Seiler Microlux IV User manual

Microlux IV

LED

Operations Manual

3433 Tree Court Industrial Blvd.

St. Louis, MO 63122

(800) 489-2282

(314) 968-2282

Email: [email protected]

www.seilerinst.com

Contents

1. Parts Name 1

2. Specication 2

3. Installation 3

4. Operation 4

5. Installation & Operation for Attachments 5

6. Maintenance 5

7. Troubleshooting 10

8.Outts11

A3. Eyepiece

B2. Diopter

adjuster

A9. Notch for

attachment

A7. Clamp

B3. Aperture

diaphragm cover

B4. Condenser

Adjusting screw

(left & right)

A8. Condenser

A10. Filter

B5. Field diaphragm

revolver

B6. Condenser

thumb screw

B7. B8. Stage moving knobs

B9. Potentiometer

A11. Conden

set holder

A6. Mechanical

stage

A5. Objective

A1. Body

A4. Nosepiece

B1. Head thumb screw

A3. Eyepiece

1. Parts Name

Fig. 1-1

1

A12. Handle

B10. Condenser

focusing screw

A13. Power Input

A14. Fuse

B11. Power Switch

B12. Tension

adjustment ring

B13. Coarse

focusing knobs

B14. Fine

focusing knobs

Fig. 1-2

A1. Body A2. Seidentopf binocular head A3. Eyepiece A4. Nosepiece A5. Objective A6. Mechanical

Stage A7. Clamp A8. Condenser A9. Notch for attachment A10. Filter A11. Condenser holder

A12. Handle A13. Power Input A14. Fuse A15. Lamp Plate

B1. Head thumb screw B2. Diopter adjuster B3. Aperture diaphragm lever B4. Condenser adjusting screw

B5. Field diaphragm revolver B6. Condenser thumb screw B7. B8. Stage moving knobs B9. Potentiometer

B10. Condenser focusing screw B11. Power switch B12. Tension adjustment ring B13. Coarse focusing

knobs B14. Fine focusing knobs B15. Lamp plate thumb screw

2. Specication

2.1 Total magnications

10X

16X

4X

40X

64X

10X

100X

160X

20X

200X

320X

40X

400X

640X

100X

1000X

1600X

Objectives

Eyepiece

2

2.3 The other specication

2.3.1 Mechanical tube length: 160mm

2.3.2 Conjugate distance: Finite 195mm

Innite

2.3.3 Head: Seidentopf binocular (trinocular) 30º

Interpupillary adjustable distance is 50-75mm

Diopter adjustable range ±5,

Anti-fungal systems

2.3.4 Nosepiece: Quadplex or quinplex nosepiece

2.3.5 Mechanical Stage: Size 190mm X 140mm

X-Y travel 55mm X 78mm

2.3.6 Focusing systems: Coaxial coarse and ne focusing knobs

Coarse stroke 25mm, ne division 2 µ m

Condenser up-down range 25mm

2.3.7 Condenser: Abbe condenser, N.A. 1.25, Adjustable aperture

Aperture center is ajustable

2.3.8 Illumination: Koehler illumination system

2.3.9 Filter: Blue lter is for standard outts, green and amber is optional

2.3.10 Electric components: Input voltage AC 100-265V, 50/60Hz

Output voltage DC1.3.4V

3W LED lamp

Rotation potentiometer

Fuse 2A 5 X 20

2.2 Objectives (with eyepiece 10x)

3

Eyepiece

Binocular Head

1 X CCD Adaptor

Trinocular Head

Notch

obje

Condenser

N.A. 1.25

Filter

Fig. 2

3. Installation

Please install the microscope as follows:

Installation Process: (see Figure 3 on page 5)

1) Installing Lamp: LED is factory installed.

2) Installing binocular head

Loosen B1 binocular head thumb screw, put out A2 head, put it on top of body as in Fig. 1,

tighten the screw.

4

A15 Lamp plate

B15 Lamp plate

screw

Fig. 3

3) Installing objectives

Take out the objective from the packing box, and drive them into the holes of nosepiece orderly and

tightly according to times.

4) Installing eyepiece

Take out the eyepiece tube cover, then get the eyepiece from the packing bag, and insert into the tubes.

5) Installing condenser

a. Turn B13 coarse focusing knob, rise A6 mechanical stage to top;

b. Turn B10 condenser focusing screw, and take A11 condenser holder to the lowest position;

c. Loosen B6 condenser thumb screw, put the condenser to the holder, tighten B6 condenser thumb

screw.

d. Turn B10 condenser focusing screw, and raise the condenser to working position.

6) Installing blue lter or the other attachment

If blue lter will be used, the installation should be done before process 5, or do the installing during

process 5-C, then put A10 blue lter or the other attachment to the bottom hole of A8 condenser.

