Cal.5M54A

9/22

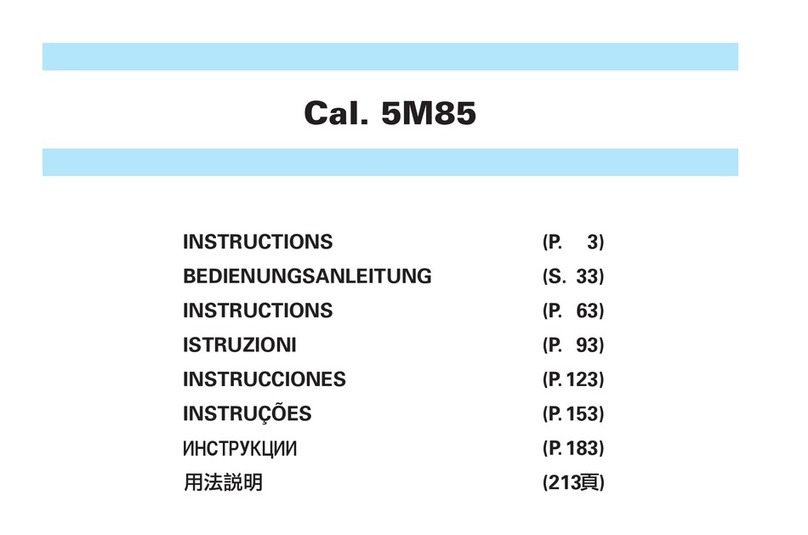

PARTSLIST

0022247

• DAY LEVER BRIDGE SCREW (3 PCS.)

• RECHARGEABLE BATTERY CLAMP SCREW (2 PCS.)

• CIRCUIT BLOCK COVER SCREW (2 PCS.)

• OSCILLATING WEIGHT BRIDGE SCREW (2 PCS.)

• COIL BLOCK SCREW (1 PC.)

• TRAIN WHEEL BRIDGE SCREW (1 PC.)

0022490

• OSCILLATING WEIGHT SCREW (1 PC.)

39 CIRCUIT BLOCK 4000732

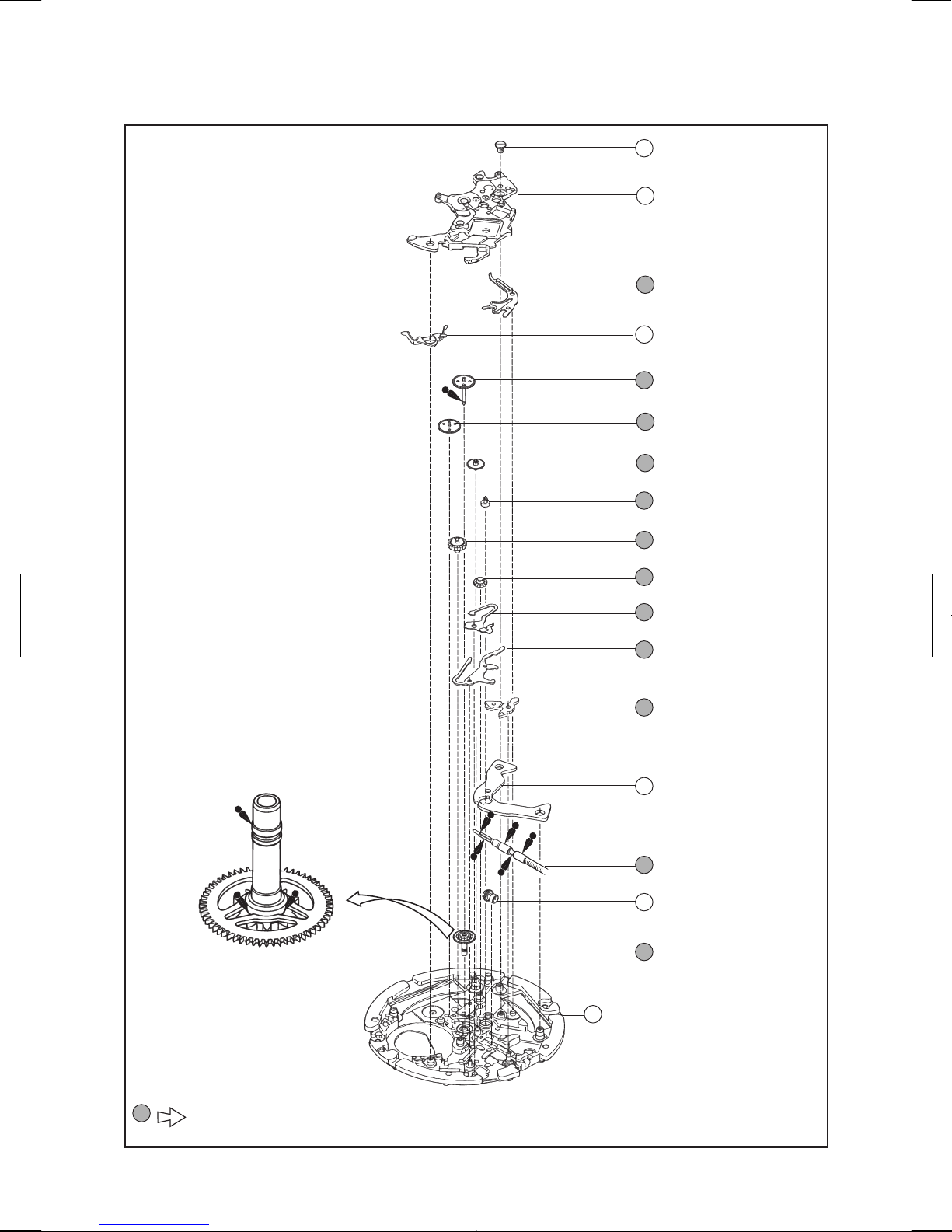

The CIRCUIT BLOCK for Cal. 5M54 and 5M6 Seriesand thatfor Cal. 5M4 Series have a close resemblance

in shape. They can be discriminated in the point that the CIRCUIT BLOCK for Cal. 5M54 and 5M6

Series has no diode element unlike that for Cal. 5M4 Series. When repairing the CIRCUIT BLOCK,

check that it has no diode element to make sure you are using the proper one.

Having no diode element Diode element

[ CIRCUIT BLOCK for Cal. 5M54 and 5M6 Series ] [ CIRCUIT BLOCK for Cal. 5M4 Series ]

43 GENERATING COIL BLOCK 4002514

The GENERATING COIL BLOCK for Cal. 5M54 and 5M6 Series and that for Cal. 5M4 Series have a close

resemblance in shape. They can be discriminated by the size of the pattern on the lead terminal. If

the GENERATING COIL BLOCK for Cal. 5M4 Series is assembled by mistake, no electricity will be

generated. When repairing the GENERATING COIL BLOCK, check the size of the pattern on the lead

terminal to make sure you are using the proper one.

Smaller pattern Larger pattern

[ GENERATING COIL BLOCK for Cal. 5M54 and 5M6 Series ] [ GENERATING COIL BLOCK for Cal. 5M4 Series

]