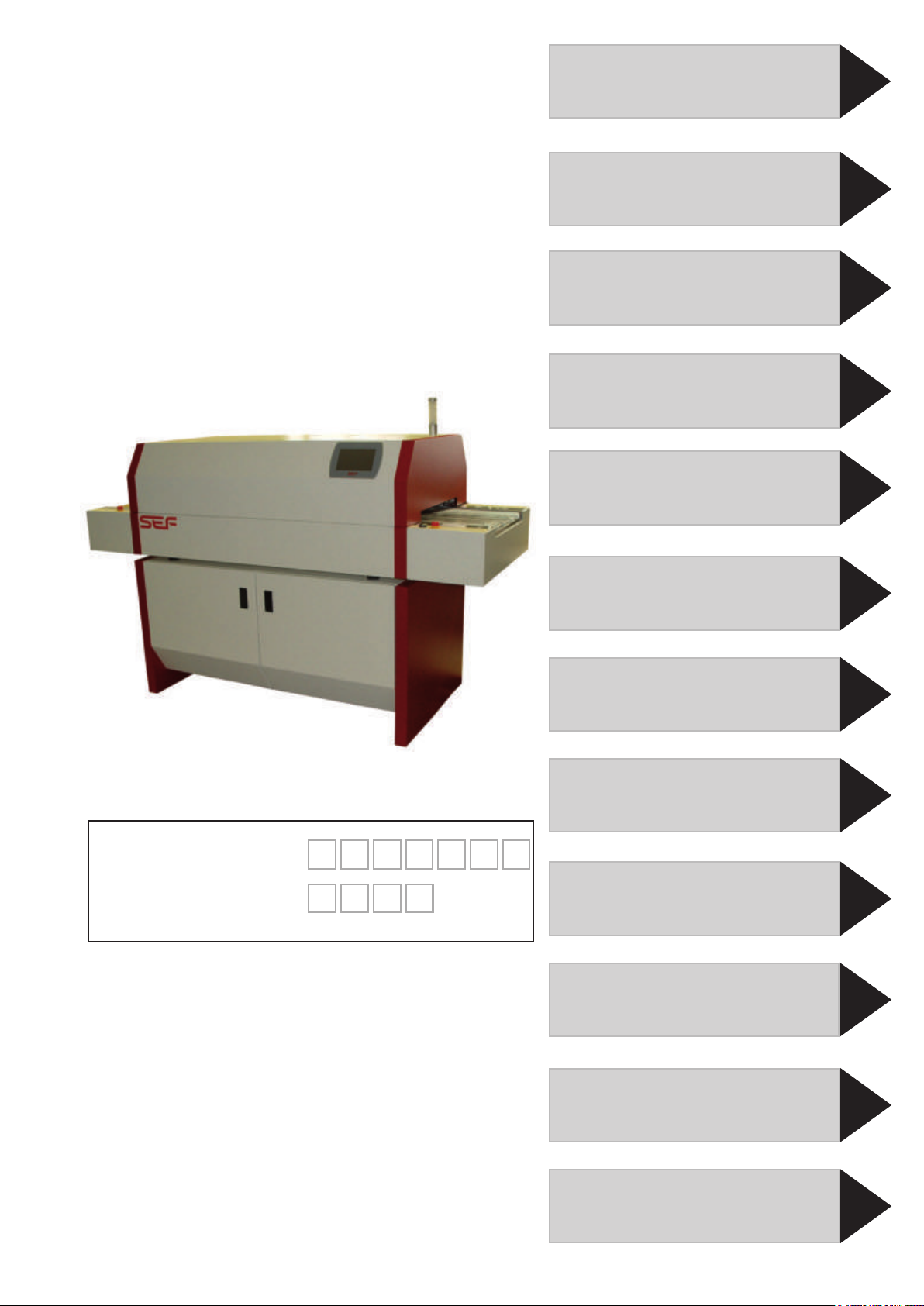

SEF 551.10 User manual

Serial number:

Year of manufac-

turing:

Keep this manual for a later use.

2

1

3

4

5

6

7

8

9

10

11

12

Schematic diagram

Options and

spare parts

Notes

© SEF Systec GmbH, December 2015

Translation of original instruction.

Subject to technical changes.