7) Installing the module attachment

The microscope can be with A9 module attachment and is multifunctional. Analyzer and wavelength

plate can be installed in A9 notch. Polarizer is installed over eld diaphragm or below the condenser.

Filter can be installed in the notch if the other attachment is in the bottom hole of condenser.

8) Installing CCD adaptor

Loosen the thumb screw in trinocular tube, put the CCD adaptor into trinocular tube, then tighten the

screw.

5

4. Operation

4.1 Operation process instructions

1) Turn power switch, adjust light

2) Place the sample

3) Put 10X objective into light

path and focus the sample

4) Adjust interpupillary distance

and diopter

5) Adjust condenser aperture

diaphragm

6) Adjust and center eld diaphragm

Put the objective into light path

and focus

Observe

Turn on B11 power switch and turn B9 pentiometer

Put the sample on A6 stage (open the clamp, and

put the sample on it), turn B7, B8 stage knobs to

put the sample into light path

Turn A4 nosepiece, put 10x objective into light path,

turn B13, B14 coarse and ne focus knobs.

Adjust A2 head to make two elds into one;

adjust B2 diopter adjuster to make diopter

for both eyes the same.

Adjust A8 condenser (B10 condenser focusing screw)

and aperture (B3 Aperture diaphragm lever).

Adjust eld diaphragm (B5 eld diaphragm

revolver), adjust center screw B4 to center

eld diaphragm.

4.2 Operation

1) Illumination

1. Conrm the voltage is available

2. Turn on power switch B11

3. Turn B9 potentiometer to adjust light

6

2) Sample placing

Put the sample (cover is up) on stage A6 and t it with clamp A7. Turn B7, B8 stage knobs to put the sample

into the light path (Fig. 4).

uTwo samples can be placed on the stage together

3) Focusing (Fig. 5)

Put 10x objective into light path, turn coarse

focusing knob B13, observe from right eyepeice

with right eye, then turn slowly ne focusing

knob B14 to make the image clear after nding image.

u The tension adjustment ring B12 can adjust the tension of the coarse and ne focusing unit to prevent

the stage from sliding down automatically and to improve the comfort of operation. Rotate clockwise to

decrease tension, rotate counter-clockwise to increase tension.

u Don’t turn left and right coarse and ne focusing knobs in different directions with power at the same

time, if so, the focusing system will be damaged. (Fig. 6)

4) Interpupillary distance and diopter adjustment

a. Interpupillary distance adjustment

Interpupillary distance is different for everyone, so interpupillary

distance should be adjusted before using binocular microscope.

Please take the two eyepiece tubes to turn until the bright rings

observed by two eyes are in superposition entirely. (Fig. 7)

b. Diopter adjustment (Fig. 8)

As focusing for binocular, user should observe right eyepiece with right eye and make the right eyepiece

clear by focusing adjustment, then observe the left eyepiece at the same time, adjust the diopter ring of the

left eyepiece tube to make the image of the left eyepiece clear as same as the right eyepiece.

Fig. 4

Fig. 5

Fig. 6

7

5) Condenser and aperture diaphragm adjustment

a. Condenser up-down

Turn the condenser focusing screw B10 to adjust the

distance between condenser front and the specimen,

and change the equal illumination to obtain the best

brightness.

b. Aperture diaphragm adjustment

Stir the handle of iris aperture of condenser to adjust

size of iris aperture for ajusting the contrast of the

specimen.

6) Centering eld diaphragm (this process is for microscope with eld

diaphragm)

a. Put 10x objective into light path, turn B5

condenser focusing screw, adjust condenser up or down to get the

image of eld diaphragm.

b. Observe throught eyepiece, turn B10 condenser focusing screw, adjust

condenser up or down to get image of eld diaphragm.

c. Turn B4 condenser adjusting screw to move the image

to the center of eld.

d. Put 40x objective into light path, turn B5 eld diaphragm revolver to

make the eld diaphragm image bigger than eld diaphragm.

Please center it again if the image is not in center.

4.3 Usage of immersion oil objective

The 100x objective of B series microscope can be used for observation even without immersion oil. However,

adding moderate immersion oil between the front lens of 100x objective and the cover glass of specimen can

make the image clearer. Please pay attention that air bubbles and impurities cannot be in the immersion oil,

otherwise, the image would be affected.

First, take 40x objective which has been focused well out from bright path, then take 100x objective into bright

path. At this time, nosepiece or stage moving knob should be turned slightly, and also slightly turn ne focusing

knob to clear away the air bubble of immersion oil, otherwise, the air bubble would affect the image badly.

