Schweitzer Engineering Laboratories, Inc. SEL-487B Data Sheet

5

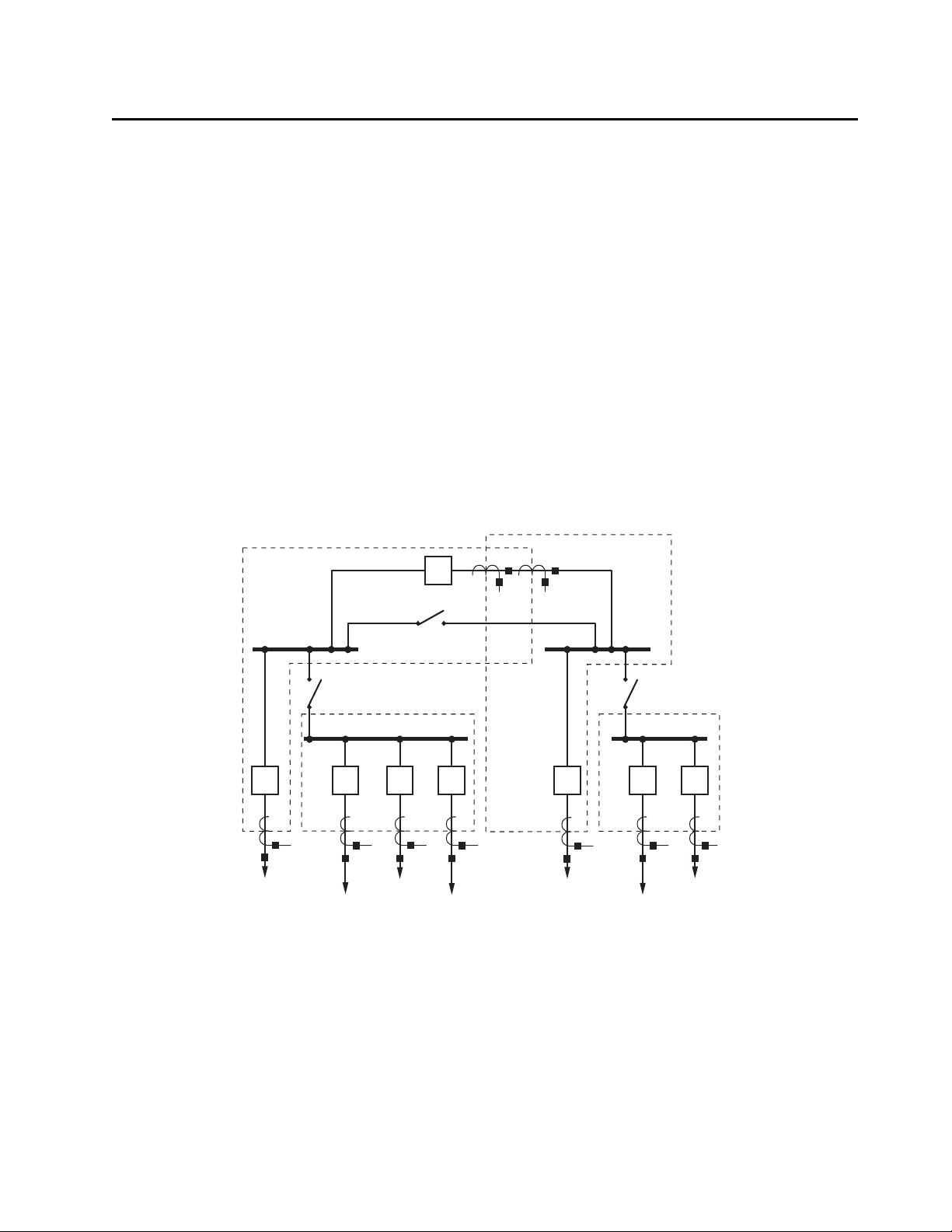

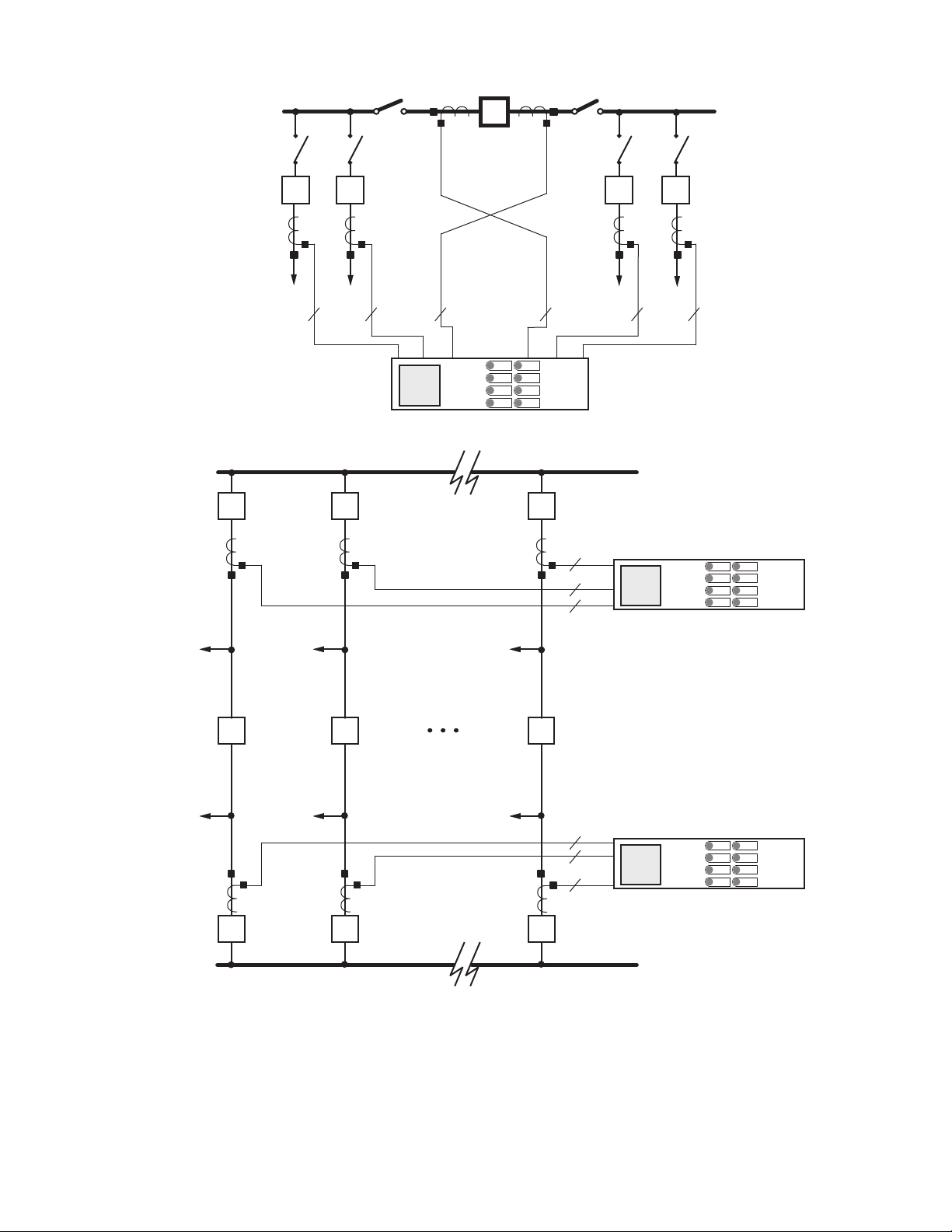

Closing disconnect DS2 combines Zone 1 and Zone 2,

resulting in a single zone. Figure 4 shows the new

protection zone configuration. In this combination, Zone

1 includes North and East bus-zones. Figure 5 shows the

new Zone 1 that includes bus-zones North and East.

Zone Selection Logic

Busbar protection requires assignment of the correct cur-

rent values to the appropriate differential elements as a

function of user-defined conditions. To achieve this, the

SEL-487B employs a two-step process:

➤Evaluates the user-defined conditions.

➤Assigns the currents to the differential element of

the appropriate zone.

Current assignment conditions vary from simple to

complex. A simple condition would be a statement such

as “always include this terminal in the differential

calculations.” A more complex condition statement could

be “when Disconnect 2 is closed, and the transfer

disconnect is open.”

SELOGIC control equations provide the mechanism by

which the user enters the conditions for assigning the

currents to the differential elements when these

conditions are met. When a SELOGIC control equation

becomes true (e.g., the disconnect is closed), the relay

dynamically assigns the current to the differential

elements. Conversely, when the SELOGIC control

equation is false (the disconnect is open), the relay

dynamically removes the currents from the differential

elements. This is also true for the trip output. When the

SELOGIC control equation of a terminal is false, the relay

issues no trip signal to that terminal. Table 1 shows a

simple case where the disconnect status is the only

condition for the relay to consider.

End-Zone Protection

To illustrate the flexibility of use of SELOGIC control

equations for user-defined conditions, consider the ease

of achieving end-zone protection with the SEL-487B.