Operating Manual

System settings

Operation and

start-up

Transport and

installation

Technical data

Safety instructions

Preface

Warranty

Prole administration

Maintenance and

service

p551.10 4heating zones

p551.15 5heating zones

p551.19 8heating zones

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.3

2.0 Safety instructions

Safety signs............................................................................................... 2.2

General instructions................................................................................... 2.3

Safety notes............................................................................................... 2.3

Used norms ............................................................................................... 2.4

Intended use.............................................................................................. 2.5

Remaining risks ..................................................................................... 2.5

Responsibility of operator and operating staff ........................................... 2.6

Owner ................................................................................................... 2.6

Operator................................................................................................ 2.6

Skilled and qualied operating staff ...................................................... 2.6

Authorised service staff......................................................................... 2.6

Responsibility of operator and operating staff ........................................... 2.7

Legal safety requirements .................................................................... 2.7

Personal safety ..................................................................................... 2.7

Reference to other suppliers................................................................. 2.7

Spare parts ........................................................................................... 2.7

Safety notes for installation and initial start-up.......................................... 2.9

Connection conditions .......................................................................... 2.9

Location ................................................................................................ 2.9

Exhaustion ............................................................................................ 2.9

Safety notes for daily start of operation and automatic operation ........... 2.11

Safety at the working place................................................................. 2.11

Solder paste and chip adhesive.......................................................... 2.11

Protective equipment .......................................................................... 2.11

Failures ............................................................................................... 2.13

Optical signals .................................................................................... 2.13

Safety notes for maintenance and service .............................................. 2.14

Five safety rules.................................................................................. 2.14

Dismounting of safety devices ............................................................ 2.15

Disposal notes .................................................................................... 2.16

1.0 Preface

Preface ....................................................................................................... 1.1

3.0 Warranty

Warranty ................................................................................................... 3.2

Rights of use.......................................................................................... 3.2

Assignment of the rights of use ............................................................. 3.2

Liability................................................................................................... 3.2

Reshipment ........................................................................................... 3.2

Modications or improvements of the product....................................... 3.3

Special restrictions ................................................................................ 3.3

Caveat emptor.......................................................................................... 3.3

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.4

4.0 Technical data

Dimensions of the soldering system 551.10 / 551.15................................ 4.2

Technical data 551.10 / 551.15.................................................................. 4.3

Dimensions............................................................................................. 4.3

Electrical connection values ................................................................... 4.3

Allowed climatic demands ...................................................................... 4.3

Allowed component sizes ....................................................................... 4.3

Characteristics........................................................................................ 4.3

Emissions ............................................................................................... 4.3

Dimensions of the soldering system 551.10 / 551.15

with power supply 220V triangle circuit .................................................. 4.4

Technical data

Option power supply 220V in triangle circuit .......................................... 4.5

Dimensions............................................................................................. 4.5

Electrical connection values ................................................................... 4.5

Maße des Lötsystems 551.19 ................................................................... 4.6

Technical data 551.19................................................................................ 4.7

Dimensions............................................................................................. 4.7

Electrical connection values ................................................................... 4.7

Allowed climatic demands ...................................................................... 4.7

Allowed component sizes ....................................................................... 4.7

Characteristics........................................................................................ 4.7

Emissions ............................................................................................... 4.7

Functional scheme 551.10 - 4 heating zones ........................................... 4.8

Funktional scheme 551.15 - 5 heating zones ........................................... 4.8

Funktional scheme 551.19 - 8 heating zones ........................................... 4.8

Functional scheme ................................................................................... 4.9

Heating chamber .................................................................................... 4.9

Cooling zone, Exhaust hood................................................................... 4.9

Transport ................................................................................................ 4.9

Operating panel 7‘‘ touch screen ............................................................ 4.11

Controller (SBCC-Board)......................................................................... 4.13

Central electrics 551.10 / 551.15............................................................. 4.14

Central electrics 551.19........................................................................... 4.14

Central electrics....................................................................................... 4.15

Controller RO-R2R .................................................................................. 4.17

Allocation of the signals for 551.19.......................................................... 4.18

Controller 551.19 Master / Slave............................................................. 4.19

Option pin chain conveyor for 551.10/.15 ............................................. 4.19