Fig. 7

Fig. 8

8

u After immersion oil is used, the oil of specimen and the microscope surface should cleaned by absorbent

cotton, lens paper, gauze or soft cotton cloth with moderate mixture of pure industrial alcohol and ether

(proportion 1:4)

u Standard thickness 0.17mm cover glass should be chosen when high times objective used, and thickness

error should be within 0.01mm, otherwise, image denition would be affected.

4.4 Points of attention after using

4.4.1 Power of microscope should be turned off after using and the plug should be pulled out. If immersion

oil used, clean objective and specimen. Finally, cover the microscope with dust cover.

4.4.2 Please take eyepiece and objectives out of microscope if not being used for a long period of time.

Place eyepiece and objectives into drier with drying agent. Cover microscope with dust cover.

5. Installing and using camera and CCD attachment

5.1 Installing

Connect the C-mount with CCD camera or connect with camera adapter, then connect it with c-mount, nally

put it into microscope.

5.2 Using

First get a clear image from eyepiece, then pull out lever on the side of trinocular head and collect image with

camera. Clear image should be in screen. Adjust B14 ne focusing knobs to get it clear if image isn’t clear.

6. Maintenance

6.1 Clean microscope

6.1.1 Do not touch the lens with hand. Dust on lens should be cleaned by soft brush, absorbent cotton or

lens paper with a mixture of alcohol and ether (proportion 1:4)

6.1.2 Alcohol and ether are ammable, please keep them away from re. Be careful when turning power on

and off.

6.1.3 Don’t clean painted metal and galvanizing metal with organic solvent such as alcohol, ether or the

mixture of both. Silicon cloth or soft cleaning preparation is suggested to clean it.

6.1.4 Plastic should be cleaned by soft cloth with clear water.

6.2 Environment of using and placing

6.2.1 Microscope should be used and placed in a cool, dry, non-dust, non-shake and non-corrosive

environment.

6.2.2 Microscope should be used in environment of indoor temperature 0º – 40º C and maximum relative

humidity of 85%.

6.2.3 Removing equipment is suggested to be installed when microscope is used in heavy humidity area to

avoid fungus and mist damage.

6.2.4 Please pay attention to prevent the microscope from violent shaking and vibration in applications and

carrying. Don’t drag it on the surface of worktable to avoid damage to microscope and worktable.

6.3 Replacement of LED

6.3.1 Turn off power and pull out plug.

6.3.2 Lay aside microscope reliably, unscrew the knurled thumb screw of the lamp housing cover on the

underside of base.

6.3.3 Pull over the lamp housing cover.

6.3.4 Order LED lamp, assembly and replace.

6.3.5 Close the lamp housing cover and screw the knurled thumb screw.

* after working for 10 hours or more, it’s best to turn off the microscope for 30 minutes.

6.4 Replacement of fuse (shown in Fig. 8)

6.4.1 Cut off power of microscope and pull out th plug.

6.4.2 Unscrew fuse cap in the back of the base. Remove old fuse.

6.4.3 Replace with a new fuse and screw on fuse cap.

7. Troubleshooting

In the period of using, if any trouble occurs, please refer to the following chart for some common resolutions.

Trouble

Power on but

no light

Brightness of view

eld isn’t enough

or uneven

Cause

Plug is unreliable

Bulb is broken

Fuse is broken

Brightness isn’t

adjusted correctly

Objective isn’t in

correct position

The size of iris

aperture is too small

Remedy

Plug in again

Change bulb

Change fuse

Adjust rotation

potentiometer

Put the objective

in correct position

Adjust the size of

iris aperture

10

Cause

Lens (objective, eyepiece,

condenser,light collector)

has dust

Position of condenser

is too low

Cover glass of specimen

doesn’t meet the

requirement

Cover glass of specimen

isn’t in up direction

Surface of objective lens

is dirty (especially it is

easy for the front lens of

40x objective to dip in

immersion oil)

Immersion oil isn’t used

for 100x objective (oil)

Immersion oil doesn’t

meet the requirment

There is a bubble in

immersion oil

Size of iris aperture isn’t

proper

Position of condenser is

too low

Objective isn’t in correct

position

Specimen isn’t placed

correctly

Cover glass of specimen

isn’t in the up direction

Cover glass doesn’t meet the

requirement

Interpupillary distance

isn’t adjusted correctly

Diopter isn’t adjusted

correctly

Trouble

Brightness of view eld isn’t

enough or

is uneven

Image isn’t clear

(contrast or denition

isn’t enough)

One side of image is

dark or image is

moving as focsuing

Objective touches

specimen as changing

low times objective to

high times objective

Image observed by two

eyes aren’t in

superposition entirely

It is easy for eyes to be

tired during observing

Remedy

Clean it

Higher condenser

Use required thickness cover

glass (0.17mm)

Place specimen correctly

Clean it

Use immersion oil

Use immersion oil supplied by

us

Clear the bubble way

Adjust the size of iris aperture

Readjust the position of

condenser

Make the objective in correct

position

Place specimen levelly on stage

and clip it with clamp

Place specimen correctly

Use required thickness cover

glass (0.17mm)

Adjust interpupillary distance

according to two eyes

Readjust diopter

11

We are here to serve you!

