SEL- 2664S Data Sheet Schweitzer Engineering Laboratories, Inc.

4

Profile Report Monitoring

Profile report monitoring provides a periodic snapshot

(selectable rate of every 1, 5, 15, 30, or 60 minutes) of as

many as 17 selectable analog quantities from the

complete list of analog quantities the SEL-2664S

generates. Examples of analog quantities available

include the following:

➤Stator insulation resistance

➤Injected rms current

➤Neutral ground resistance

➤Third-harmonic neutral voltage

When used with the SEL-2664 Field Ground Module, the

relay can also record the field insulation resistance.

The SEL-2664S maintains profile information in a

nonvolatile buffer memory. The memory can hold data for

9800 time-stamped entries.

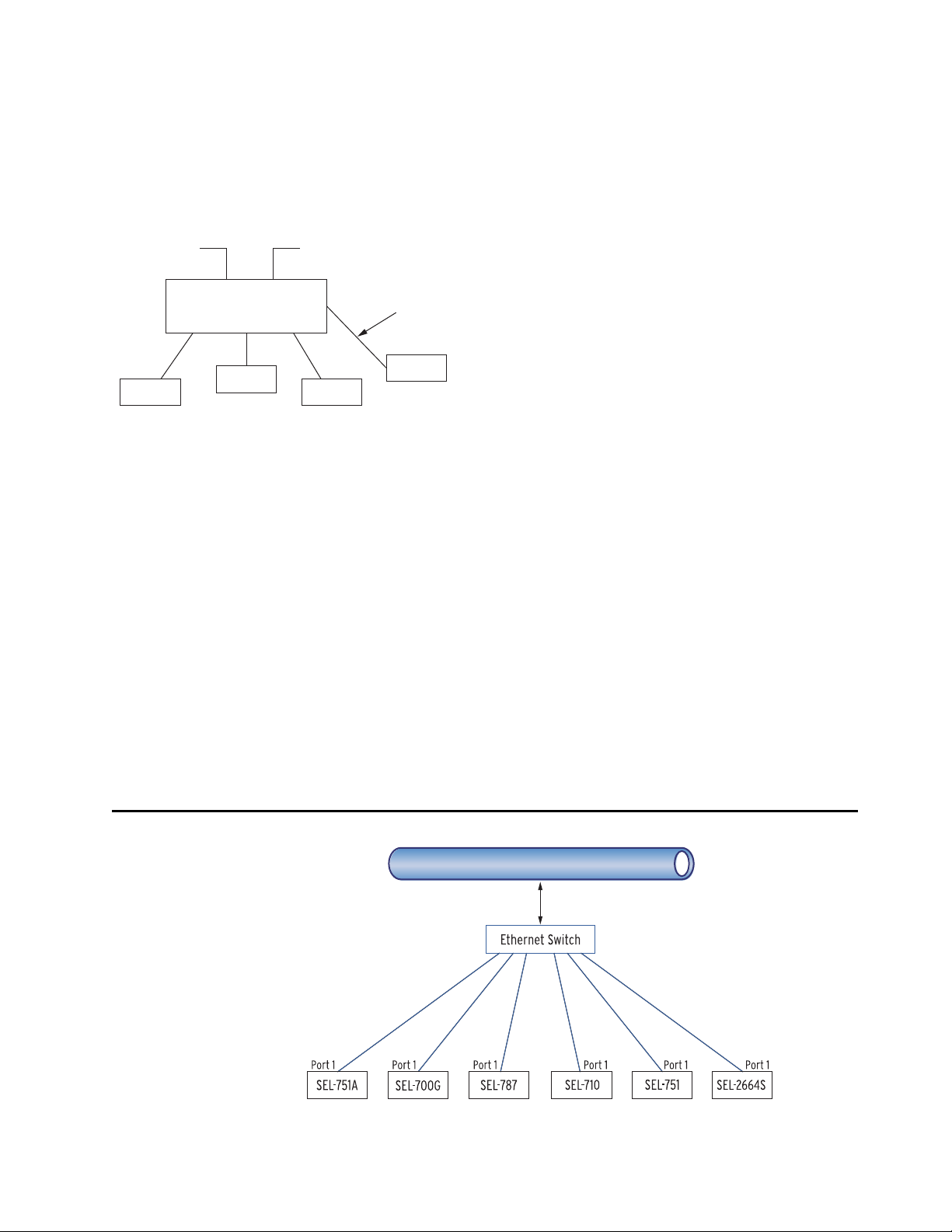

Automation

Flexible Control Logic and Integration Features

The SEL-2664S has three independently operated serial

ports: one front and one rear EIA-232 serial port and one

rear fiber-optic serial port. Also, the relay supports dual

fiber Ethernet ports in the rear. The relay needs no special

communications software. You can use any system that

emulates a standard terminal system. Establish

communication by connecting computers, modems,

protocol converters, printers, an SEL real-time

automation controller (RTAC), SEL communications

processor, SEL computing platform, SCADA, and/or

RTUs for local or remote communication. Refer to

Table 2 for a list of communications protocols available in

the SEL-2664S.

Neutral Currents (A sec) Magnitude of neutral currents at the injected frequencies in secondary amperes

Stator Insulation (k) Resistance of the stator insulation to ground at the injected frequencies in kilohms, primary

aSecondary and Primary reference the Neutral Grounding Transformer (NGT), not CTN.

bNeutral current (A sec) is shown if CTN_LOC := SEC; otherwise, it is hidden.

Table 1 Metered Quantities (Sheet 2 of 2)

Quantities Description

Table 2 Communications Protocols

Type Description

Simple ASCII Plain language commands for human and simple machine communication.

Use for metering, setting, self-test status, event reporting, and other functions.

Compressed ASCII Comma-delimited ASCII data reports.

Allows external devices to obtain relay data in an appropriate format for direct import into spreadsheets and

database programs. Data are checksum protected.

Fast Meter and Fast

Operate

Binary protocol for machine-to-machine communication.

Quickly updates SEL communications processors, RTUs, and other substation devices with metering informa-

tion, relay elements, I/O status, time tags, and summary event reports. Data are checksum protected. Binary and

ASCII protocols operate simultaneously over the same communications lines, so there is no loss of control, sta-

tus, or metering information while a technician transfers an event report.

Fast SER Protocol Provides SER events to an automated data collection system.

Modbus Serial or Ethernet-based Modbus with point remapping.

Includes access to metering data, protection elements, contact I/O, targets, SER, relay summary event reports,

and settings.

DNP3 Serial or Ethernet-based DNP3 protocols.

Provides default and mappable DNP3 objects that include access to metering data, protection elements, Relay

Word bits, contact I/O, targets, SER, and relay summary event reports.

IEC 61850 Ethernet-based international standard for interoperability among intelligent devices in a substation.

Operates remote bits and I/O. Monitors Relay Word bits and analog quantities.

SNTP Ethernet-based protocol that provides time synchronization of the relay.