Component sizes pin chain conveyor................................................. 4.19

Parameters pin chain conveyor.......................................................... 4.19

Base cabinet 551.10.1............................................................................. 4.21

Option exhaust box 551.10.2 ............................................................... 4.23

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.5

5.0 Transport and setting up

Transport notes ......................................................................................... 5.2

Safety instructions for mounting and dismounting..................................... 5.3

Liability.................................................................................................... 5.3

Unpacking.................................................................................................. 5.5

Checking scope of delivery..................................................................... 5.5

Transport on pallet.................................................................................. 5.5

Dimensions and data of the soldering system 551.10 / 551.15................. 5.6

System 551.10 / 551.15 setup and alignment ........................................... 5.7

Working table.......................................................................................... 5.7

Dimensions and data of the soldering system 551.19............................... 5.8

System 551.19 setup and alignment ......................................................... 5.9

Align soldering system horizontally....................................................... 5.10

Mains supply......................................................................................... 5.10

Name plate 400VAC/N/PE.................................................................... 5.10

Power supply 400VAC/N/PE ................................................................ 5.10

Name plate 220VAC D...................................................................... 5.11

Power supply 220VAC D.................................................................. 5.11

Exhaust connection .............................................................................. 5.13

Interfaces.............................................................................................. 5.14

Main switch........................................................................................... 5.14

Operating switch On/Off ....................................................................... 5.14

Operation by touch panel ..................................................................... 5.14

Prole setting........................................................................................ 5.14

Integrated temperature proler............................................................. 5.14

Final check .............................................................................................. 5.15

Dismounting, storage and preservation................................................... 5.16

Dismounting.......................................................................................... 5.16

Short-term out-of-operation .................................................................. 5.16

Preservation ......................................................................................... 5.16

6.0 Function and start-up

Functional description................................................................................ 6.3

Heating chamber .................................................................................. 6.3

Thermocouples ..................................................................................... 6.3

Cooling zone......................................................................................... 6.3

Exhaustion ............................................................................................ 6.3

Mesh belt .............................................................................................. 6.5

Operating the system............................................................................ 6.5

Machine status...................................................................................... 6.5

Temperature proler.............................................................................. 6.7

Emergency-stop.................................................................................... 6.7

Safety circuit ......................................................................................... 6.7

The operating panel................................................................................... 6.9

Touch screen controller based on SBCC.............................................. 6.9

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.6

7.0 Prole administration

Parameter adjustment ............................................................................... 7.3

Parameters for temperature prole....................................................... 7.3

Preheating time..................................................................................... 7.3

Critical prole parameters

Time above liquidus .............................................................................. 7.5

Cooling time.......................................................................................... 7.5

Critical prole parameters

Example component thickness 1,6 mm - 2,5 mm(small components) . 7.6

Critical prole parameters

Example component thickness > 2,5 mm (small components)............. 7.6

Peaktemperature .................................................................................. 7.7

Ramp-up / Ramp-down gradient........................................................... 7.7

Load program .......................................................................................... 7.10

Select program ................................................................................... 7.11

Load program .................................................................................... 7.11

Edit program............................................................................................ 7.13

Create soldering or curing prole........................................................ 7.13

Adjust nominal temperature................................................................ 7.13

Adjust conveyor speed ....................................................................... 7.15

Save program.......................................................................................... 7.17

Overwrite program .............................................................................. 7.18

Turn the soldering system on/off ............................................................ 6.11

Main switch ......................................................................................... 6.11

Turn soldering system on.................................................................... 6.11

The system screen .................................................................................. 6.11

Basic structure of screen .................................................................... 6.12

System display.................................................................................... 6.13

Operating modes of soldering systems series 551............................. 6.13

Menu structure Load program ................................................................. 6.14

Load program .......................................................................................... 6.15

Select program ................................................................................... 6.15

Load program .................................................................................... 6.15

Menu structure Edit program................................................................... 6.16

Edit program............................................................................................ 6.17

Create soldering or curing prole........................................................ 6.17

Menu structure Save program................................................................. 6.18

Save program.......................................................................................... 6.19

Save program.......................................................................................... 6.19

Prole measurement ............................................................................... 6.23

Temperature proler............................................................................ 6.23