If you have any questions regarding Seiler’s products or services,

please feel free to contact us.

Toll-Free: 800.489.2282

Local: 314.968.2282

Fax: 314.968.3601

www.seilerinst.com

•Microscope Division Manager

Dane Carlson

•Corporate Sales Representative

Nicole Rasch

•Technical Product Information

Tony Leise

•Bulb Order Information

Sandra Jeremich

PRECISION MICROSCOPES

A Division of Seiler Instrument Company

Table of contents

Other Seiler Microscope manuals

Popular Microscope manuals by other brands

Richter Optica

Richter Optica MDS1 instructions

AmScope

AmScope ZM-4 Series user manual

VAST Technologies

VAST Technologies DMC-2513 user manual

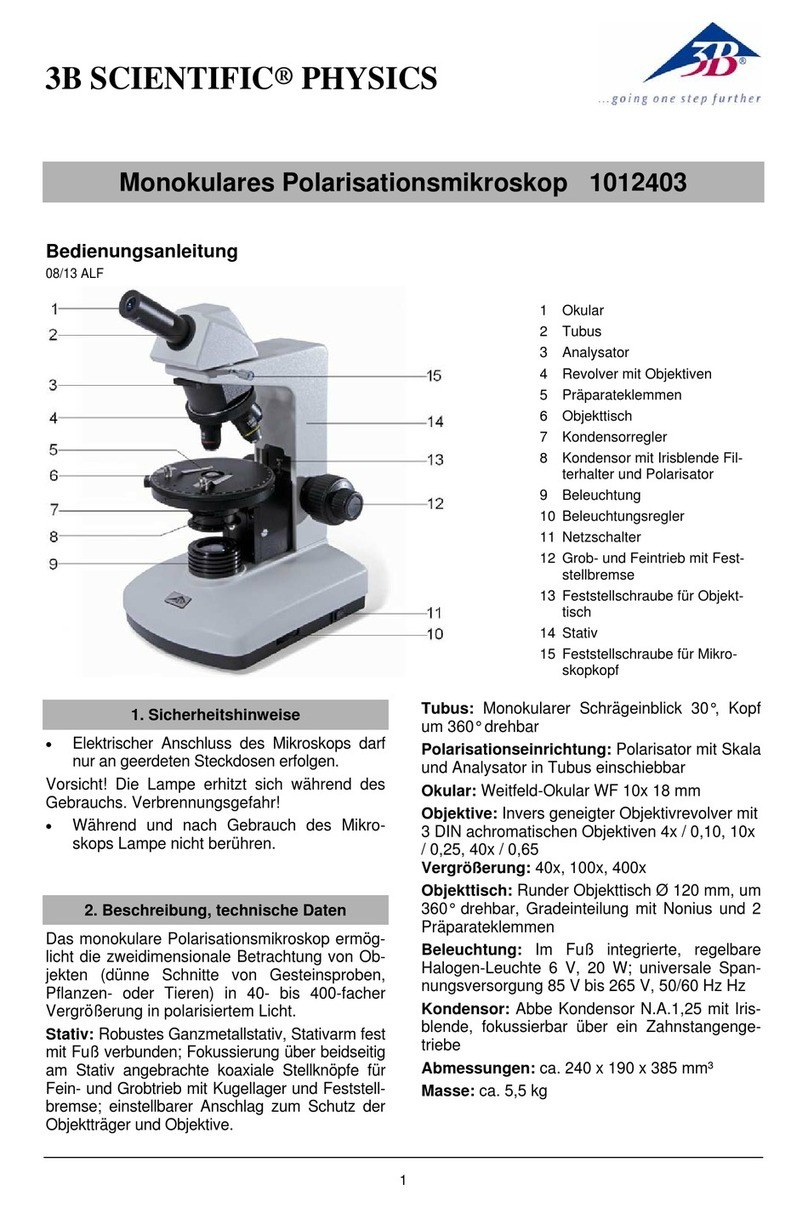

3B SCIENTIFIC PHYSICS

3B SCIENTIFIC PHYSICS 1012403 instruction manual

Fluke

Fluke Fiber Inspection Series quick start guide

Optika

Optika B-510 Series instruction manual