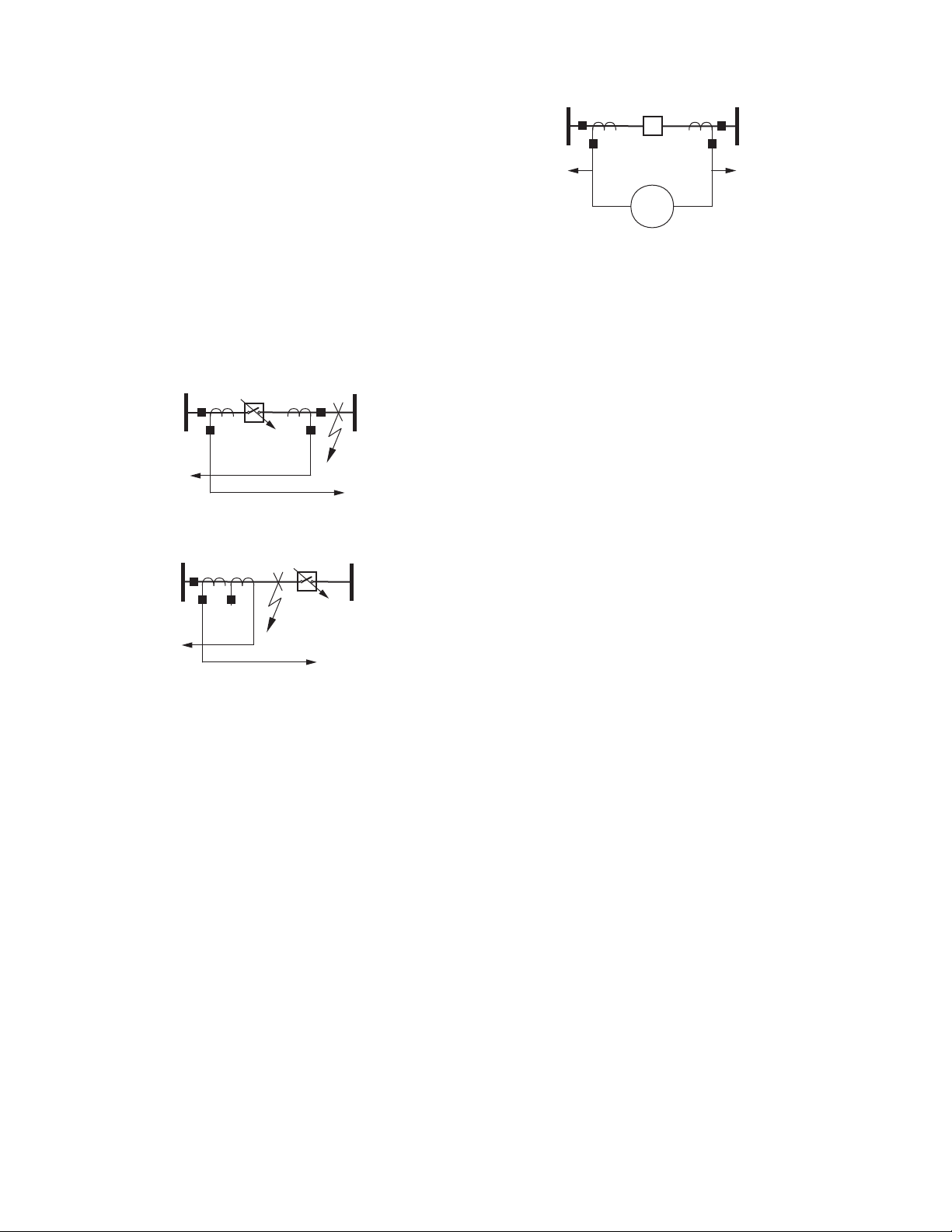

Figure 6 shows fault F1 between an open circuit breaker

and CT of a feeder at a substation. This area is a “dead”

zone because neither busbar protection nor local line

protection can clear this fault; the remote end of the

feeder must clear this fault. Because the feeder circuit

breaker is already open, operation of the busbar

protection serves no purpose. The busbar protection must

not operate for this fault.

Figure 6 Fault Between Breaker and CT

By including the circuit breaker auxiliary contact in one

of the SELOGIC control equations (Figure 7), we can

cause the value of the SELOGIC control equation to be

false when the circuit breaker is open, removing the

current from the differential element calculations. This

capability ensures stability of the busbar protection. By

our use of SELOGIC control equations and normal

communications channels to configure the protection

system, the relay sends a trip signal to the remote end of

the feeder.