Menu structure Prole measurement ...................................................... 6.24

Menu structure Setup .............................................................................. 6.26

Setup ....................................................................................................... 6.27

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.7

8.0 System settings

Language selection ................................................................................... 8.3

Set language......................................................................................... 8.3

Colour scheme .......................................................................................... 8.5

Select colour scheme ........................................................................... 8.5

Temperature display .................................................................................. 8.7

Select temperature display ................................................................... 8.7

Activate password protection for programs ............................................... 8.9

Activate password protection................................................................ 8.8

Standby parameters ................................................................................ 8.11

“Power Save Package” ....................................................................... 8.11

Set standby time ................................................................................. 8.11

Set standby temperature .................................................................... 8.11

Software-Update...................................................................................... 8.13

Install update ...................................................................................... 8.13

9.0 Maintenance and service

General safety instructions........................................................................ 9.2

Safety instructions for opening and closing the hood................................ 9.3

Set system out of operation....................................................................... 9.3

Opening the hood ................................................................................. 9.4

Closing the hood................................................................................... 9.5

Cleaning and maintenance intervals ......................................................... 9.6

Cleaning .................................................................................................... 9.6

Maintenance.............................................................................................. 9.6

Save program ..................................................................................... 7.19

Option pin chain conveyor ................................................................... 7.21

Adjust working width of pin chain conveyor ........................................ 7.21

Start production ....................................................................................... 7.22

Start system........................................................................................ 7.22

Heat-up phase .................................................................................... 7.22

Fill the oven ........................................................................................ 7.24

Start soldering or curing process ........................................................ 7.24

Cooling down phase 551.10 ............................................................... 7.25

Cooling down phase 551.19 ............................................................... 7.25

Cooling down phase 551.15 ............................................................... 7.25

Finish process..................................................................................... 7.25

Prole measurement ............................................................................... 7.27

Temperature proler ................................................................................ 7.27

Start measurement ............................................................................. 7.27

Stop measurement ............................................................................. 7.28

Stop or change production ...................................................................... 7.29

Change production ............................................................................. 7.29

Stop production................................................................................... 7.29

Switch system off..................................................................................... 7.30

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.8

Lubrication................................................................................................. 9.7

Cleaning work............................................................................................ 9.9

Cleaning work at the outer machine body ............................................ 9.9

Cleaning of the reected-light barrier.................................................... 9.9

Cleaning of the blowers ..................................................................... 9.11

Cleaning of the fans............................................................................ 9.13

Cleaning of the exhaust hood “inlet” ................................................... 9.15

Cleaning of heating module ................................................................ 9.16

Cleaning of cooling module ................................................................ 9.16

Cleaning of the exhaust hood “outlet”................................................. 9.17

Cleaning of the guiding rails ............................................................... 9.19

Cleaning of the chamber oor............................................................. 9.19

Cleaning of the mesh belt ................................................................... 9.19

Error diagnosis ........................................................................................ 9.20

Check and exchange fuses ..................................................................... 9.23

Check and exchange fuses 551.10 / .15 ............................................ 9.23

Exchange damaged fuse ............................................................... 9.23

Check and exchange fuses 551.19 .................................................... 9.25

Exchange damaged fuse ............................................................... 9.25

Option power supply 220V in triangle circuit ................................... 9.26

Mounting plate inlet ................................................................... 9.27

Mounting plate outlet ................................................................. 9.27

Exchange blower..................................................................................... 9.29

Dismount blower ................................................................................. 9.29

Exchange fan........................................................................................... 9.31

Dismount fan....................................................................................... 9.31

Exchange heating elements of the upper heating modules .................... 9.33

Dismount heating module ................................................................... 9.33

Exchange upper heating element ....................................................... 9.36

Mount upper heating module .............................................................. 9.37

Exchange heating elements of lower heating zones ............................... 9.38

Dismount lower heating element ........................................................ 9.39

Exchange lower temperature sensor .................................................. 9.40

Mount lower heating element.............................................................. 9.40

Exchange temperature sensors in the upper heating modules ............... 9.43

Dismount upper heating module......................................................... 9.44

Exchange upper temperature sensor ................................................. 9.46

Mount upper heating module .............................................................. 9.46

