Zeiss EM 10 A User manual

Other Zeiss Microscope manuals

Zeiss

Zeiss VISU 200 User manual

Zeiss

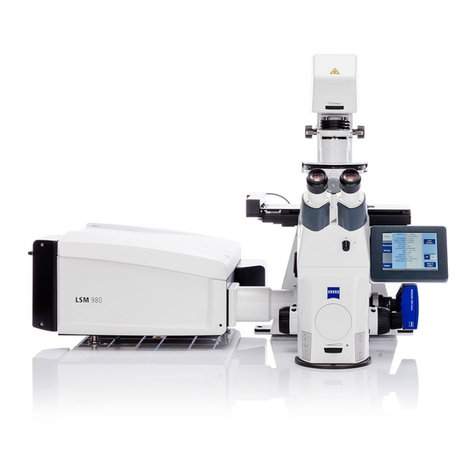

Zeiss LSM 710 User manual

Zeiss

Zeiss ?IGMA VP-FE-SEM User manual

Zeiss

Zeiss IV FL User manual

Zeiss

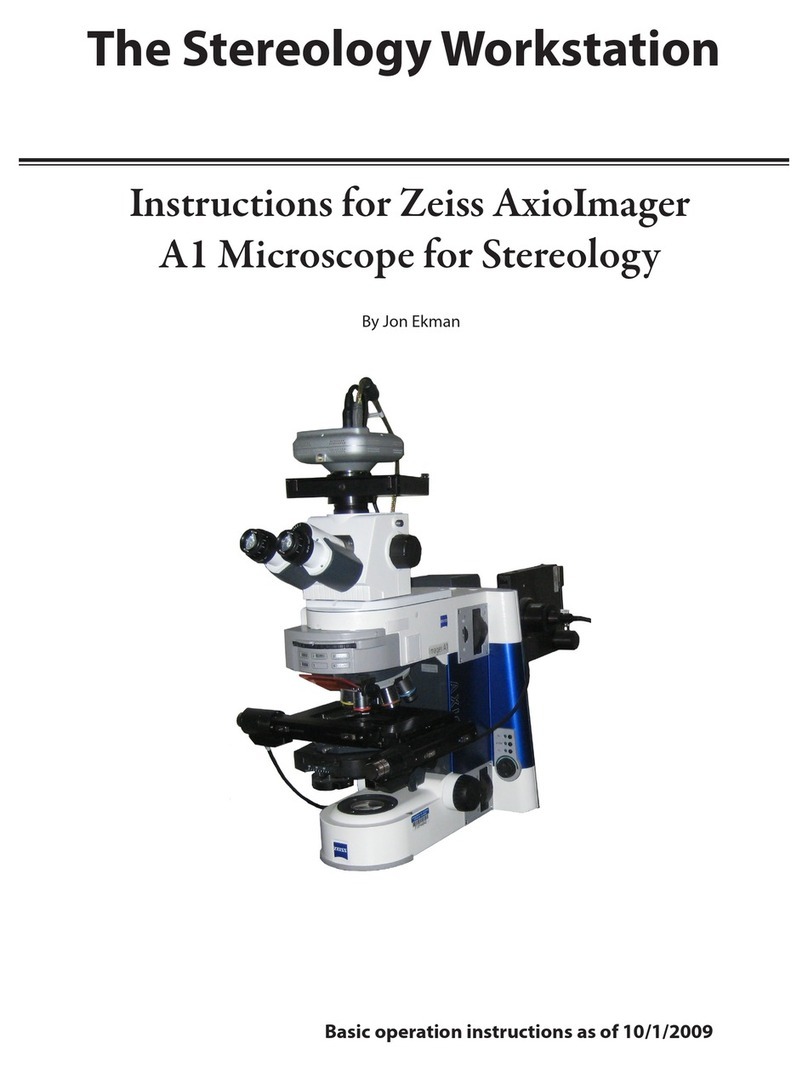

Zeiss AxioImager A1 Assembly instructions

Zeiss

Zeiss AxioObserver D1 User manual

Zeiss

Zeiss Axio Observer Series User manual

Zeiss

Zeiss OPMI VISU 160 User manual

Zeiss

Zeiss Stemi 305 User manual

Zeiss

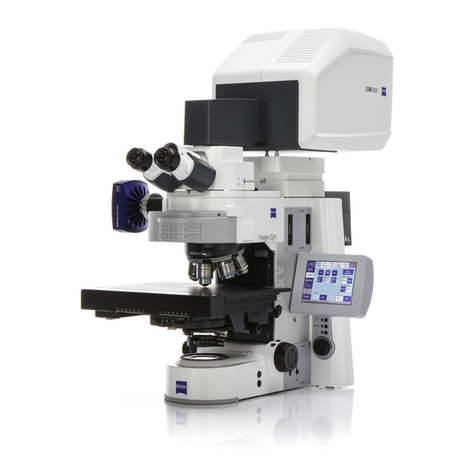