Figure 7 Bus Protection Is Not Affected by Fault, F1;

Use Transfer Trip to Clear the Fault

Check Zones

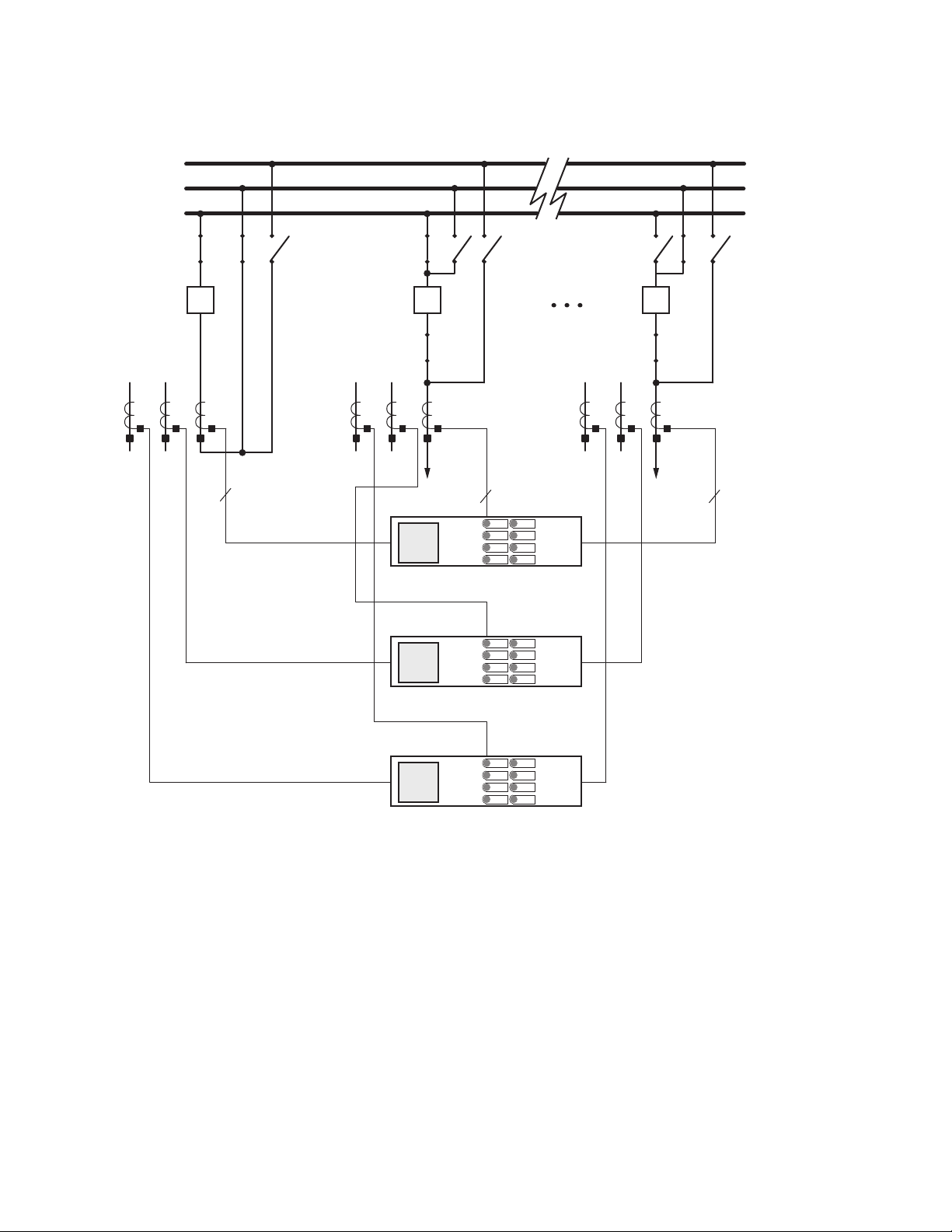

The SEL-487B provides three completely independent

check zones, each with its own adaptive differential

element. Supervise zone differential elements by using

the independent check zones to monitor all incoming

sources and outgoing feeders on a per-phase basis.

During an internal fault, the check zone differential

element will assert. During an external fault, the check

zone element will remain deasserted.

Differential Protection

The SEL-487B includes six independent current differ-

ential elements. Operating time for internal faults,

including high-speed output contact closure, is less than

one cycle. Figure 8 shows an example of an internal fault

and differential element operation.

Table 1 Conditions for Automatic Terminal Assignment

Example of

Condition

SELOGIC

Control

Equation

Result

Consider

Terminal in

Protection

Calculations?

Issue

Trip?

Disconnect is open False No No

Disconnect is closed True Yes Yes

Busbar Primary

Fault Current

Circuit

Breaker Open

End-Zone

Fault

52

F1

Busbar Primary

Fault Current

End-Zone

Fault

52a Auxiliary

Contact

52

F1