Exchange temperature sensor in lower heating zone ............................. 9.49

Exchange lower temperature sensor .................................................. 9.50

Dismount operating panel........................................................................ 9.52

Exchange operating panel .................................................................. 9.53

Mount operating panel ........................................................................ 9.53

Dismount controller RO-R2R .................................................................. 9.54

Exchange controller board RO-R2R ................................................... 9.55

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.9

10.0 Schematic diagram

12.0 Notes

11.0 Options and spare parts

Hardware for the network connection...................................................... 11.2

Option Communication Package ......................................................... 11.3

Network structure of SEF soldering system 551.xx.............................. 11.4

Default settings network conguration.................................................. 11.7

Network setup....................................................................................... 11.8

Network conguration........................................................................... 11.8

Windows control panel - network.......................................................... 11.8

Soldering system software RO-R2 - settings........................................ 11.8

Option Communication Package - network setup................................ 11.9

Create directories ............................................................................... 11.10

Server computer - directories ............................................................. 11.10

Soldering system software RO-R2 - settings...................................... 11.10

Server software setup......................................................................... 11.12

Port setup ........................................................................................... 11.13

Set admin interface ............................................................................ 11.13

Create user......................................................................................... 11.14

Assign directory .................................................................................. 11.15

Set up external operation ................................................................... 11.18

Option Communication Package - external operation ....................... 11.19

Congure VNC ................................................................................... 11.19

Option lamp pole for soldering systems 551.10/15/20....................... 11.21

Operating mode of the soldering system series 551 .......................... 11.21

MESY 570.77 A Temperature proler ................................................... 11.23

MESY 570.77 Insulating box ................................................................ 11.23

MESY 570.80 A Proler set .................................................................. 11.23

Thermocouples...................................................................................... 11.23

Spare part list soldering system 551.10 / 551.15 / 551.19 .................... 11.24

Exchange motor / drive belt..................................................................... 9.57

Dismount motor .................................................................................. 9.57

Dismount drive belt ............................................................................. 9.58

Tension drive belt................................................................................ 9.59

Table of content

Table of content 551.19 \ 12.2015 \

Page 0.10

Page 1.1

1.0 Preface

Preface 551_19 \ 12.2015 \

Dear customer,

congratulations for the purchase of your new reow soldering system

from the SEF series 551. You have now a modern and efcient device

available for your reow process.

It is necessary that you read this operation manual carefully prior to

operate the soldering system. It contains important information on

how to operate your reow system properly and safely.

This operation manual has been written for the authorized user. Basic

knowledge in SMD soldering methods are assumed.

y By reading this manual you help to avoid dangers, reduce

repair costs and downtimes as well as raise the depend-

ability and life time of the system.

y Observe the safety instructions.

We will not take any liability for damages or interruptions cause by

non-observance of this information.

Use the soldering system only in proper condition, according to the

intended use, safety- and danger conscious, and under consideration

of all information provided in this operation manual.

This manual belongs to the product and must be kept nearby to pro-

vide important information regarding safety and operating to you and

all future users.

For further questions regarding the soldering system or to order spare

parts, please contact your dealer

Page 1.2

1.0 Preface

Preface 551_19 \ 12.2015 \

Designations in the text

For an easier reading and searching inside this manual we have

marked some text parts especially:

To be found before important informations or explana-

tions regarding better handling of the system.

To be found before general listings.

yTo be found before working or operating steps to be

conducted in the described order.

This symbol indicates information that relate to a

product variant.

<Key> These gures mark switches or keys.

[Display] These gures mark display elements.

Page 2.1

2.0 Safety instructions

Safety instructions 551.15 \ 12.2015 \

Table of content

Safety signs............................................................................................... 2.2

General instructions................................................................................... 2.3

Safety notes............................................................................................... 2.3

Used norms ............................................................................................... 2.4

Intended use.............................................................................................. 2.5

Remaining risks ..................................................................................... 2.5

Responsibility of operator and operating staff ........................................... 2.6

Owner ................................................................................................... 2.6

Operator................................................................................................ 2.6

Skilled and qualied operating staff ...................................................... 2.6

Authorised service staff......................................................................... 2.6

Responsibility of operator and operating staff ........................................... 2.7