Zeiss LSM 800 User manual

Zeiss

Zeiss Crossbeam 350 User manual

Zeiss

Zeiss Transillumination top 450 mot. User manual

Zeiss

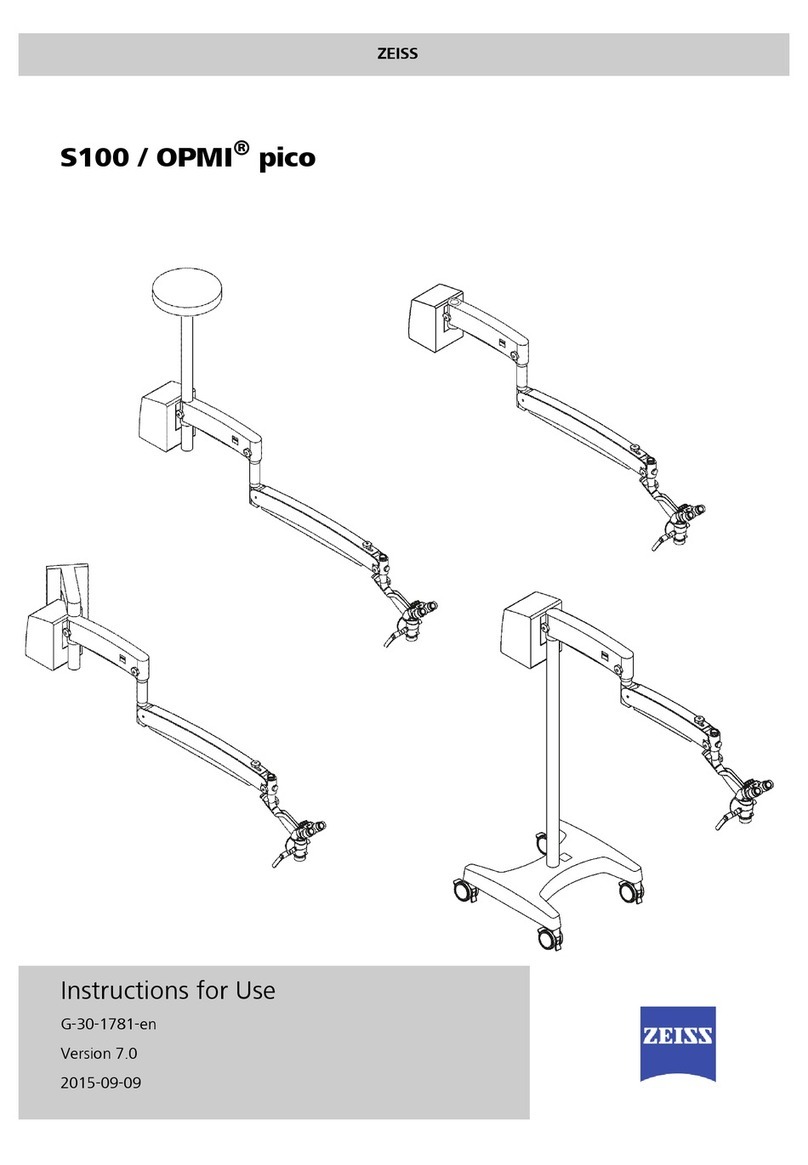

Zeiss S100/OPMI pico User manual

Zeiss

Zeiss LSM 900 User manual

Zeiss

Zeiss Smartzoom 5 User manual

Zeiss

Zeiss Smartzoom 5 User manual

Zeiss

Zeiss SIGMA Series User manual

Zeiss

Zeiss OPMI PROergo S7 User manual

Zeiss

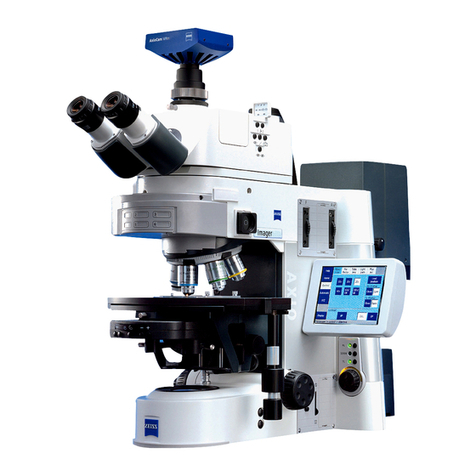

Zeiss Axio Imager User manual

Zeiss

Zeiss Axio Scope.A1 User manual