock the guide bushing (403) in.

-Use tool (W5).

Tool (W5/ Drift).

403W4 600403

403

W4 307403

307600 405 401 402

307600 405 402 403W5

20

9.2

Rotating Unit

Individual Parts

Ausgabe

issue A / 21.03.07 Dokument

document OM.PJT.16e Blatt

sheet 3(3)

9.2.3.2 Retaining sleeve (401) - reassembly

Tool (W4/ assembly

mandrel)

!Knock back the retaining sleeve (401).

•Use tool (W4).

!Secure the retaining sleeve (401) in a

displaced manner (2x180°).

•Use suitable tool (WK).

Tool (W15/Mounting plate)

!Remove tool (W15).

9.2.3.3 Universal joint sleeve (405) – reassembly

!Moisten the surface of the coupling rod

(400)/ interior of the universal joint

sleeve (405) with joint grease

(maintenance, Chapter 7.0).

!Slide on the universal joint sleeve

(405).

Vent the inside area of the joint.

Use suitable tool (WS).

Assemble holding band

Holding band assembly (Chapter 9._).

405600

WS

405

405 406407

401

WK

307

401W4

21

Holding Band

Re-assembly

Ausgabe

issue A / 23.02.1995 Dokument

document OM.HBD.01e Blatt

sheet 1(2)

Holding Band (HBD) - Assembly

Tools required for the re-assembly, see document

OM.SPT.01.

•Prepare holding band

Onlyprefabricateddouble-bandholdingbands

should be used. The diameter (!)and in particular

the breadth (b) of the holding band is matched to the

universal joint sleeve.

•Test holding band

Thebentholdingband(HBD)mustfitagainstthe

holding band loop (SCL), if necessary apply

pressure with the tool/pliers (WZ).

•Assembly of holding band

Insert holding band in tool (W3/ see Point 9). Hold

free end of holding band with control lever (EX),

turn crank (KU) until the holding band is strained

and fitting against the holding band loop (SCL).

Carefully contract holding band until it fits inside the

circular groove of the universal joint sleeve.

•Correct holding band tension (HBD)

Correct

Holding band

(HBD) has

slightly con-

tracted outer

form of

univers-al joint

sleeve and is

stuck in

position.

Incorrect

Holding band

(HBD) is too

slack and

liable to slip.

Incorrect

Holding band

(HBD) is too tight.

Universal joint

sleeve will be

damaged/sheared

off.

•Folding back the holding band (HBD)

Slowly swivel mounting tool upward by 60°, at the

same time slackening the crank (KU) by

approximately one half revolution. Swivel cutting

lever (SH) forward until the pressure plate fits

against the holding band loop (SCL).

22

Table of contents

Other Seepex Water Pump manuals

Seepex

Seepex BCSB Series Product guide

Seepex

Seepex BN 5-12 Series Manual

Seepex

Seepex BN 2-12S Product guide

Seepex

Seepex BTQ Series Product guide

Seepex

Seepex BCSO 025-24 to 130-6L Product guide

Seepex

Seepex Macerator 110 Series Product guide

Seepex

Seepex BTVE 10-12 Product guide

Seepex

Seepex BN 52-6LS Product guide

Seepex

Seepex BN 2-12S Product guide

Popular Water Pump manuals by other brands

Pentair

Pentair HYDROMATIC OSP50 Installation and service manual

Standard Pump

Standard Pump SP-800DD Operating instructions and parts manual

BUSCH

BUSCH Dolphin LX 0030 A Installation and operating instructions

Utilitech

Utilitech 50AC-110 Install manual

Antares

Antares P.023 Installation and instruction manual

Nash

Nash Boat Life user guide