SEL-487E-3, -4 Data Sheet Schweitzer Engineering Laboratories, Inc.

6

the distance elements when there is transient on the system

with CCVTs that may cause the distance element to over-

reach. All mho elements use positive-sequence memory

polarization that expands the operating characteristic in

proportion to the source impedance. This provides depend-

able and secure operation for close-in faults. The quadri-

lateral phase and ground distance elements provide improved

fault and arc resistance coverage, including application

on short lines.

Out-of-Step Detection

The SEL-487E supports out-of-step detection by using

timers and blinders that are set outside any of the distance

elements. A power swing is declared when an impedance

locus travels through the blinders slower than a preset

time. This logic blocks the distance elements in case of a

stable power swing.

Adaptive Time-Overcurrent

Elements (51S)

The relay supports 20 adaptive time-overcurrent elements

with selectable operate quantity and programmable time-

delay and pickup levels. Choose from the ten time-

overcurrent curves shown in Table 1 (five IEC and

five U.S.). Each torque-controlled time-overcurrent ele-

ment has two reset characteristics. One choice resets the

elements if current drops below pickup for one cycle

while the other choice emulates the reset characteristic of

an electromechanical induction disk relay.

The adaptive time-overcurrent elements in the SEL-487E

allow the selection of a wide variety of current sources as

operate quantities to the element. Select the time-overcurrent

element operate quantity from any one of the following

current sources:

➤Filtered phase currents: IAmFM, IBmFM, ICmFM

➤Maximum filtered phase current: IMAXmF

➤Combined filtered phase currents (any two

terminals): IAmmFM, IBmmFM, ICmmFM

➤Maximum filtered combined phase current:

IMAXmmF

➤Filtered positive-, negative-, and zero-sequence:

I1mFM, 3I2mFM, 3I0mFM, I1mmM, 3I2mmM,

3I0mmM

➤RMS currents: IAmRMS, IBmRMS, ICmRMS,

IMAXmR IAmmRMS, IBmmRMS, ICmmRMS,

IMAXmmR

where:

m= Relay current terminals S, T, U, W, X, Y

mm = Relay current terminals ST, TU, UW, WX

F = Filtered

M = Magnitude

MAX = Maximum magnitude A-, B-, C-phase currents

In addition to the selectable operate quantity, the 51S ele-

ment time-delay and pickup level inputs are SELOGIC-

programmable settings. This flexibility allows these inputs

to be set to fixed numerical values to operate as standard

time overcurrent elements, or the pickup and time-dial

settings can be programmed as SELOGIC math variables.

Programming the time-delay and pickup levels as math

variables allows the numeric value of the pickup and time-

delay settings to change based on system conditions with-

out the added delay of having to change relay setting groups.

For example, change pickup and time-delay settings

dynamically in a parallel transformer application based

upon single or parallel transformer configurations. Another

example would be changing feeder time-overcurrent ele-

ment pickup and coordination delays based upon distributed

generation being connected downstream of a transformer.

REF Protection

Apply the REF protection feature to provide sensitive detec-

tion of internal ground faults on grounded wye-connected

transformer windings and autotransformers. Use single-

phase neutral current inputs for providing neutral CT oper-

ating current for as many as three windings. Polarizing

current is derived from the residual current calculated for

the corresponding protected winding. A directional ele-

ment determines whether the fault is internal or external.

Zero-sequence current thresholds supervise tripping. The

relay can accommodate CT ratio mismatch as great as 35:1.

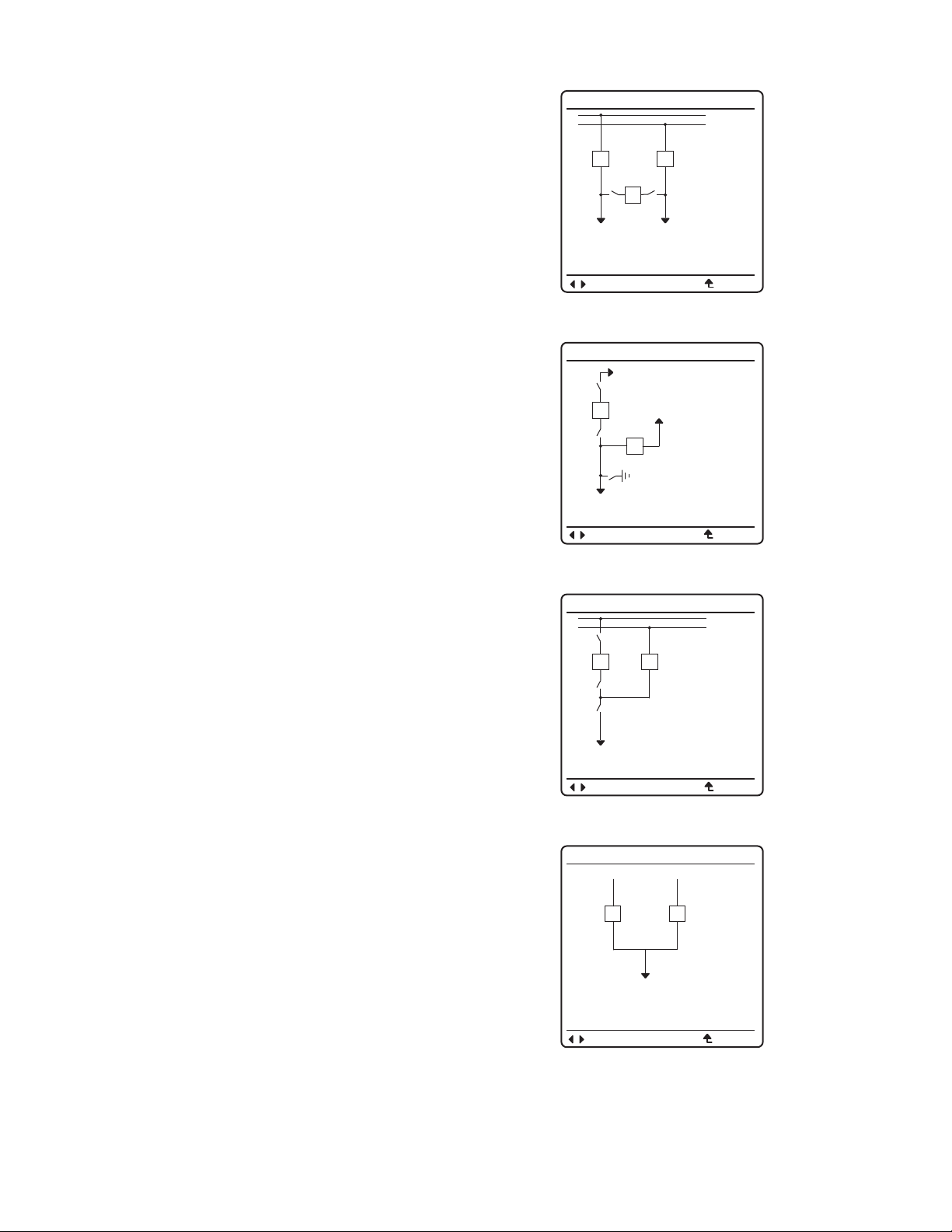

Figure 4 Mho Characteristics

Table 1 Supported Time-Overcurrent Curves

U.S. Curves IEC Curves

U1 (moderately inverse) C1 (standard inverse)

U2 (inverse) C2 (very inverse)

U3 (very inverse) C3 (extremely inverse)

U4 (extremely inverse) C4 (long-time inverse)

U5 (short-time inverse) C5 (short-time inverse)

Expanded

Characteristic

Steady-State

Characteristic

Relay Reach

Z

R

Z

S

X

R