Legal safety requirements .................................................................... 2.7

Personal safety ..................................................................................... 2.7

Reference to other suppliers................................................................. 2.7

Spare parts ........................................................................................... 2.7

Safety notes for installation and initial start-up.......................................... 2.9

Connection conditions .......................................................................... 2.9

Location ................................................................................................ 2.9

Exhaustion ............................................................................................ 2.9

Safety notes for daily start of operation and automatic operation ........... 2.11

Safety at the working place................................................................. 2.11

Solder paste and chip adhesive.......................................................... 2.11

Protective equipment .......................................................................... 2.11

Failures ............................................................................................... 2.13

Optical signals .................................................................................... 2.13

Safety notes for maintenance and service .............................................. 2.14

Five safety rules.................................................................................. 2.14

Dismounting of safety devices ............................................................ 2.15

Disposal notes .................................................................................... 2.16

2.0 Safety instructions

Page 2.2

Safety instructions 551.15 \ 12.2015 \

At and inside the device you will nd different warning and additional

signs.

Safety signs

IT IS FORBIDDEN,

to remove warning notes, safety symbols and designation labels

or to interfere their clear recognizability.

Warning of electrical voltage

Warning of high temperatures

Warning of entanglement hazard at the inlet and outlet

Page 2.3

2.0 Safety instructions

Safety instructions 551.15 \ 12.2015 \

General instructions

This manual is used for the intended and secure work at and with the

soldering system.

Improper or unintended use of the device can cause

Danger to life

damages at the system or other properties of the user as

well as

interferences to the efcient work of the soldering system

or of the user.

Therefore, operate the system only in perfect technical condition,

intended and safety-conscious according to all instructions in this

manual.

yObserve the safety instructions.

yStart your work with caution and safety-conscious.

yEach person, working with this system, should have read

and understood the complete operation manual and espe-

cially this chapter.

Not only the general safety instructions in this chapter have to be

followed but also the special safety instructions in the other chap-

ters.

yKeep this manual always nearby the soldering system.

The SEF Systec GmbH indicates to assume no liability for damages or

breakdowns which are caused by the non-observance of this manual.

No completeness is claimed with these safety instructions.

For questions or problems please contact the company SEF Systec

GmbH.

Safety notes

2.0 Safety instructions

Page 2.4

Safety instructions 551.15 \ 12.2015 \

Basic for the mechanical and electrical construction and design of the

following described controller, mechanics and electrics are:

EC machinery directive 2006/42/EC with its addenda and

related norms.

For the electrical part of the system is additionally valid:

EC low voltage directive 2004/108/EG

Directive of electromagnetic compatibility 2006/95/EG.

The following harmonized norms were observed for the design of the

reow oven:

EN 12100 Safety of machinery -

General principles for design-

Risk assessment and risk reduction

EN 60204-1 Safety of machines -

Electrical equipment of machines.

Part 1: General requirements

EN 60519-1 Safety in electroheat installations

Part 1: general requirements

EN 60519-2 Safety in electroheat installations

Part 2: Particular requirements for resistance heat-

ing equipment

EN 61000-6-1: Electromagnetic compatibility (EMC) - Part 6-1: Ge-

neric standards - Immunity for residential, commer-

cial and light industrial environments (IEC 61000-6-

1:2005)

EN 61000-6-2 Electromagnetic compatibility - Generic standards

Immunity for industrial environments

EN 61000-6-3: Electromagnetic compatibility (EMC) - Part 6-3: Ge-

neric standards - Emission standard for residential,

commercial and light-industrial environments (IEC

61000-6-3:2006)

EN 61000-6-4 Electromagnetic compatibility - Part 6-4 Generic

standards - Emission standard for industrial

environments

yObserve and follow the mentioned norms for installation,

start-up, programming and operation as well as mainte-

nance and service.

Used norms

Page 2.5

2.0 Safety instructions

Safety instructions 551.15 \ 12.2015 \

Intended use

This soldering system from series 551 has been designed and con-

structed according to the latest technology. However, there is a risk of

danger if the system is used improperly or not according to the instruc-

tions.

Soldering systems from series 551 are solely designed for the fol-

lowing tasks:

Soldering of PCBs with SMD components, curing of chip

adhesives, LED-manufacturing, component qualica-

tion and processing of shrink hoses. Any other use is not

intended! Unauthorised modications or changes are not

allowed.

