54

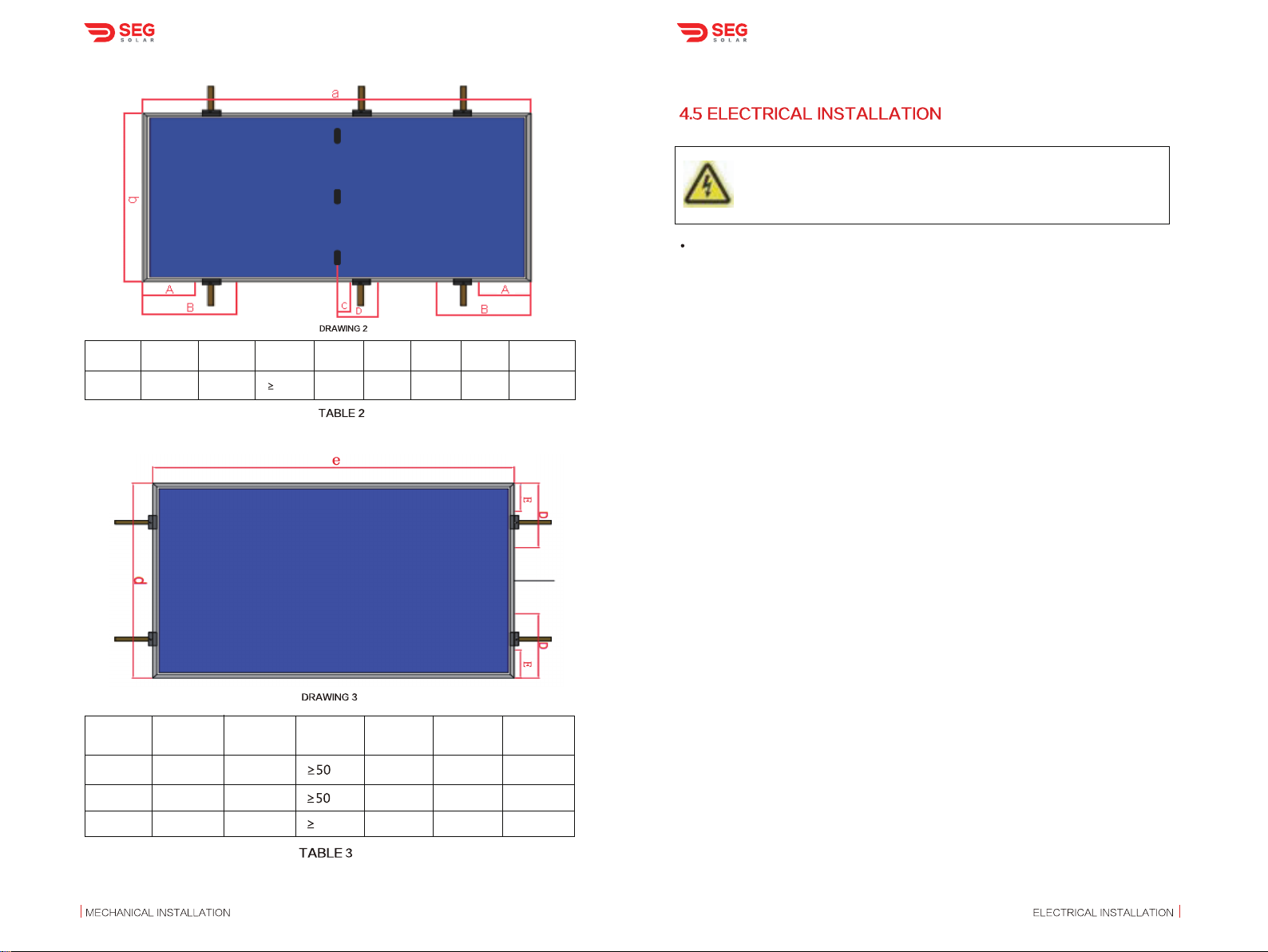

• Do not use PV modules with broken glass or torn back sheet which presents

danger of electrical shock.

• Do not handle panels in wet conditions without appropriate protection.

• Do not exposePV module to sunlight until installation to avoid unnecessary

degradation.

• Any module without a frame (laminate) shall not be considered to comply

with the requirements of UL1703 unless the module is mounted with hardware

that has been tested and evaluated with the module under this standard or by

a field Inspection certifying that the installed module complies with the

requirements of UL 1703.

• Installation shall conform with UL standards and Safety Standards for Electri-

cal Installations.

• Do not disconnect under load.

• Do not touch conductive parts of PV modules, such as terminals, which can

result in burns, sparks and lethal shock whether or not the PV module is con-

nected.

• Do not touch the PV module unnecessarily during installation.

• Do not work in the rain, snow or windy conditions.

• Do not expose artificial sunlight to PV modules. Completely cover the PV

module with an opaque material during installation to prevent electricity from

being generated.

• Do not wear metallic rings, watchbands, ear, nose, lip rings or other metallic

objects while installing or troubleshooting.

• Only use insulated tools that are qualified for working on electrical installa-

tions.

• Follow the safety regulations for all other system components, including wire

and cables, connectors, charging regulators, inverters, storage batteries,

rechargeable batteries, etc.

• Under normal outdoor conditions the current and voltagegenerated will

differ from those listed onthedatasheet. Current and short-circuit current

should be multiplied by a factor of 1.25 to determine component ratings.

• Only use connectors compatible with thePV module connectors. Removing

the connectors without prior authorization will invalidate the warranty.

• Do not move installed modules to another location, which may invalidate the

warranty.

Each module has three Barcode stickers and one label which have the same

unique serial no. of each module.

Barcode 1: Laminated into PV modules.

Barcode 2: Sticker on the backside of PV modules.

Barcode 3: Sticker on the middle location of long frame side.

Label: Sticker on the backside of PV modules, contains model no. and specific

information pertaining to the module.

• The fire rating of this module is valid only if this Guide is followed.

• Consult your localauthority for Guidelines and requirements for building or

structural fire safety.

• Do not use PV modules near equipment or in places where flammable gases

may be generated.

• Follow local codes and laws when installing the modules

• Roof construction and installation may affect the fire safety of a building;

Improper installation may create a hazard in the event of a fire.

• Do not install module that is damaged in any way as it canpose a fire or elec

trical shock hazard.

• Do not install modules within 50m of theshoreline

UL INSTALLATION GUIDE FOR SEG

PHOTOVOLTAIC MODULE

UL INSTALLATION GUIDE FOR SEG

PHOTOVOLTAIC MODULE

Check the serial No. in the barcode with the packing list whenunpacking.

Provide the PV module serial No. When you need support from SEG SOLAR

for a particular PV module.