Operate the system only in perfect technical condition, according to

the intended use and safety-conscious according to all instructions in

this manual.

Remaining risks are not obvious risks caused by the system. Even if

the system is used properly, risks for the life or physical condition of

the user or third parties respectively impairment of the system or other

material assets, can not be completely excluded.

Remaining risks

Please observe:

The intended use includes also the observance of the

prescribed installation and operating conditions, the EMC

notes as well as the prescribed maintenance and disposal

measures.

Only qualied, authorised and trained staff must work at

the system. Additionally the operator must inform the staff

about possible dangers.

The operator must ensure that this manual and especially

the chapter "Safety instructions" have been read by all

persons working with this system.

Interferences which can impact the safety must be elimi-

nated by authorised service staff immediately.

One sample of the manual must be kept nearby the system

at a designated place.

2.0 Safety instructions

Page 2.6

Safety instructions 551.15 \ 12.2015 \

Responsibility of operator and operating staff

Owner is each natural person or legal entity who has purchased the

system.

Operator is each natural person or legal entity who is using the system

on his own or by whose order the system is used.

The operator respectively his safety representative must assure,

that all relevant regulations, instructions and laws are ob-

served,

the system is only used in a safe and functional state,

that only qualied staff works at and with the system,

that the manual is available for the staff during the respec-

tive work,

that all manuals and especially the chapter "Safety instruc-

tions" have been read and understood,

that all safety instructions are trained regularly (once a

year),

that the operating staff is informed about kind and cover-

age of the work as well as about possible dangers by the

safety representative or within a training,

that not qualied persons don't work at the system,

that service staff is authorised by a user specic training.

Skilled and quali-

ed operating staff

Operator

Owner

Skilled, qualied and briefed are persons who

have sufcient knowledge about the function and the

operation of the system due to their technical education,

experience and specic training,

are familiar with relevant work safety and accident preven-

tion provisions as well as with the generally accepted rules

of technique.

Service and maintenance work must be only proceeded by authorised

service staff.

Authorised

service staff

Page 2.7

2.0 Safety instructions

Safety instructions 551.15 \ 12.2015 \

yCheck the system before start-up for the observance of

user safety regulations, accident prevention regulations

and regulations of the professional association.

Legal safety re-

quirements

The operator is obliged to

take measures that the system is only operated in a

safe and functional state

Personal

safety

When operating the system or proceeding maintenance work the staff

should be in a good health.

The staff should not

have taken any medication or other agents decreasing the

reaction time.

Each method of operation, which is impacting the personal safety

must be defaulted

Responsibility of operator and operating staff

Use only original spare parts.

Reference to other

suppliers

Operate the system only with accessories and add-on parts men-

tioned in the manual. Don't use any external devices or components

which are not allowed by SEF explicitly.

yRead also the manuals of external devices or compo-

nents

Spare parts

2.0 Safety instructions

Page 2.8

Safety instructions 551.15 \ 12.2015 \

Working areas

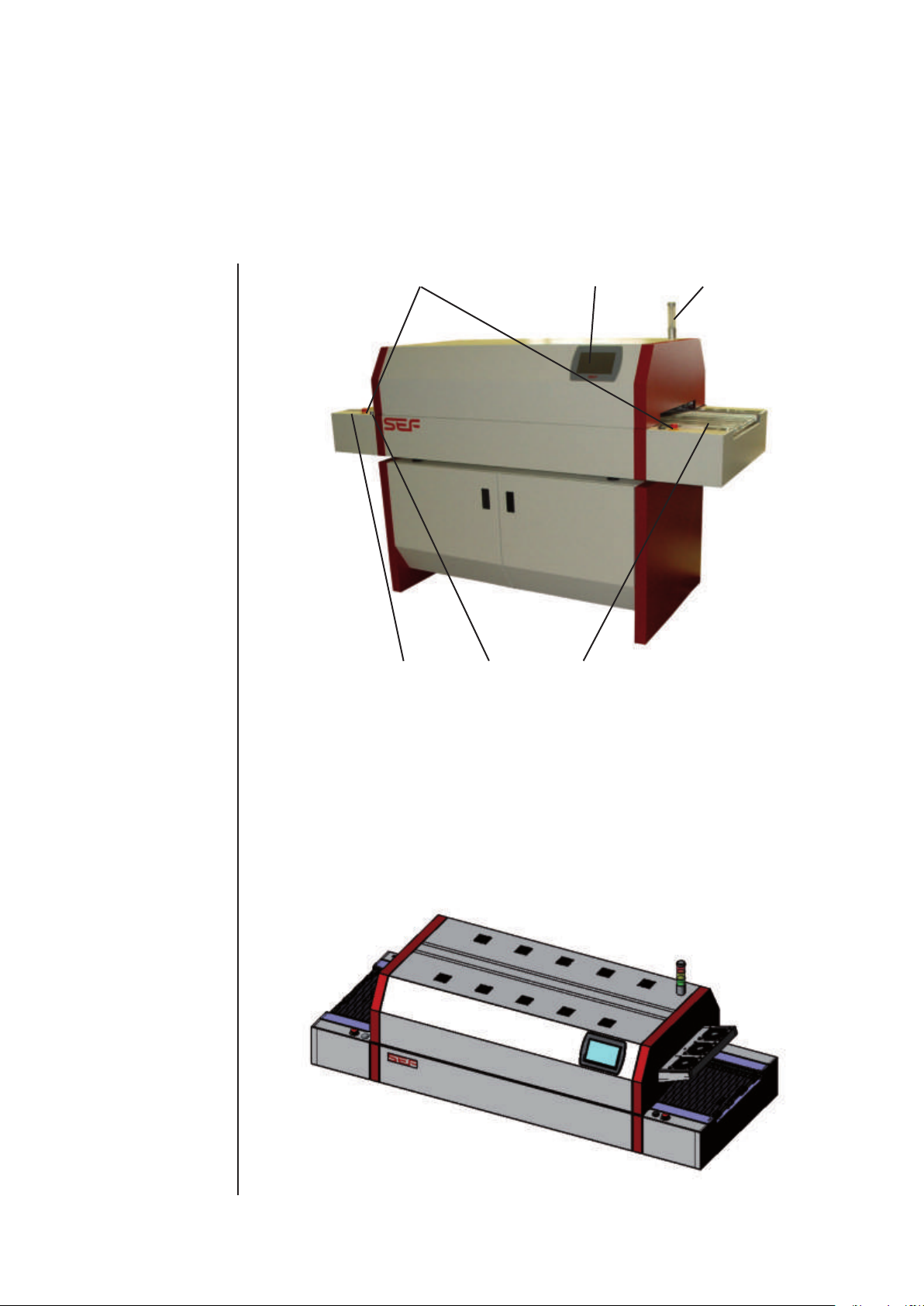

Overview of working areas:

1Charging zone

2Emergency-stop switch

3 Operating switch On/Off

4Operating and programming via touch panel

5Lamp pole

6Discharging zone

1 3 6

2 4 5

2006

553 162,5

750

800

60

898

Reflowofen

1303-0A-BG-00-0

4.11.

1:10

A 2

-

Benennung:

+0,2

-0,3

Maßstab:

Format

Werkstoff:

Zeichnungsnummer

Blatt 1

Bl.

Allgemeintoleranzen

ISO 2768-mH

2014

Datum

Name

Tolerierung ISO 8015

Bearb.

Gepr.

Norm

Piepenbrink

Oberfläche:

SEF Systec GmbH

Kringelsburg

D-21379 Scharnebeck

Tel.: (04136) 909-0

-

Gewicht:

g

205212.11

551.10

Artikelnr.:

05199910

Prüfzeugnis

ja

nein

-0,1

This manual suits for next models

2

Table of contents

Other SEF Soldering Gun manuals

Popular Soldering Gun manuals by other brands

Aktakom

Aktakom ASE-1203 Operation and maintenance manual

Pace

Pace SODRTEK ST 125 Operation and maintenance manual

Weller

Weller wsd 81 operating instructions

jbc

jbc Precision B-iRON Station instruction manual

Kurtz Ersa

Kurtz Ersa CHIP TOOL operating instructions

Weller

Weller WE1010NA Original instructions